Patents

Literature

53results about How to "Robust mechanical bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor chip assembly with post/base heat spreader with ESD protection layer

InactiveUS20110089465A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

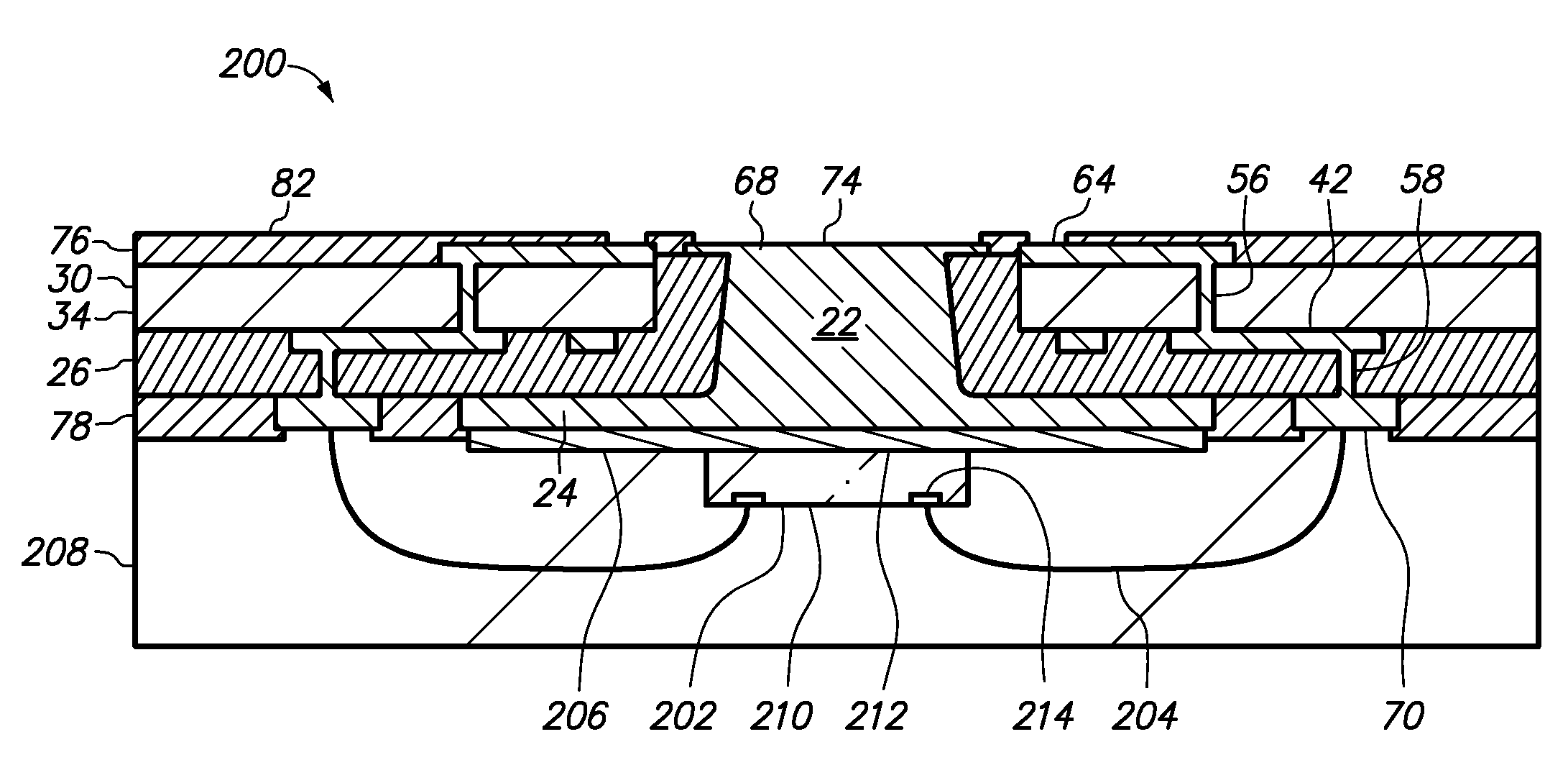

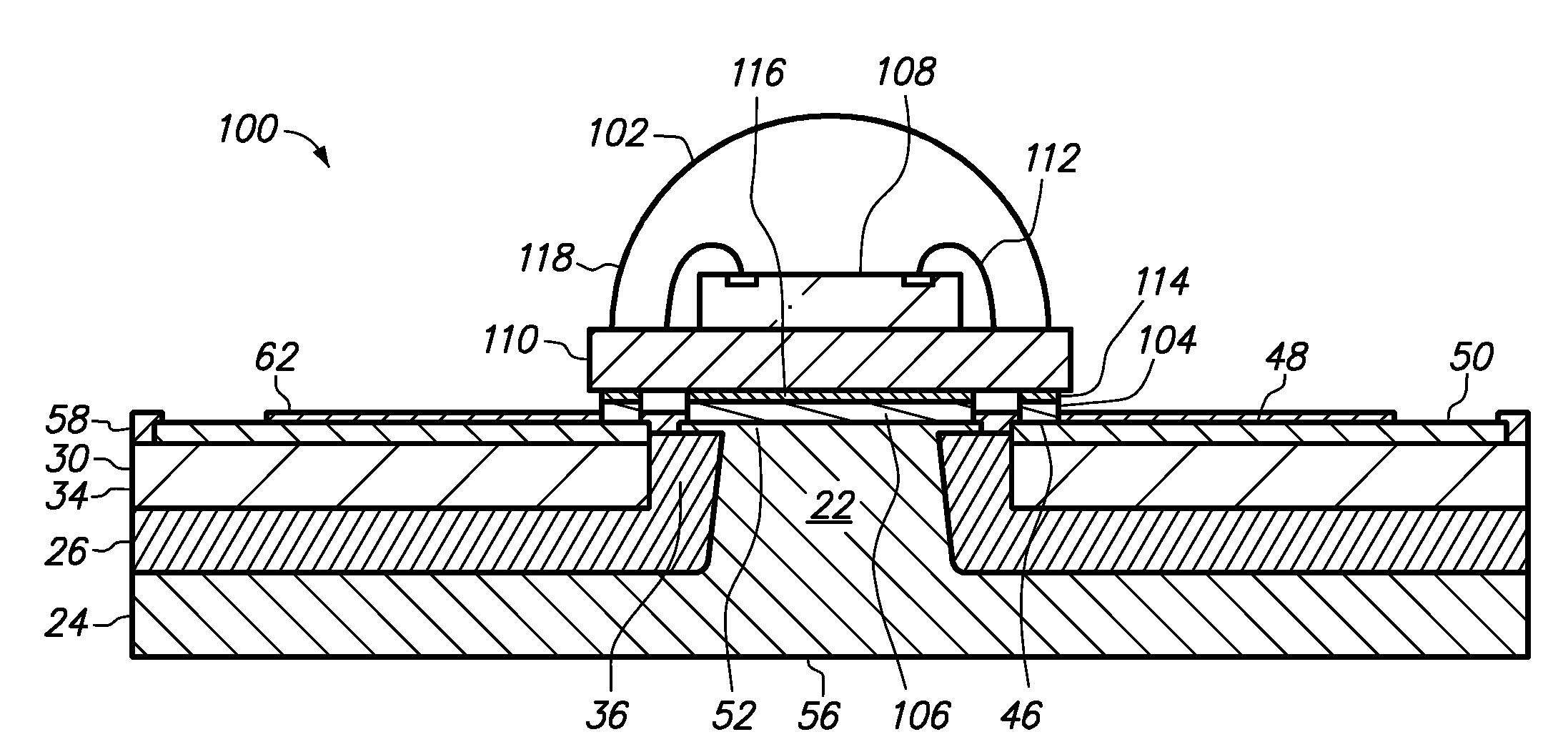

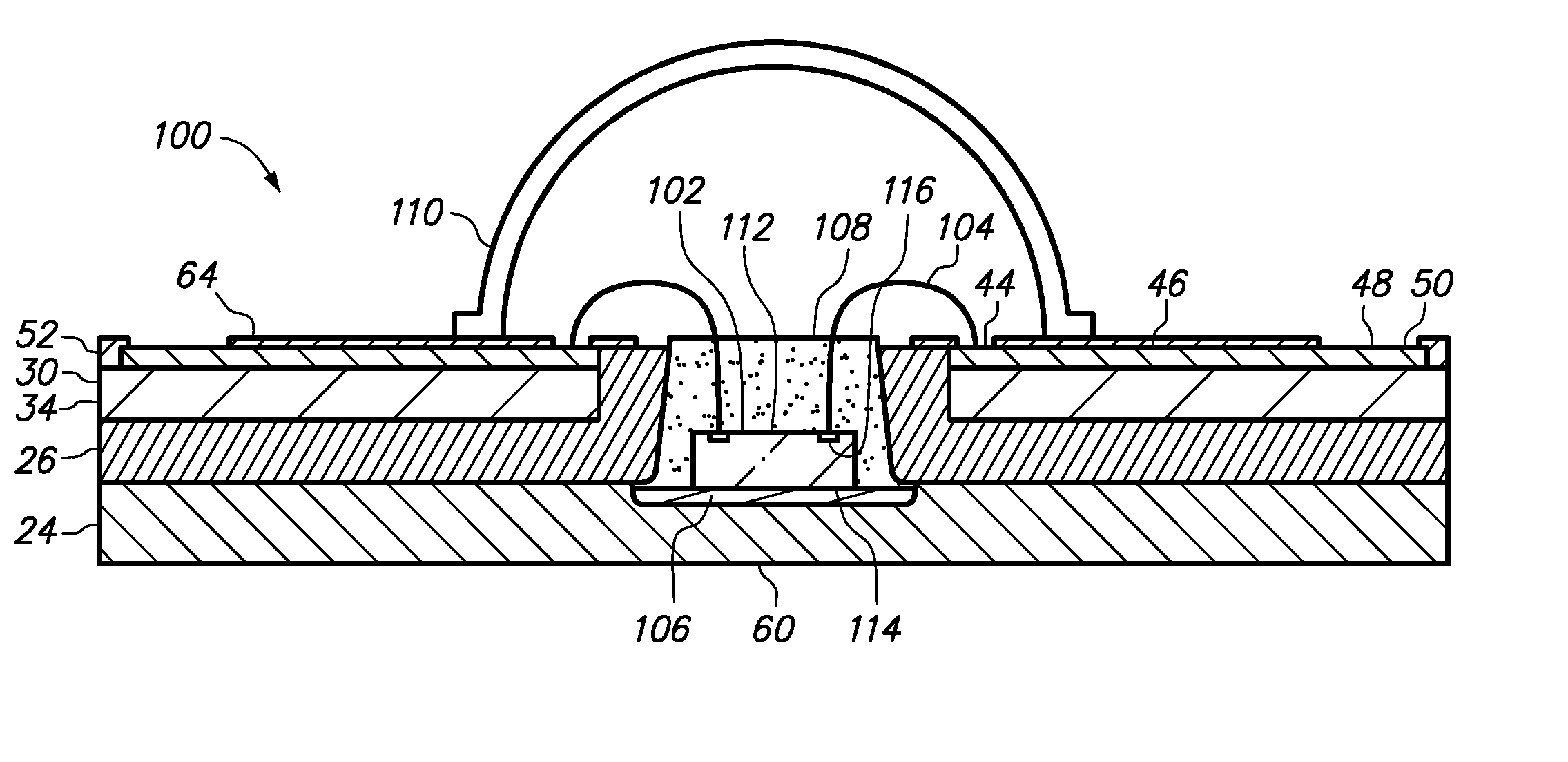

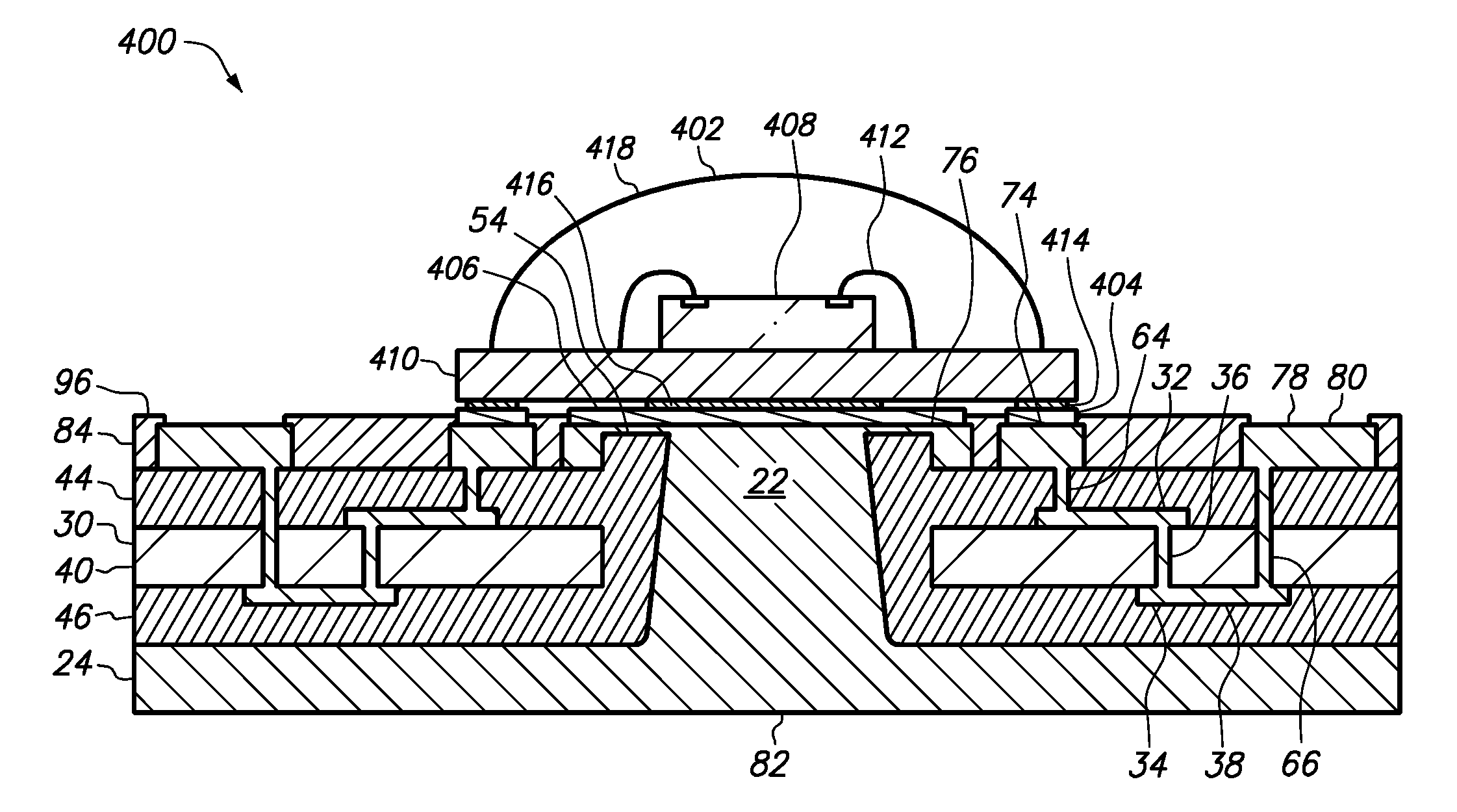

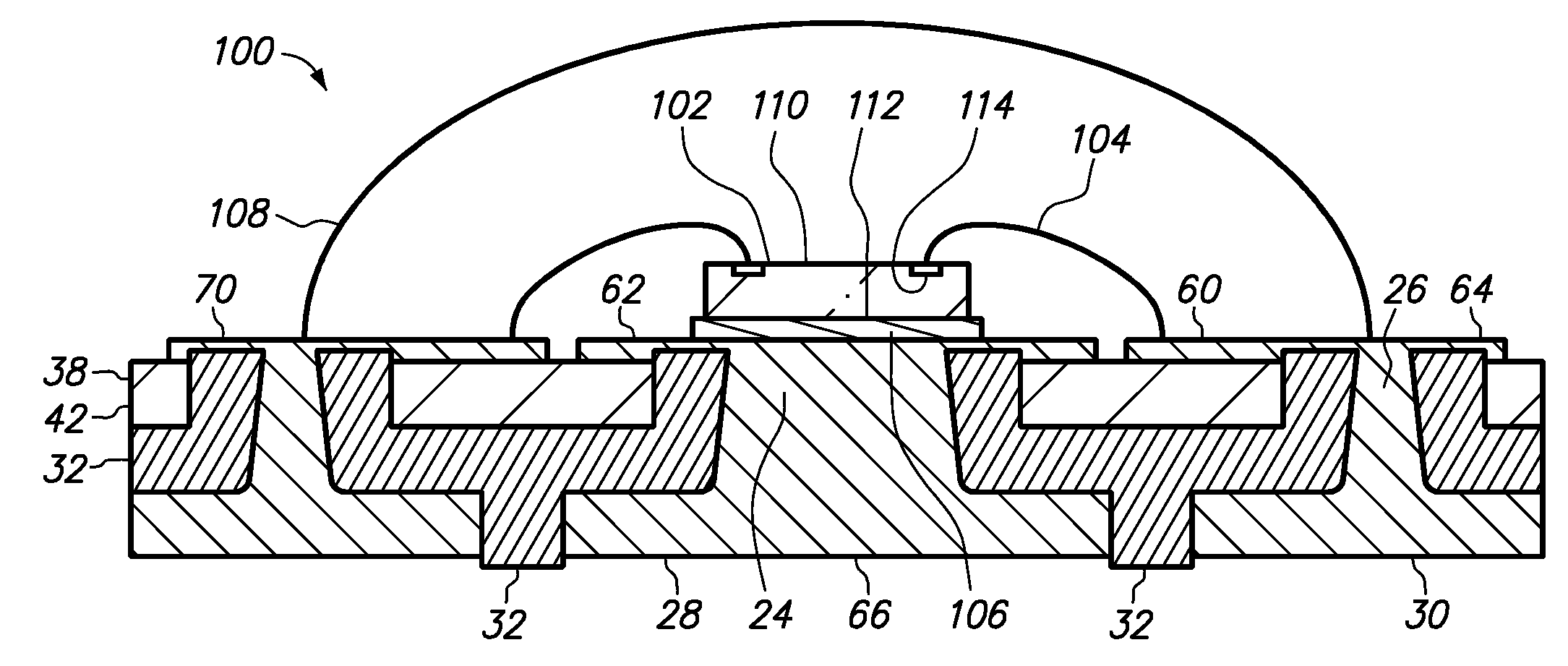

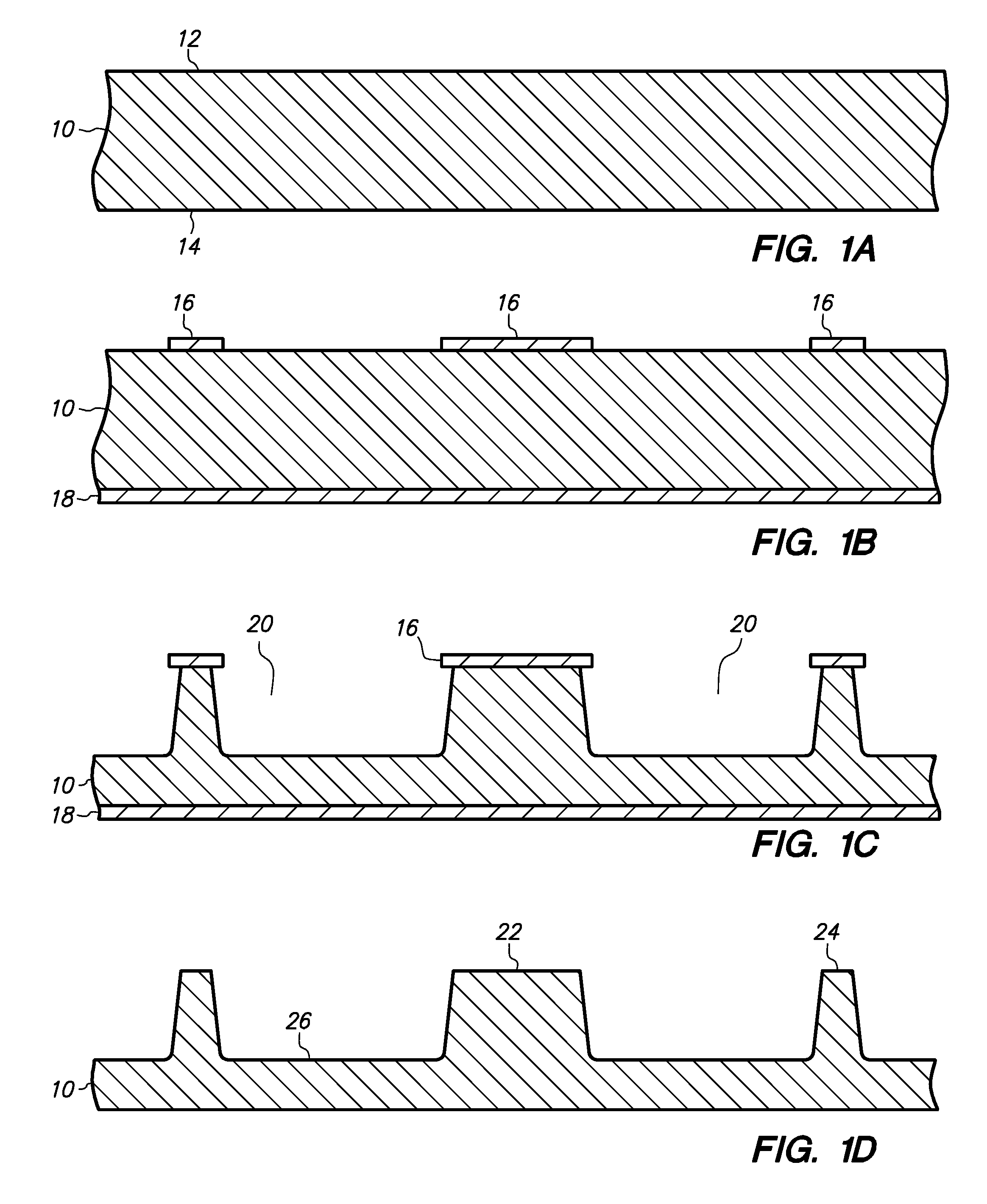

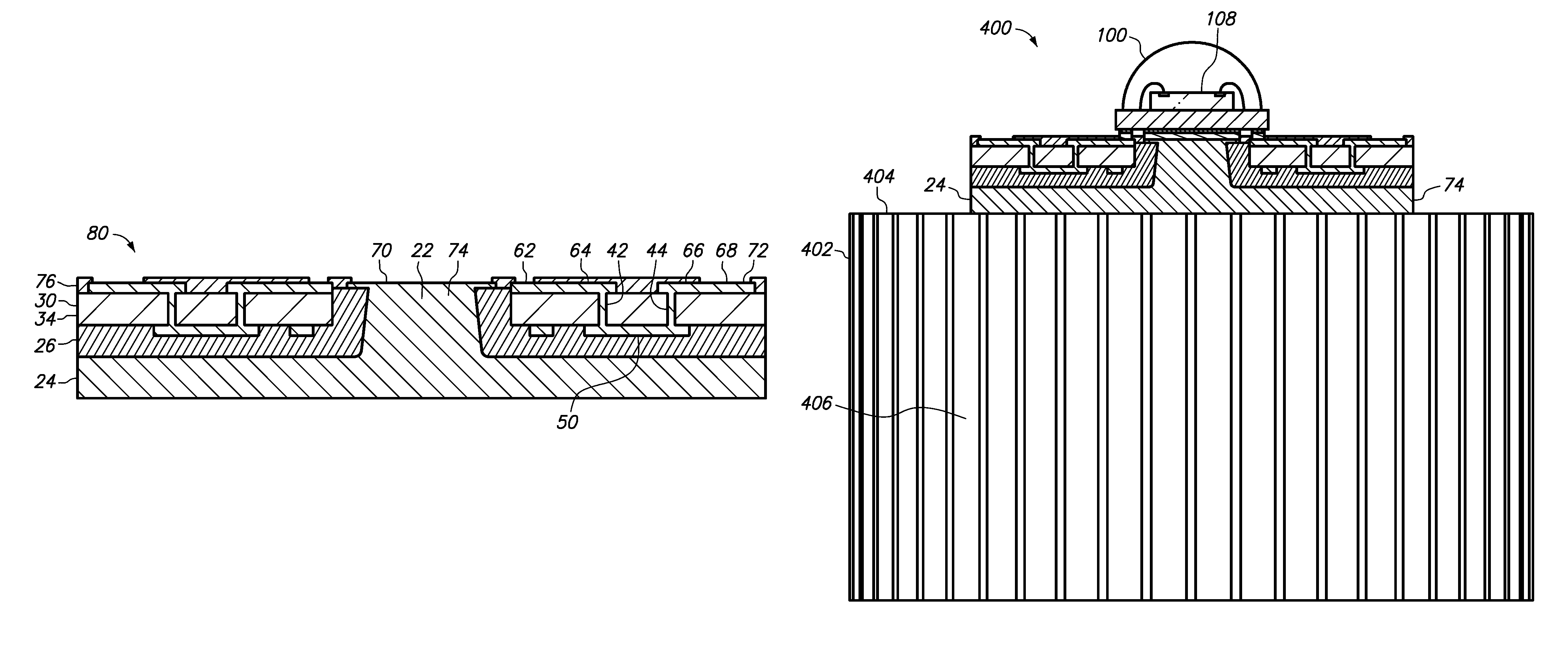

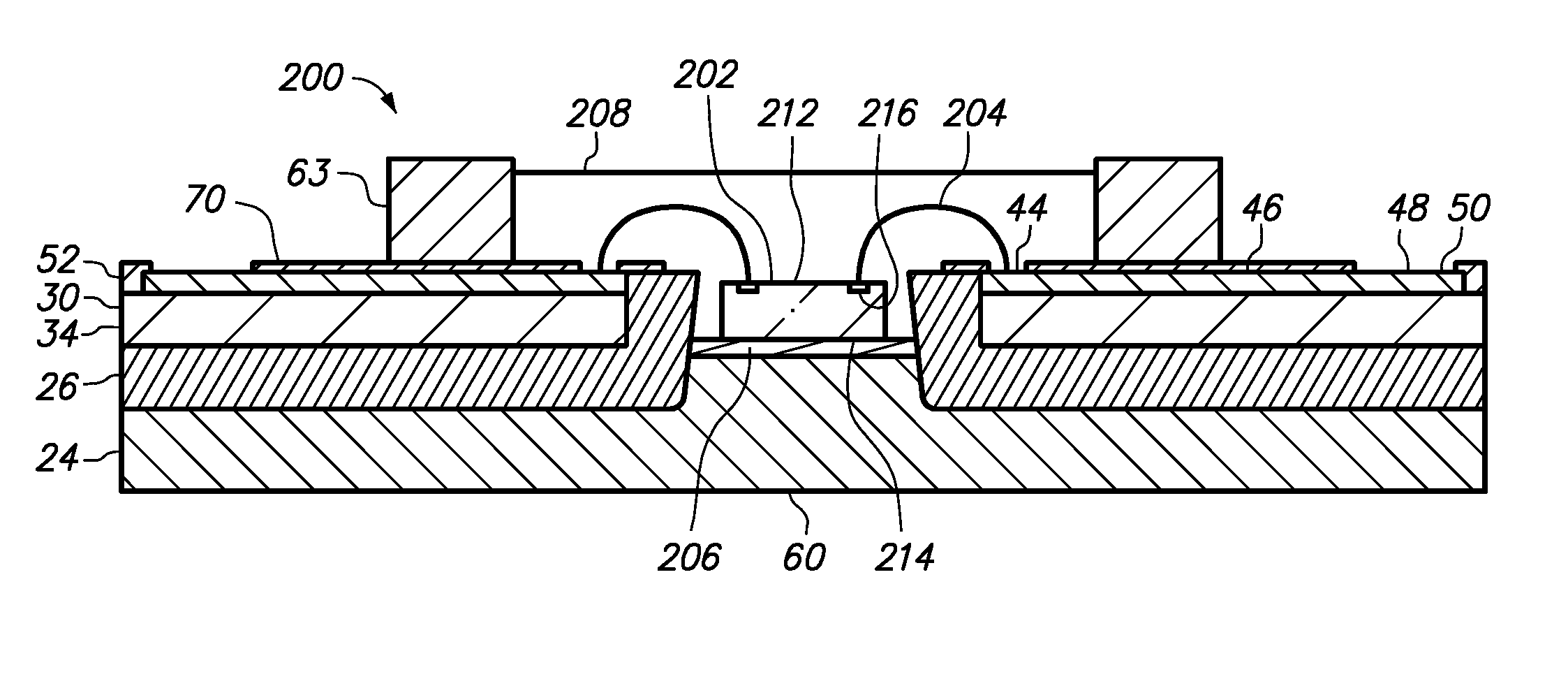

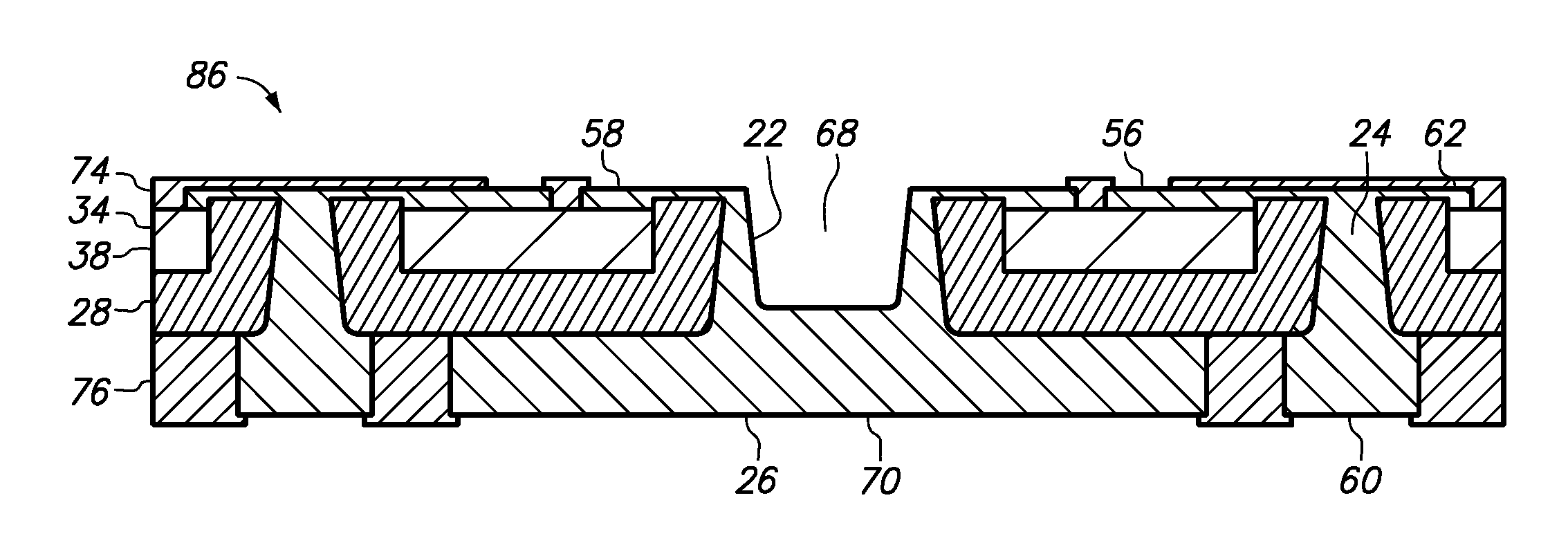

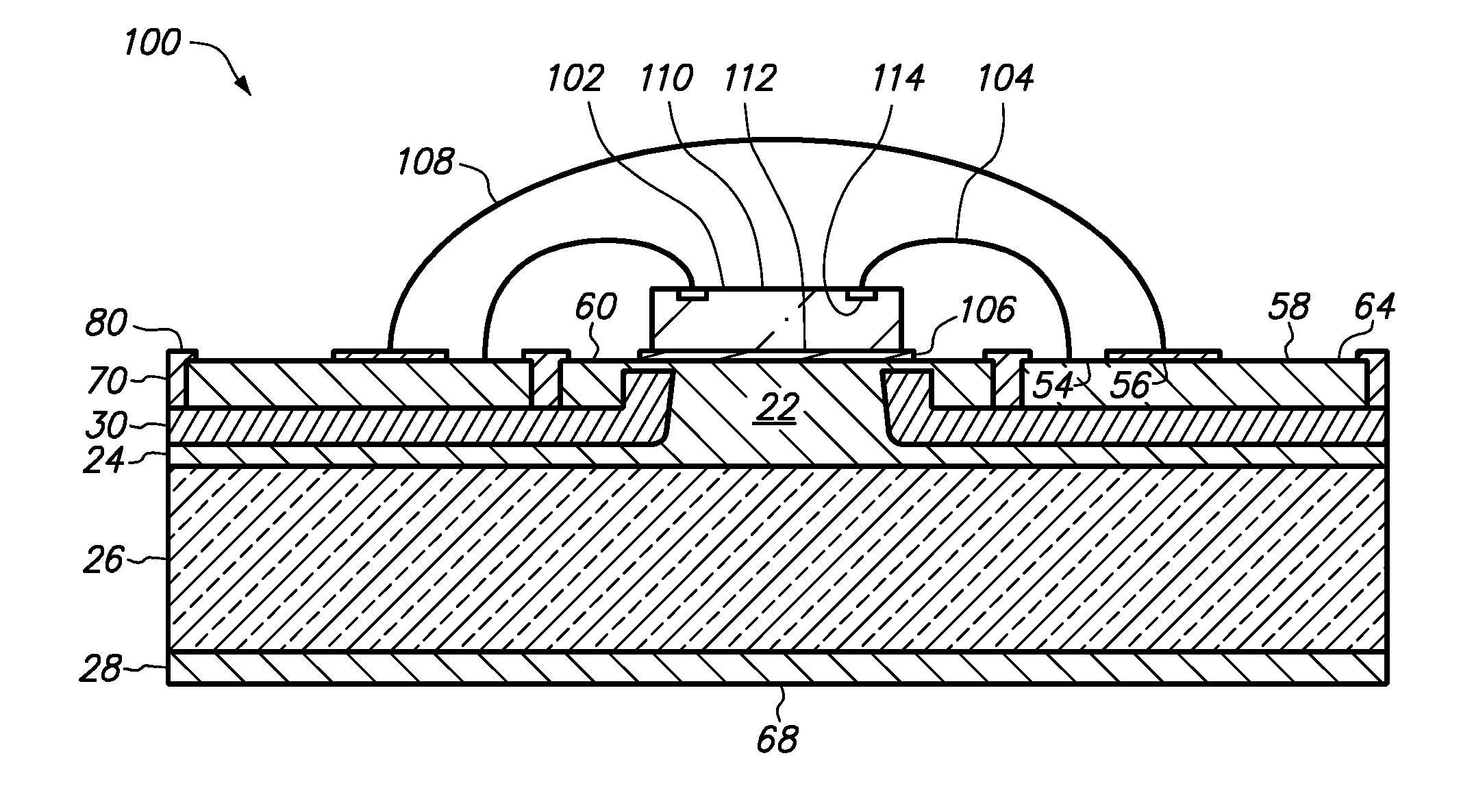

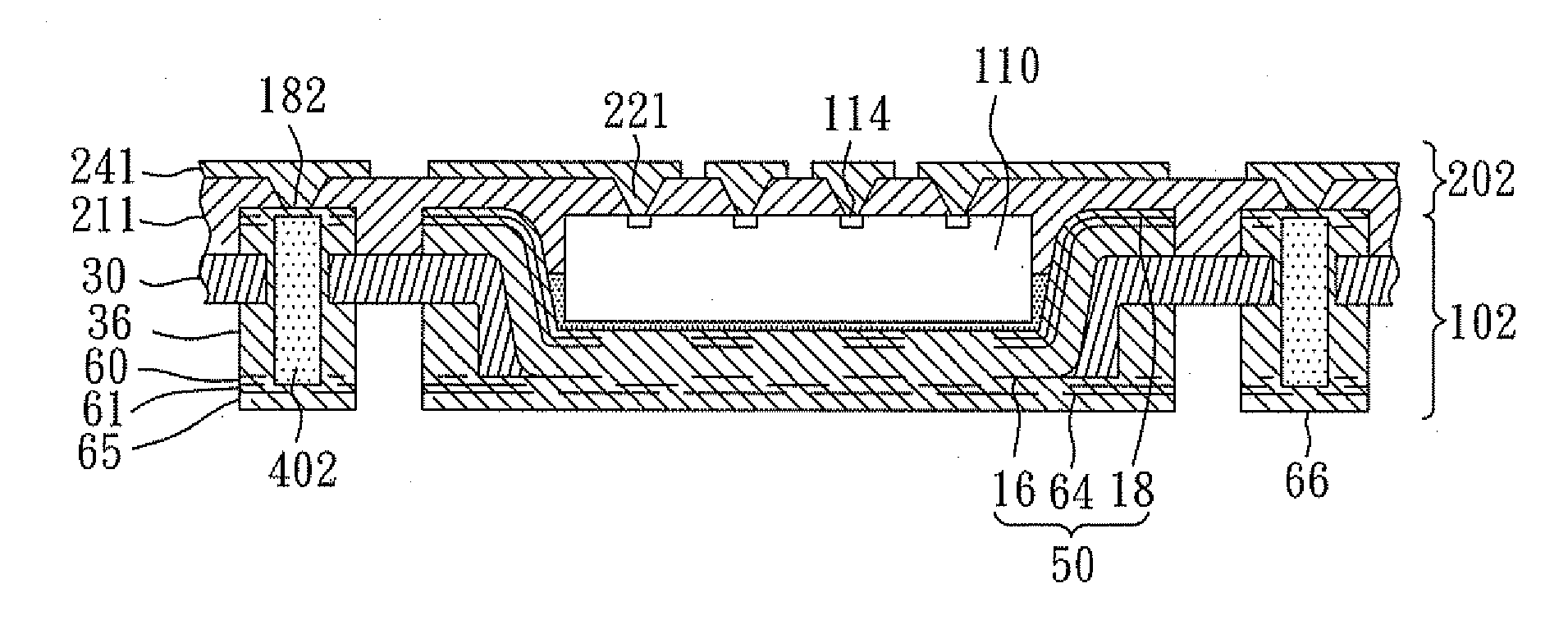

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a post, a base, an ESD protection layer and an underlayer. The conductive trace includes a pad and a terminal. The semiconductor device is electrically connected to the conductive trace, electrically isolated from the underlayer and thermally connected to the heat spreader. The post extends upwardly from the base into an opening in the adhesive, the base extends laterally from the post and the ESD protection layer is sandwiched between the base and the underlayer. The conductive trace provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

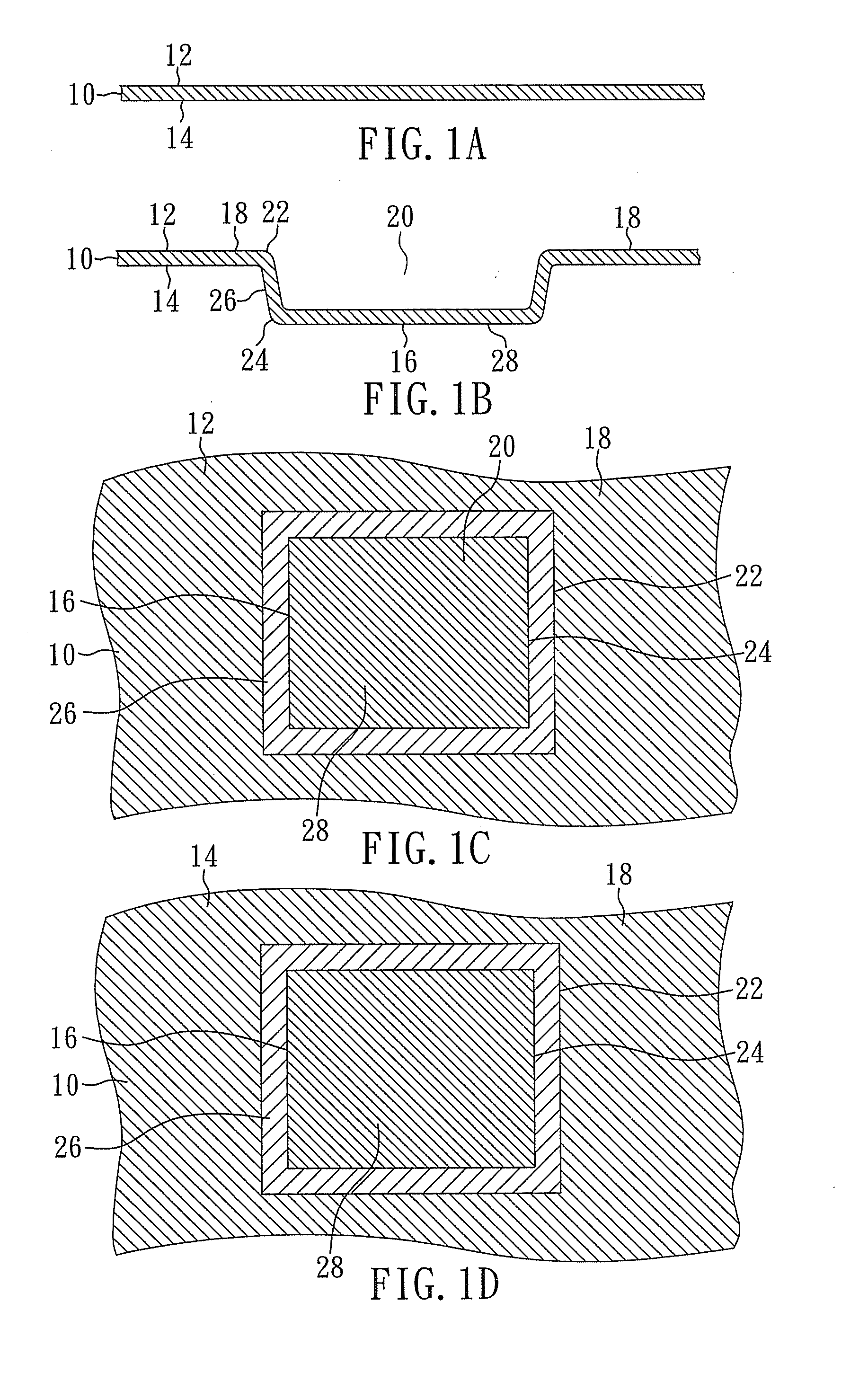

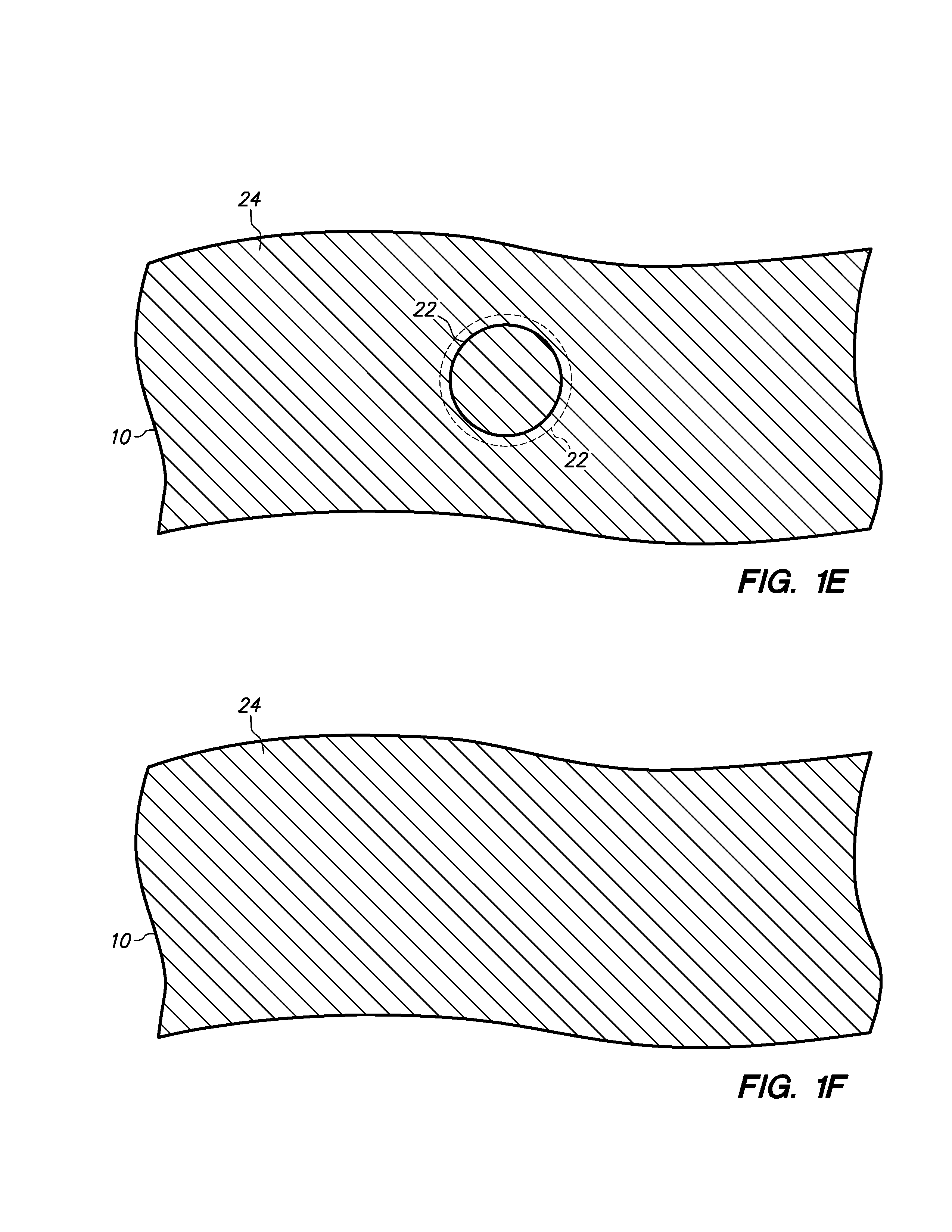

Semiconductor chip assembly with post/base heat spreader and horizontal signal routing

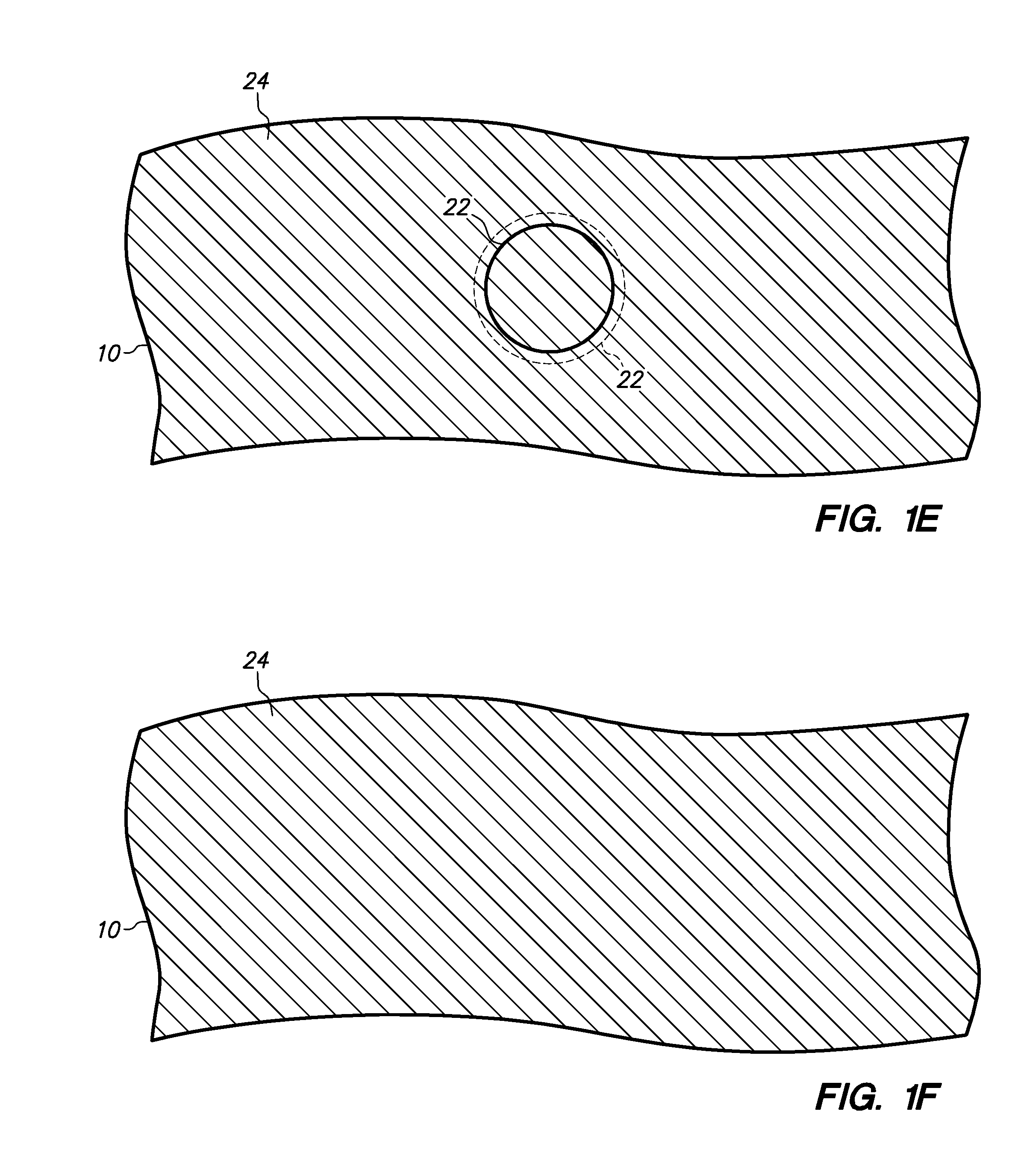

InactiveUS20100001309A1Enhance thermal connectionRobust mechanical bondSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringAdhesive

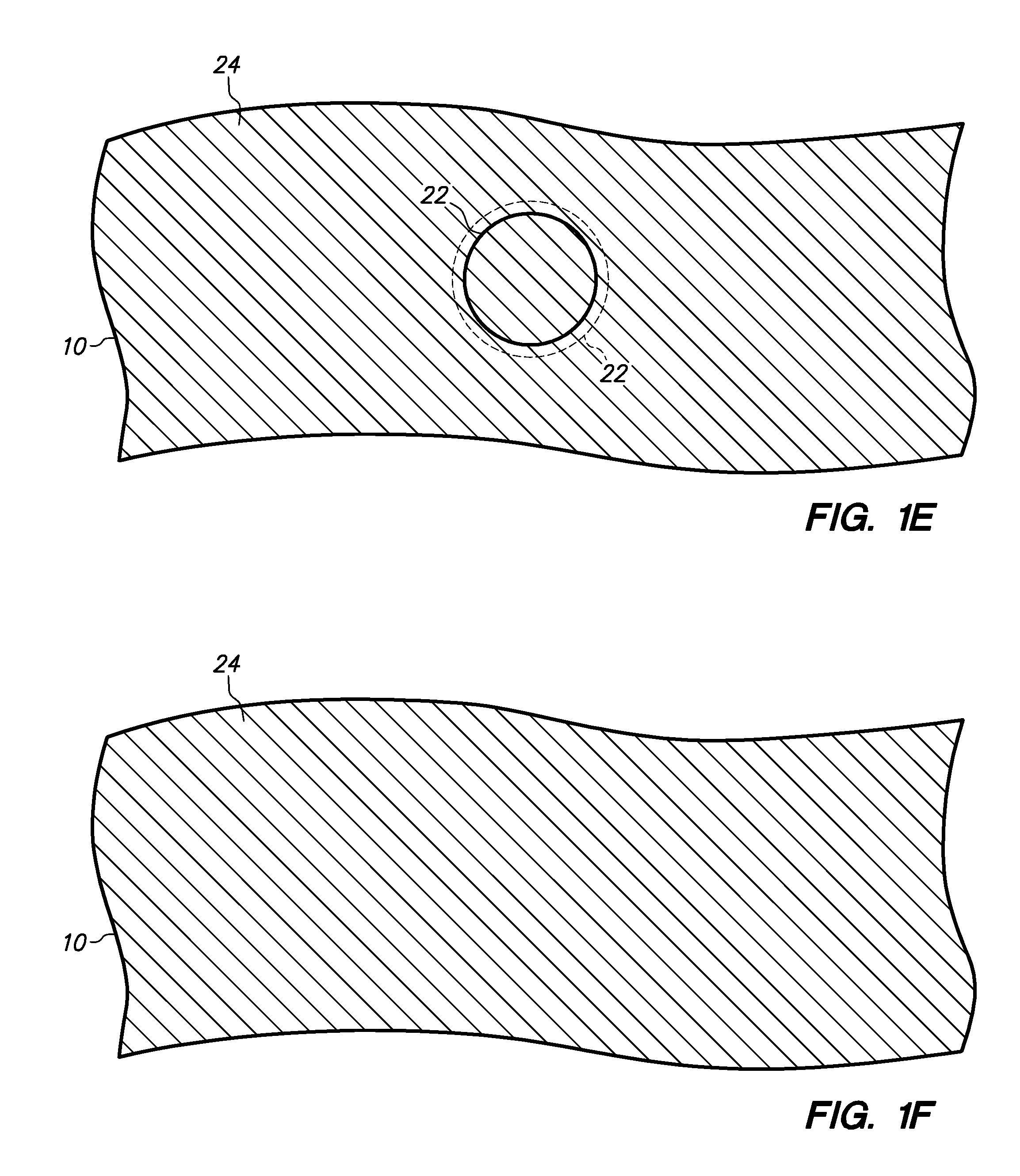

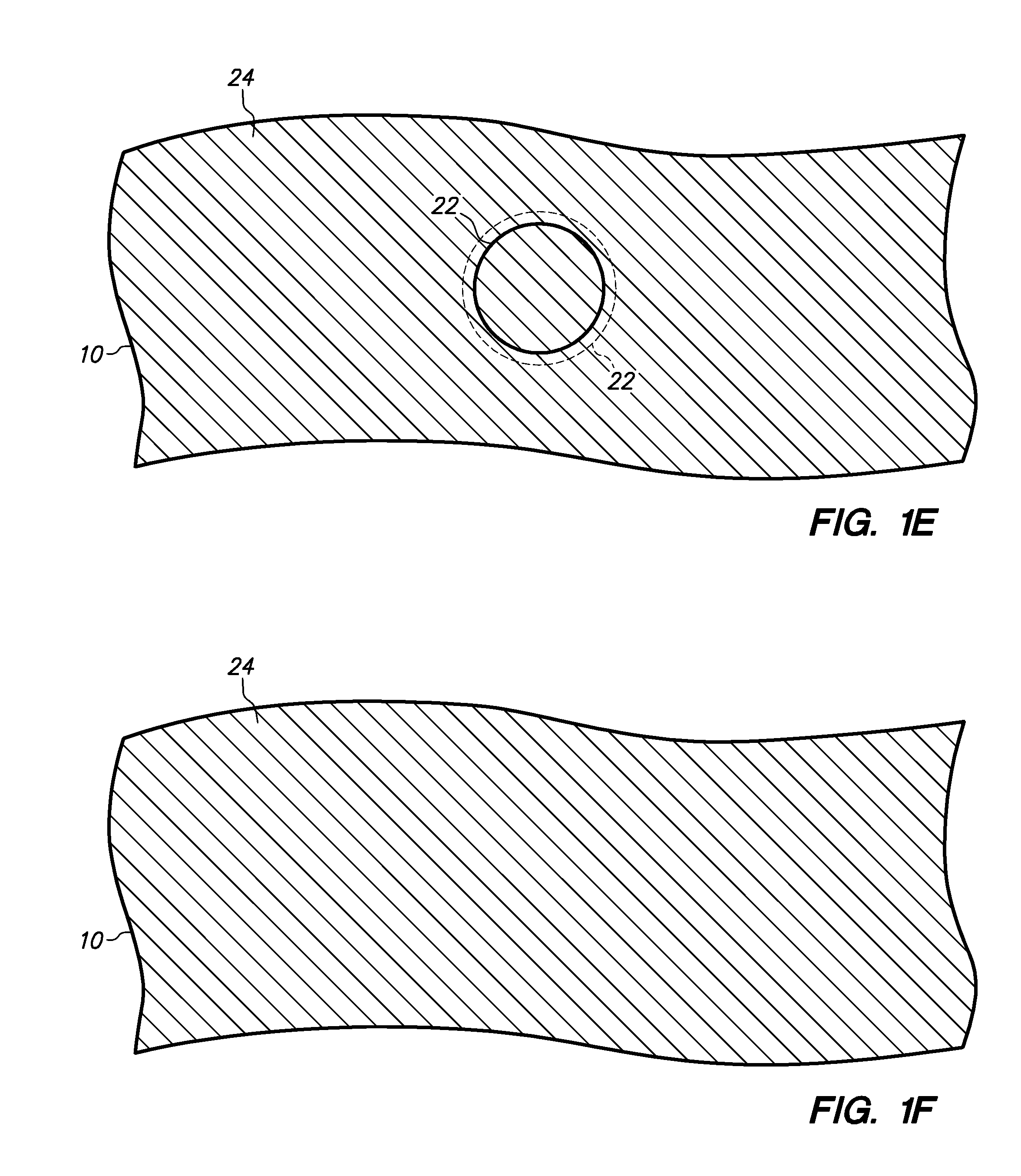

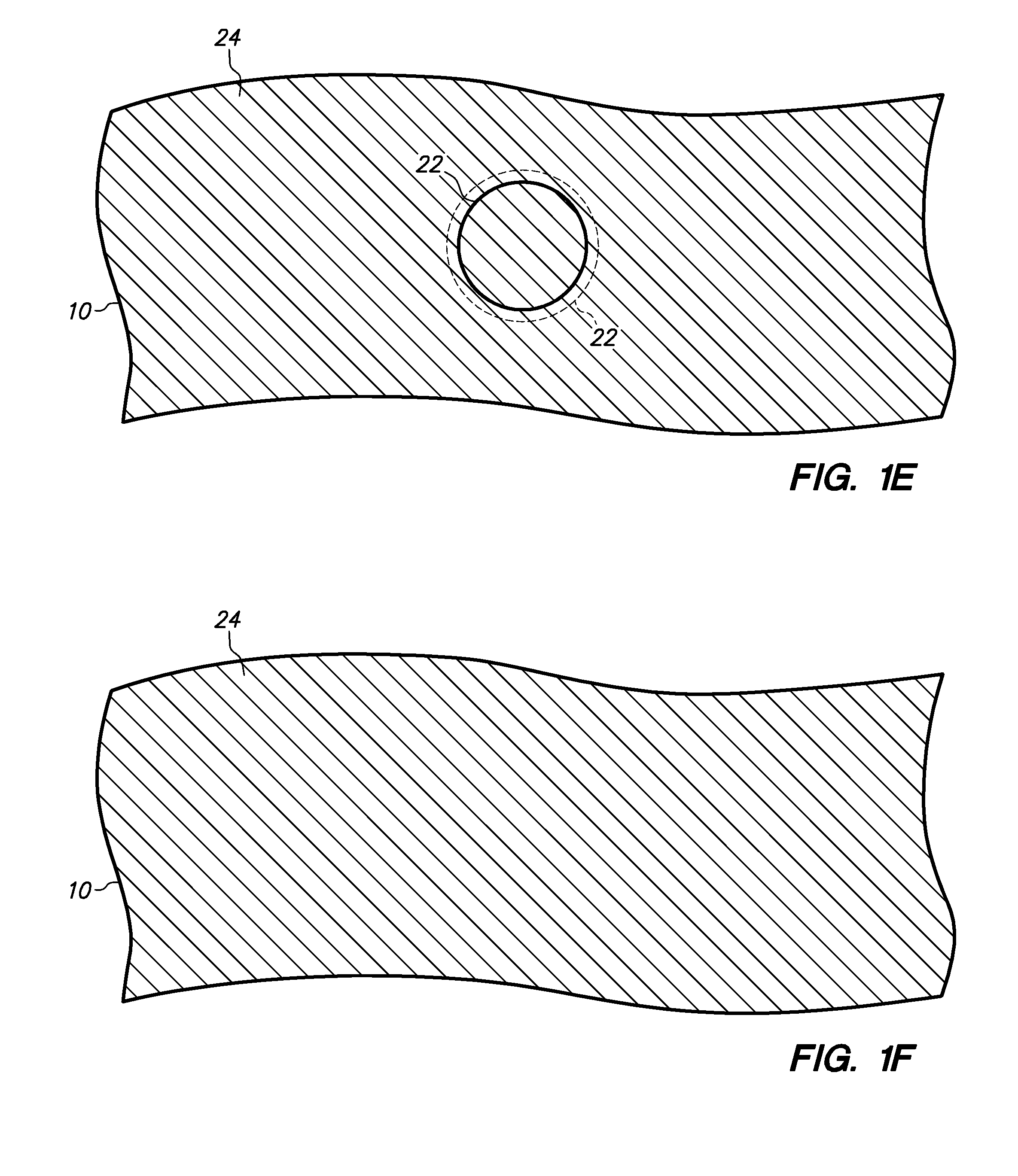

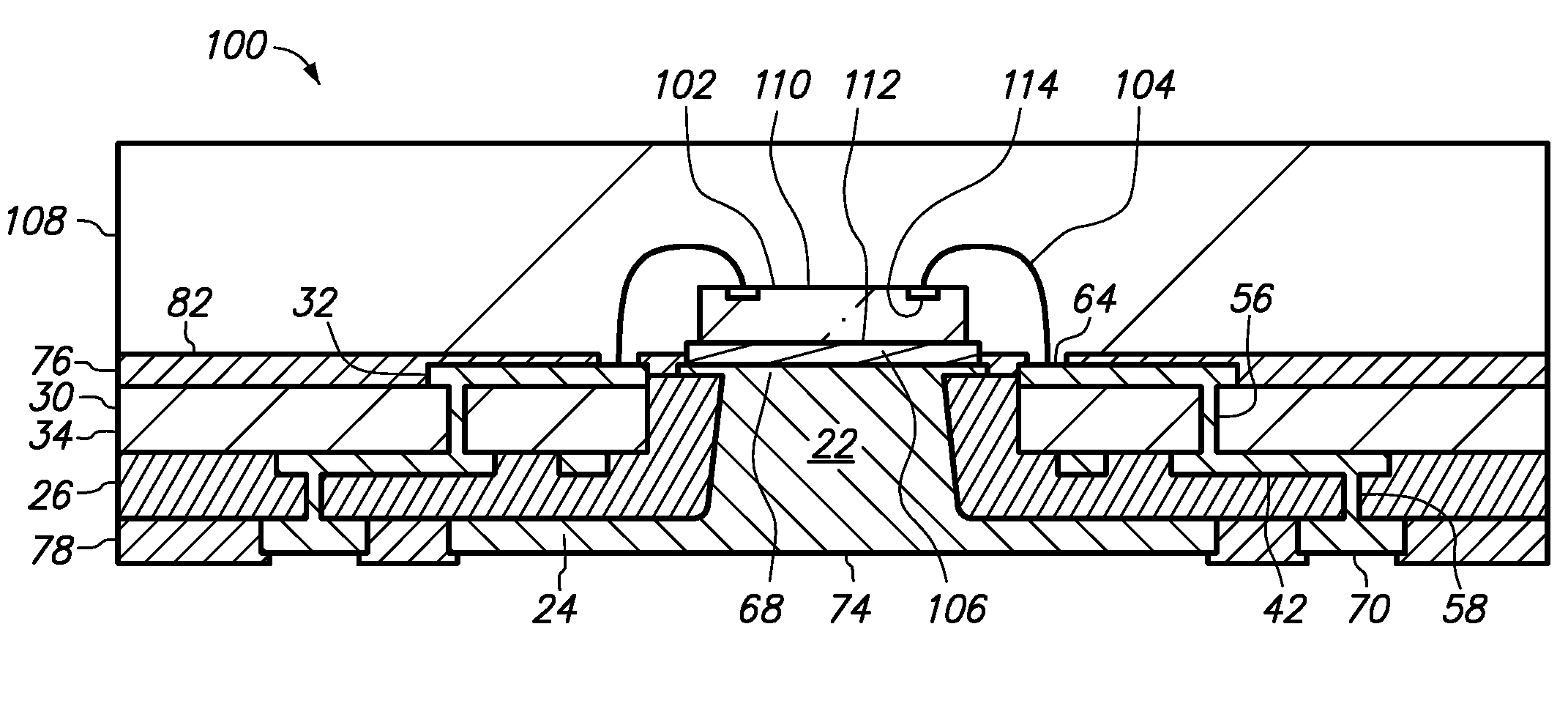

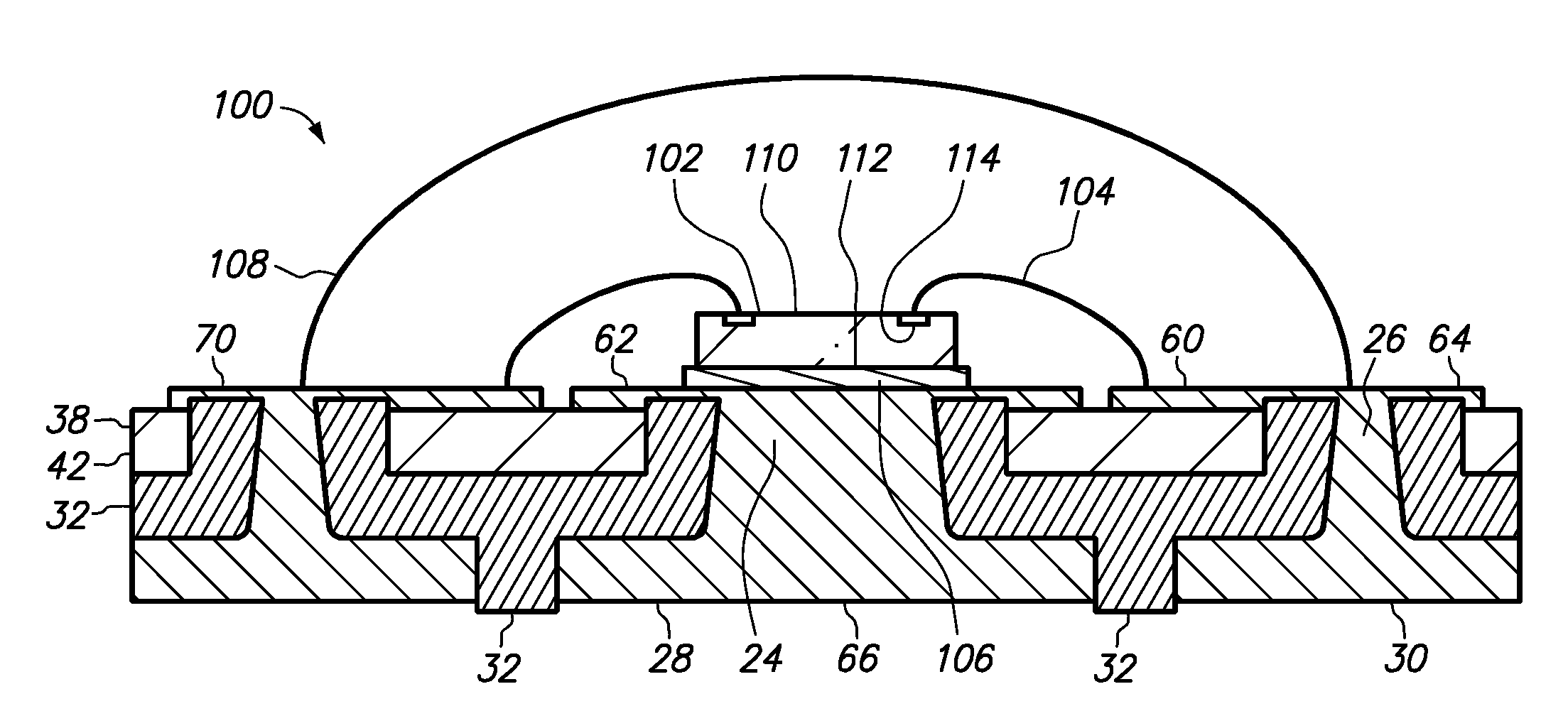

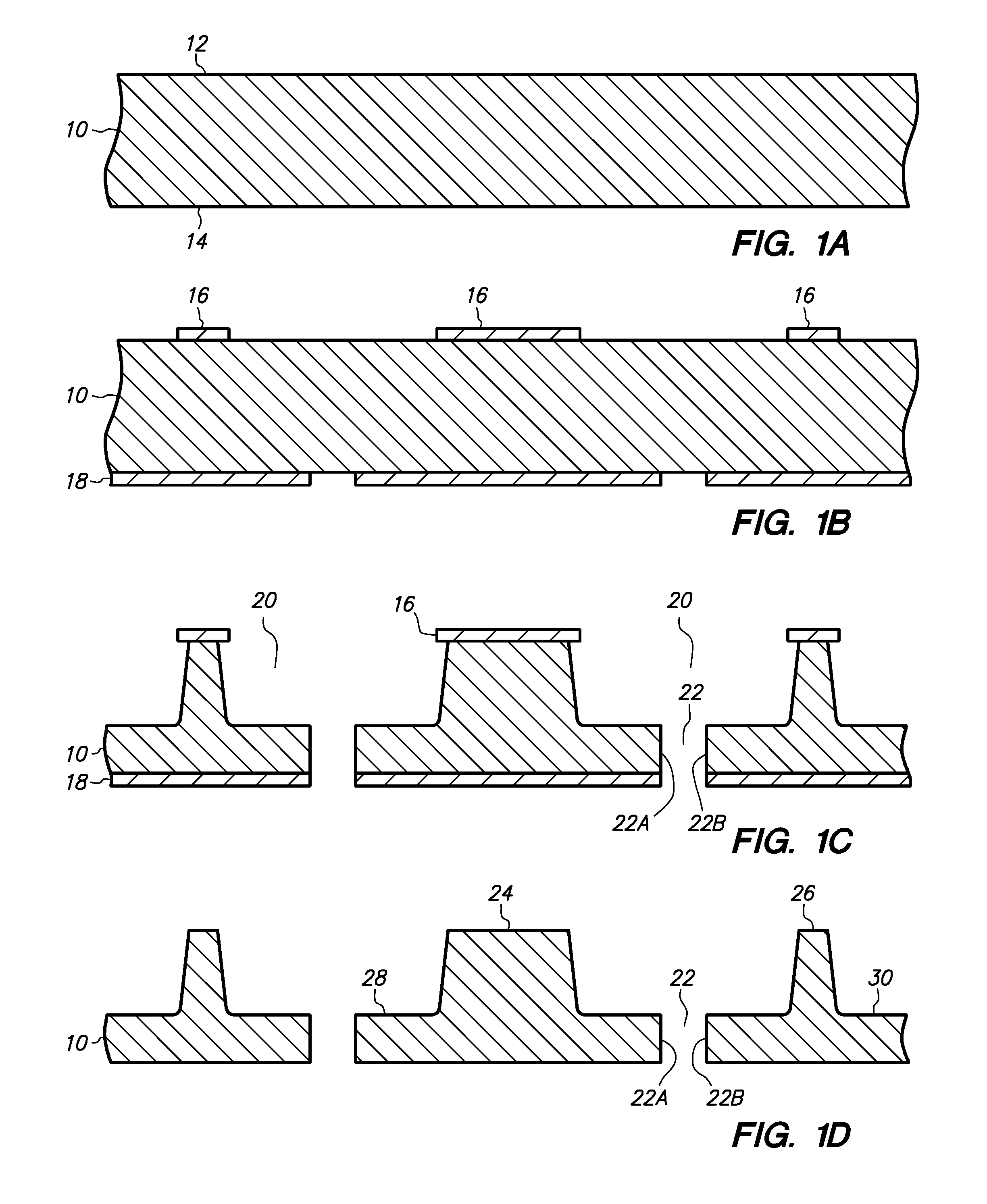

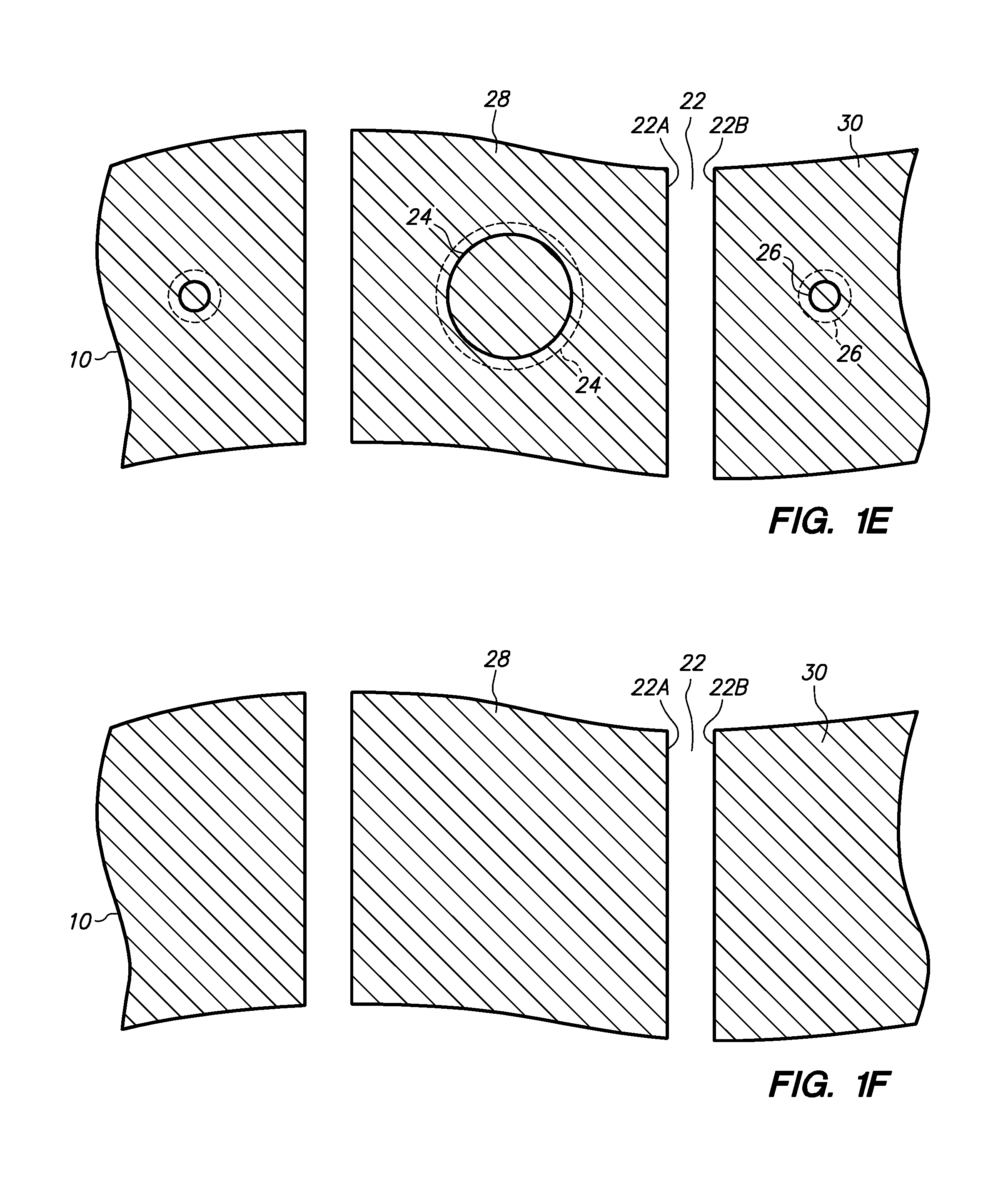

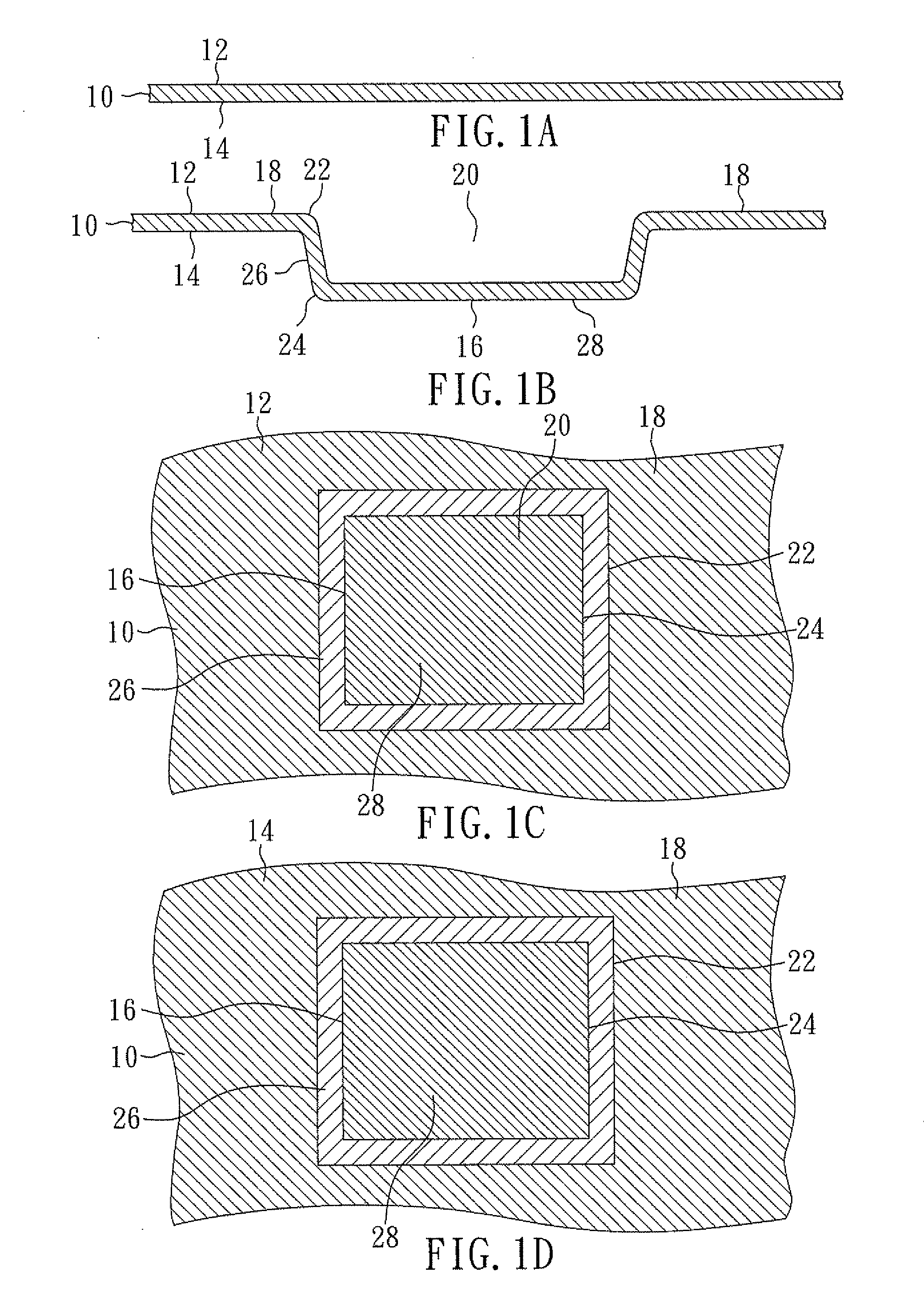

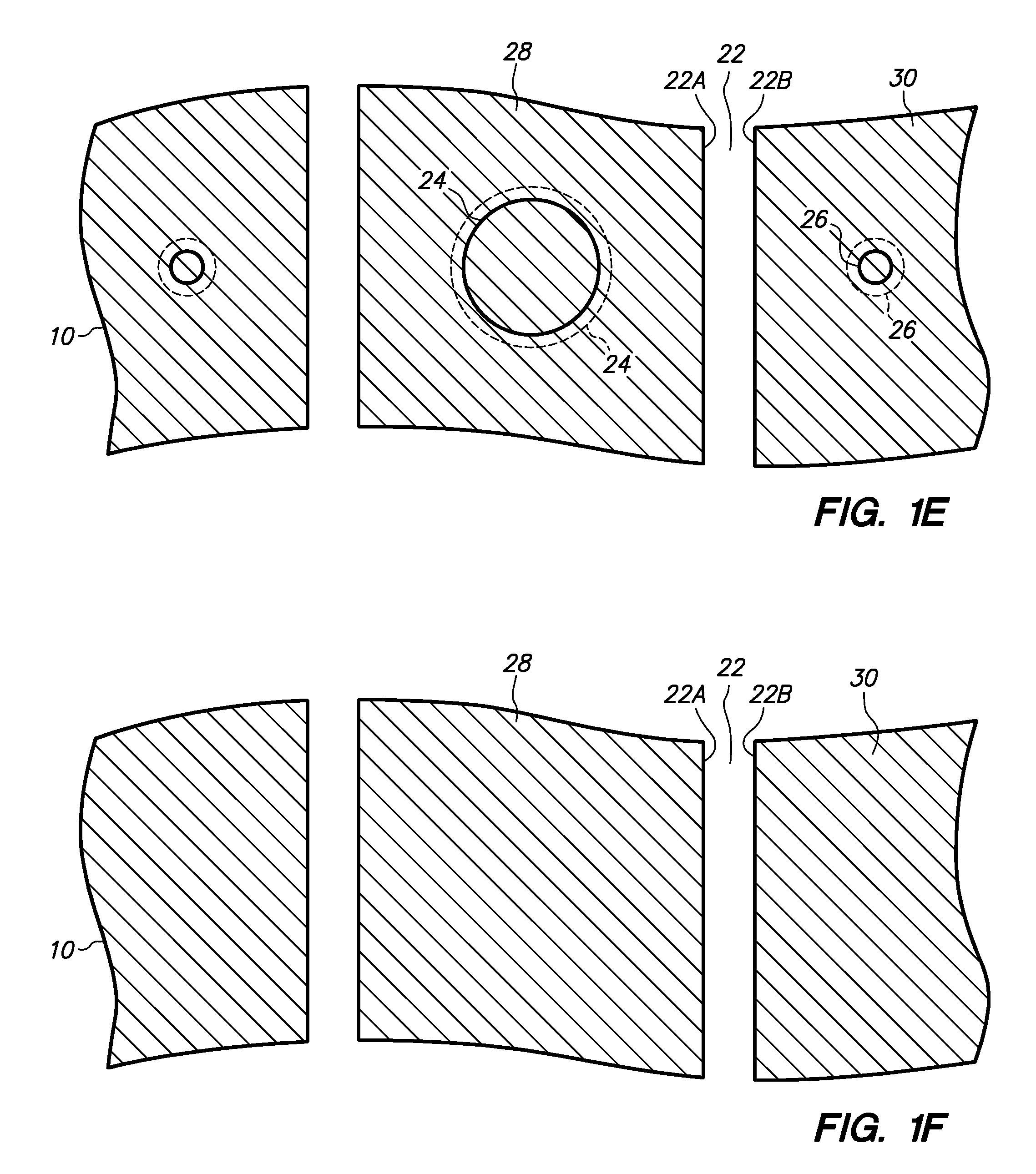

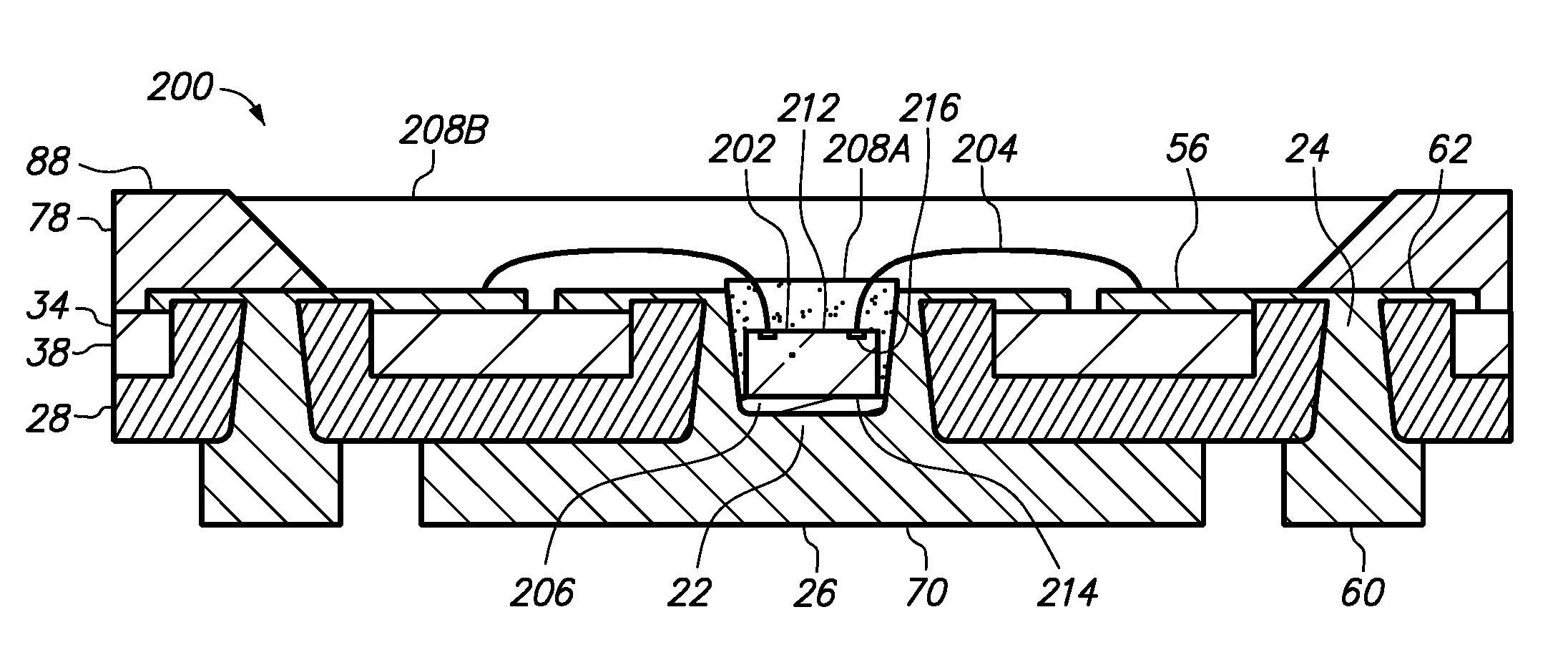

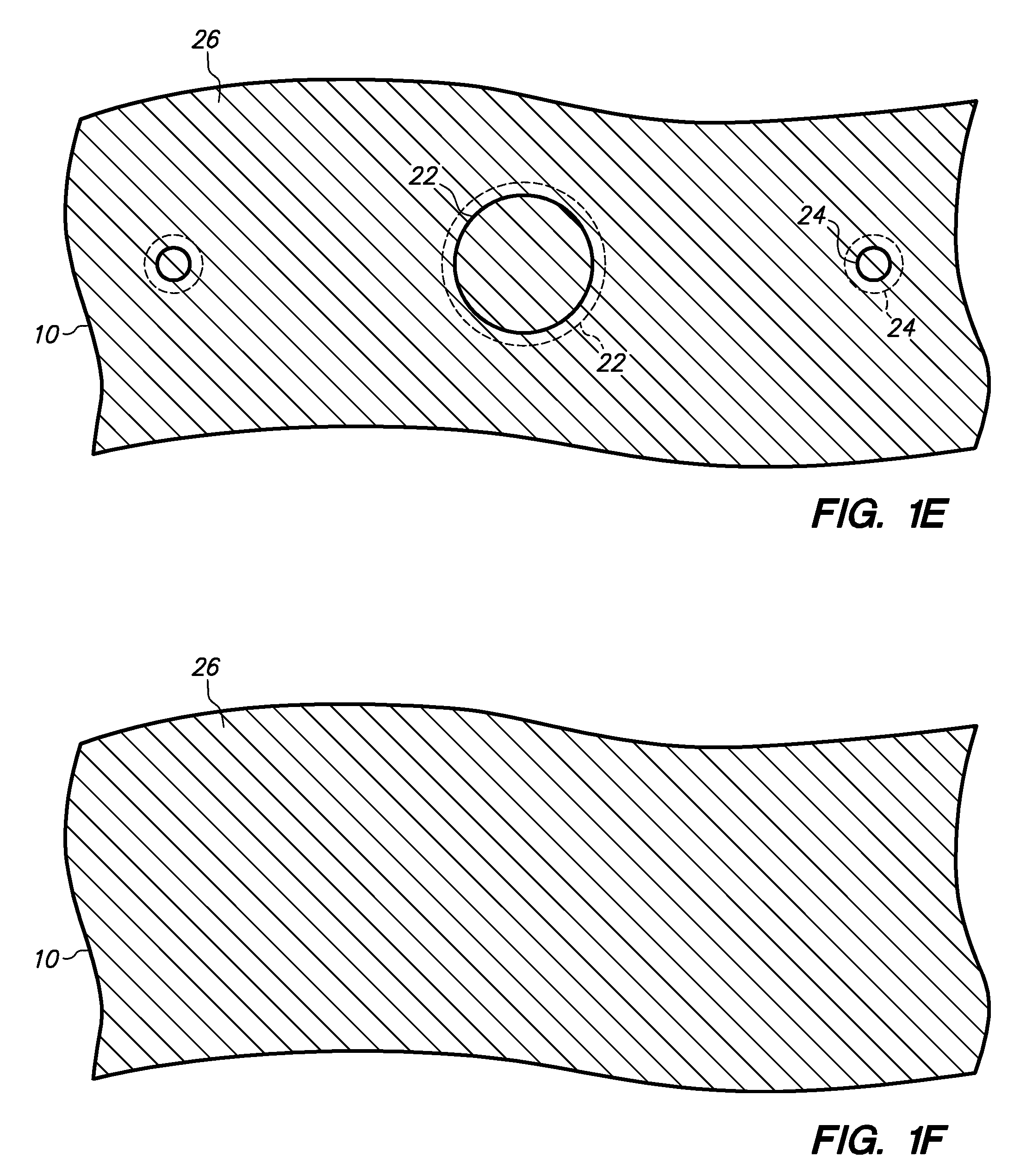

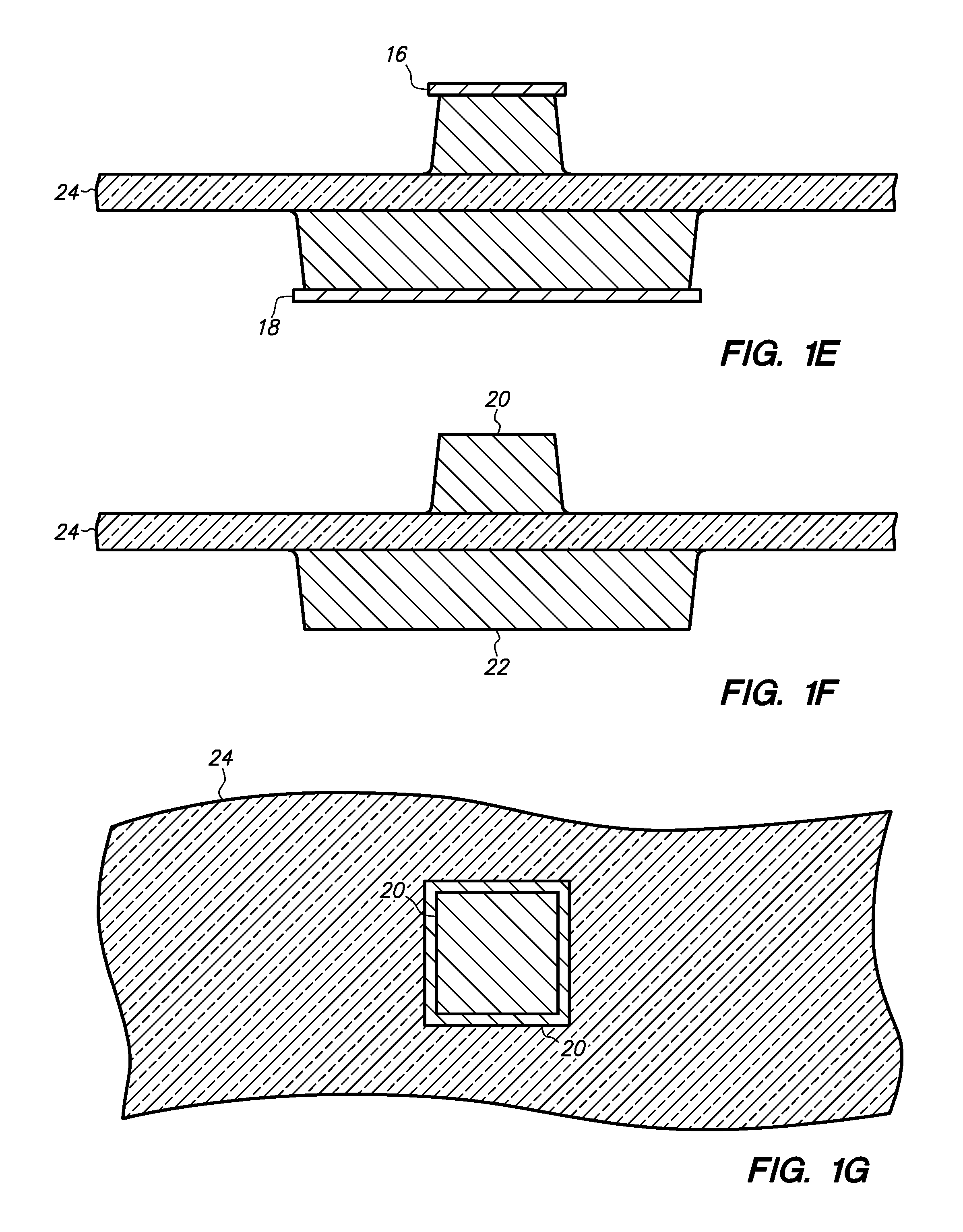

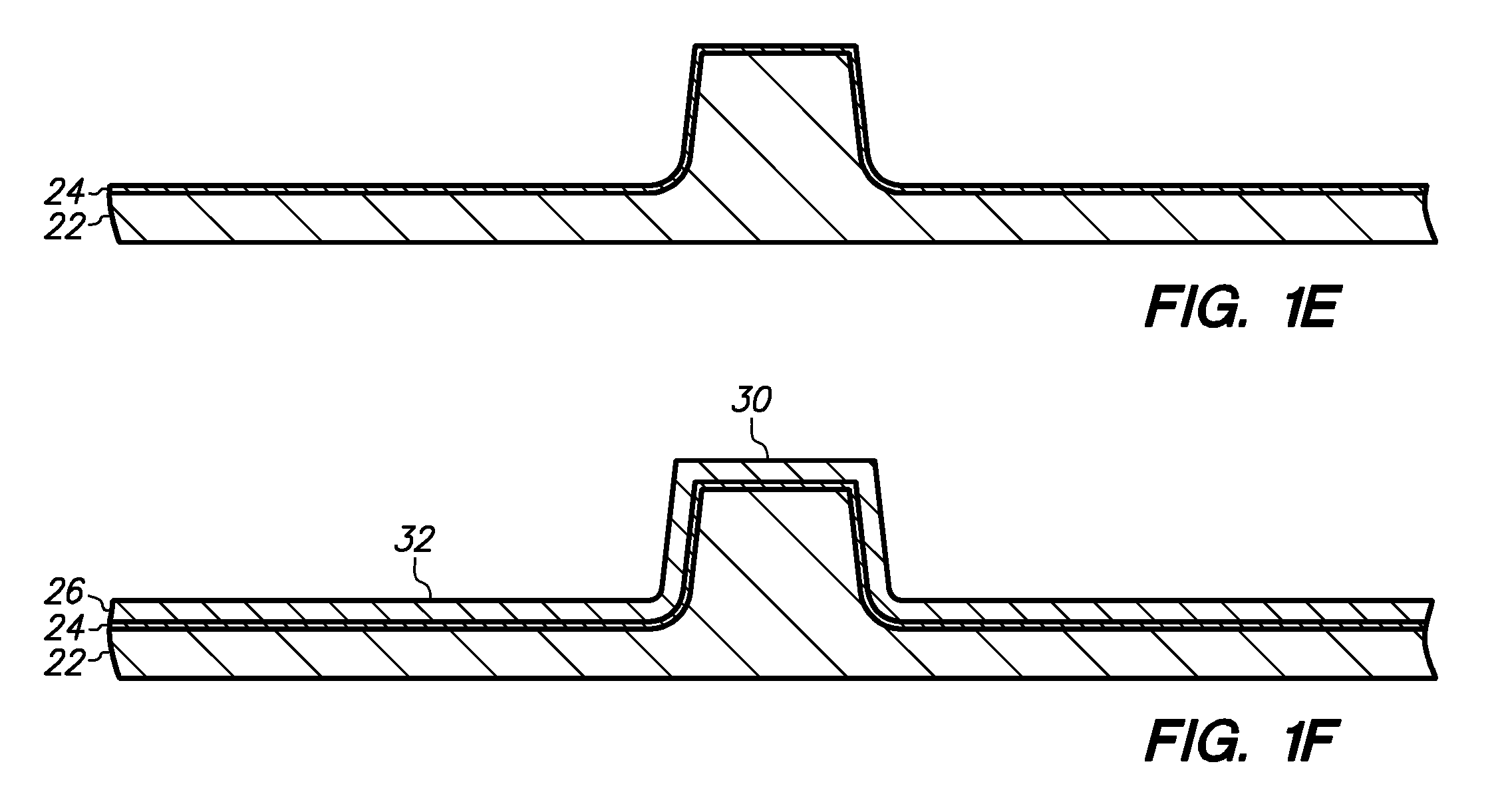

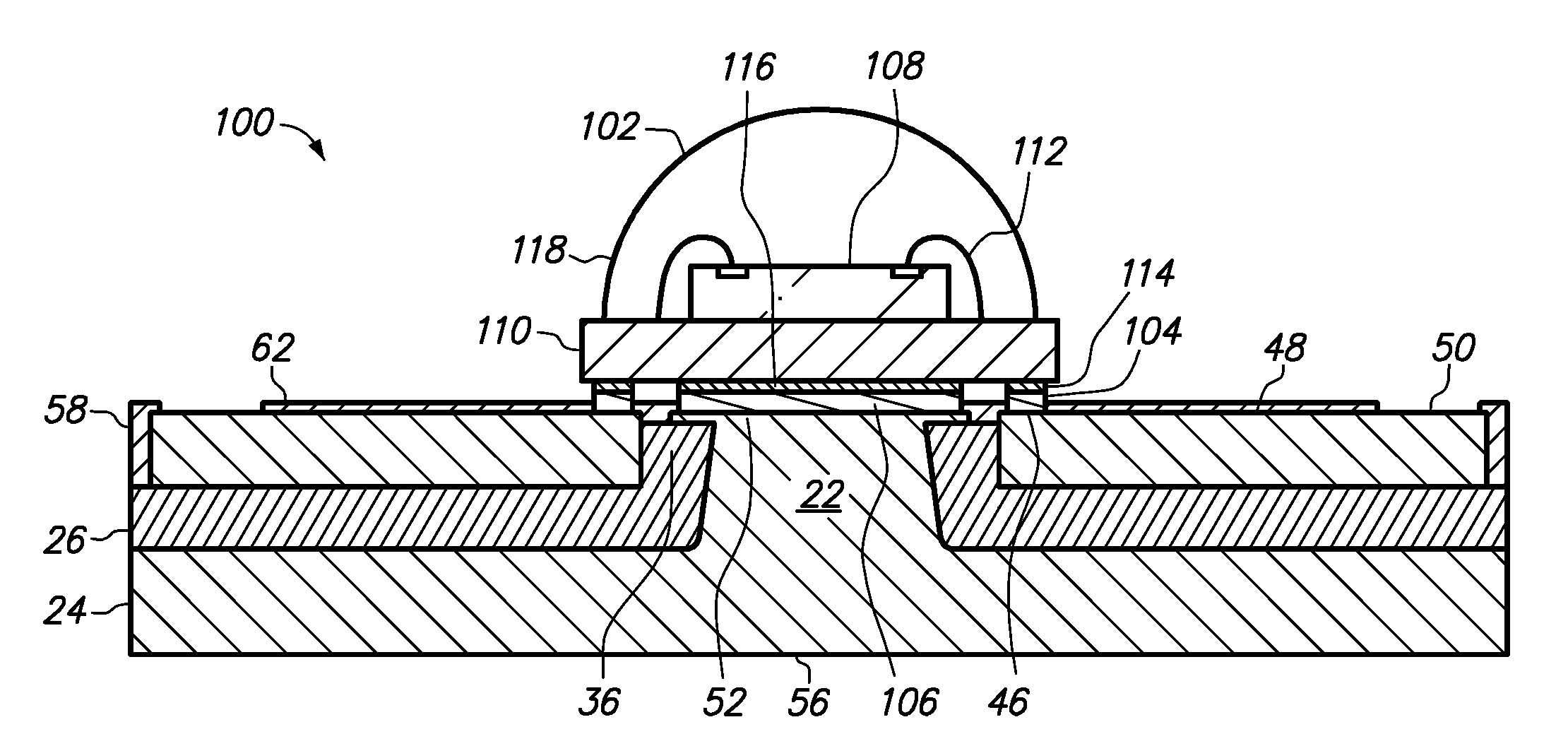

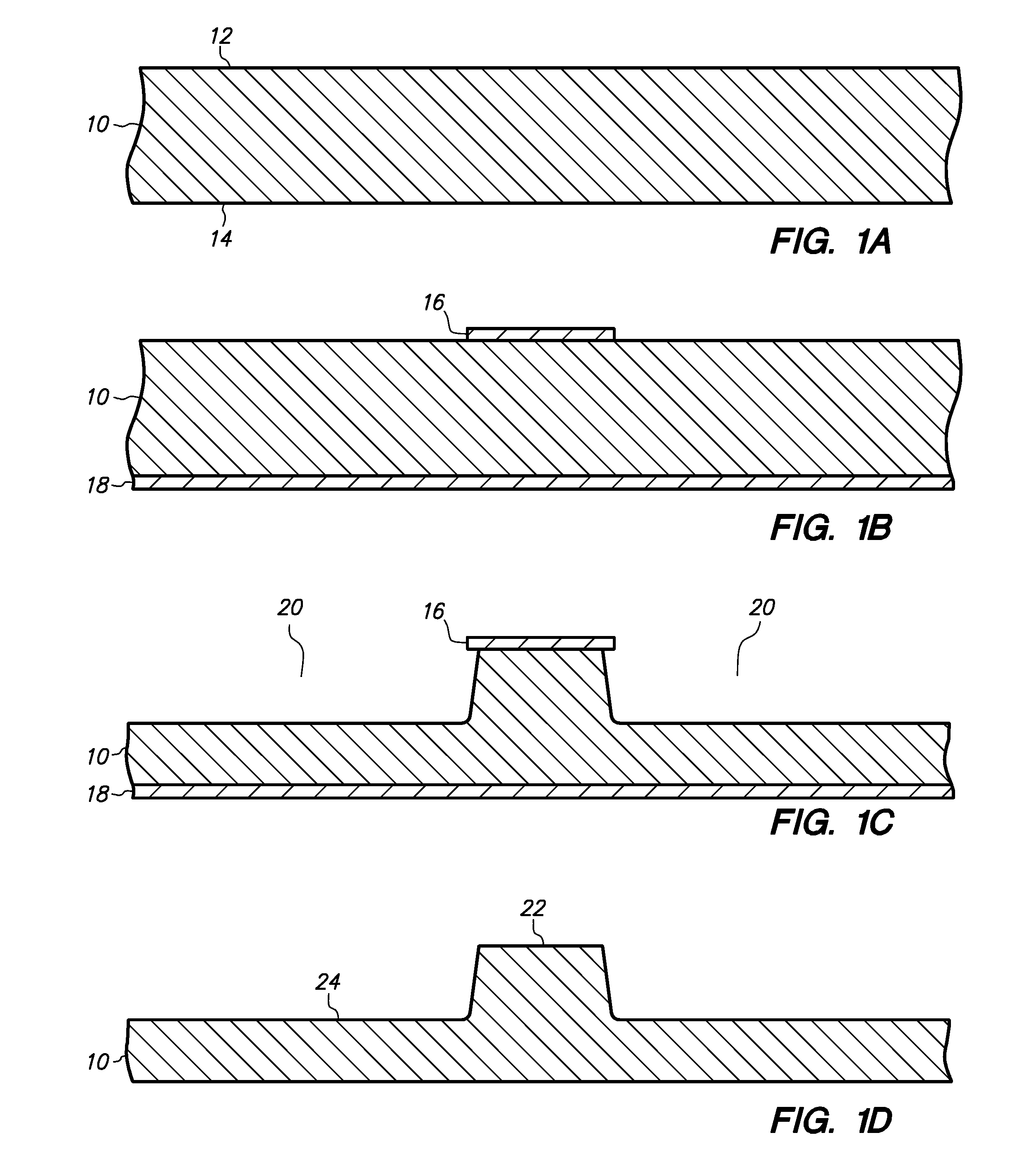

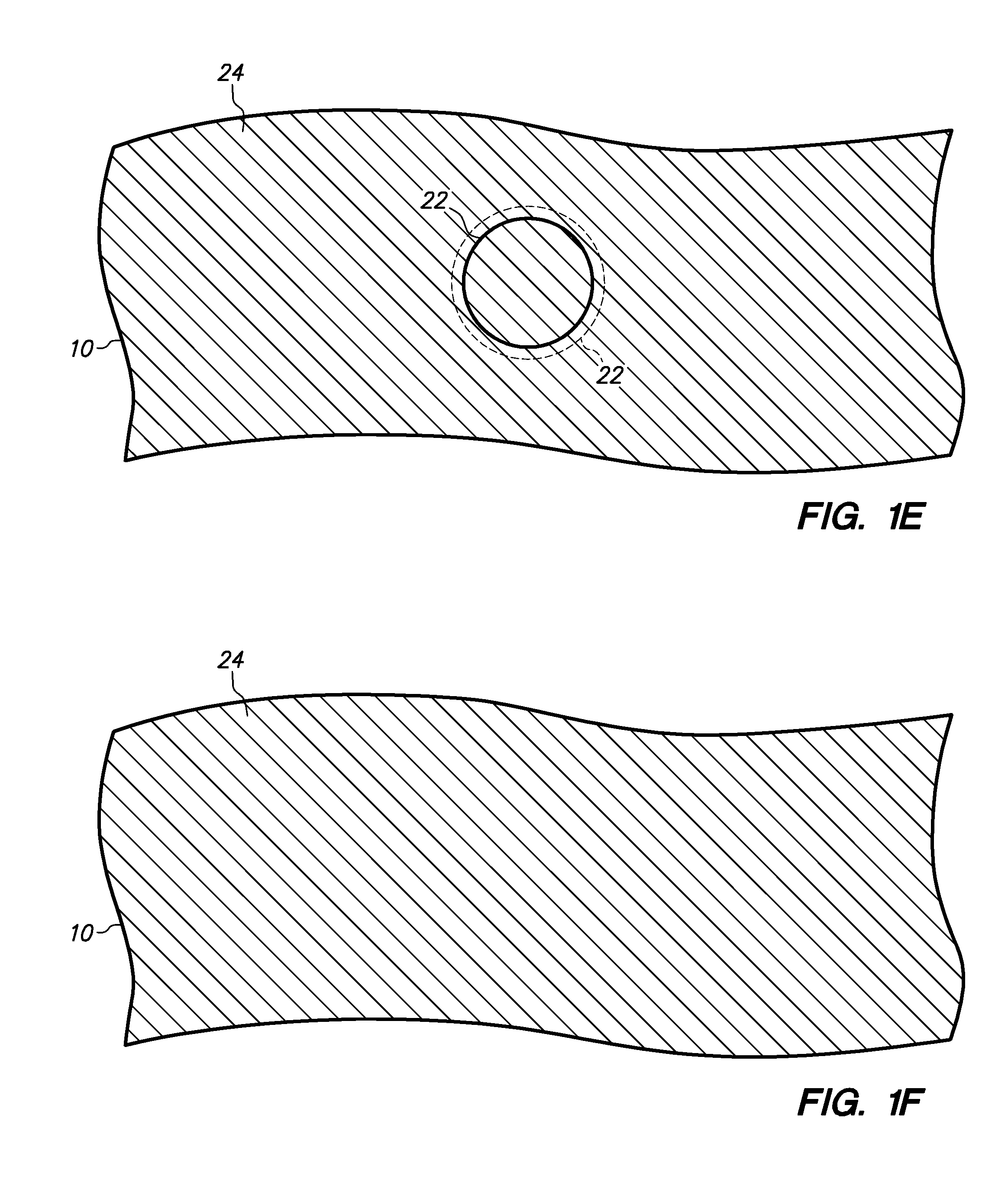

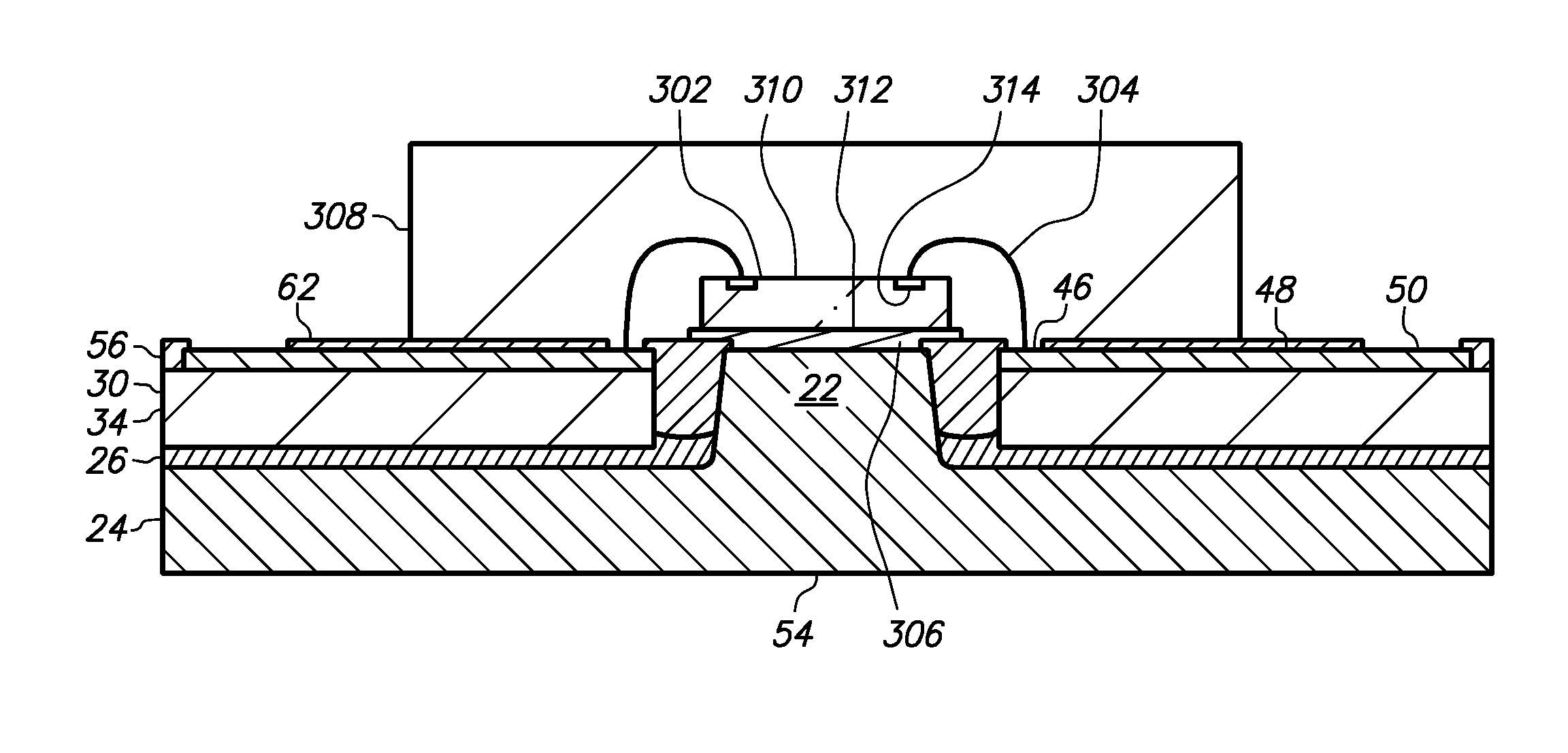

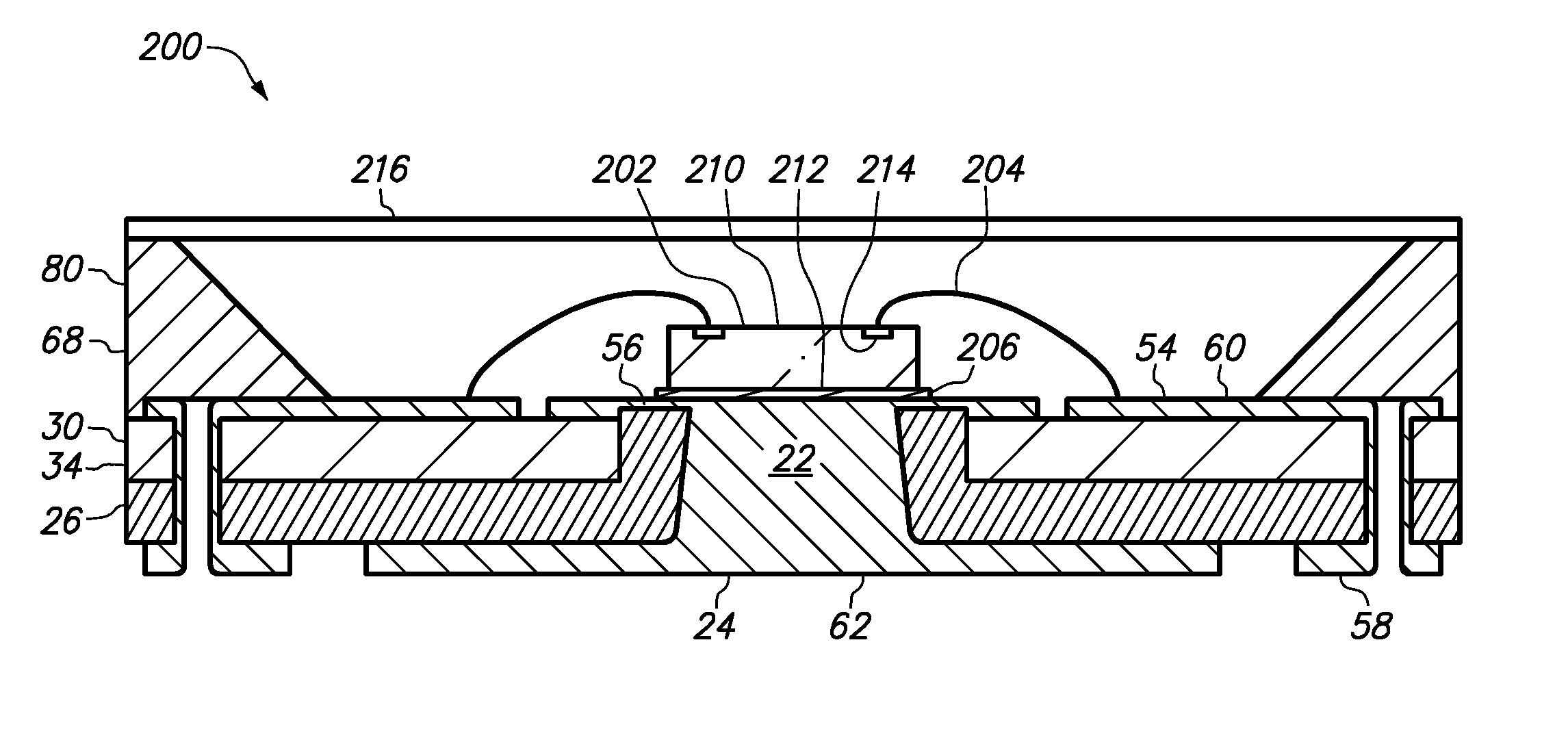

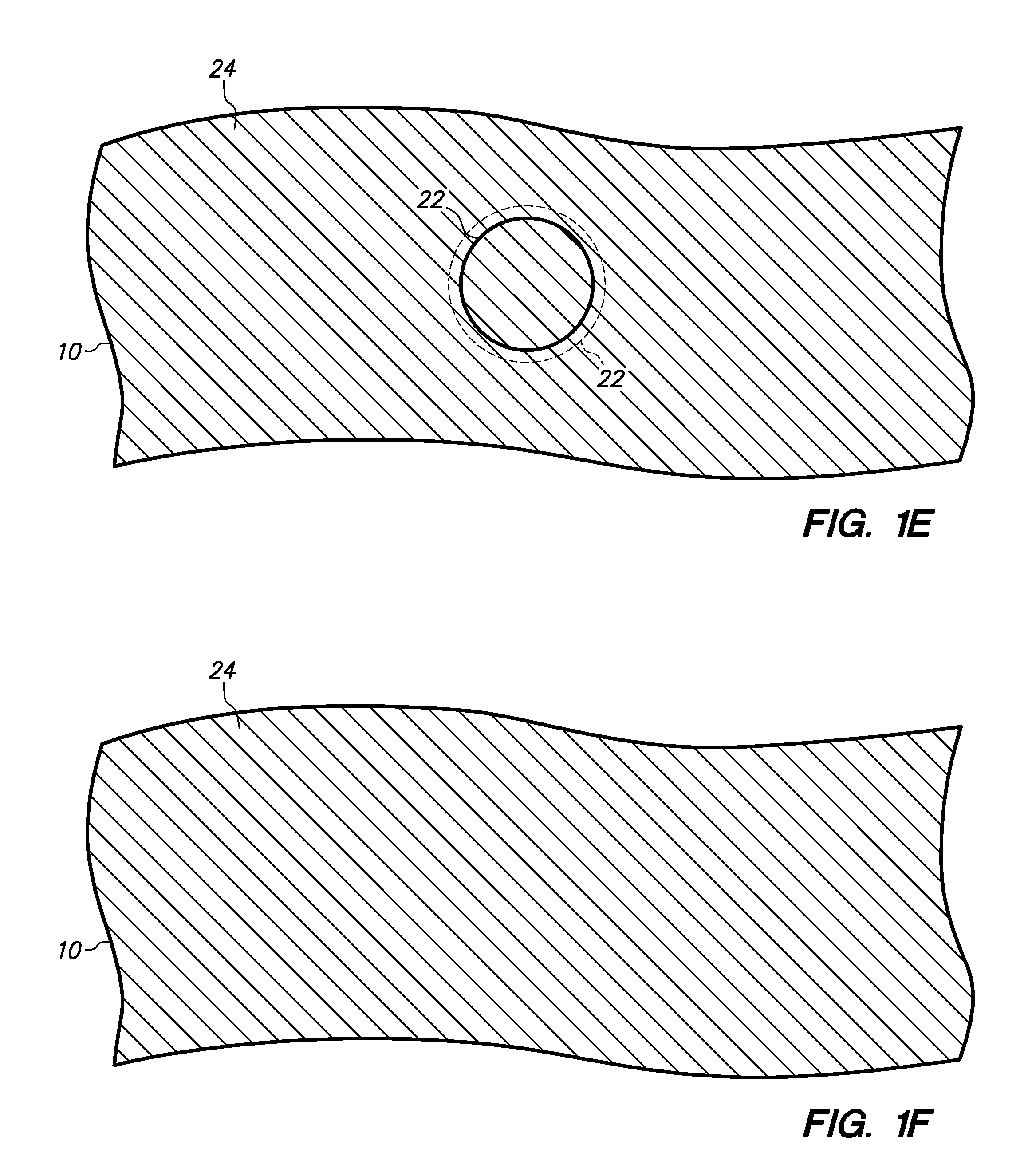

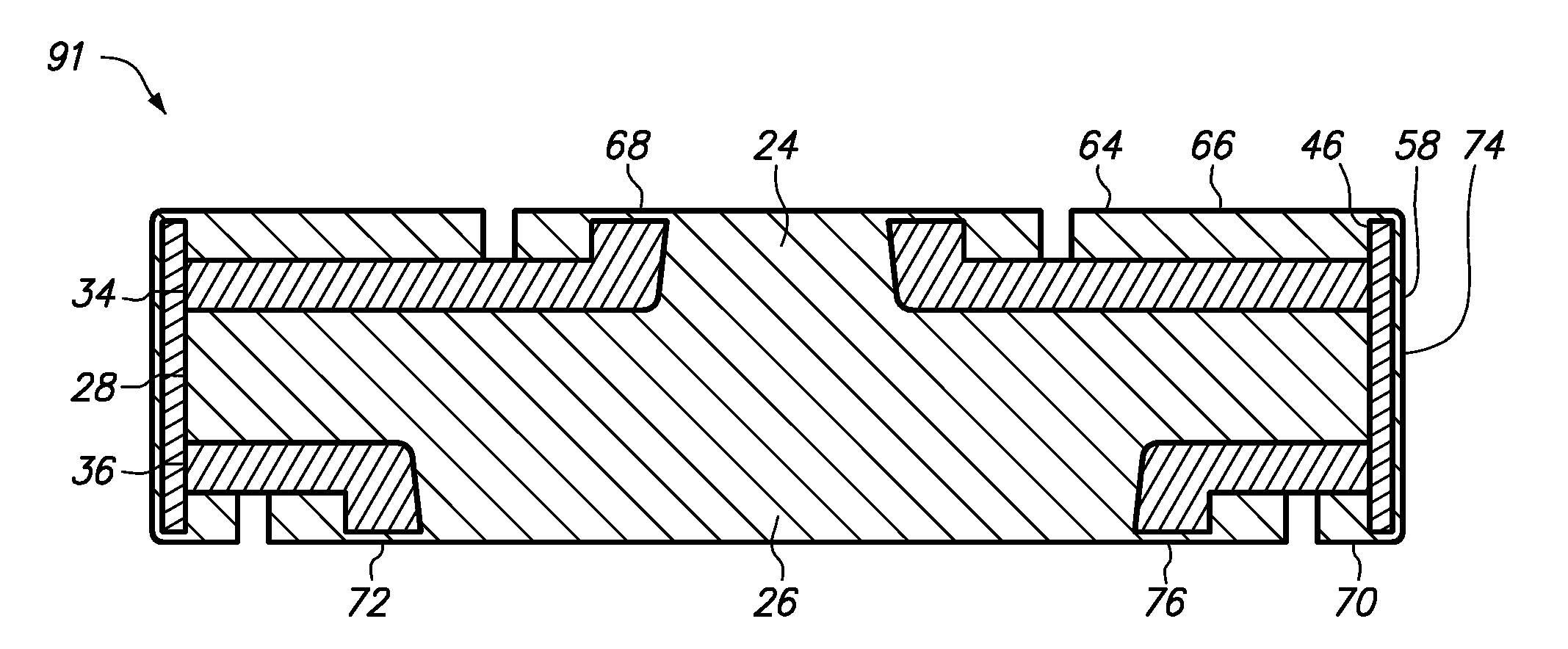

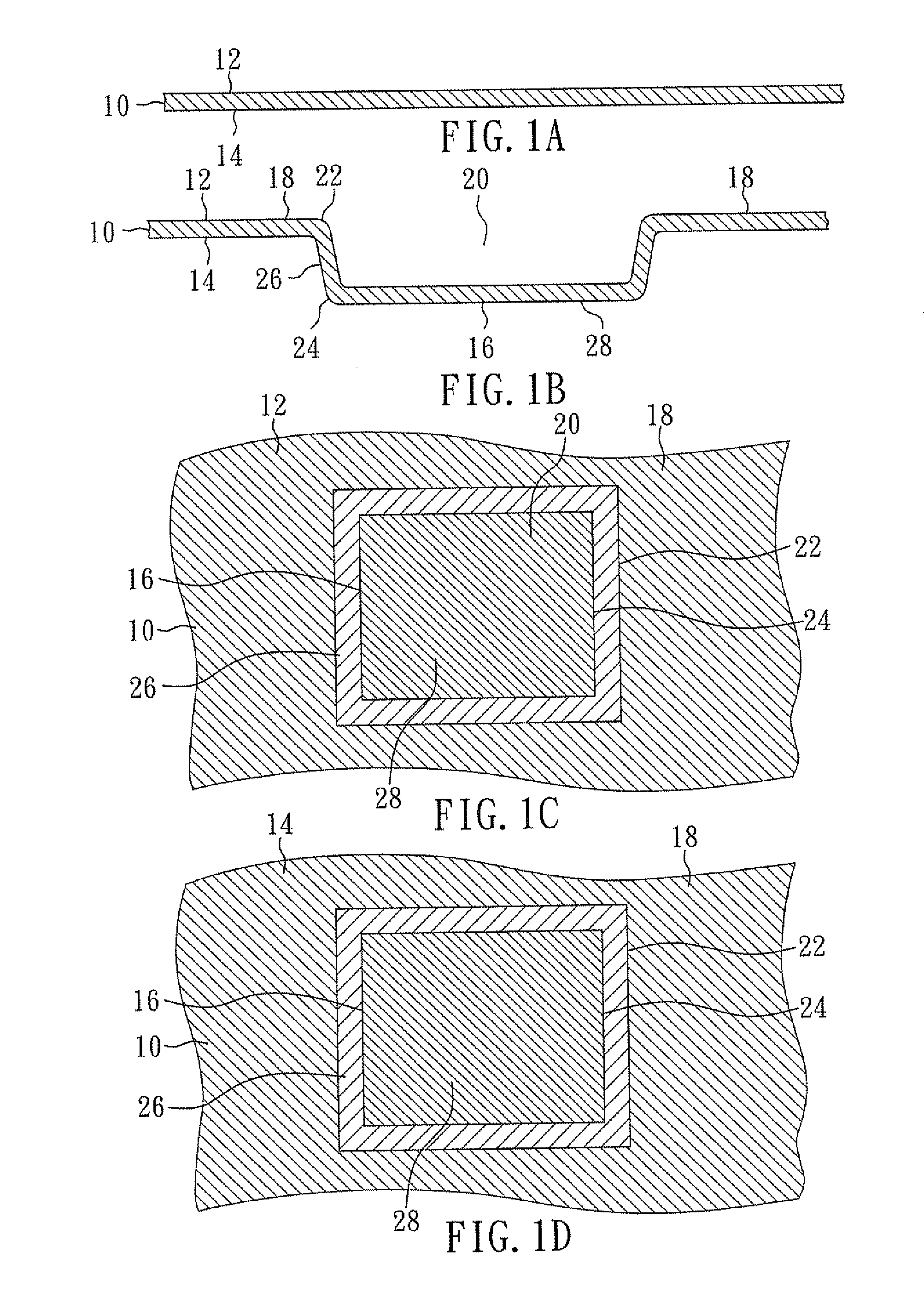

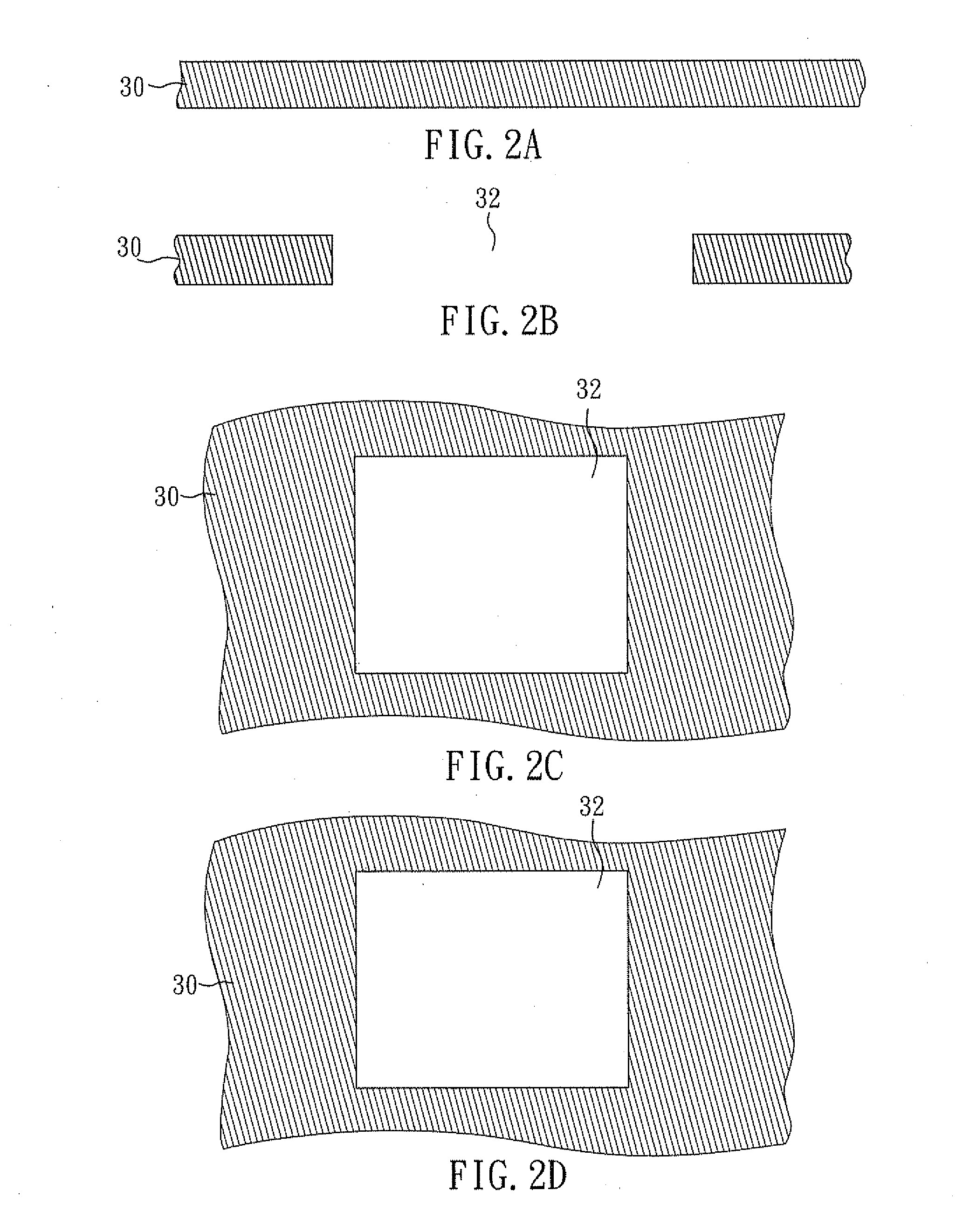

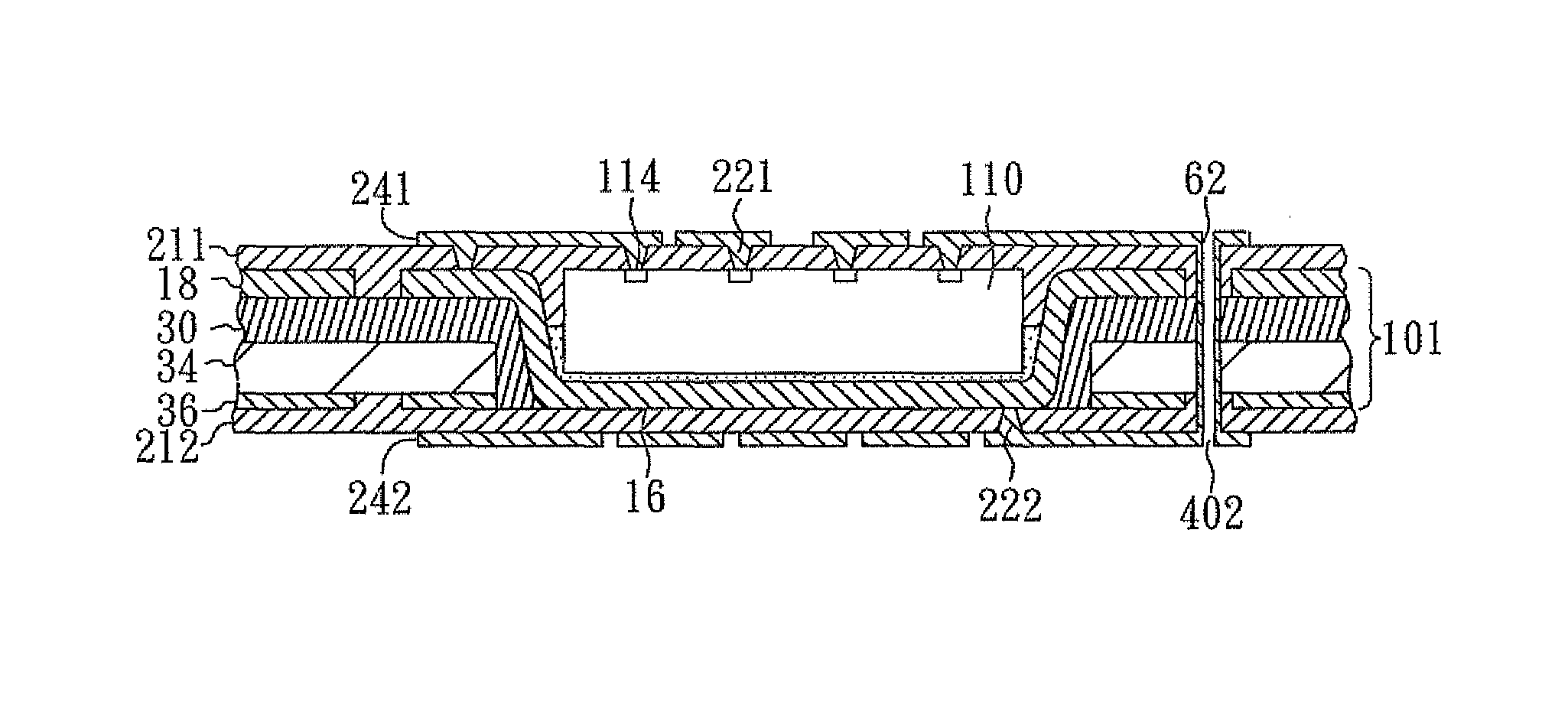

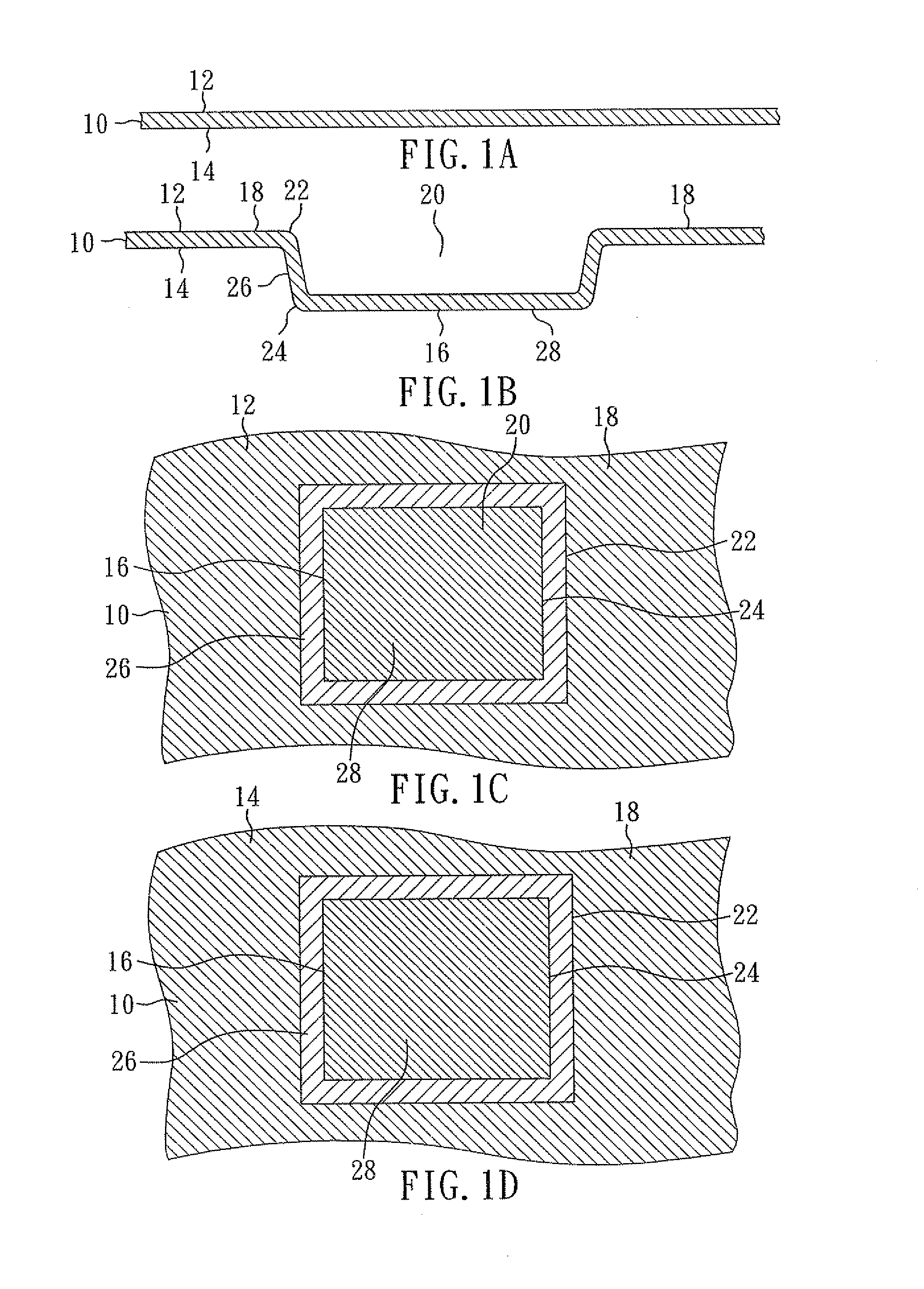

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly through an opening in the adhesive into an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate. The substrate includes first and second conductive layers and a dielectric layer therebetween and provides horizontal signal routing between a pad and a terminal at the first conductive layer.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base heat spreader and vertical signal routing

InactiveUS20100001395A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly through an opening in the adhesive into an aperture in the substrate, and the base extends laterally and supports the substrate. The adhesive extends between the post and the substrate and between the base and the substrate. The substrate includes first and second conductive layers and a dielectric layer therebetween, and the assembly provides vertical signal routing between a pad at the first conductive layer and a terminal below the adhesive.

Owner:BRIDGE SEMICON

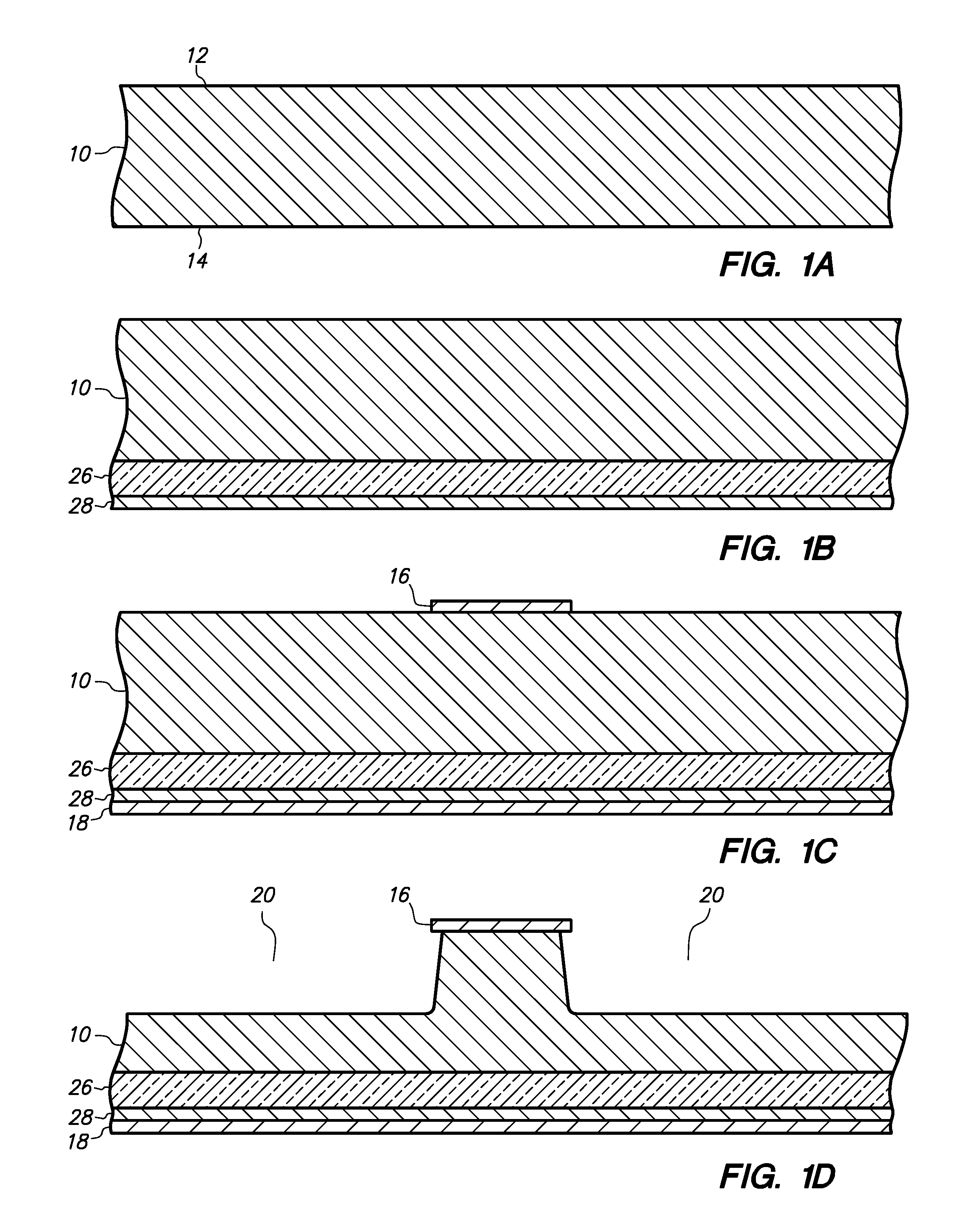

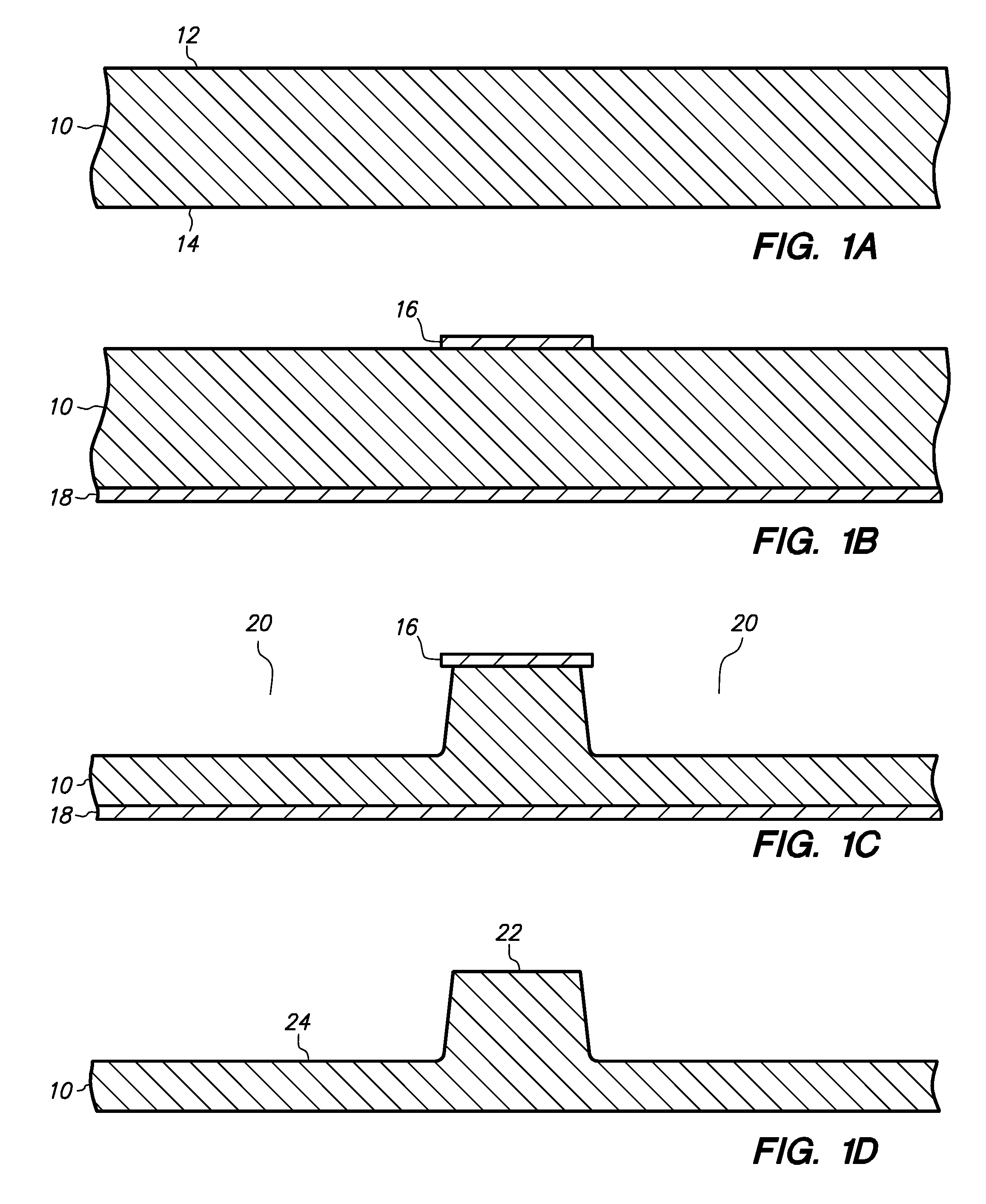

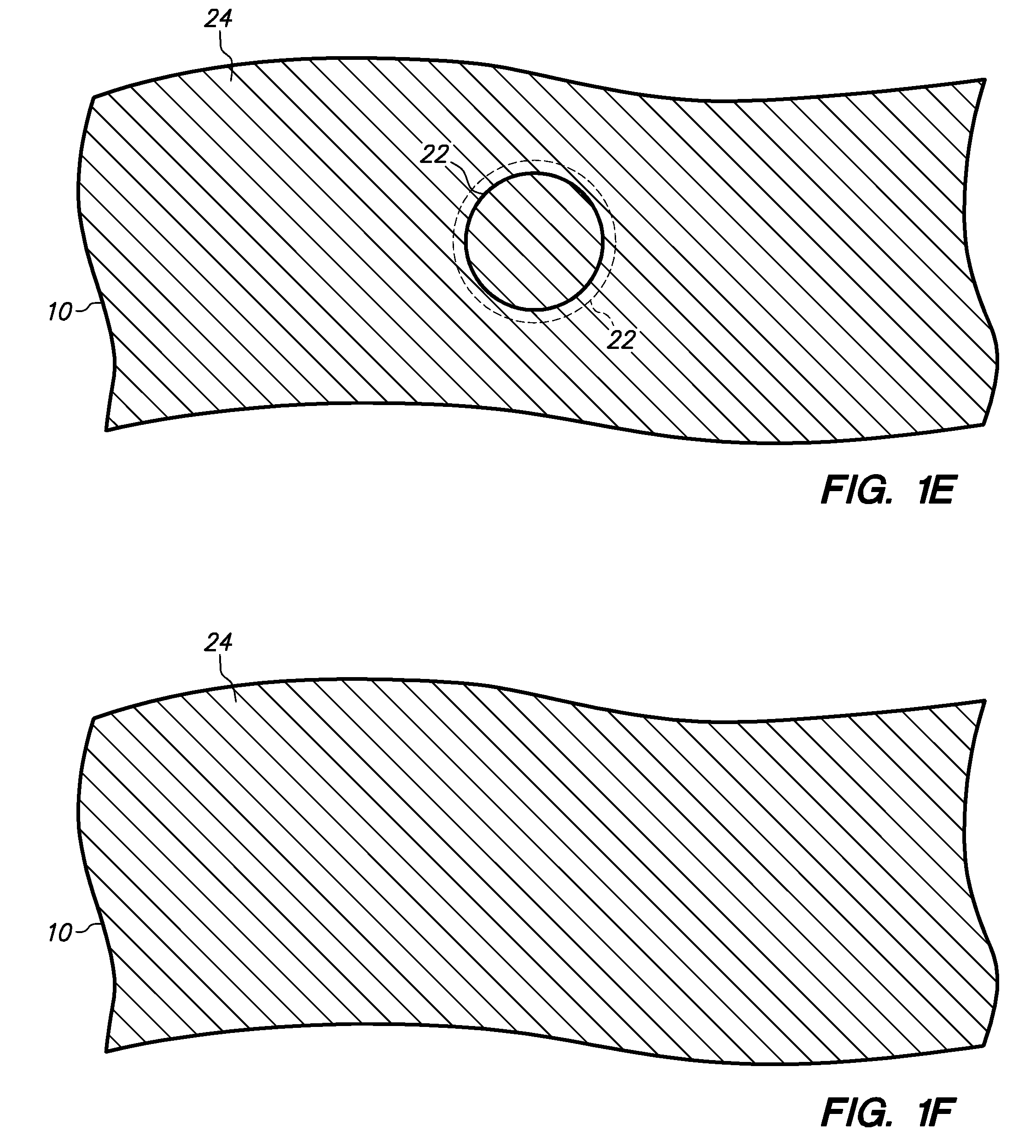

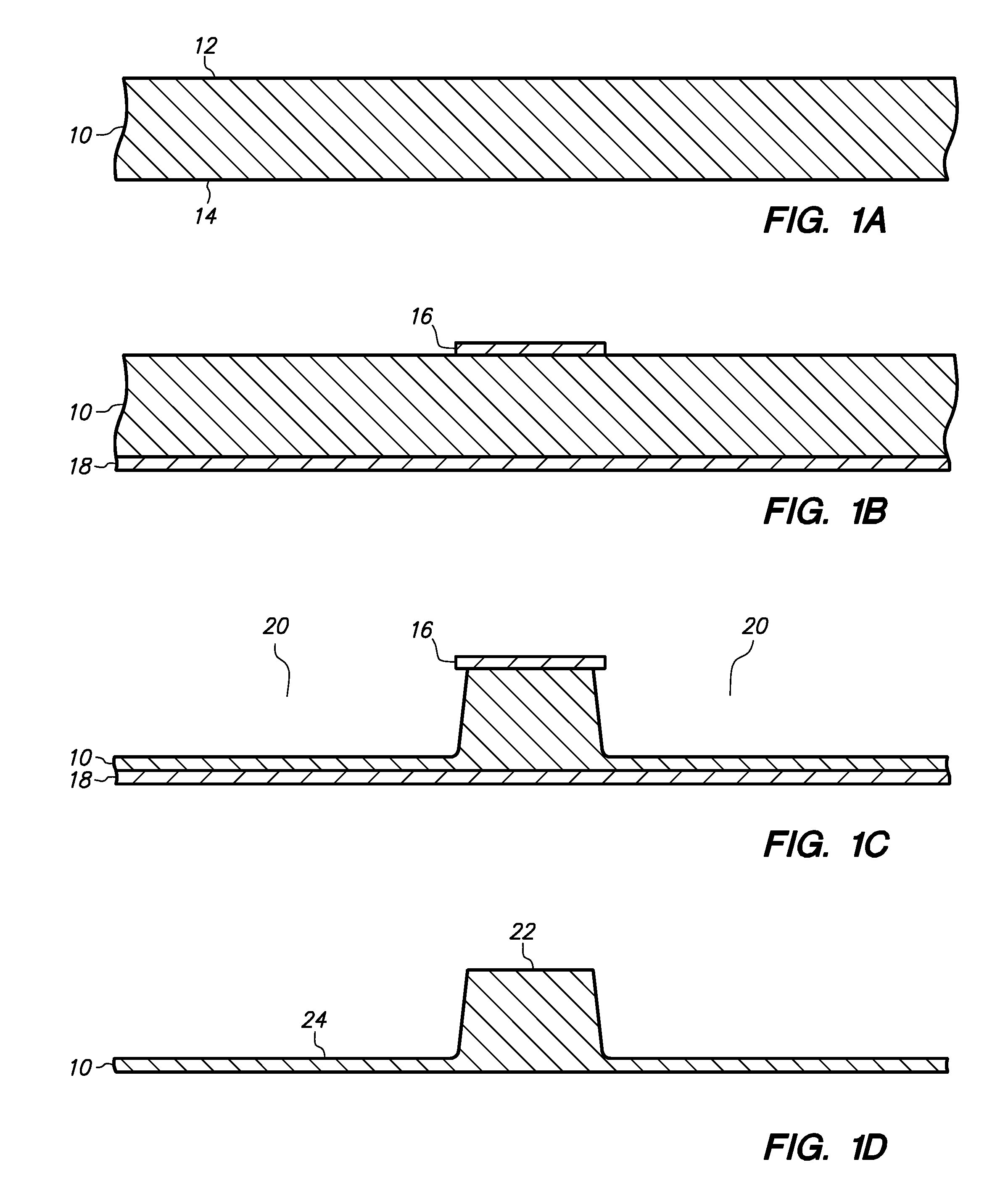

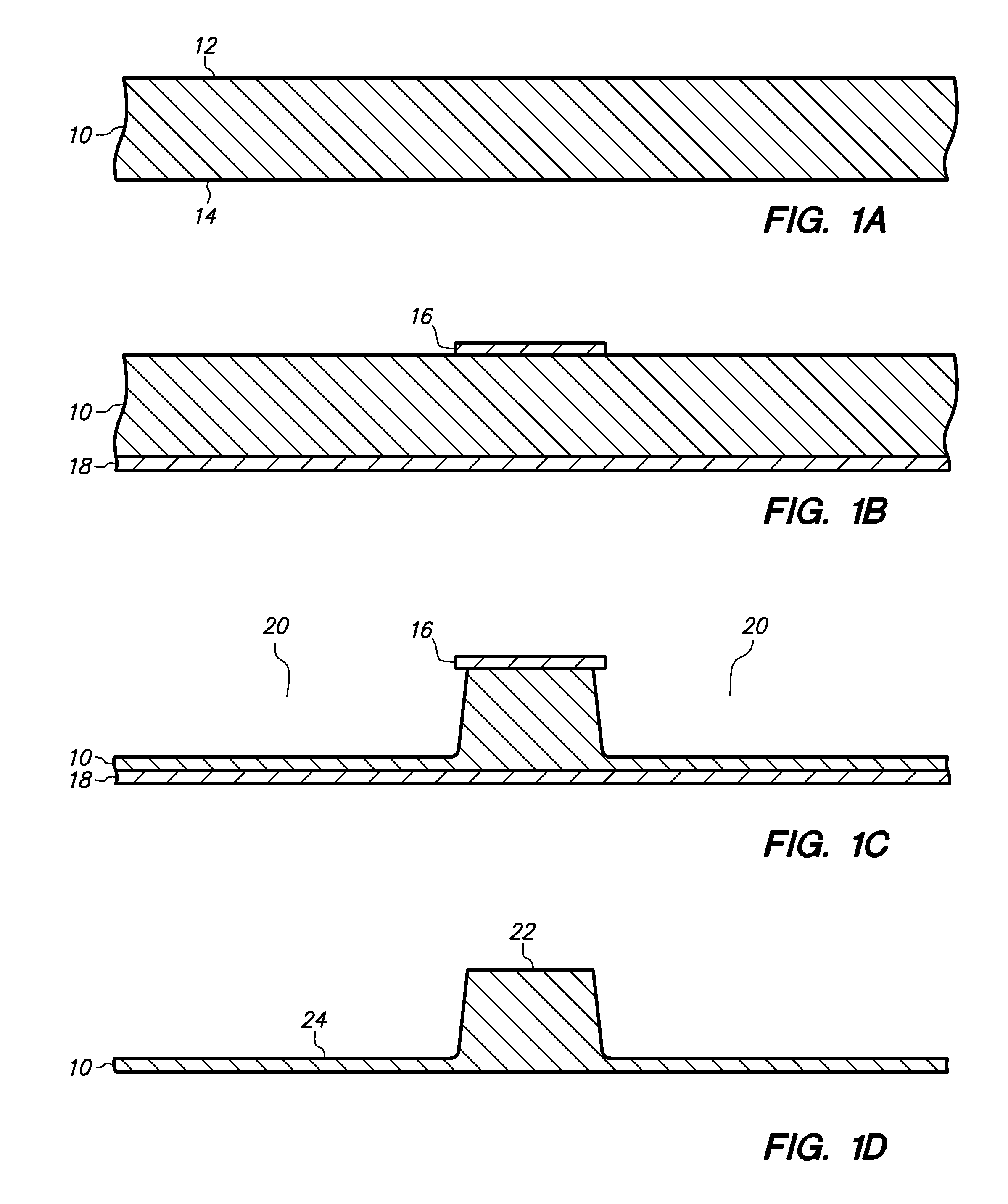

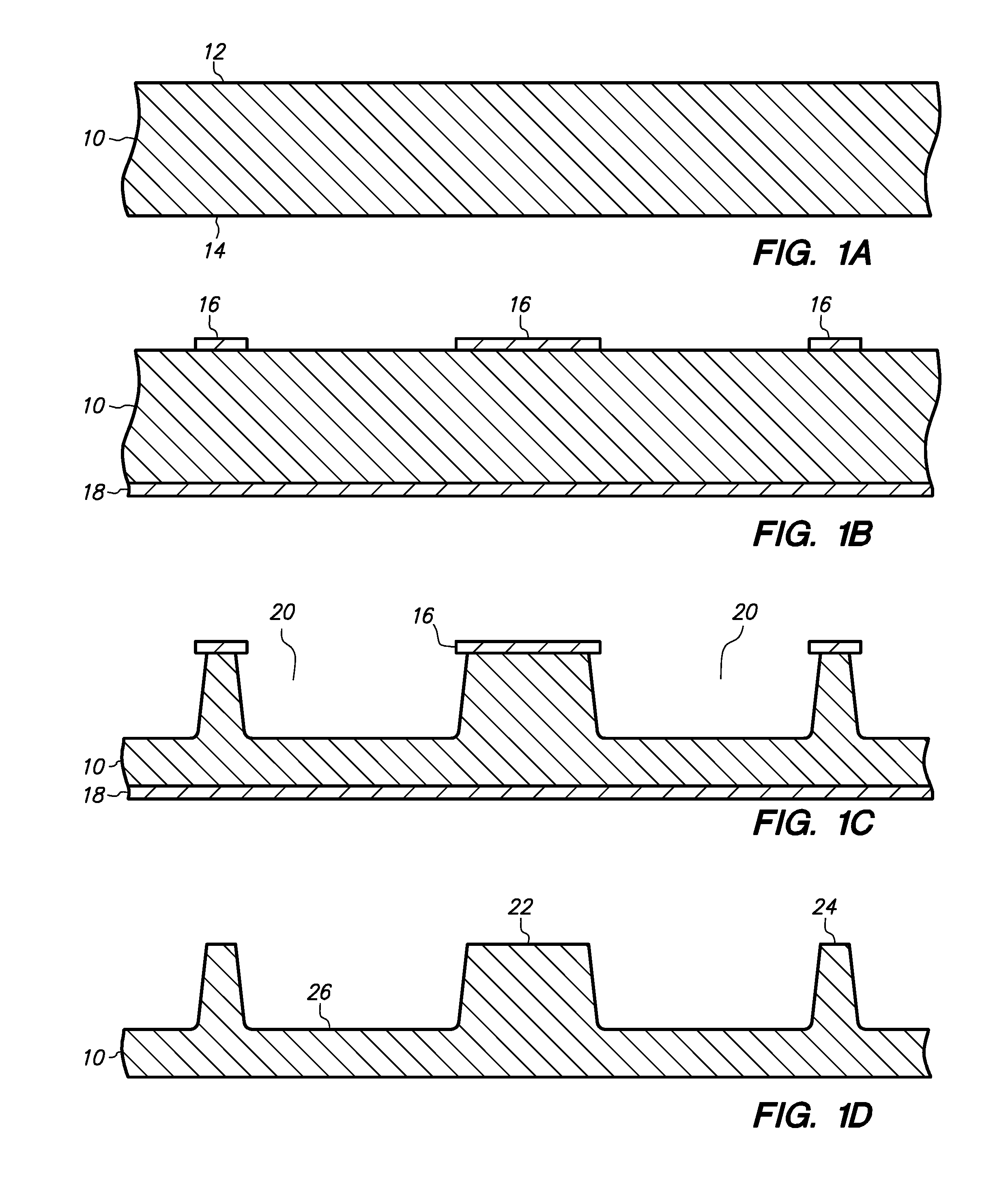

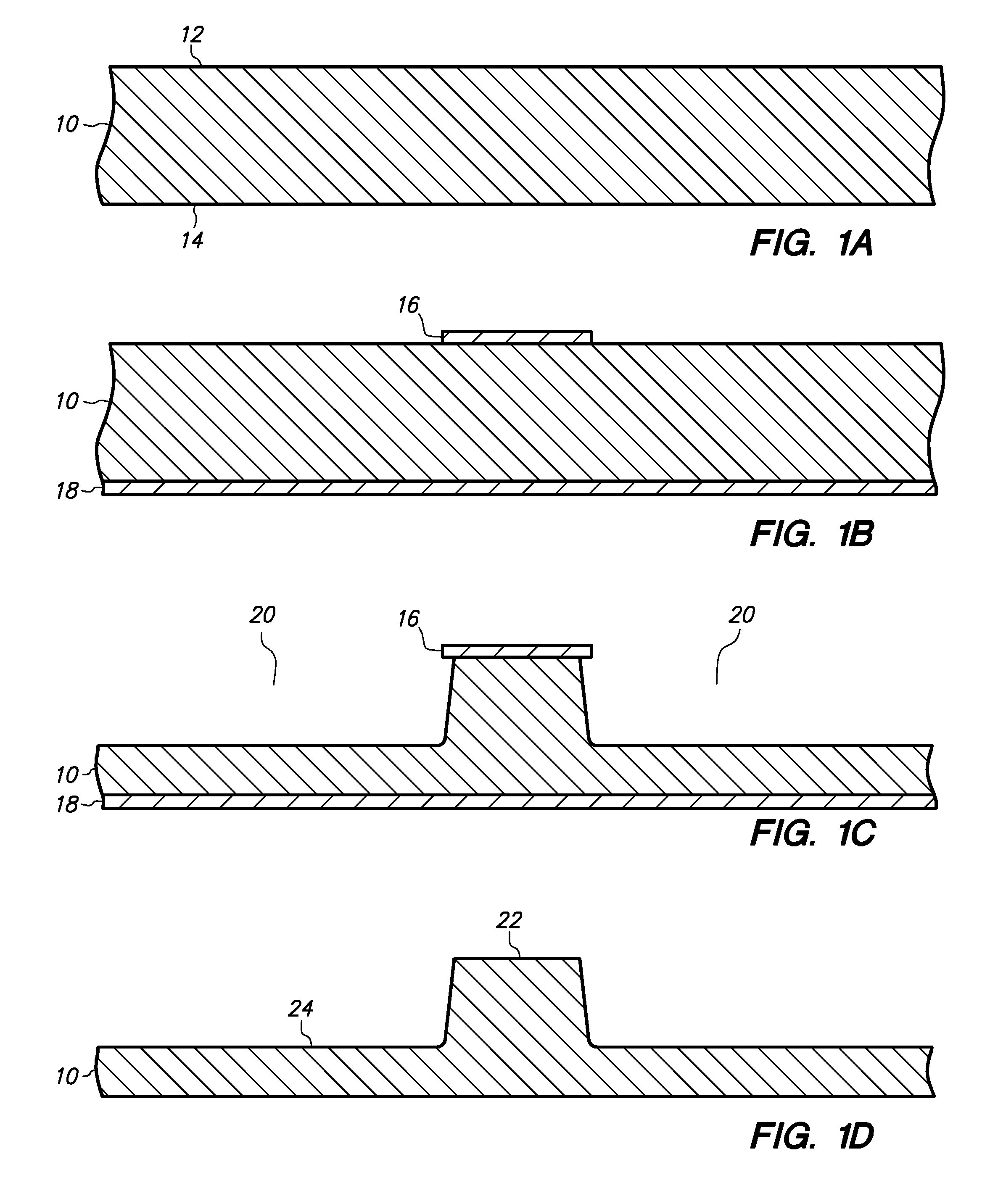

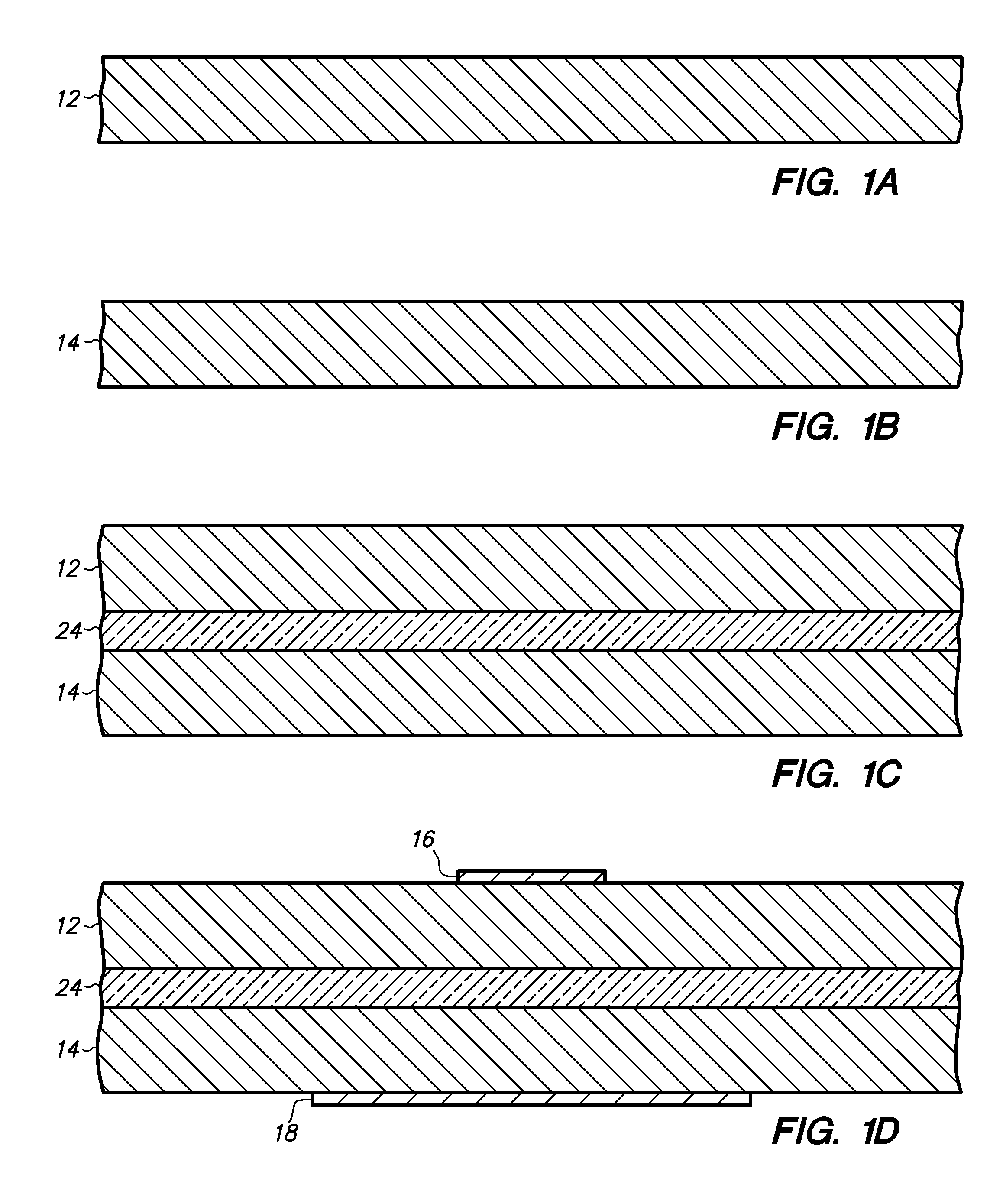

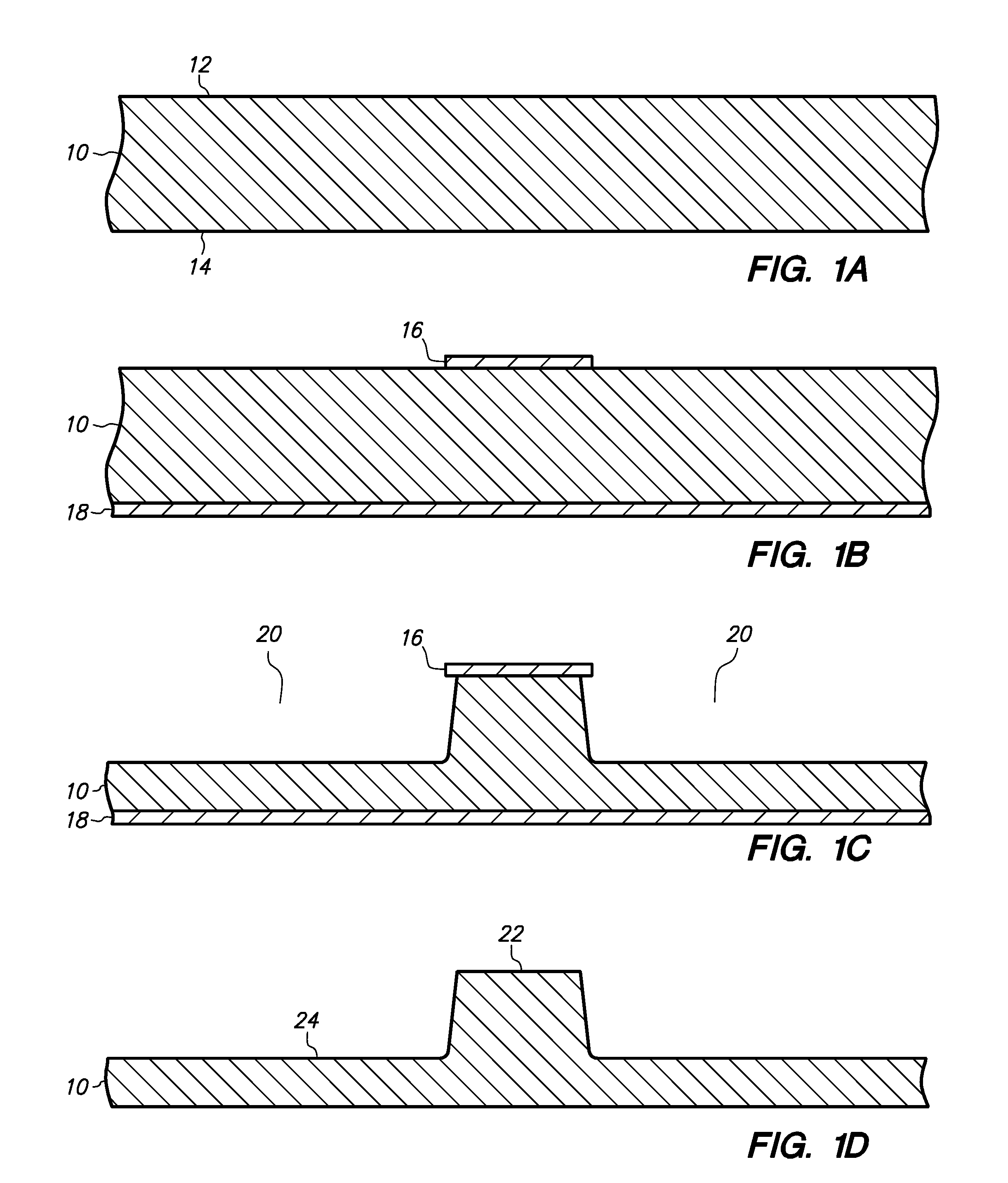

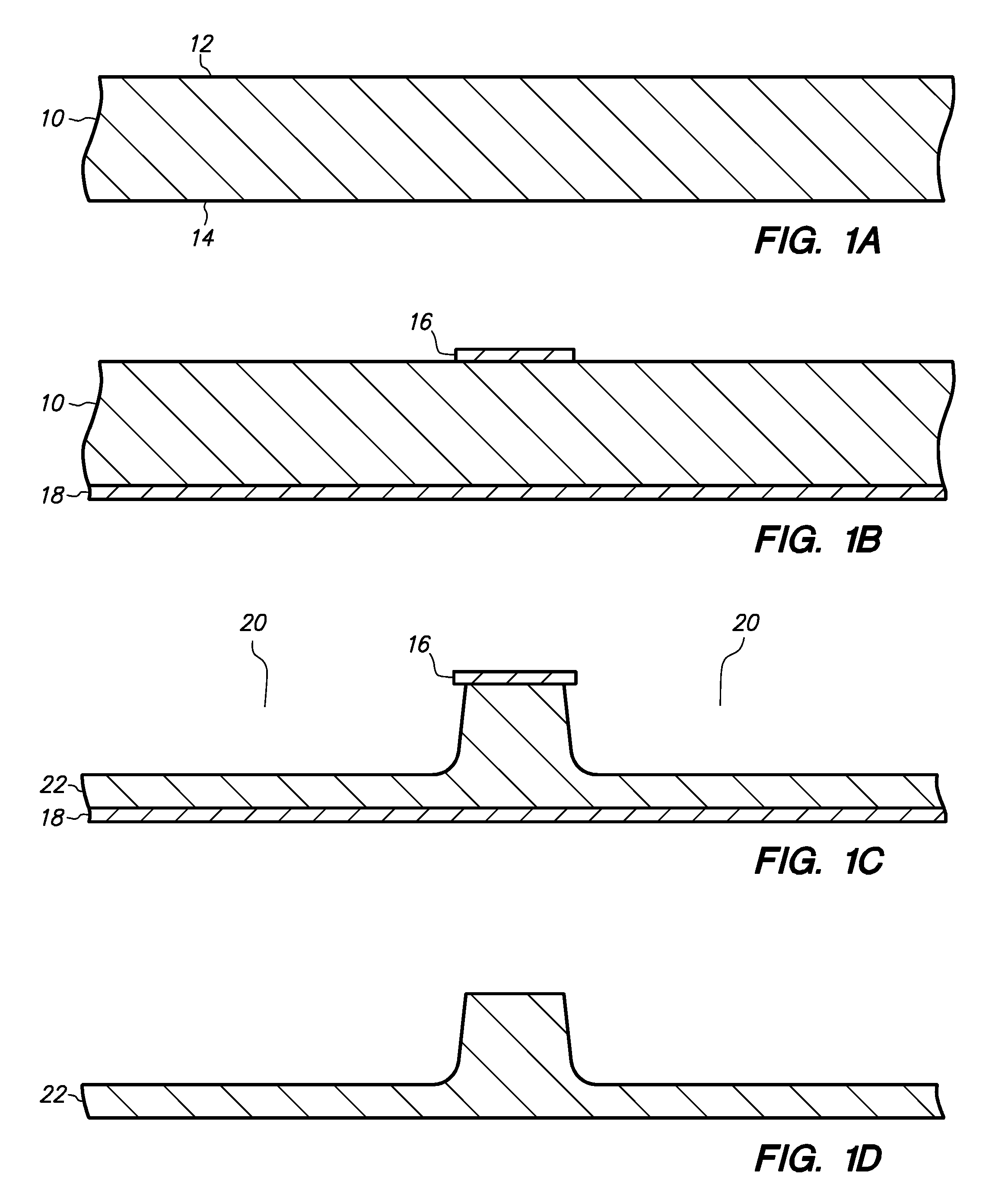

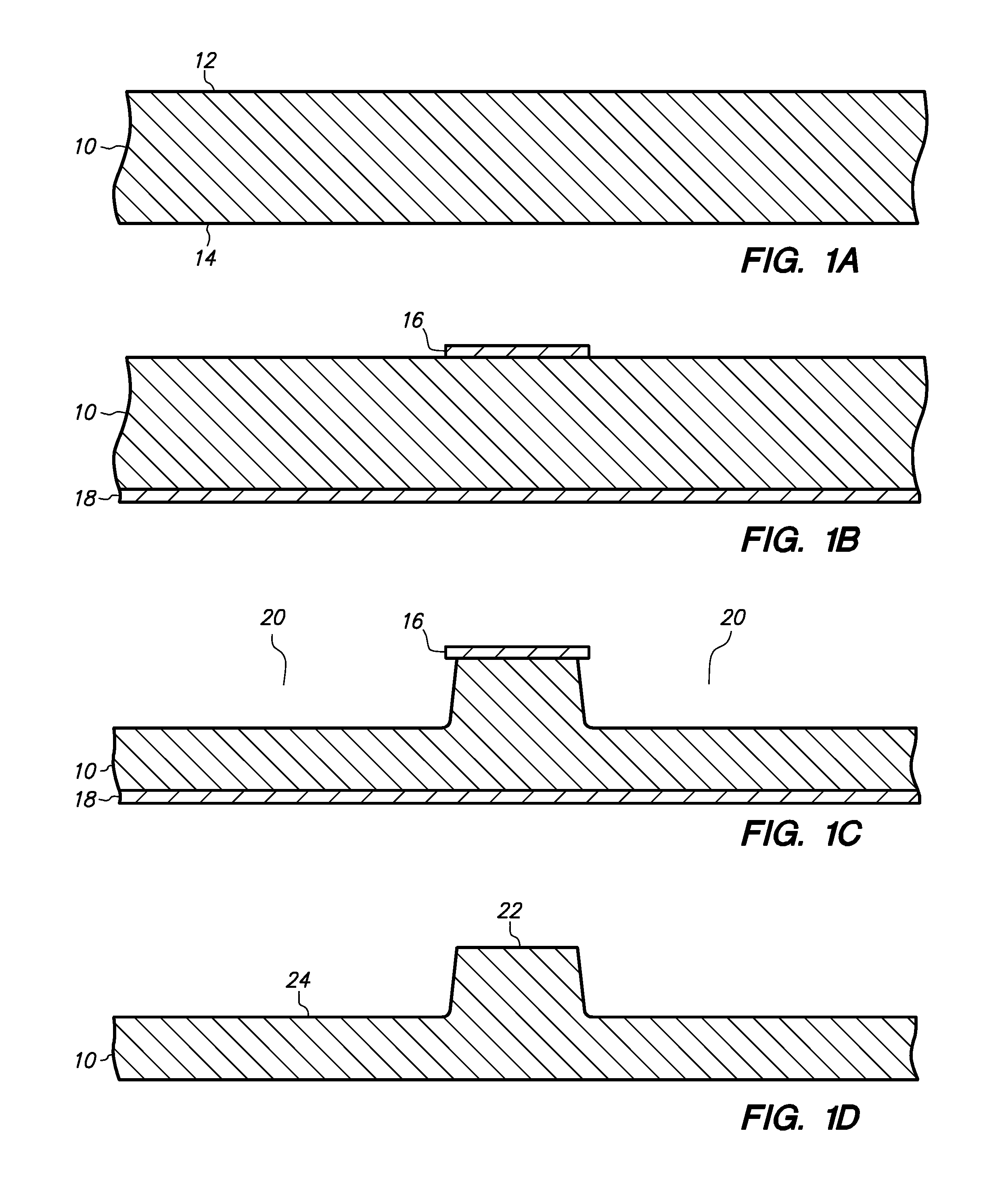

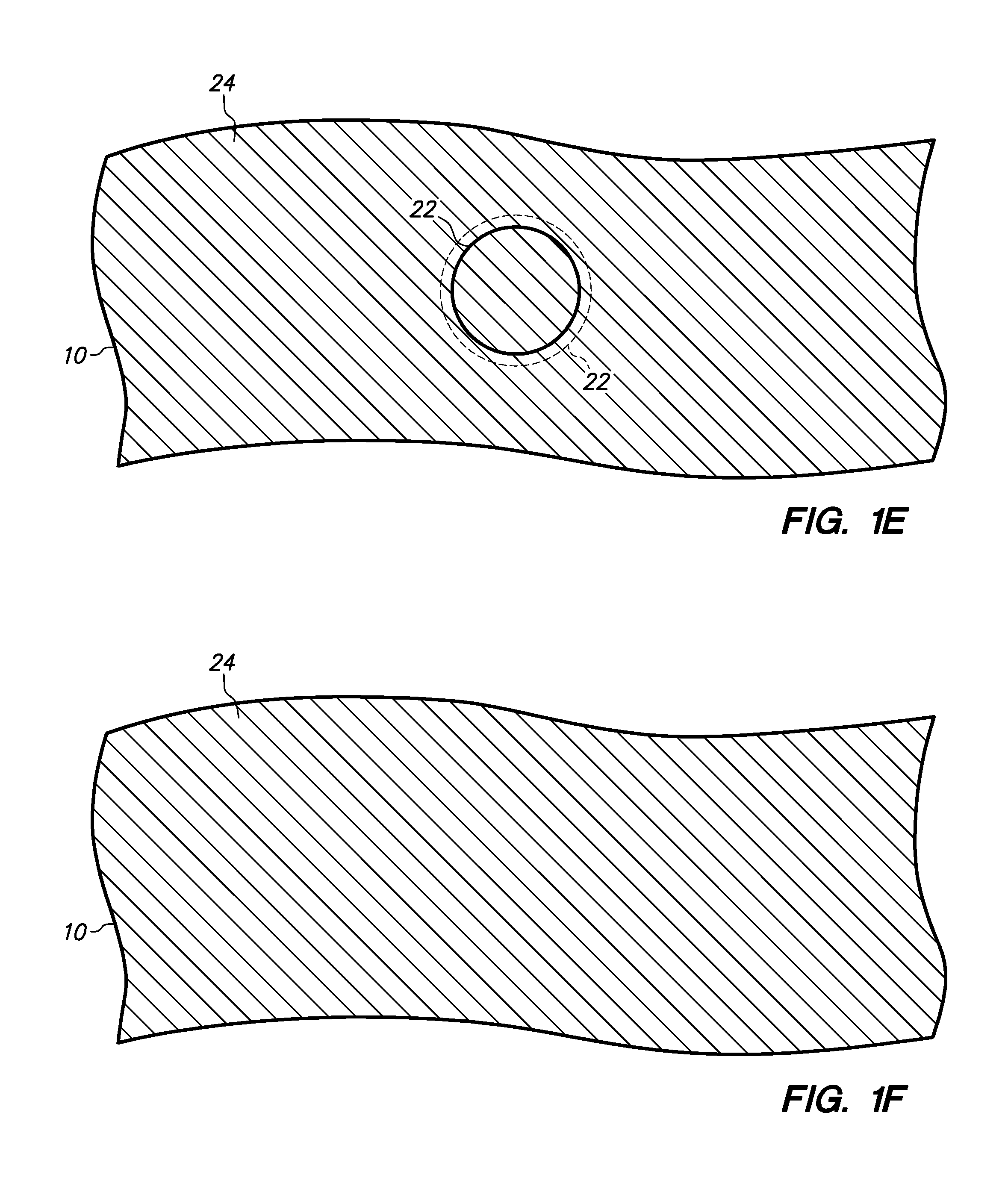

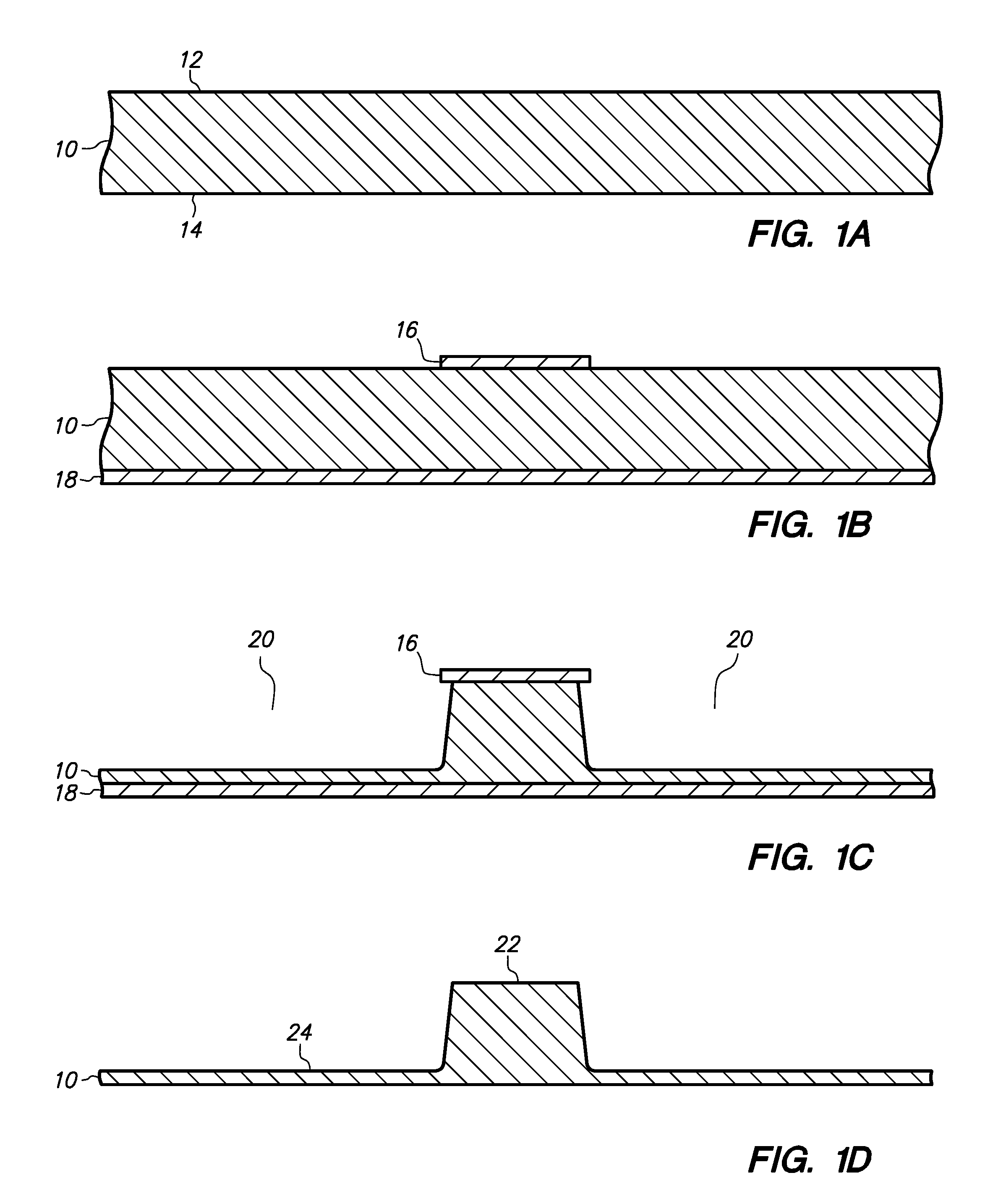

Method of making a semiconductor chip assembly with a post/base heat spreader and a substrate

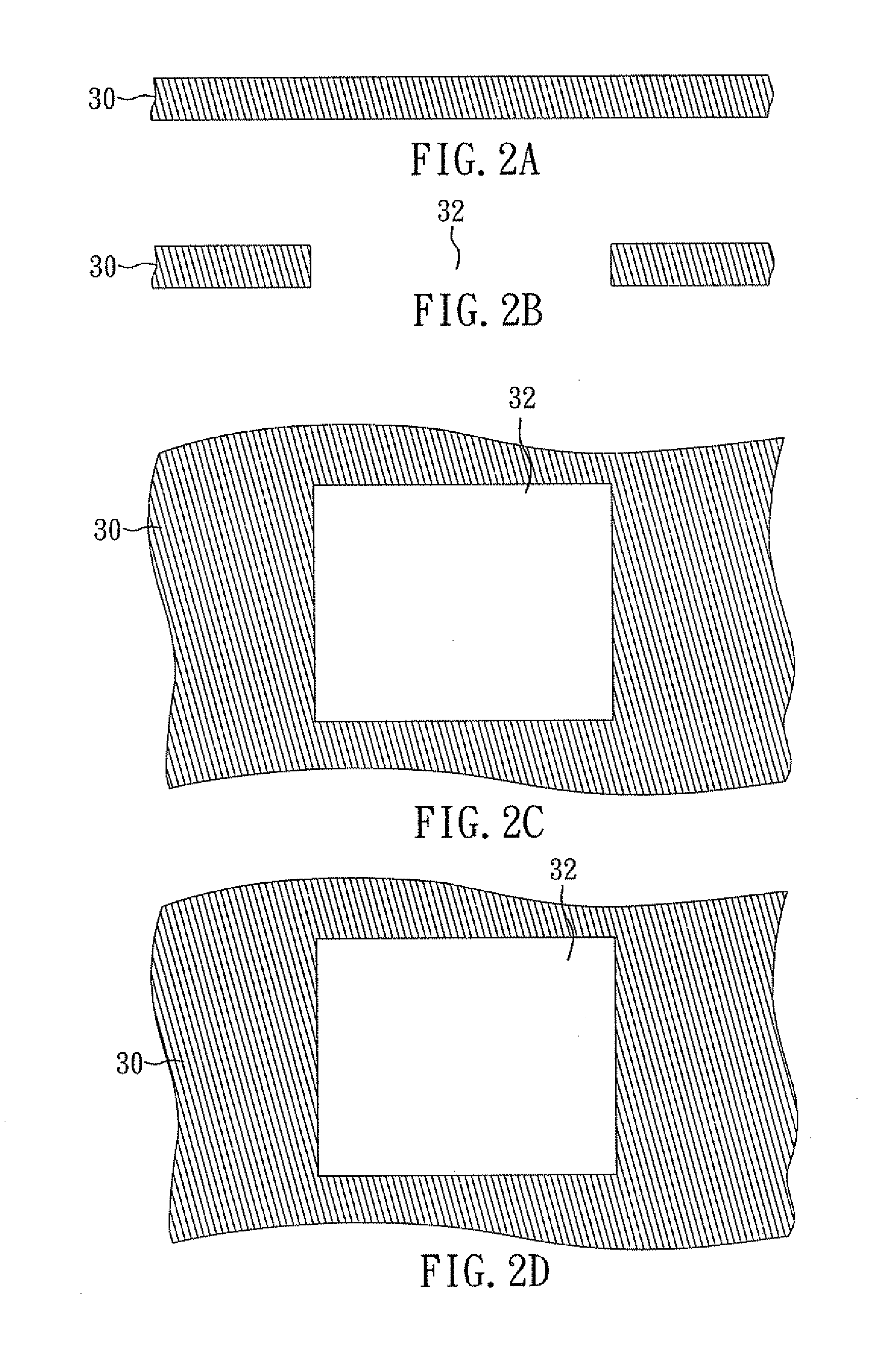

InactiveUS20100055811A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveSemiconductor chip

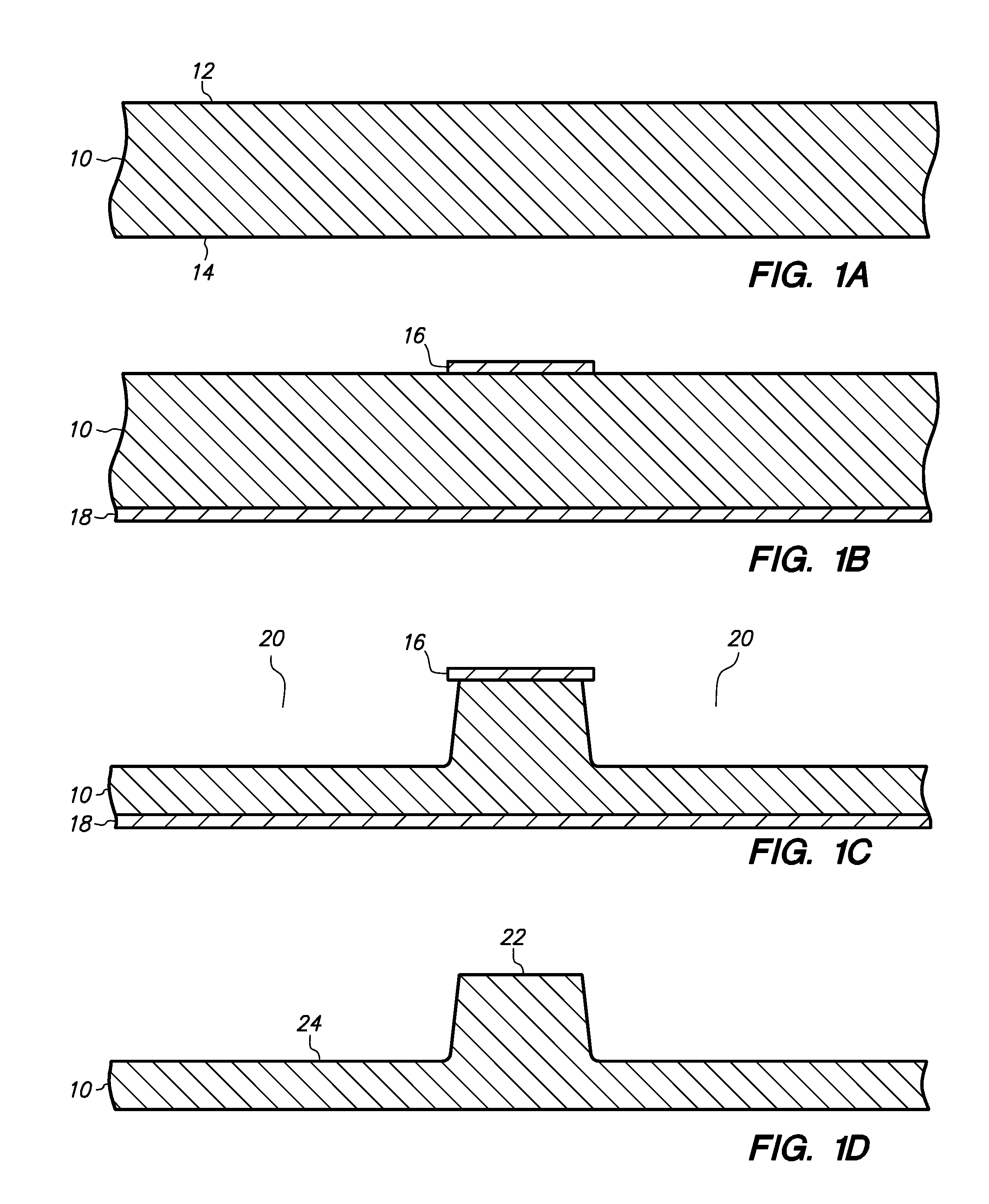

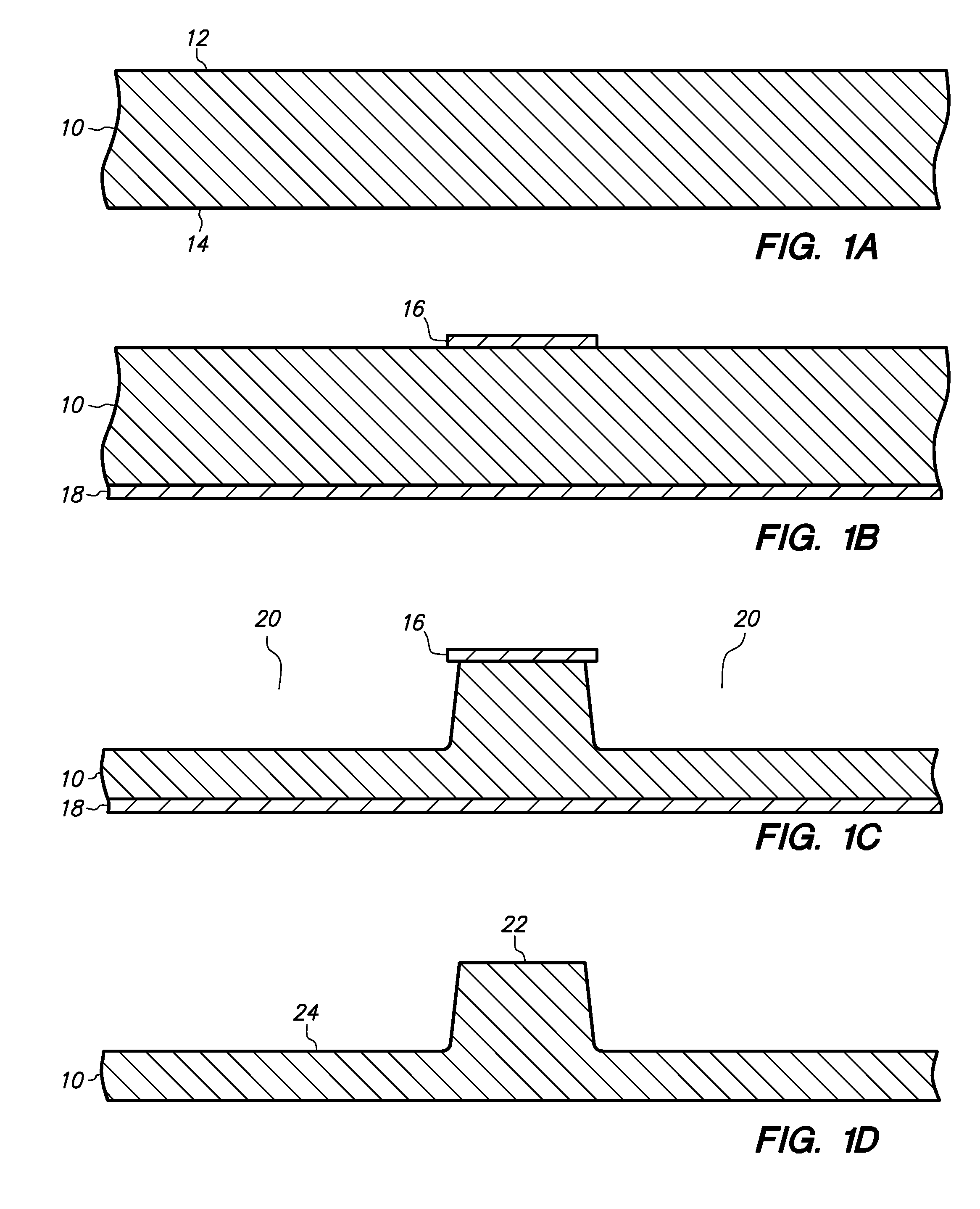

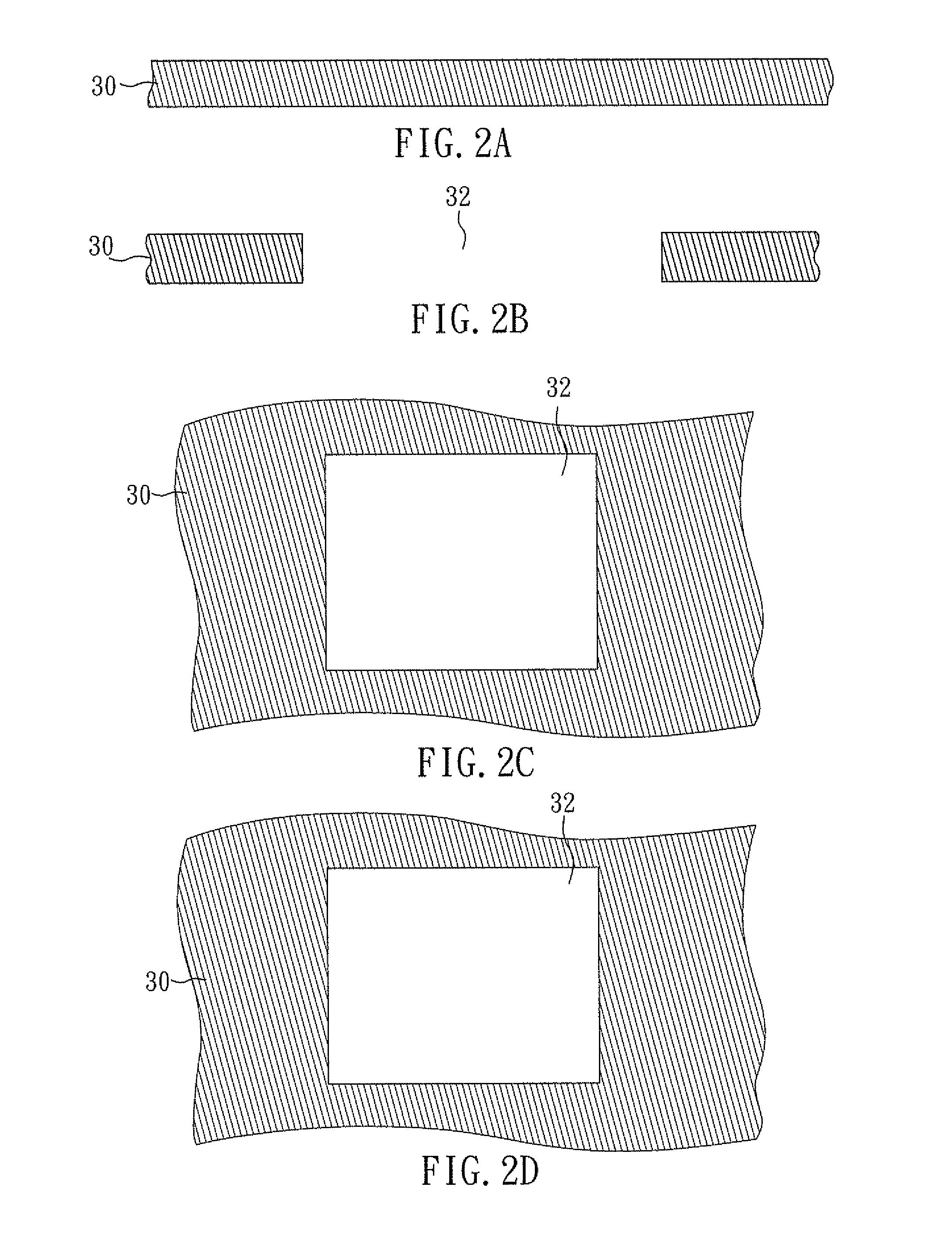

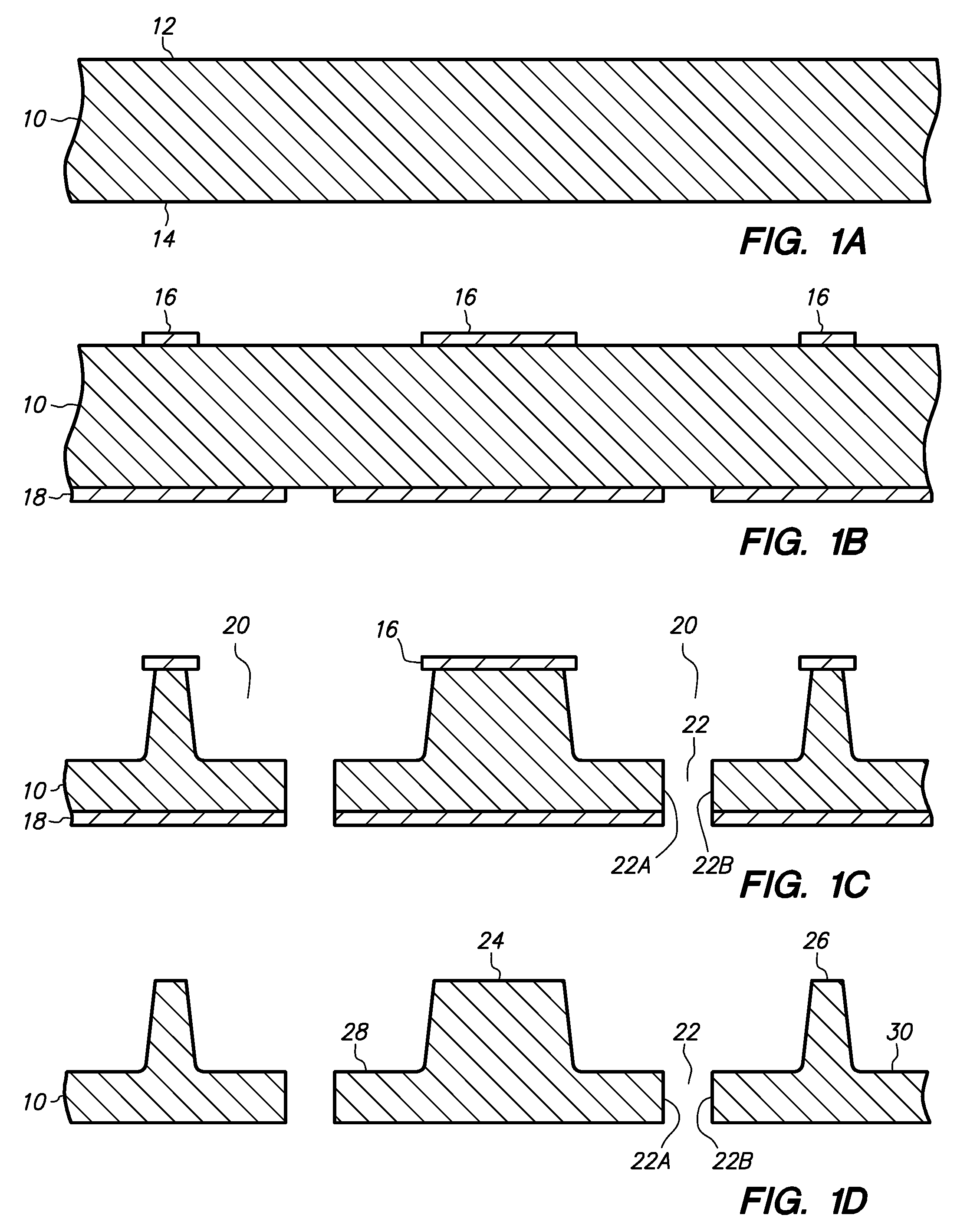

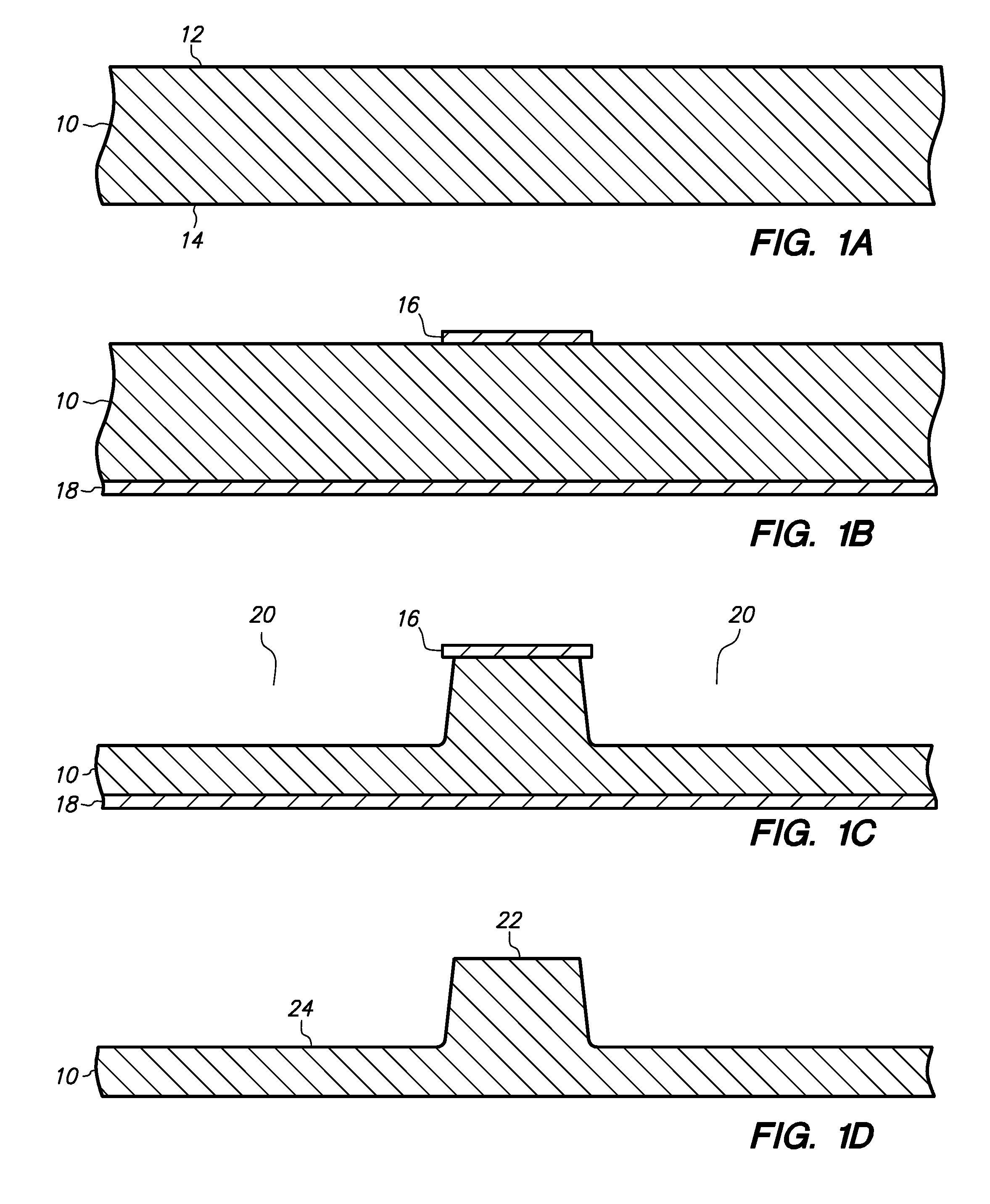

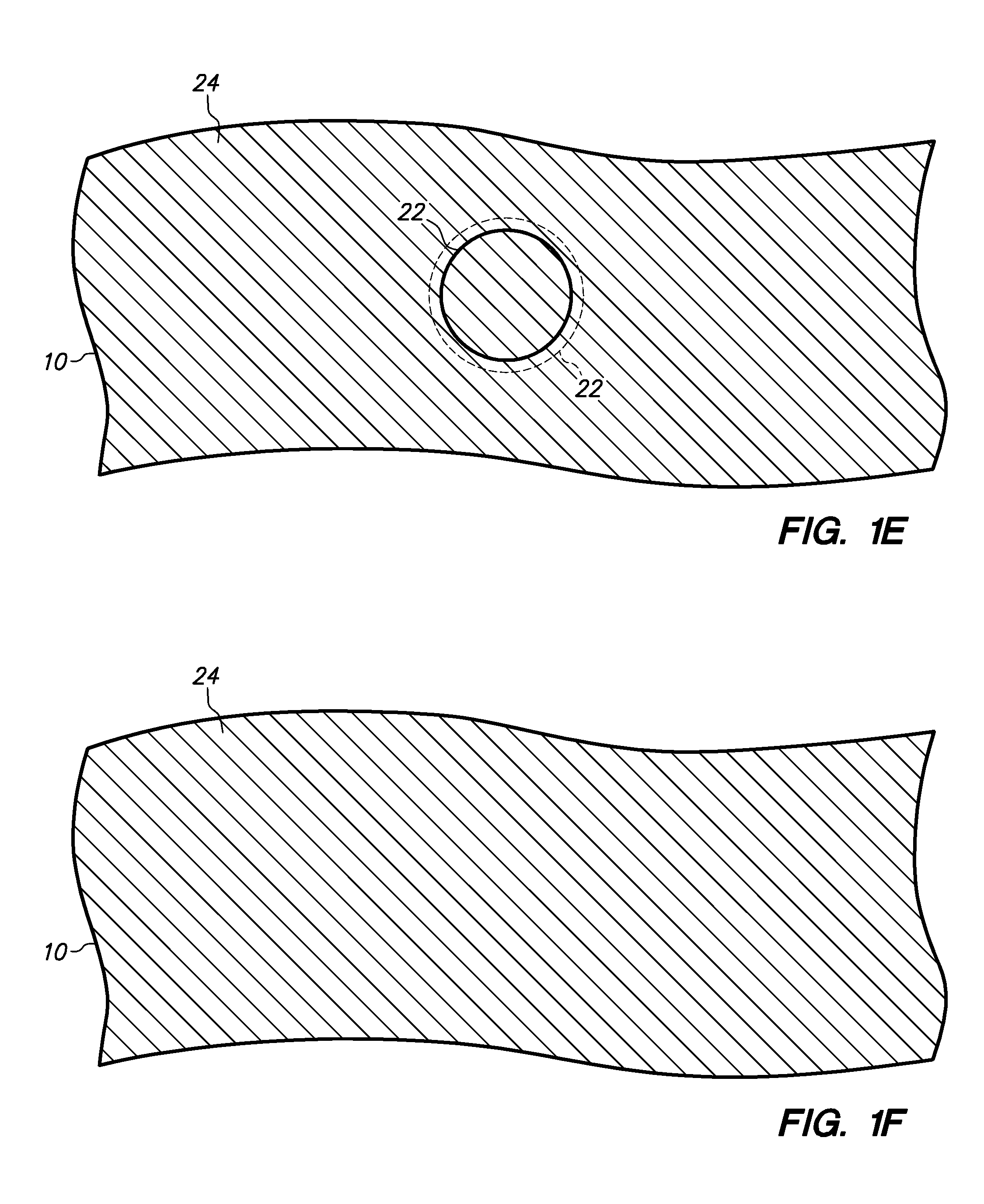

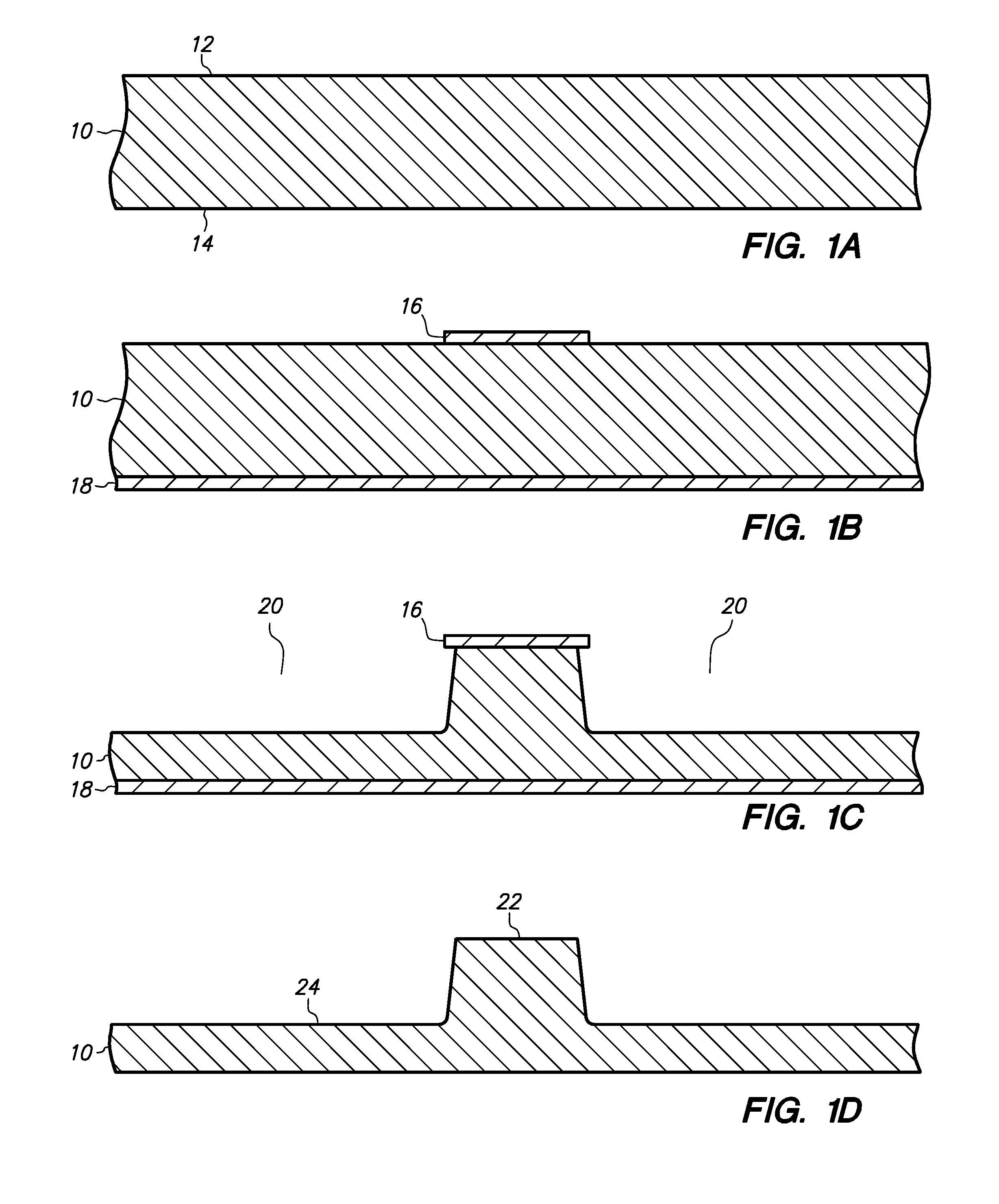

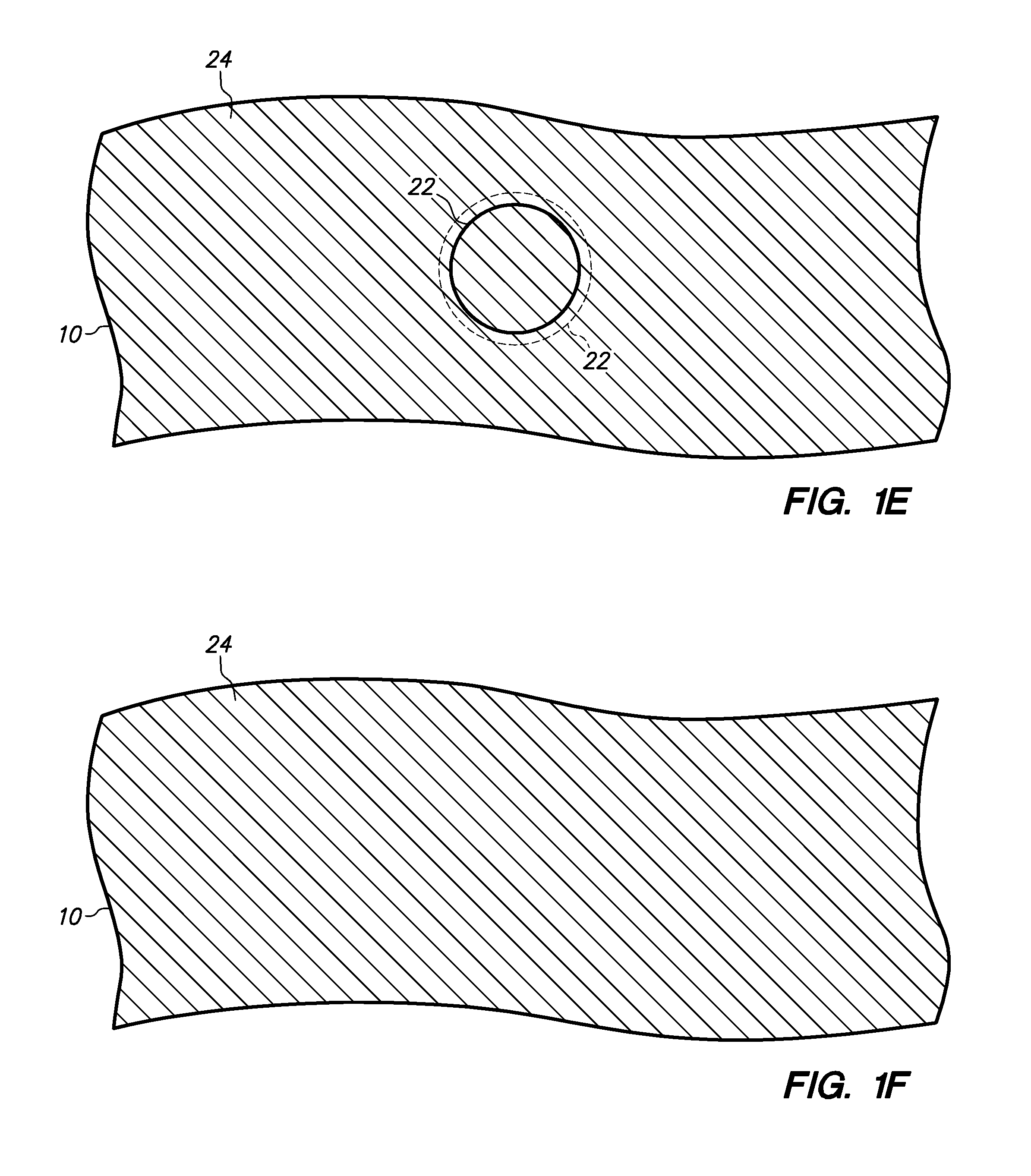

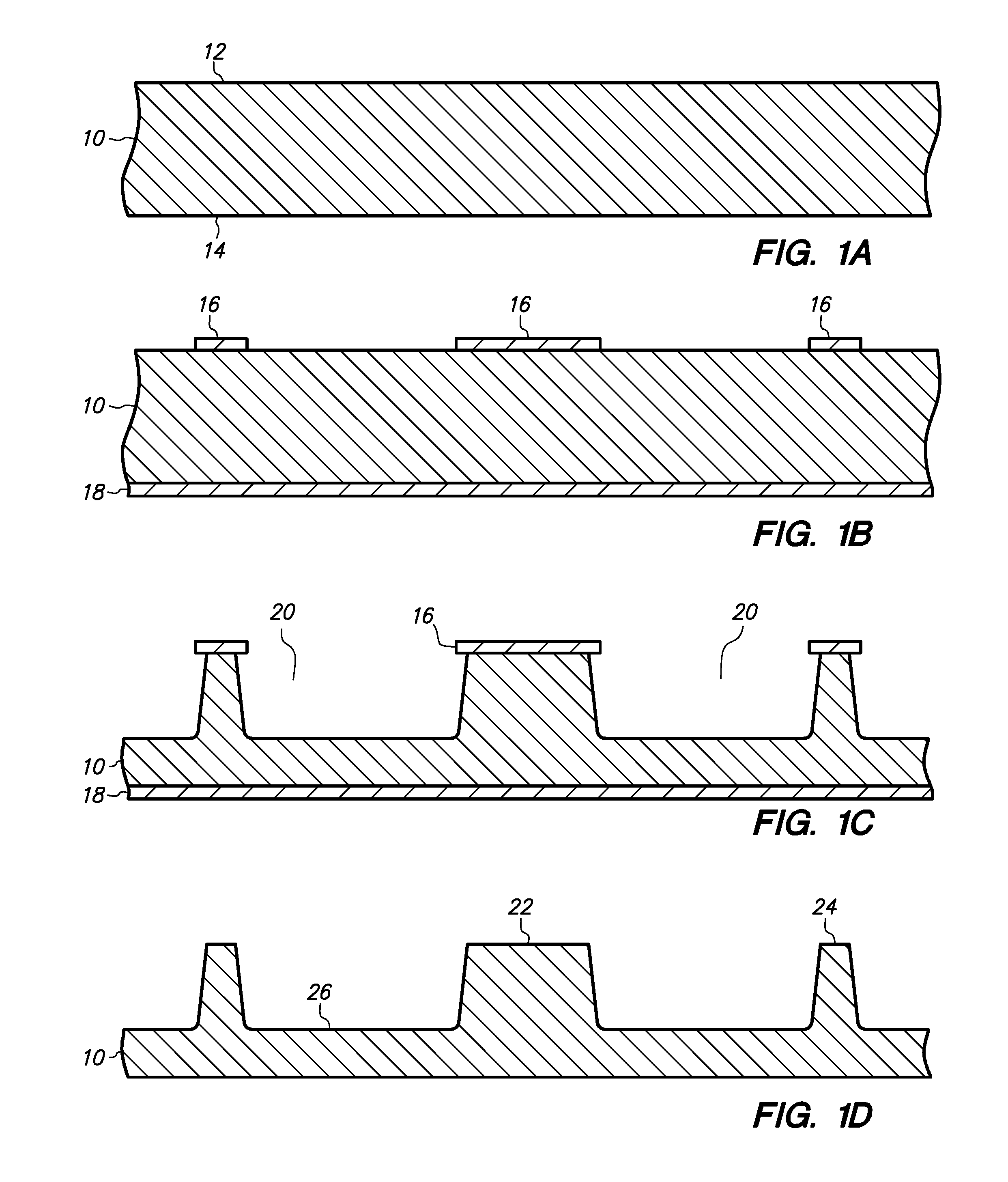

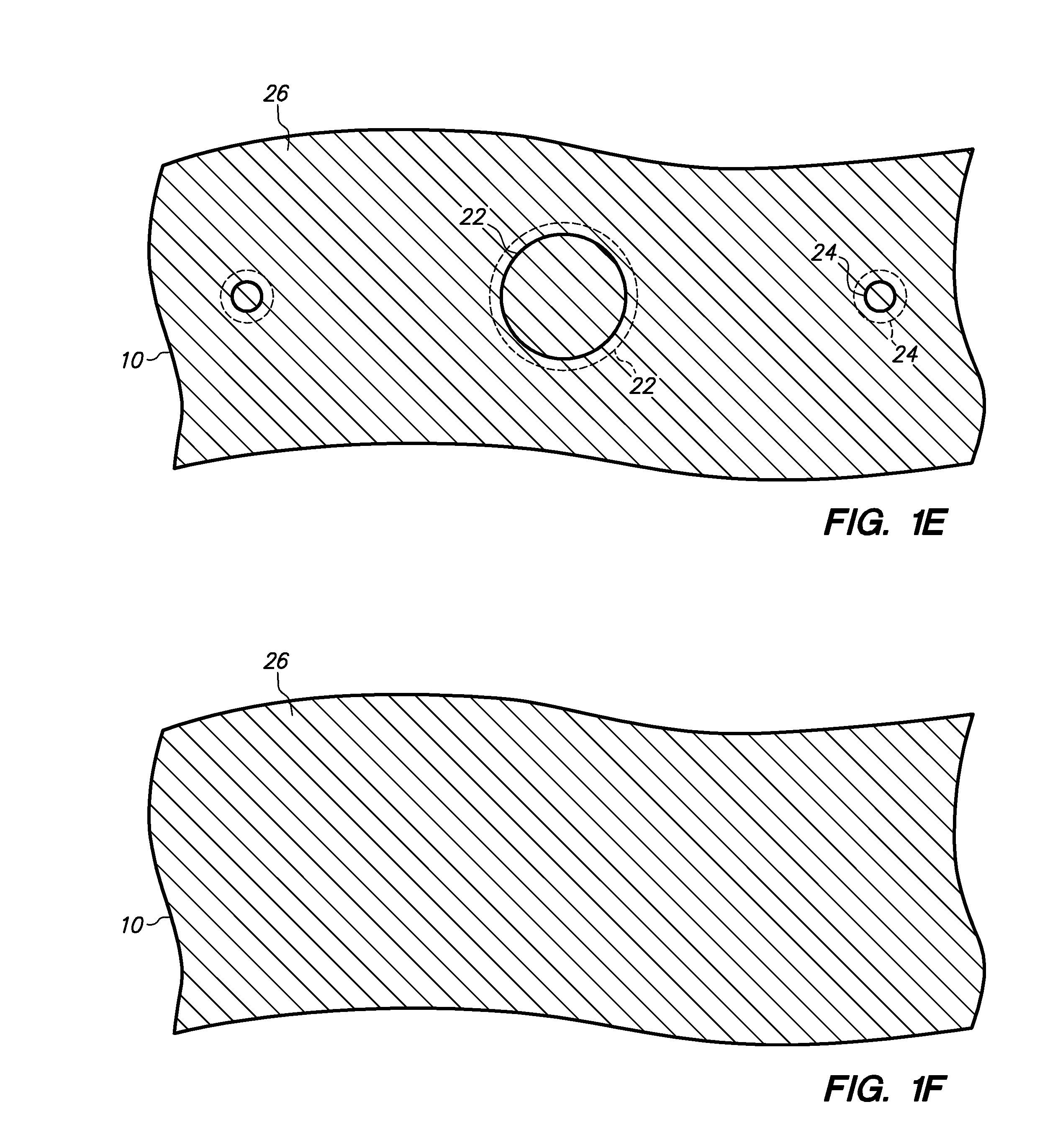

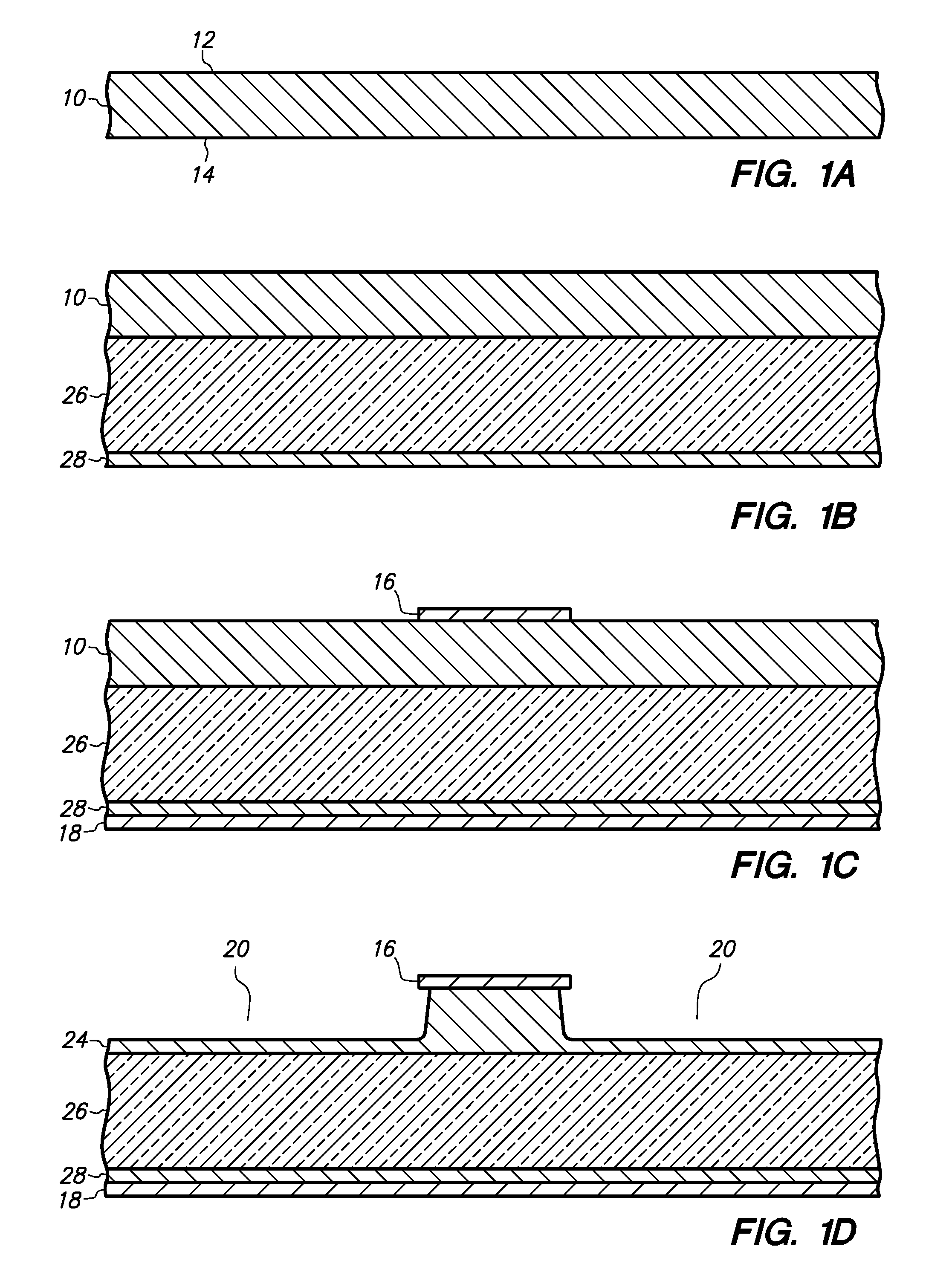

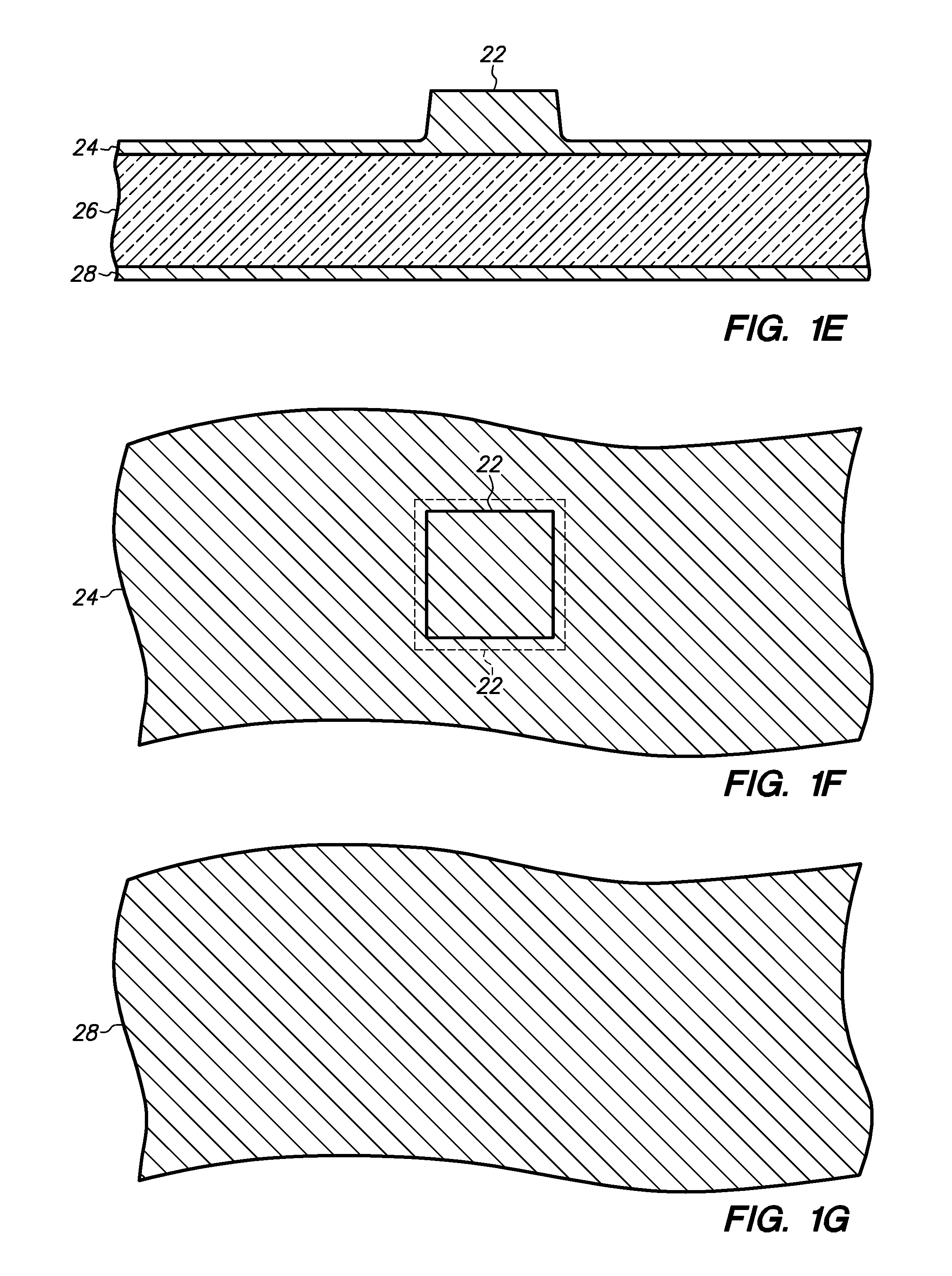

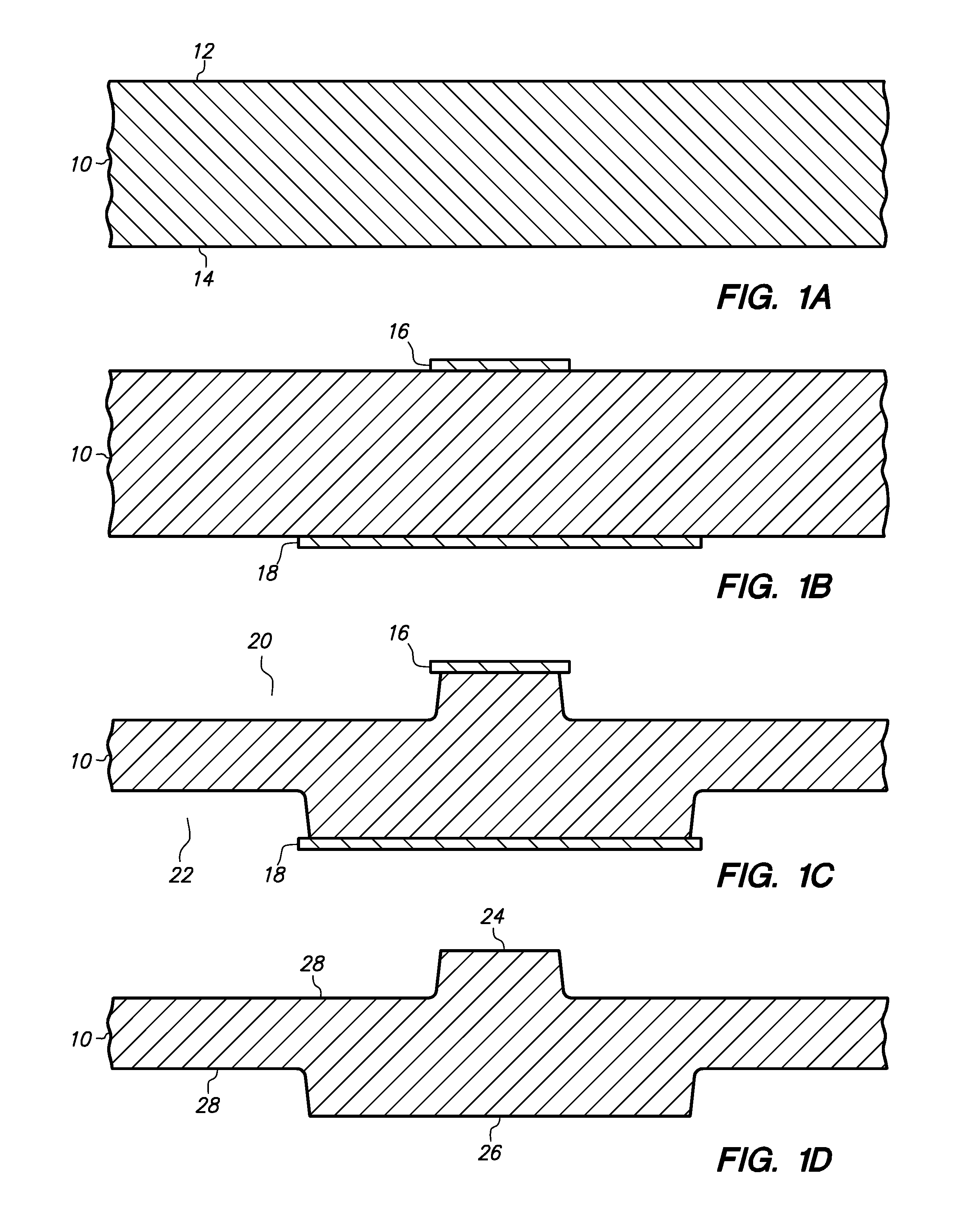

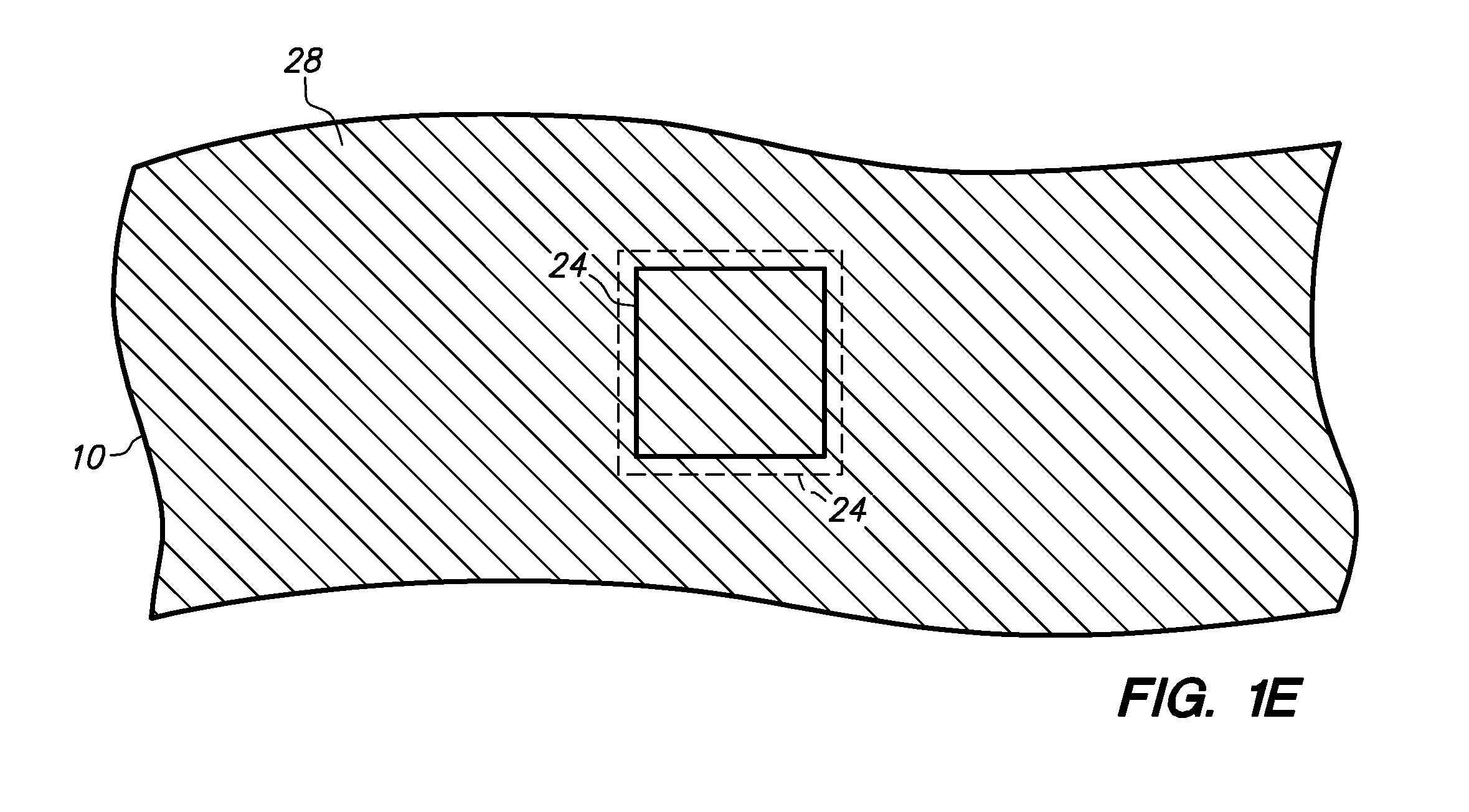

A method of making a semiconductor chip assembly includes providing a post and a base, mounting an adhesive on the base including inserting the post through an opening in the adhesive, mounting a substrate on the adhesive including inserting the post into an aperture in the substrate to form a gap in the aperture between the post and the substrate, then flowing the adhesive into and upward in the gap, solidifying the adhesive, then mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the substrate and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with base heat spreader and cavity in base

InactiveUS20100155769A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a base. A cavity extends through the adhesive into the base. The semiconductor device extends into the cavity, is electrically connected to the conductive trace and is thermally connected to the heat spreader. The adhesive extends between the cavity and the conductive trace and between the base and the conductive trace. The conductive trace is located outside the cavity and provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base heat spreader and vertical signal routing

InactiveUS7948076B2Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly through an opening in the adhesive into an aperture in the substrate, and the base extends laterally and supports the substrate. The adhesive extends between the post and the substrate and between the base and the substrate. The substrate includes first and second conductive layers and a dielectric layer therebetween, and the assembly provides vertical signal routing between a pad at the first conductive layer and a terminal below the adhesive.

Owner:BRIDGE SEMICON

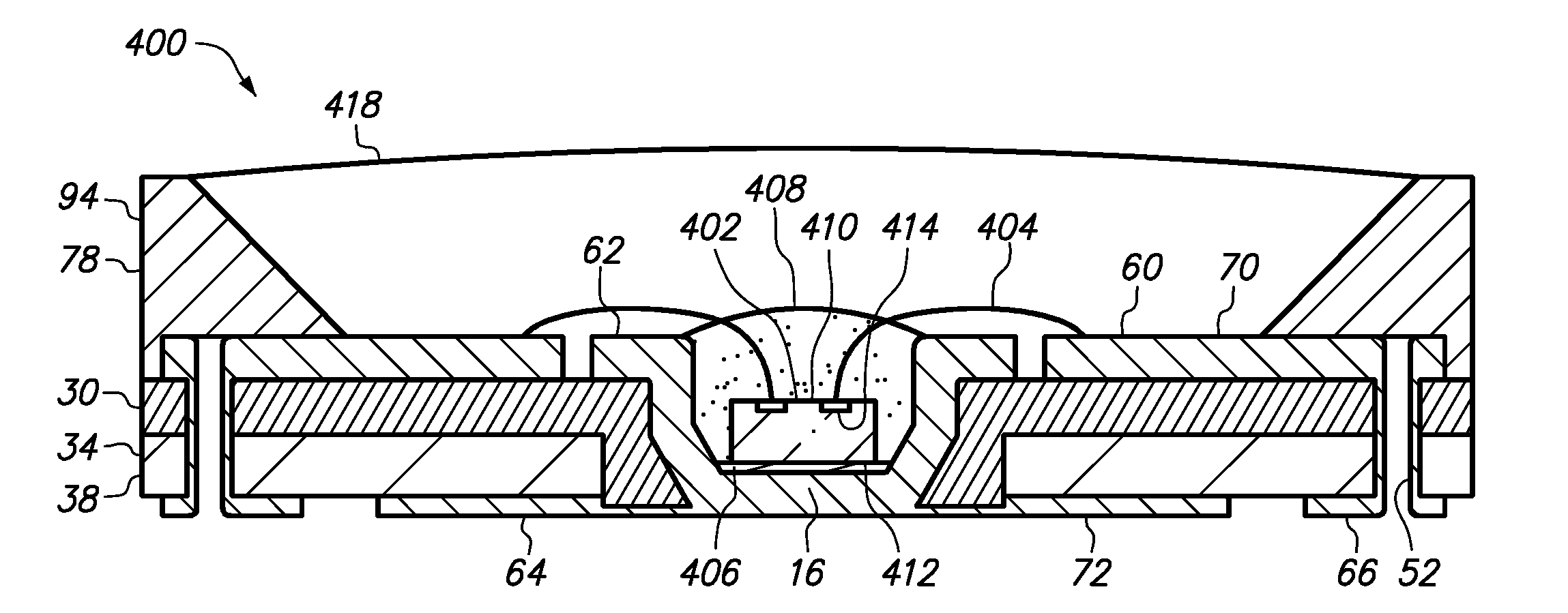

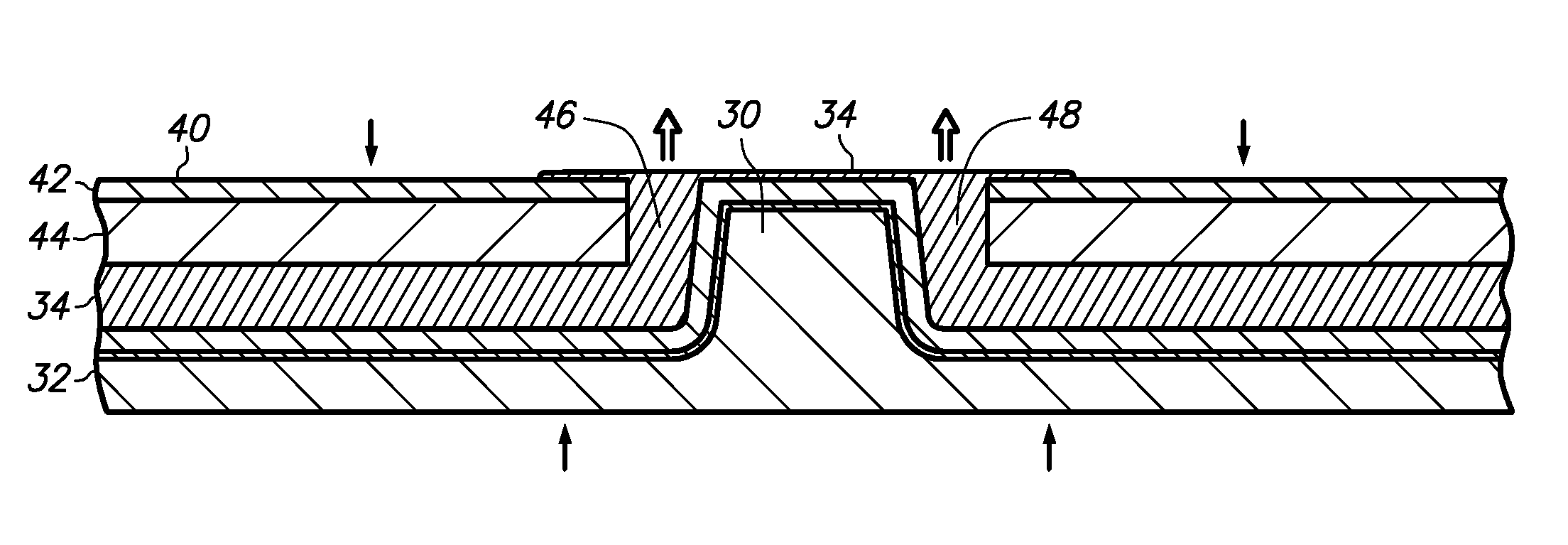

Thermally enhanced semiconductor assembly with bump/base/flange heat spreader and build-up circuitry

InactiveUS20120126399A1Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesSignal routingDevice material

A semiconductor assembly includes a semiconductor device, a heat spreader, an adhesive and a build-up circuitry. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry includes a dielectric layer and conductive traces on the semiconductor device and the flange. The conductive traces provide signal routing for the semiconductor device.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and a multilevel conductive trace

InactiveUS20110201157A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsPrinted circuit aspectsElectricityAdhesive

A method of making a semiconductor chip assembly includes providing a post and a base, mounting a second adhesive on the base, mounting a substrate with a conductive pattern on the second adhesive, mounting a first adhesive on the substrate and mounting a conductive layer on the first adhesive, then flowing the first adhesive upward between the post and the conductive layer and flowing the second adhesive upward between the post and the substrate, solidifying the adhesives, then providing a conductive trace that includes a pad, a terminal, the conductive pattern, first and second vias and a selected portion of the conductive layer, mounting a semiconductor device on the post, wherein a heat spreader includes the post and the base, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

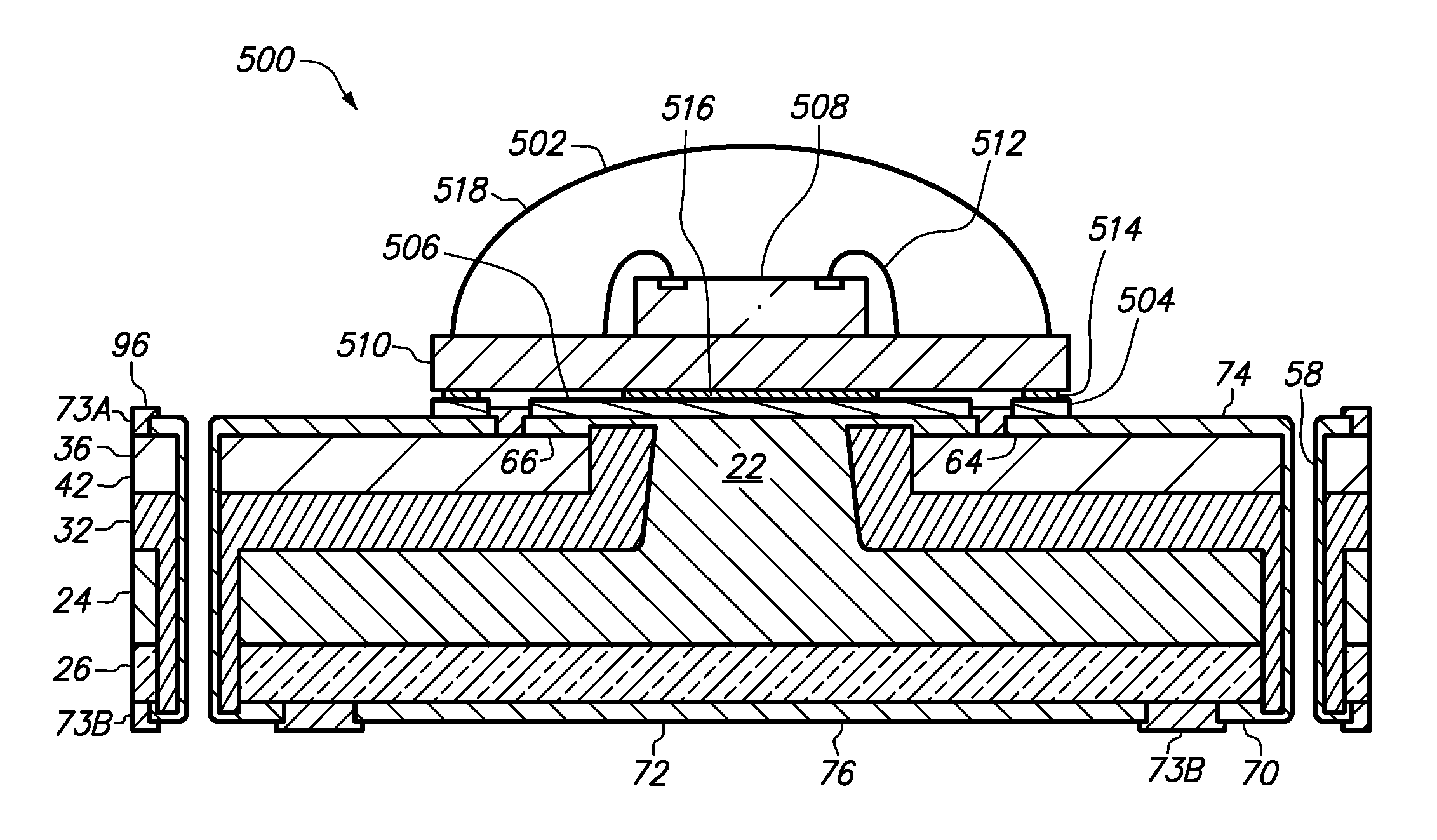

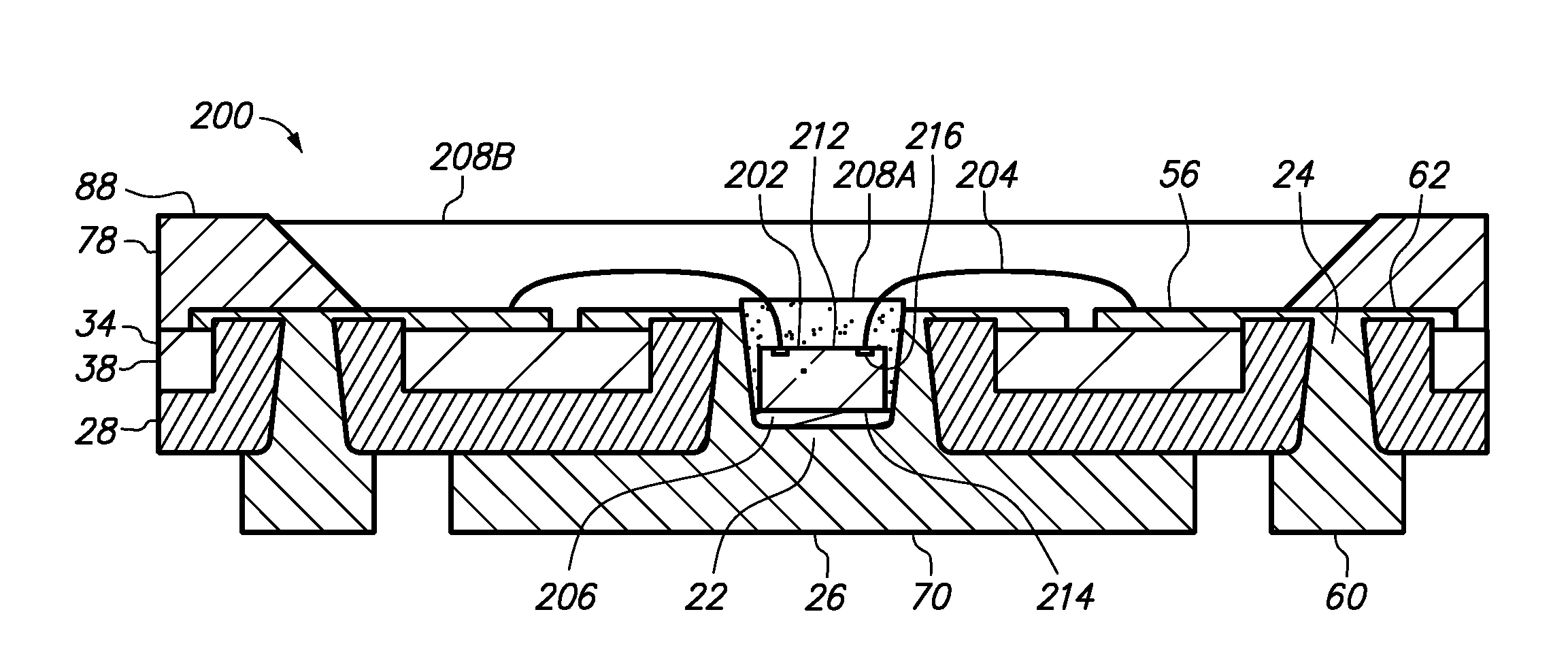

Semiconductor chip assembly with post/base heat spreader, signal post and cavity

InactiveUS20110049558A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectricitySignal routing

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a thermal post and a base. The conductive trace includes a pad, a terminal and a signal post. The semiconductor device extends into a cavity in the thermal post, is electrically connected to the conductive trace and is thermally connected to the heat spreader. The thermal post extends upwardly from the base into a first opening in the adhesive, and the signal post extends upwardly from the terminal into a second opening in the adhesive. The conductive trace is located outside the cavity and provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

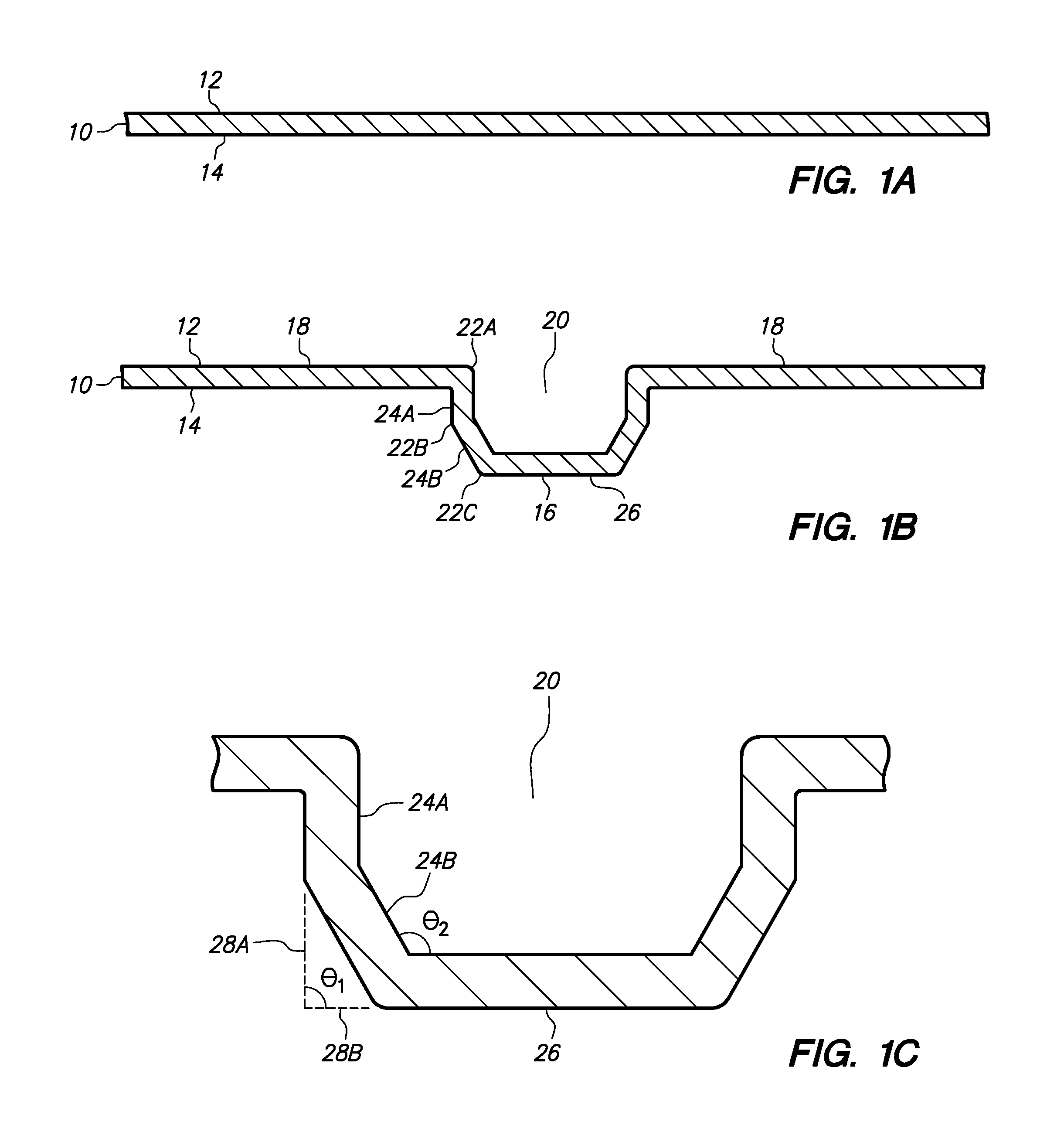

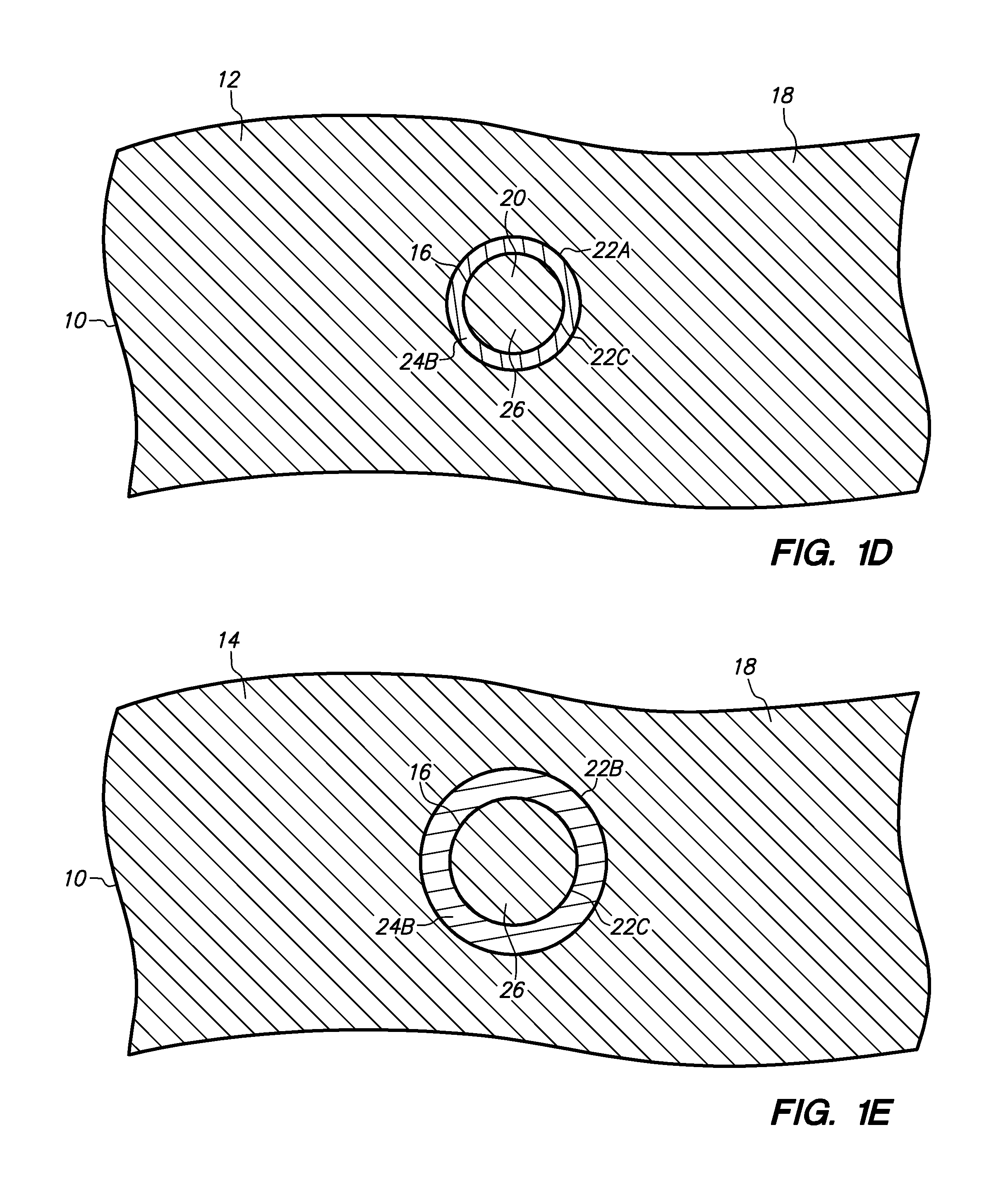

Semiconductor chip assembly with bump/base heat spreader and dual-angle cavity in bump

InactiveUS20110079811A1Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a bump that includes first, second and third bent corners that shape a cavity. The conductive trace includes a pad and a terminal. The semiconductor device is located within the cavity, is electrically connected to the conductive trace and is thermally connected to the bump. The bump extends into an opening in the adhesive and provides a recessed die paddle and a reflector for the semiconductor device. The conductive trace provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and horizontal signal routing

InactiveUS20100003787A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

The present invention provides a method of making a semiconductor chip assembly that includes providing a post and a base, mounting an adhesive on the base including inserting the post through an opening in the adhesive, mounting a substrate on the adhesive including inserting the post into an aperture in the substrate to form a gap in the aperture between the post and the substrate, then flowing the adhesive into and upward in the gap, solidifying the adhesive, then mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the substrate and thermally connecting the semiconductor device to the heat spreader. The substrate includes first and second conductive layers and a dielectric layer therebetween and provides horizontal signal routing between a pad and a terminal at the first conductive layer.

Owner:BRIDGE SEMICON

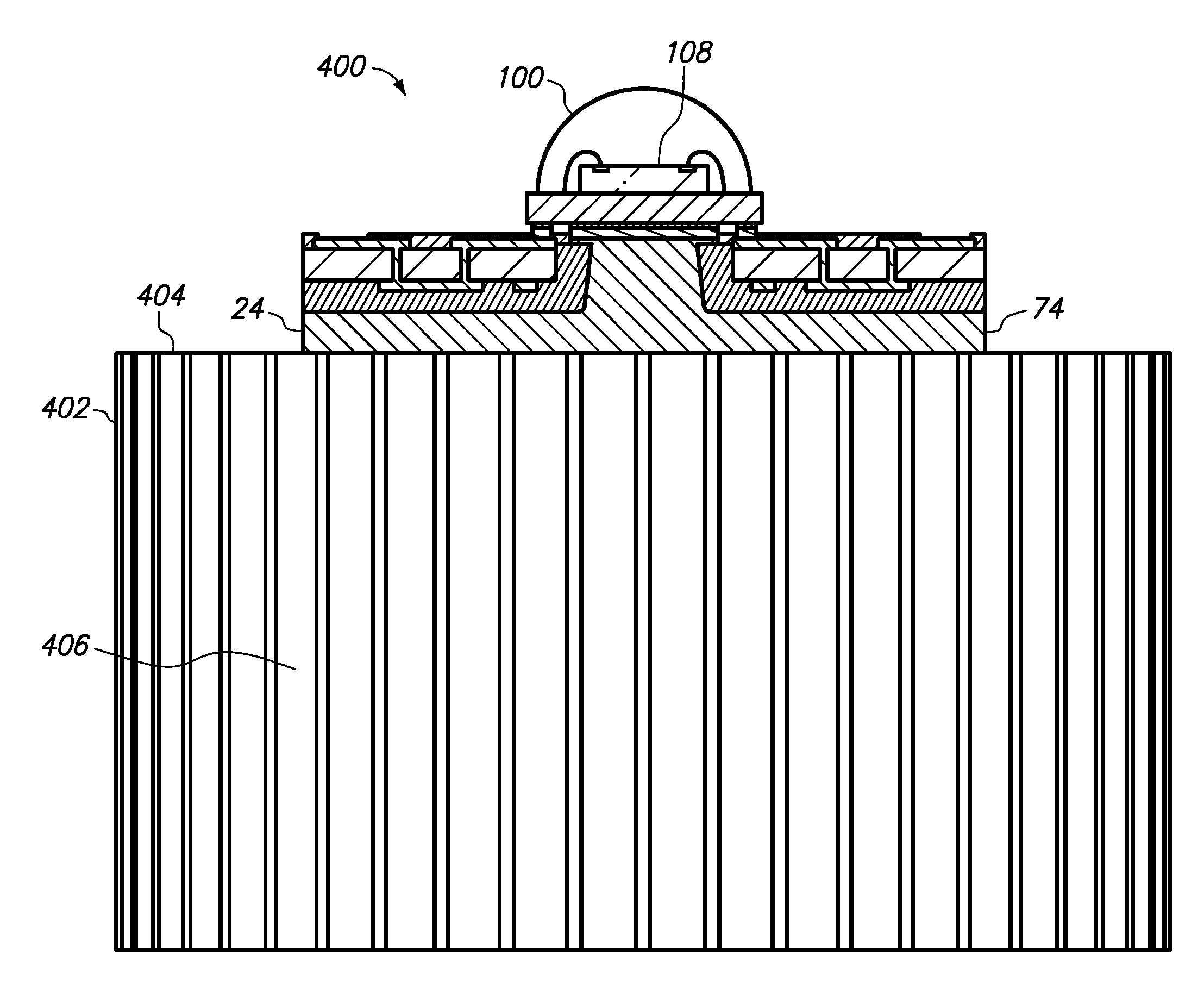

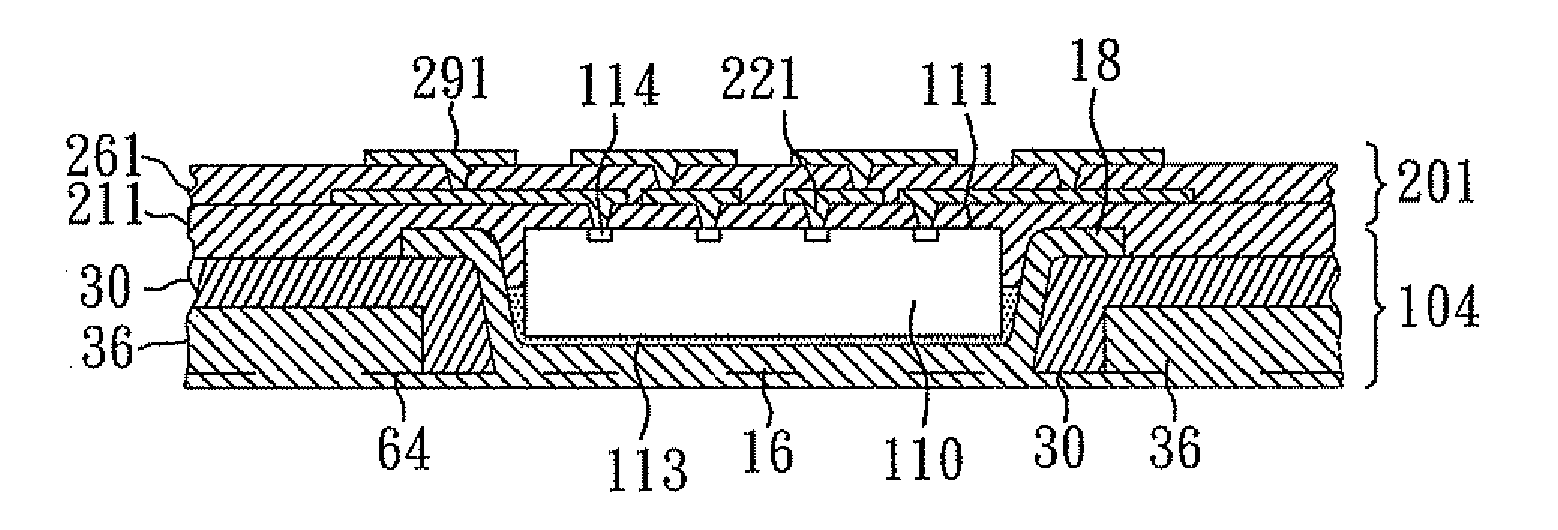

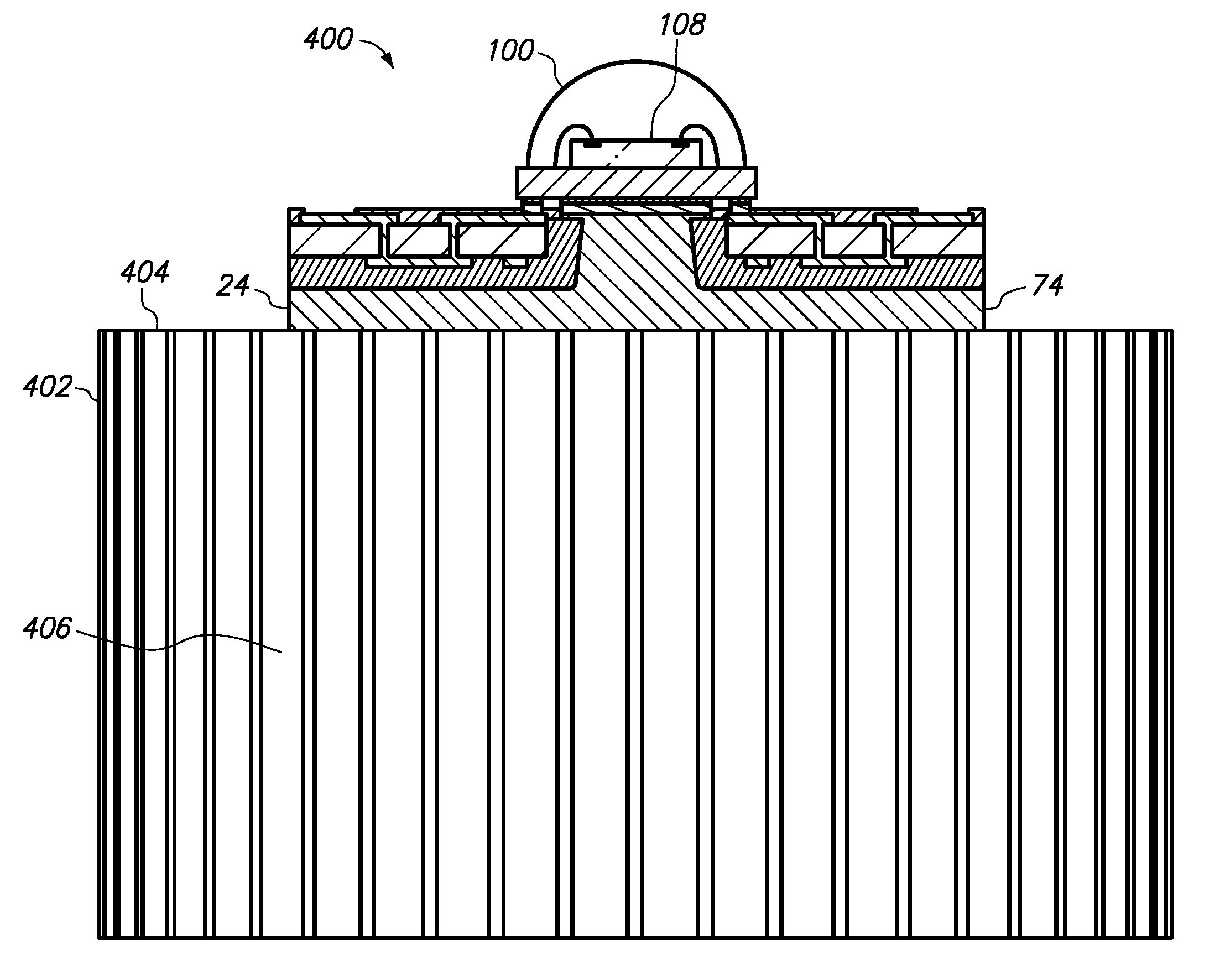

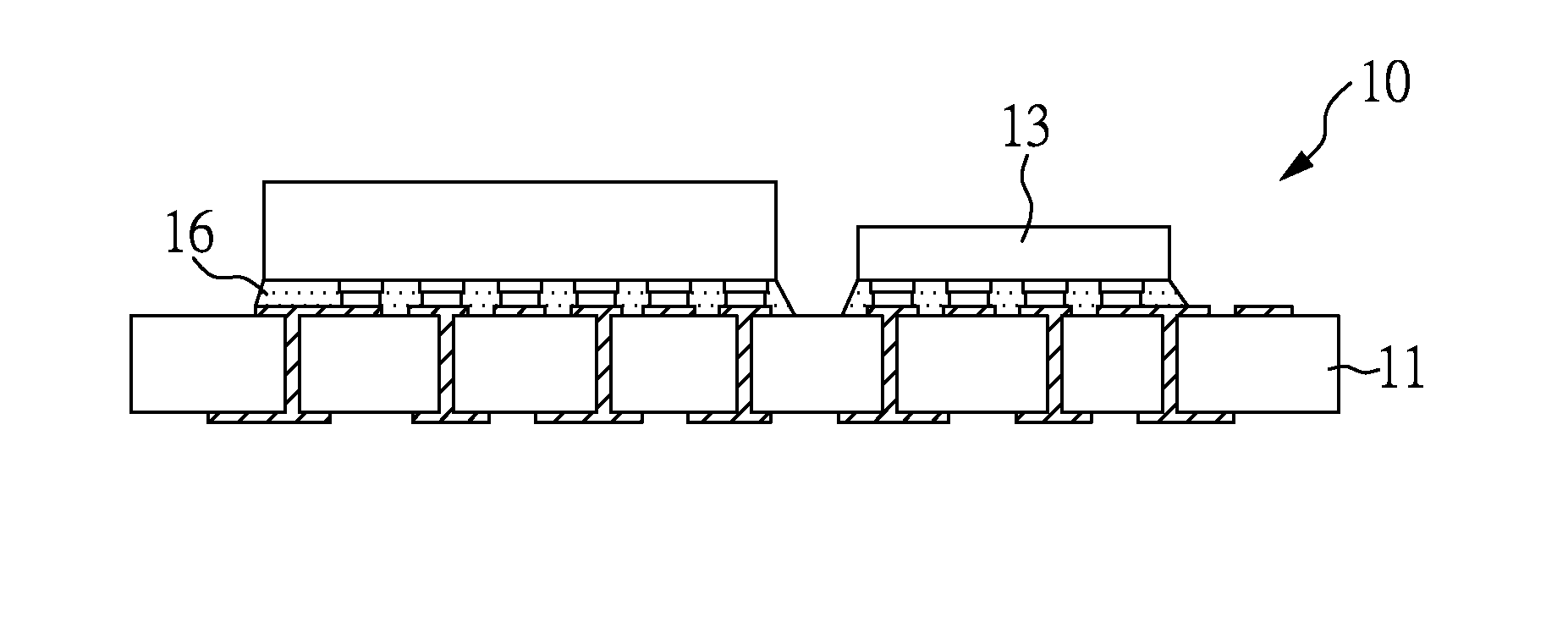

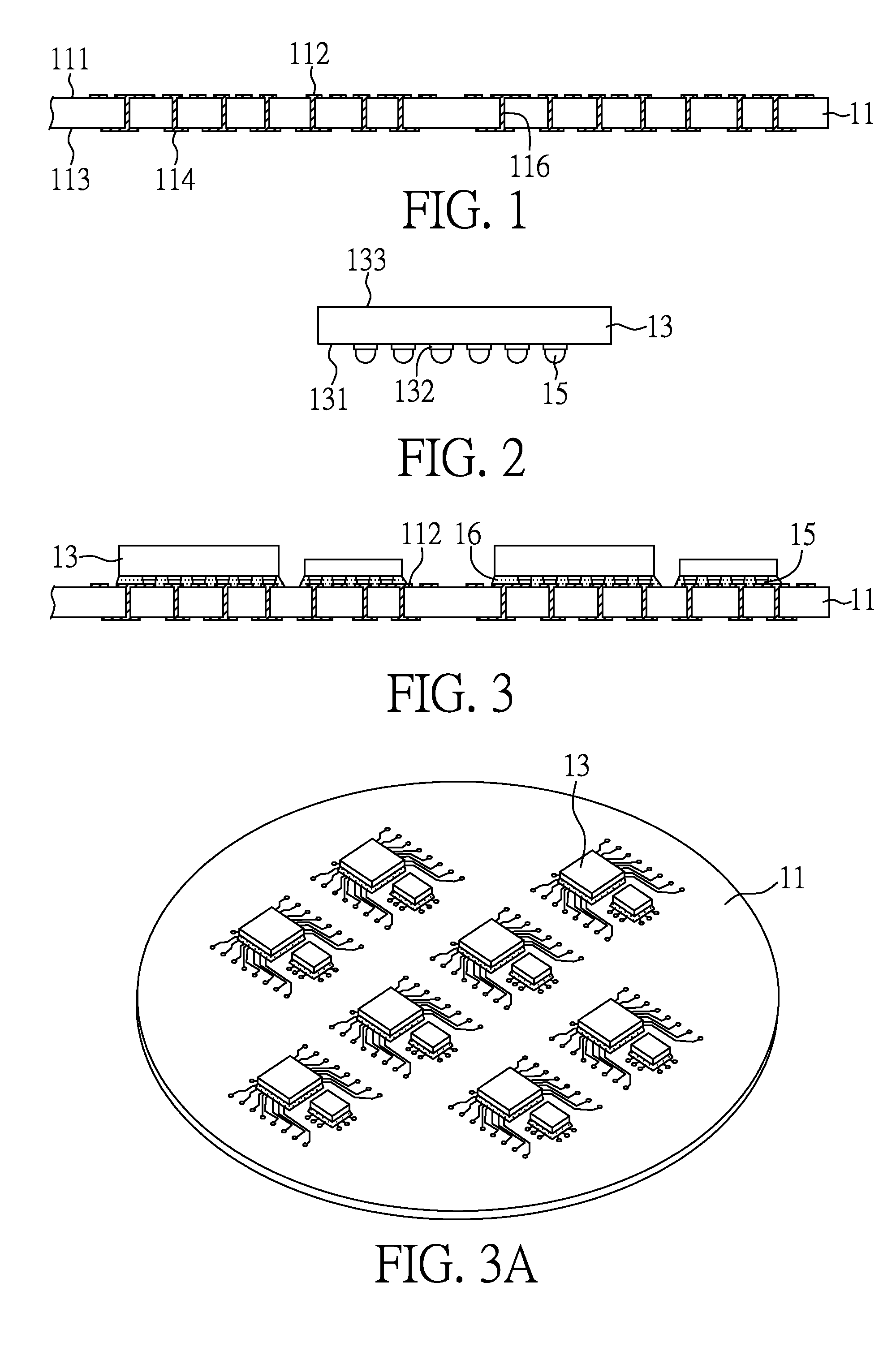

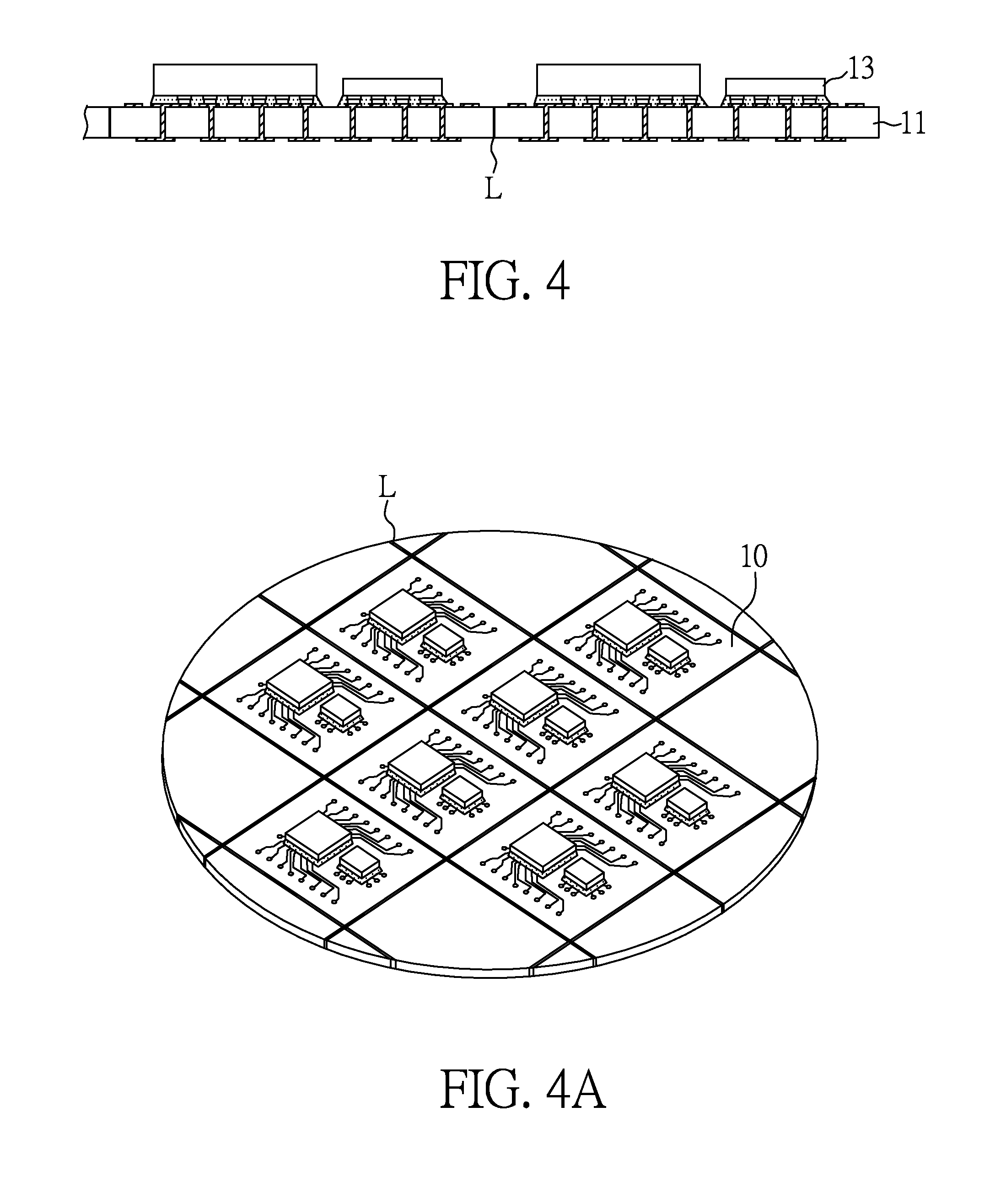

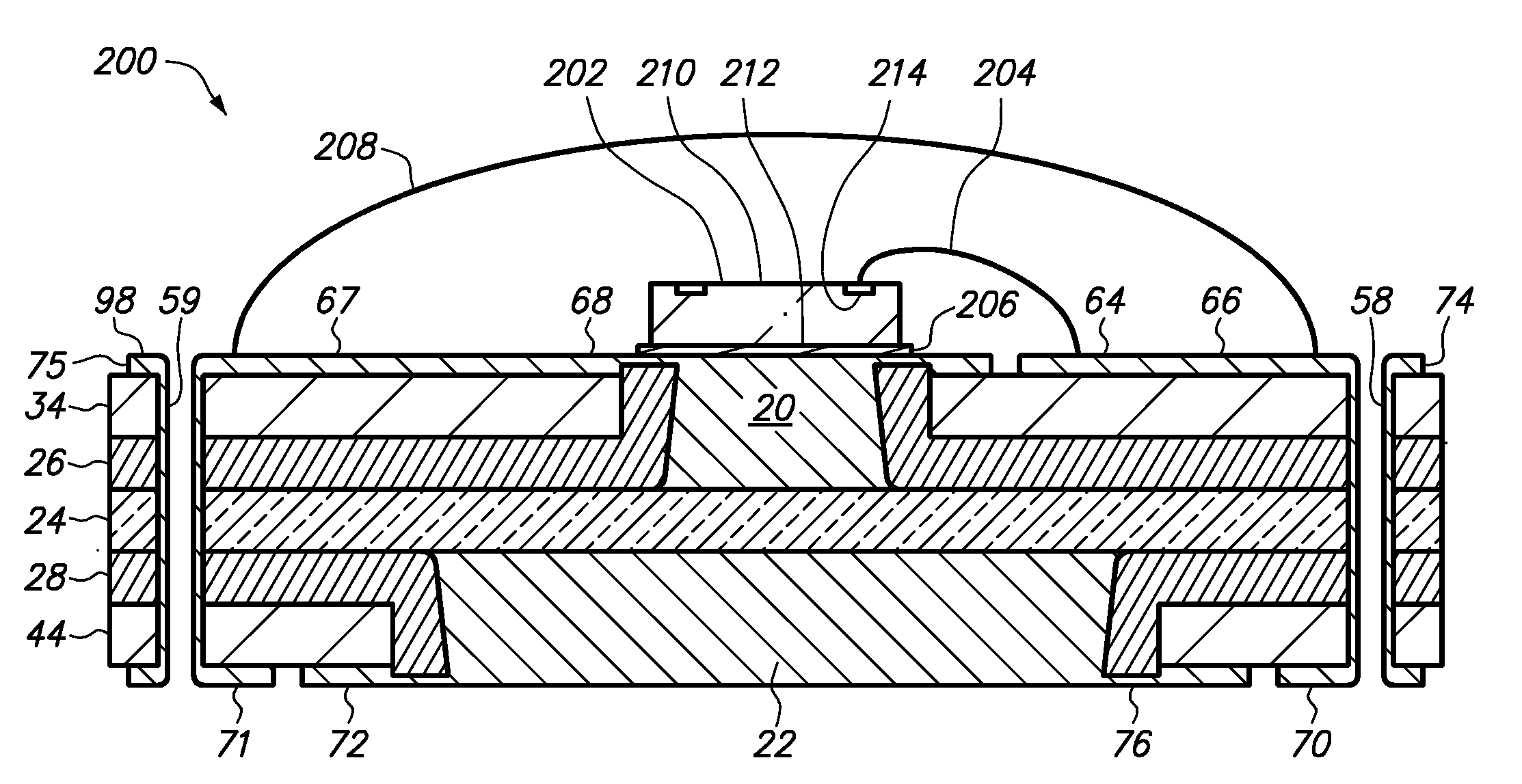

Thermally enhanced semiconductor assembly with embedded chip and interposer and method of manufacturing the same

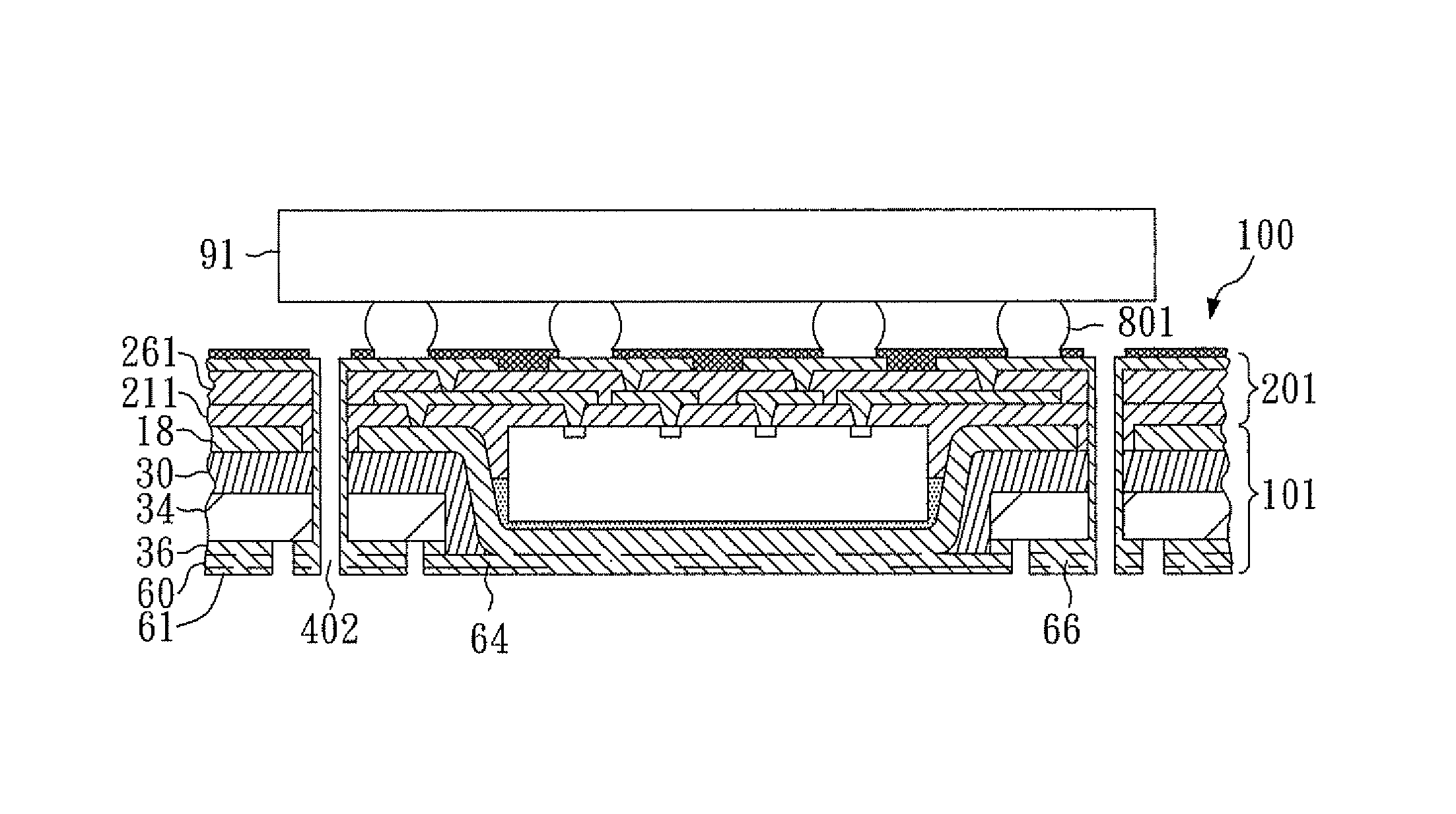

InactiveUS20140175633A1Avoid warping problemImprove manufacturing yieldSemiconductor/solid-state device detailsSolid-state devicesContact padAdhesive

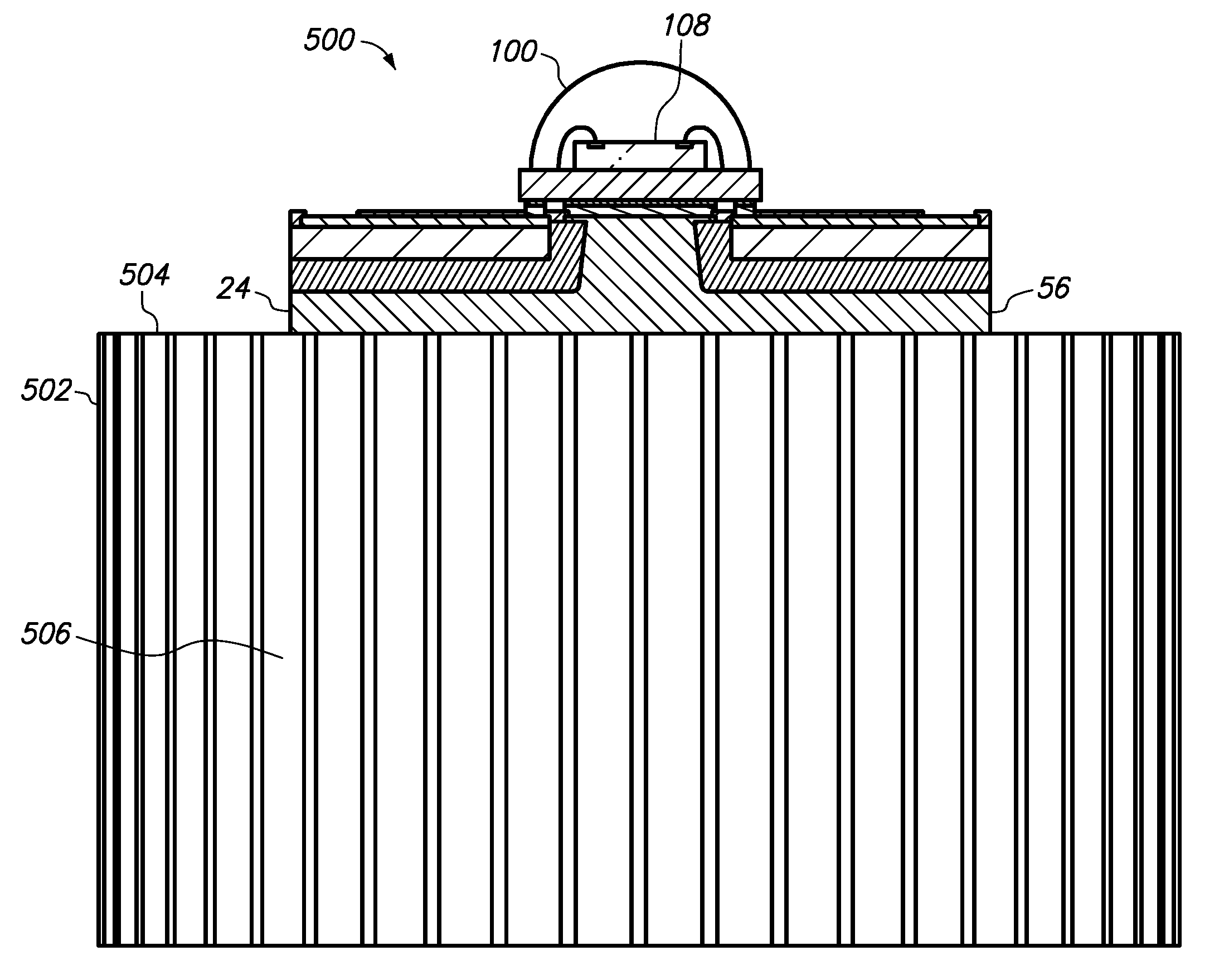

The present invention relates to a method of making a thermally conductive semiconductor assembly. In accordance with a preferred embodiment, the method includes: providing a chip; providing an interposer that includes a through via, a first contact pad on a first surface and a second contact pad on an opposite second surface; electrically coupling the chip to the first contact pad of the interposer by a conductive bump or a wire; providing a heat sink with a cavity; then attaching the chip and the interposer on the heat sink using an adhesive with the chip inserted into the cavity; and then forming a build-up circuitry on the second surface of the interposer. Accordingly, the heat sink can provide essential thermal dissipation for the embedded chip, and the interposer and build-up circuitry can respectively provide first and second level fan-out routing / interconnection for the embedded chip.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and an adhesive between the base and a terminal

InactiveUS20110039357A1Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesElectricityAdhesive

A method of making a semiconductor chip assembly includes providing a thermal post, a signal post, a base and a terminal, mounting an adhesive on the base including inserting the thermal post into a first opening in the adhesive and the signal post into a second opening in the adhesive, mounting a conductive layer on the adhesive including aligning the thermal post with a first aperture in the conductive layer and the signal post with a second aperture in the conductive layer, then flowing the adhesive upward between the thermal post and the conductive layer and between the signal post and the conductive layer and downward between the base and the terminal, solidifying the adhesive, providing a conductive trace that includes a pad, the terminal and the signal post, wherein the pad includes a selected portion of the conductive layer, mounting a semiconductor device on a heat spreader that includes the thermal post and the base, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Method of making stackable semiconductor assembly with bump/base/flange heat spreader and build-up circuitry

InactiveUS8343808B2Accelerated dissipationImprove the heating effectSemiconductor/solid-state device detailsSolid-state devicesSignal routingAdhesive

A method of making a stackable semiconductor assembly that includes a semiconductor device, a heat spreader, an adhesive, a terminal, a plated through-hole and build-up circuitry is disclosed. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry provides signal routing for the semiconductor device. The plated through-hole provides signal routing between the build-up circuitry and the terminal. The heat spreader provides heat dissipation for the semiconductor device.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base heat spreader and adhesive between base and terminal

InactiveUS20100289054A1Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The semiconductor device is electrically connected to the conductive trace and thermally connected to the heat spreader. The heat spreader includes a thermal post and a base. The thermal post extends upwardly from the base into a first opening in the adhesive, and the base extends laterally from the thermal post. The conductive trace includes a pad, a terminal and a signal post. The signal post extends upwardly from the terminal into a second opening in the adhesive. The adhesive extends above the base and between the base and the terminal.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader, a signal post and a cavity

InactiveUS20110059578A1Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A method of making a semiconductor chip assembly includes providing a thermal post, a signal post and a base, mounting an adhesive on the base including inserting the thermal post into a first opening in the adhesive and the signal post into a second opening in the adhesive, mounting a conductive layer on the adhesive including aligning the thermal post with a first aperture in the conductive layer and the signal post with a second aperture in the conductive layer, then flowing the adhesive upward between the thermal post and the conductive layer and between the signal post and the conductive layer, solidifying the adhesive, providing a conductive trace that includes a pad, a terminal and the signal post, wherein the pad includes a selected portion of the conductive layer, mounting a semiconductor device on the thermal post, wherein a heat spreader includes the thermal post and the base and the semiconductor device extends into a cavity in the thermal post, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and horizontal signal routing

InactiveUS8062912B2Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingElectricity

A method of making a semiconductor chip assembly includes providing a post and a base, mounting an adhesive on the base including inserting the post through an opening in the adhesive, mounting a substrate on the adhesive including inserting the post into an aperture in the substrate to form a gap in the aperture between the post and the substrate, then flowing the adhesive into and upward in the gap, solidifying the adhesive, then mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the substrate and thermally connecting the semiconductor device to the heat spreader. The substrate includes first and second conductive layers and a dielectric layer therebetween and provides horizontal signal routing between a pad and a terminal at the first conductive layer.

Owner:BRIDGE SEMICON

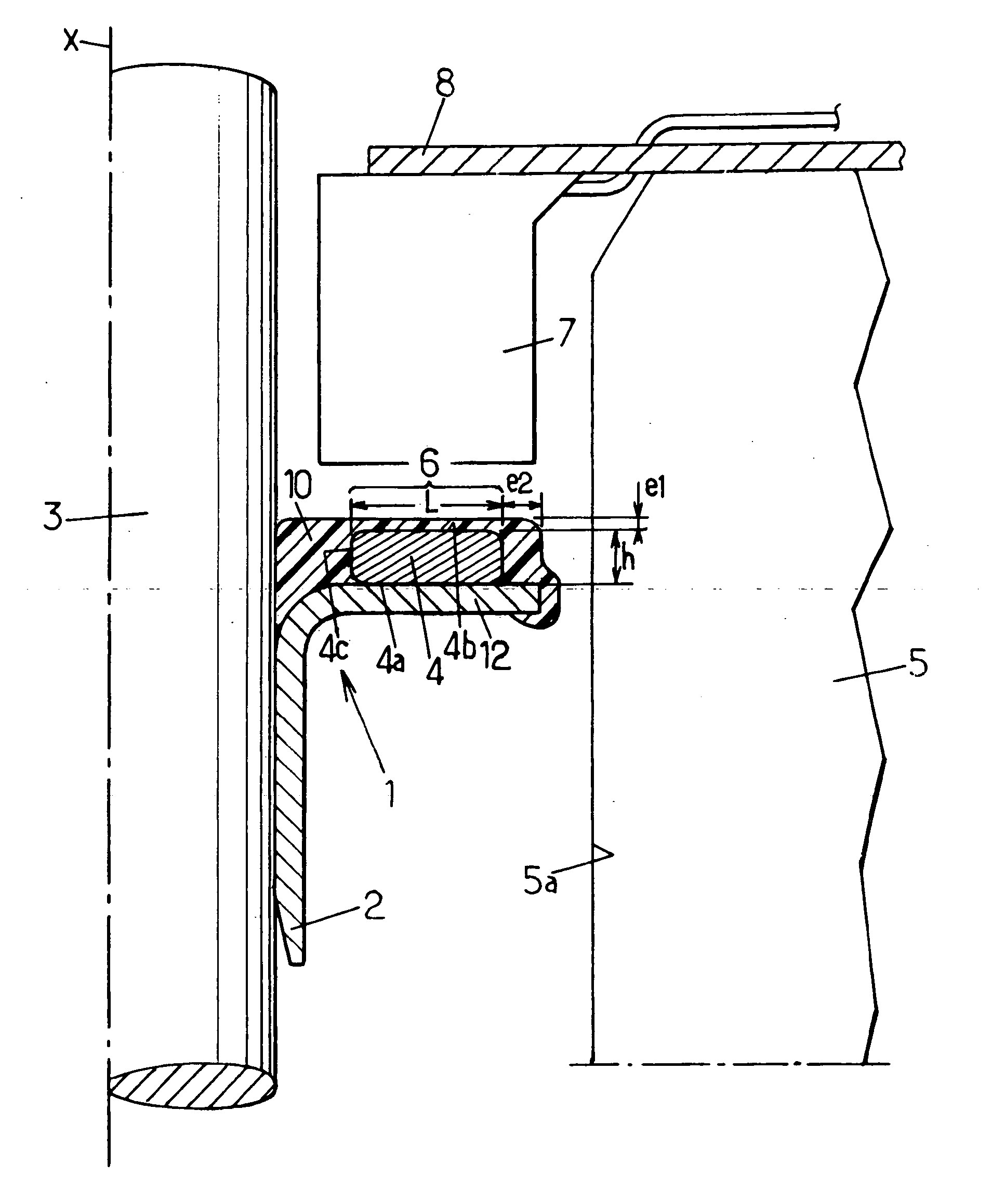

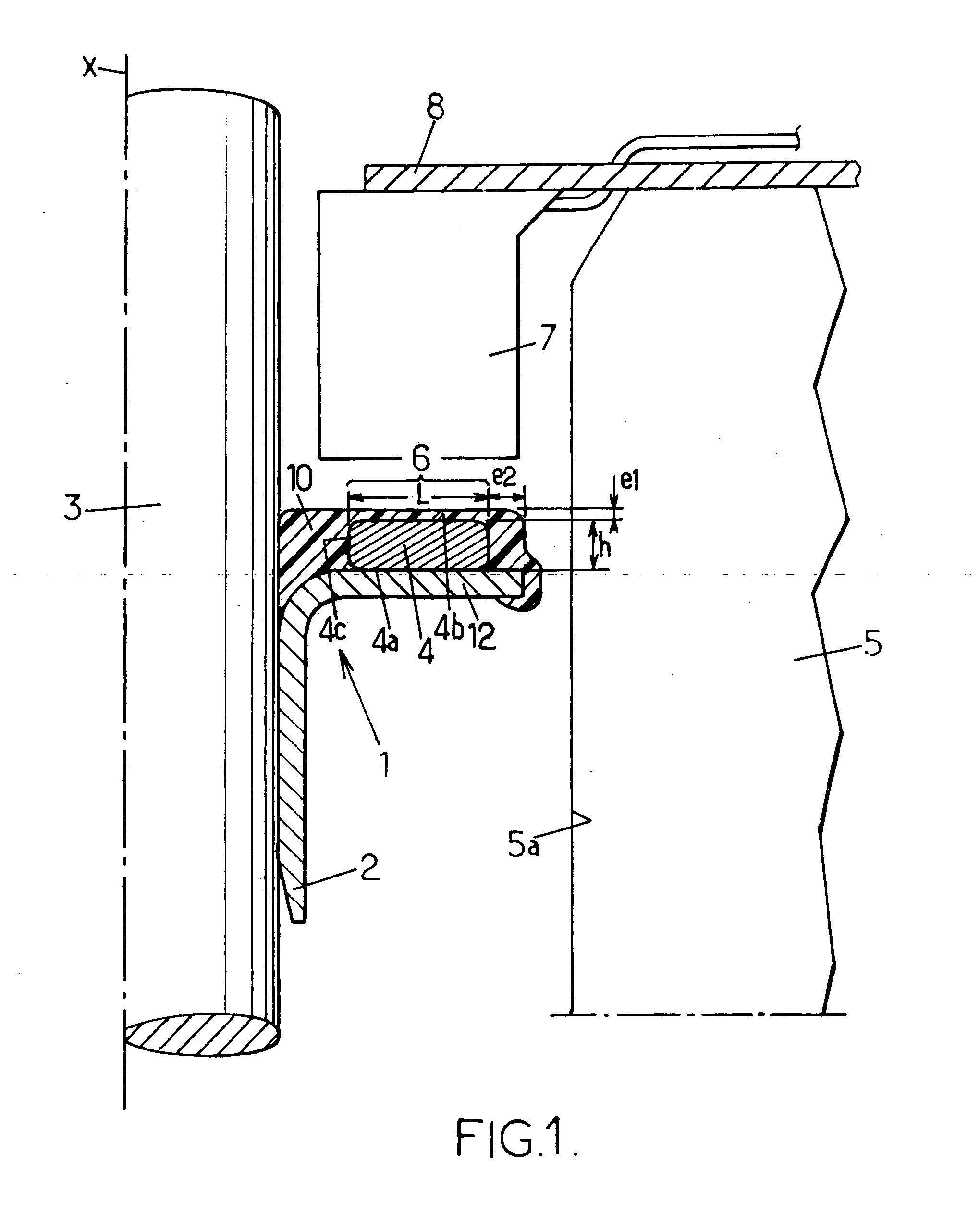

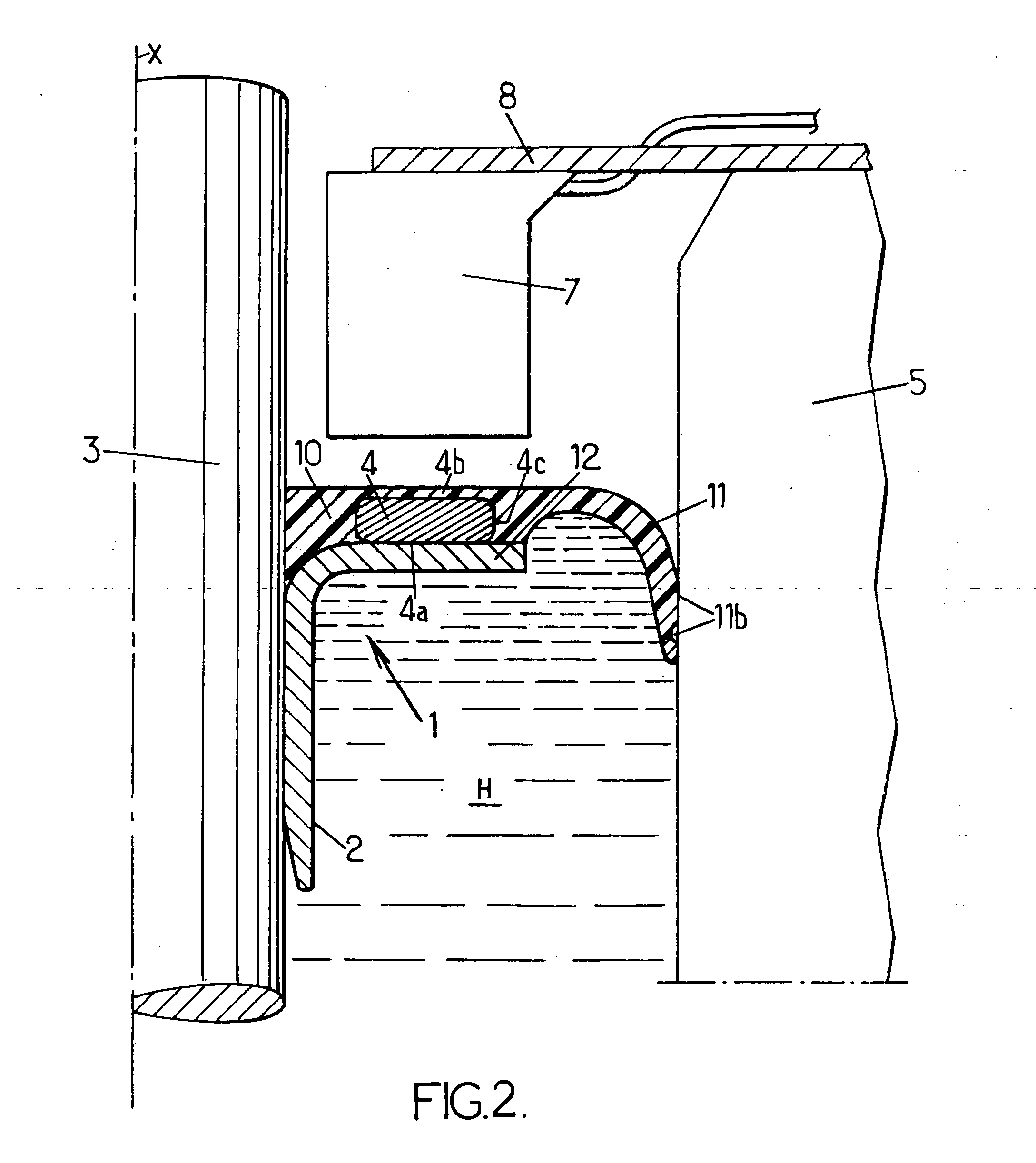

Displacement encoder, device comprising such an encoder and method of manufacturing such an encoder

InactiveUS20060049821A1Robust mechanical bondLow costUsing electrical meansDevices using electric/magnetic meansElastomerMagnet

Owner:HUTCHINSON SA

Method of making a semiconductor chip assembly with a post/dielectric/post heat spreader

InactiveUS20110287563A1High strengthImprove thermal conductivitySemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveSemiconductor chip

A method of making a semiconductor chip assembly includes providing first and second posts, first and second adhesives, first and second conductive layers and a dielectric base, wherein the first post extends from the dielectric base in a first vertical direction into a first opening in the first adhesive and is aligned with a first aperture in the first conductive layer, the second post extends from the dielectric base in a second vertical direction into a second opening in the second adhesive and is aligned with a second aperture in the second conductive layer and the dielectric base is sandwiched between and extends laterally from the posts, then flowing the first adhesive in the first vertical direction and the second adhesive in the second vertical direction, solidifying the adhesives, then providing a conductive trace that includes a pad, a terminal and selected portions of the conductive layers, wherein the pad extends beyond the dielectric base in the first vertical direction and the terminal extends beyond the dielectric base in the second vertical direction, providing a heat spreader that includes the posts and the dielectric base, then mounting a semiconductor device on the first post, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and a cavity over the post

InactiveUS20100203679A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveSemiconductor chip

A method of making a semiconductor chip assembly includes providing a post and a base, mounting an adhesive on the base including inserting the post into an opening in the adhesive, mounting a substrate on the adhesive including aligning the post with an aperture in the substrate, then flowing the adhesive into and upward in a gap located in the aperture between the post and the substrate, solidifying the adhesive, then etching the post to form a cavity in the adhesive above the post, then mounting a semiconductor device on the post, wherein a heat spreader includes the post and the base and the semiconductor device extends into the cavity, electrically connecting the semiconductor device to the substrate and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base heat spreader, signal post and cavity

InactiveUS8212279B2Low costNot easy to layerSemiconductor/solid-state device detailsSolid-state devicesElectricitySignal routing

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a thermal post and a base. The conductive trace includes a pad, a terminal and a signal post. The semiconductor device extends into a cavity in the thermal post, is electrically connected to the conductive trace and is thermally connected to the heat spreader. The thermal post extends upwardly from the base into a first opening in the adhesive, and the signal post extends upwardly from the terminal into a second opening in the adhesive. The conductive trace is located outside the cavity and provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON CORP

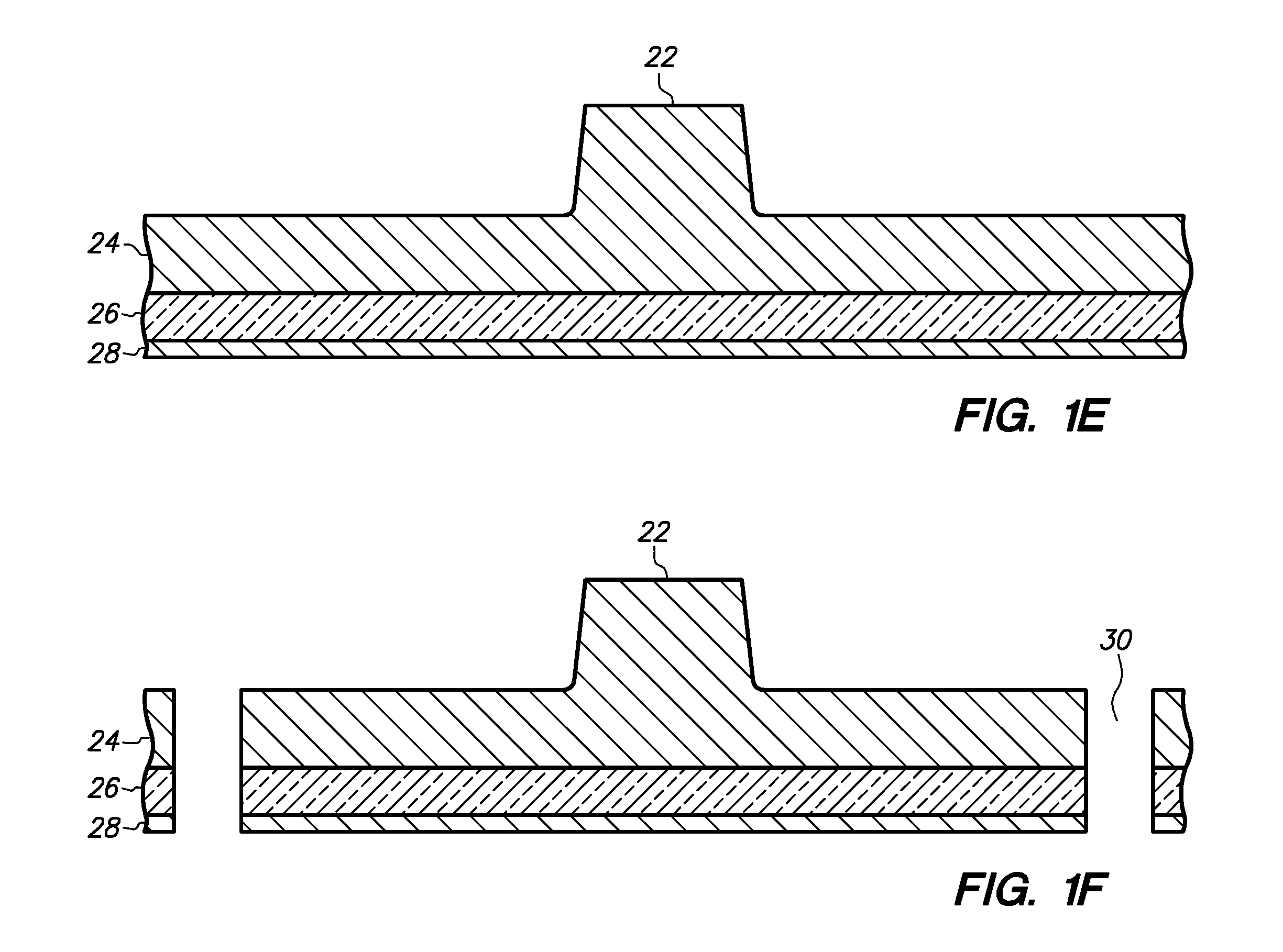

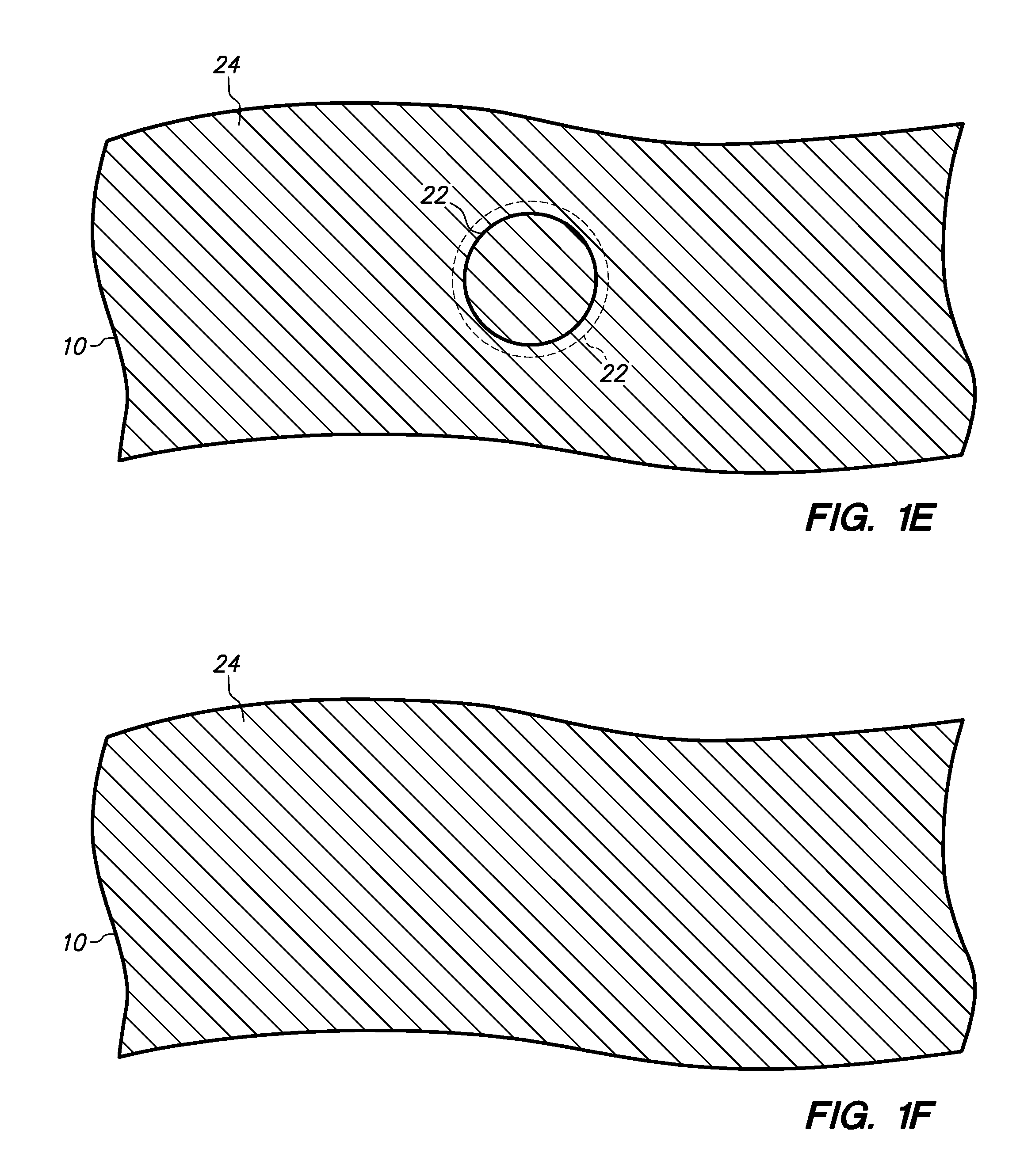

Semiconductor chip assembly with post/base heat spreader and substrate

InactiveUS20100059786A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingAdhesive

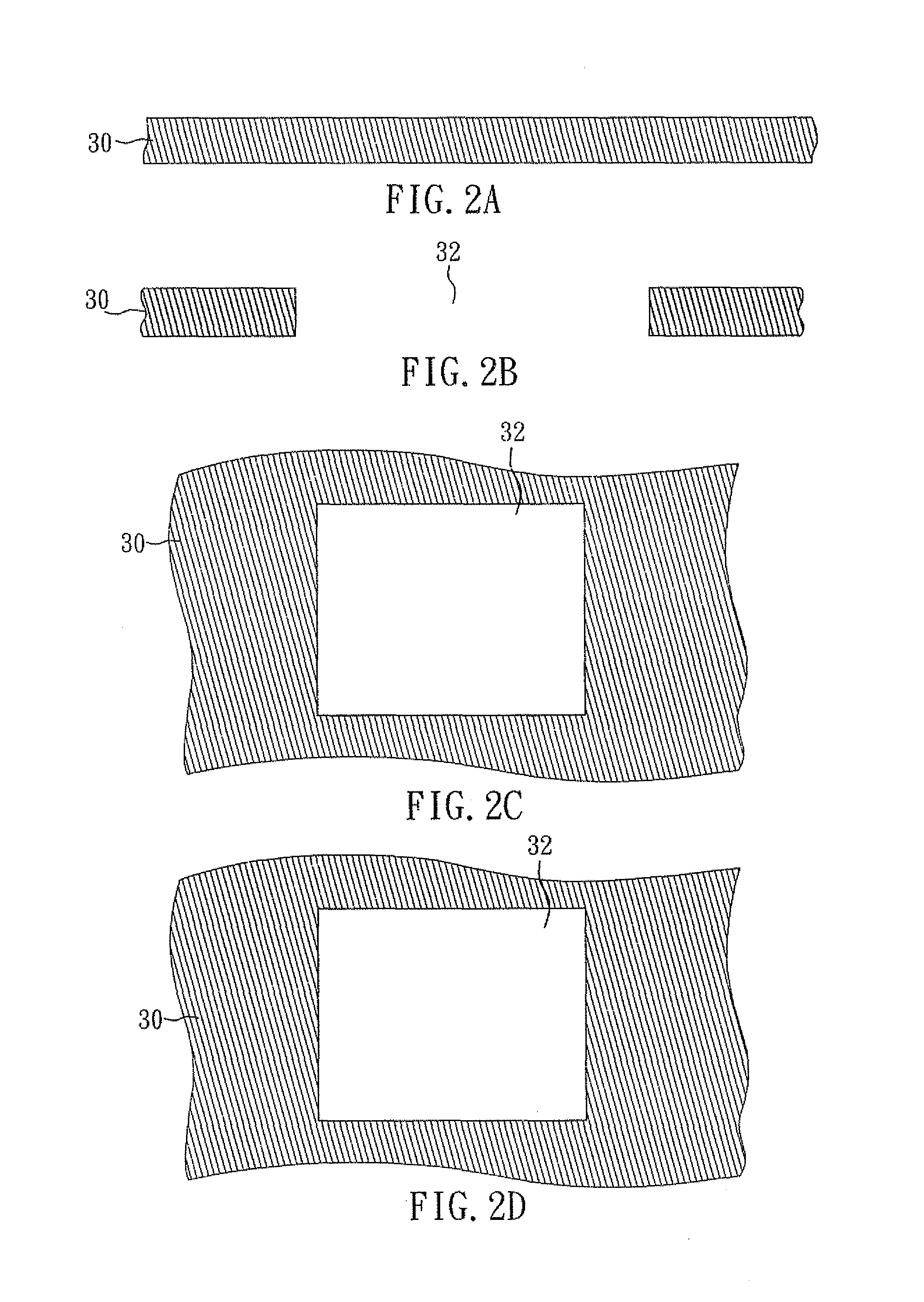

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly from the base into an opening in the adhesive and an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate. The assembly provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a copper/aluminum post/base heat spreader

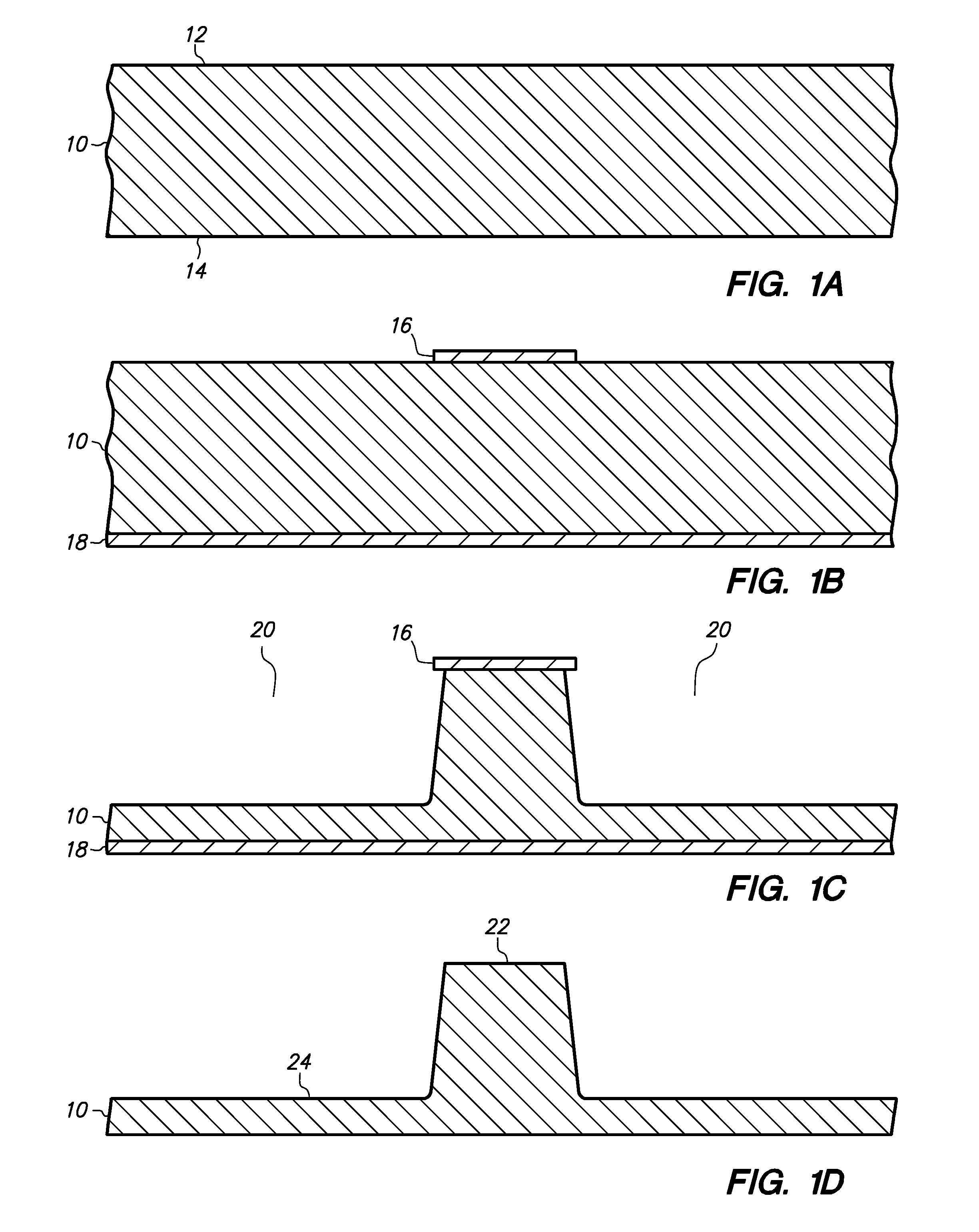

InactiveUS8034645B2Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsSurface layerAdhesive

A method of making a semiconductor chip assembly includes providing a post and a base that include a copper surface layer and an aluminum core, mounting an adhesive on the base including inserting the post into an opening in the adhesive, mounting a conductive layer on the adhesive including aligning the post with an aperture in the conductive layer, then flowing the adhesive into and upward in a gap located in the aperture between the post and the conductive layer, solidifying the adhesive, then providing a conductive trace that includes a pad, a terminal and a selected portion of the conductive layer, mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base heat spreader and conductive trace

InactiveUS20100052005A1Enhance thermal connectionImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The semiconductor device is electrically connected to the conductive trace and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly from the base into an opening in the adhesive, and the base extends laterally from the post. The adhesive extends between the post and the conductive trace and between the base and the conductive trace. The conductive trace provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader with a thermal via

InactiveUS20110275180A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveSemiconductor chip

A method of making a semiconductor chip assembly includes providing a post, a base, a support layer and an underlayer, wherein the post extends above the base and the support layer is sandwiched between the base and the underlayer, mounting an adhesive on the base including inserting the post into an opening in the adhesive, mounting a conductive layer on the adhesive including aligning the post with an aperture in the conductive layer, then flowing the adhesive upward between the post and the conductive layer, solidifying the adhesive, then providing a conductive trace that includes a pad, a terminal and a selected portion of the conductive layer, providing a heat spreader that includes the post, the base, the underlayer and a thermal via that extends from the base through the support layer to the underlayer, then mounting a semiconductor device on the post, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and dual adhesives

InactiveUS20100210049A1Low costNot easy to layerSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveSemiconductor chip

A method of making a semiconductor chip assembly includes providing a post and a base, mounting a first adhesive on the base including inserting the post through an opening in the first adhesive, mounting a conductive layer on the base including aligning the post with an aperture in the conductive layer, providing a conductive trace that includes a pad, a terminal and a selected portion of the conductive layer, then flowing a second adhesive into and downward in a gap between the post and the conductive trace, solidifying the second adhesive, then mounting a semiconductor device on a heat spreader that includes the post and the base, electrically connecting the semiconductor device to the conductive trace and thermally connecting the semiconductor device to the heat spreader.

Owner:BRIDGE SEMICON

Method of making a semiconductor chip assembly with a post/base heat spreader and a plated through-hole

InactiveUS20110183472A1Accelerated dissipationImprove the heating effectSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveDevice material

Owner:BRIDGE SEMICON

Semiconductor chip assembly with post/base/post heat spreader and asymmetric posts

InactiveUS20110156090A1Low costSimple circuitry patternSemiconductor/solid-state device detailsPrinted circuit aspectsSignal routingElectricity

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and first and second adhesives. The heat spreader includes a first post, a second post and a base. The conductive trace includes a pad and a terminal. The semiconductor device is electrically connected to the conductive trace and thermally connected to the heat spreader. The first post extends from the base in a first vertical direction into a first opening in the first adhesive and is located within a periphery of the second post, the second post extends from the base in a second vertical direction into a second opening in the second adhesive and the base is sandwiched between and extends laterally from the posts. The conductive trace provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

Stackable semiconductor assembly with bump/base/flange heat spreader and electromagnetic shielding

InactiveUS20120126401A1Excellent heat spreading heatImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSignal routingDevice material

A stackable semiconductor assembly includes a semiconductor device, a heat spreader, an adhesive, a terminal, a plated through-hole and build-up circuitry. The heat spreader includes a bump, a base and a flange. The bump defines a cavity. The semiconductor device is mounted on the bump at the cavity, electrically connected to the build-up circuitry and thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The build-up circuitry provides signal routing for the semiconductor device. The plated through-hole provides signal routing between the build-up circuitry and the terminal. The heat spreader provides heat dissipation for the semiconductor device.

Owner:BRIDGE SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com