Corrosion-resistant dual metal clad tube blank and manufacturing method thereof

A bimetallic composite pipe and production method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem that the bimetallic composite pipe cannot guarantee the complete welding of the inner and outer layers, which affects the safety of the bimetallic pipe and affects the Pipeline safety and other issues, to achieve the effect of not easy to delaminate, improve safety, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Pass 425 kg of the outer metal liquid into the pipe mold for centrifugal casting, the casting temperature is 1598°C, cool the pipe mold after pouring, and start pouring the inner metal liquid when the inner surface temperature of the outer layer cools to about 1440°C;

[0026] (2) Pass 210 kg of molten metal in the inner layer into the pipe mold and centrifugally cast it at a temperature of 1530°C. After pouring, cool down. Stop cooling after the outer layer and inner layer are completely solidified. At this time, the inner layer and outer layer have reached complete metallurgical fusion.

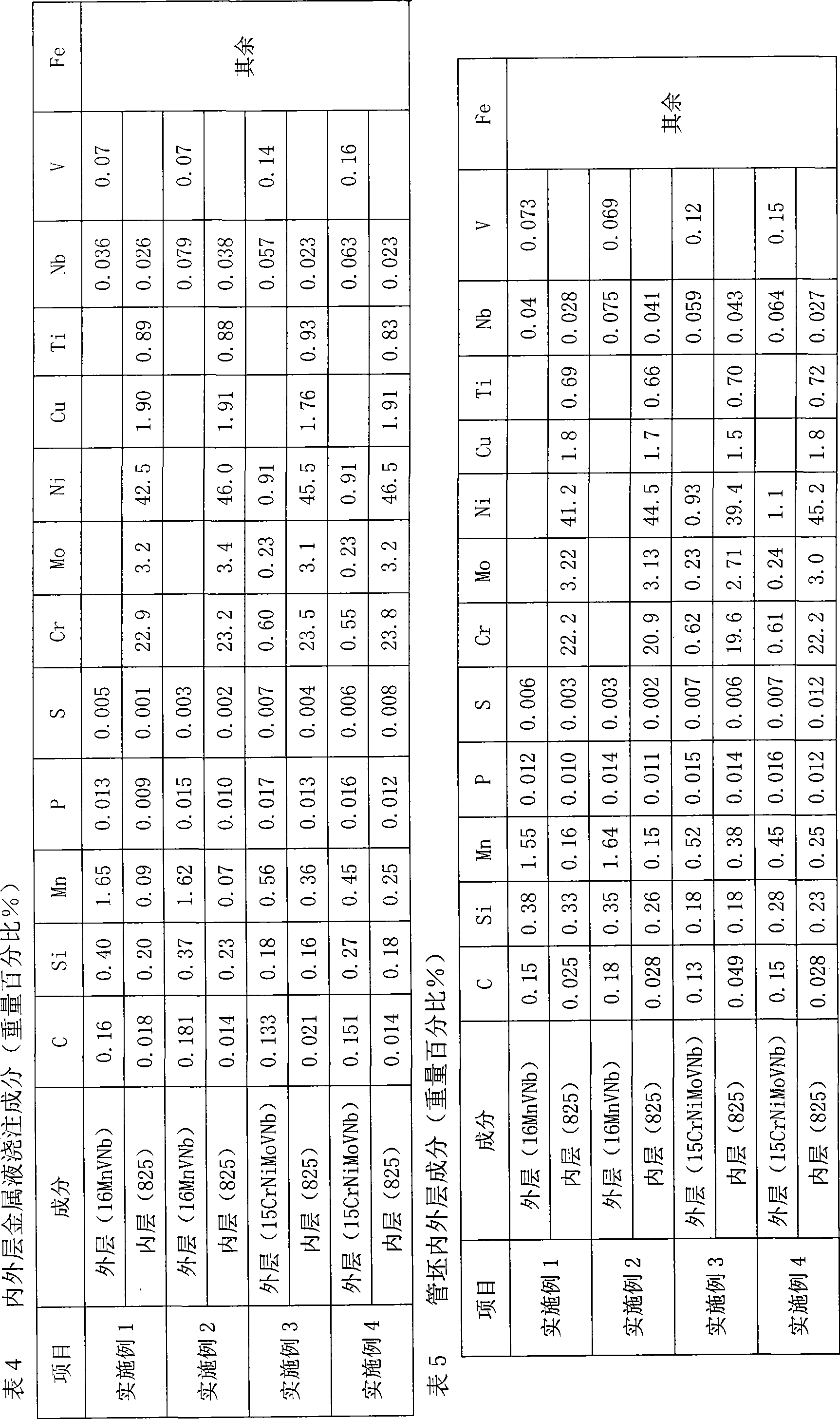

[0027] The composition of the molten metal used in this example is shown in Table 4, and the composition of the inner and outer layers of the obtained tube blank is shown in Table 5. Table 6 shows the size parameters of the raw material tube blanks obtained after machining the inner and outer surfaces of the tube blanks.

[0028] In order to reduce the content of small particle ...

Embodiment 2

[0030] (1) Pass 420 kg of the outer metal liquid into the pipe mold and pour it centrifugally. The casting temperature is 1577°C. After pouring, cool the pipe mold. When the temperature of the inner surface of the outer layer cools down to about 1460°C, pour the inner metal liquid;

[0031] (2) Put 220 kg of molten metal in the inner layer into the pipe mold and centrifugally pour it. The casting temperature is 1508°C. Cool after pouring. Stop cooling after the outer and inner layers are completely solidified. At this time, the inner and outer layers have reached complete metallurgical fusion.

[0032] The composition of the molten metal used in this example is shown in Table 4, and the composition of the inner and outer layers of the obtained tube blank is shown in Table 5. Table 6 shows the size parameters of the raw material tube blanks obtained after machining the inner and outer surfaces of the tube blanks.

[0033] In order to reduce the content of small particle inclus...

Embodiment 3

[0035] (1) Pass 425 kg of the outer metal liquid into the pipe mold for centrifugal casting, the casting temperature is 1591°C, cool the pipe mold after pouring, and start pouring the inner layer of metal liquid when the temperature of the inner surface of the outer layer cools down to about 1450°C;

[0036] (2) Put 215 kg of molten metal in the inner layer into the pipe mold for centrifugal casting, the casting temperature is 1460°C, cool after pouring, stop cooling after the outer and inner layers are completely solidified, at this time the inner and outer layers have reached complete metallurgical fusion.

[0037] The composition of the molten metal used in this example is shown in Table 4, and the composition of the inner and outer layers of the obtained tube blank is shown in Table 5. Table 6 shows the size parameters of the raw material tube blanks obtained after machining the inner and outer surfaces of the tube blanks.

[0038] In order to reduce the content of small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com