Clad tube blank of dual metal seamless steel tube used for boiler and manufacturing method thereof

A technology of seamless steel pipe and production method, which is applied in the direction of metal layered products, chemical instruments and methods, pipes/pipe joints/pipe fittings, etc., to achieve the effect of improving service life and not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

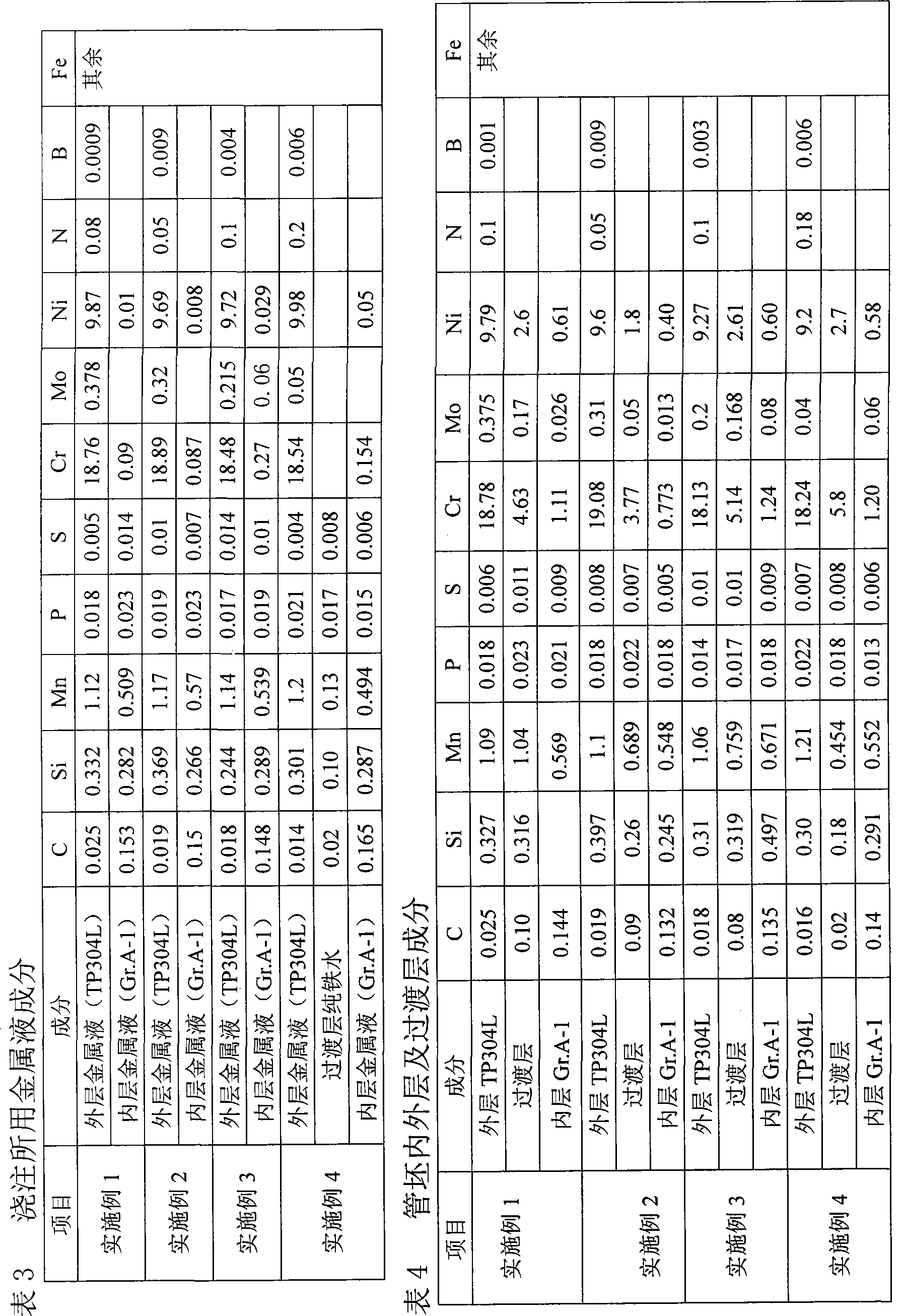

Embodiment 1

[0033] (1) Put 410 kg of molten metal in the outer layer into the tube mold for centrifugal casting, the pouring temperature is 1576°C, cool the tube mold after pouring, and start pouring the transitional layer of molten metal when the inner surface temperature of the outer layer cools down to about 1250°C;

[0034] (2) Put 110 kg of the transition layer molten metal into the pipe mold and pour it centrifugally, the pouring temperature is 1642°C, cool down after pouring, and start pouring the inner layer of metal liquid when the temperature of the inner surface of the transition layer cools down to about 1500°C;

[0035] (3) Pass 445 kg of inner metal liquid into the pipe mold and pour centrifugally at a pouring temperature of 1642°C. After pouring, cool the pipe mold, and stop cooling after the outer layer, transition layer, and inner layer are all solidified. At this time, the transition layer has Complete metallurgical fusion with the inner and outer layers, respectively.

...

Embodiment 2

[0039] (1) Put 395 kg of molten metal in the outer layer into the tube mold for centrifugal casting, the pouring temperature is 1565°C, cool the tube mold after pouring, and start pouring the transition layer of molten metal when the inner surface temperature of the outer layer is cooled to about 1300°C;

[0040] (2) Pass 115 kg of the transition layer molten metal into the pipe mold for centrifugal casting, the pouring temperature is 1610°C, cool down after pouring, and start pouring the inner layer of metal liquid when the temperature of the inner surface of the transition layer cools down to about 1510°C;

[0041] (3) Pass 450 kg of inner metal liquid into the pipe mold and pour centrifugally at a pouring temperature of 1610°C. Cool the pipe mold after pouring, and stop cooling after the outer layer, transition layer, and inner layer are all solidified. At this time, the transition layer has Complete metallurgical fusion with the inner and outer layers, respectively.

[004...

Embodiment 3

[0045] (1) Put 405 kg of molten metal in the outer layer into the pipe mold for centrifugal casting, the pouring temperature is 1572°C, cool the pipe mold after pouring, and start pouring the molten metal of the transition layer when the inner surface temperature of the outer layer cools down to about 1285°C;

[0046] (2) Pass 120 kg of the transition layer molten metal into the tube mold for centrifugal casting, the pouring temperature is 1628°C, cool down after pouring, and start pouring the inner layer of molten metal when the temperature of the inner surface of the transition layer cools down to about 1503°C;

[0047] (3) Pass 445 kg of inner metal liquid into the pipe mold and pour centrifugally at a pouring temperature of 1628°C. After pouring, cool the pipe mold, and stop cooling after the outer layer, transition layer, and inner layer are all solidified. At this time, the transition layer has Complete metallurgical fusion with the inner and outer layers, respectively. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com