Apparatus and methods for the attachment of materials to polyurethane foam, and articles made using them

a technology of polyurethane foam and apparatus, which is applied in the field of apparatus and methods for the attachment of materials to polyurethane foam, and articles made using them, can solve the problems of difficult to find non-toxic, durable adhesives to bond materials, and achieve the effect of reducing costs and facilitating moisture vapor transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

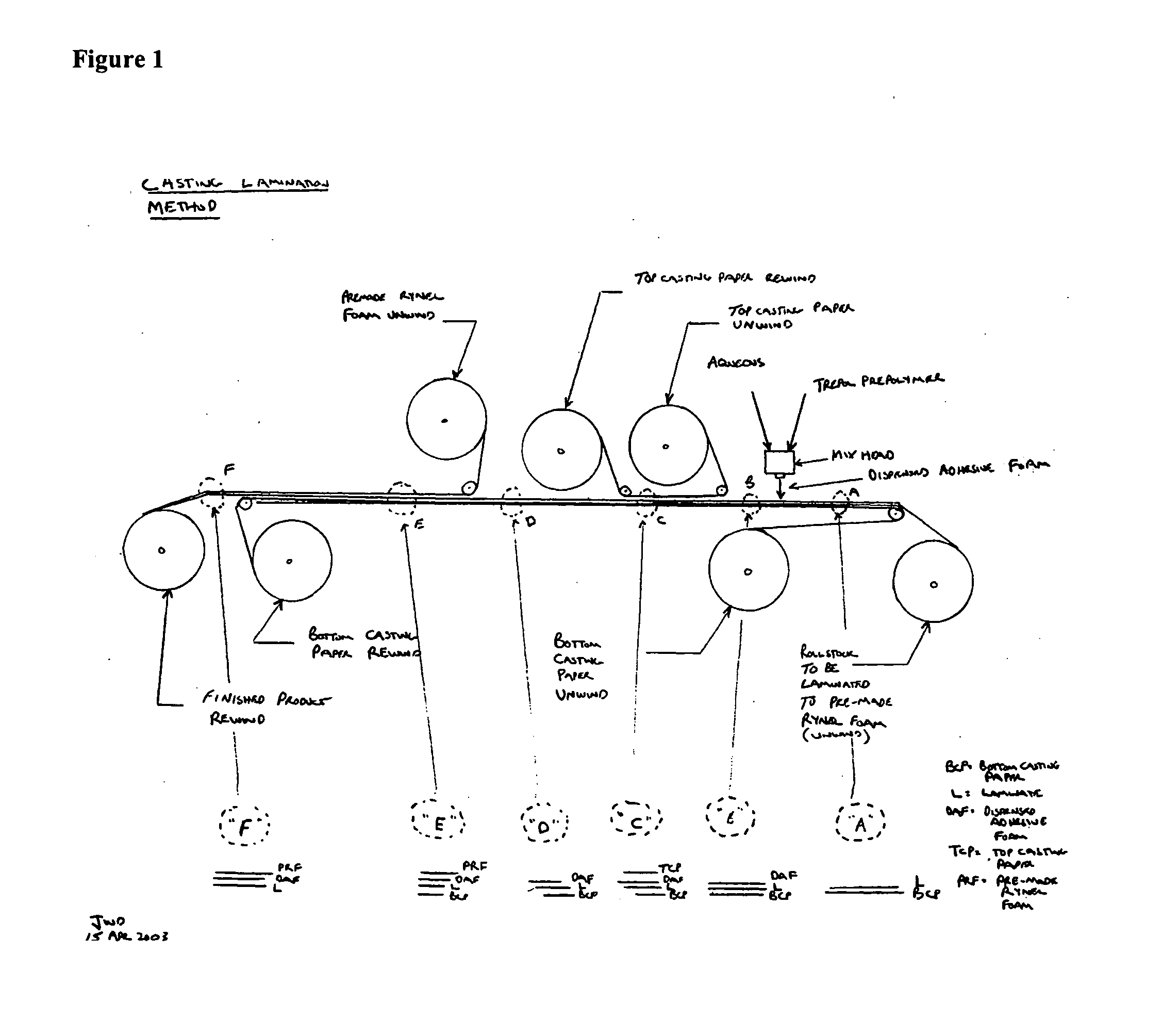

Preparation of Composite Foam by the Casting Method

A method to bind a substrate to a foam using an adhesive is illustrated in FIGS. 1, 4, and 5. The material to be laminated to the foam is orientated such that the “side-to-be-adhered-to” is facing upright and said material resides on top of the carrier (e.g. casting paper) on the production line. The casting surface and laminate material are thus being pulled underneath the foam dispensing head of the foam line. Rynel medical prepolymer (Trepol®) is combined with an aqueous solution in the mixing head in a predetermined ratio (typically 1:1 or 1:1.2) and dispensed onto the “upside” of the laminate material. A top layer of casting surface is then continuously applied to make a sandwich consisting of: bottom casting surface, laminate material, dispensed Trepol® based foam and top layer of casting surface. All layers are being pulled at the same rate presenting a static interface of the layers. The sandwich is pulled underneath a ro...

example 2

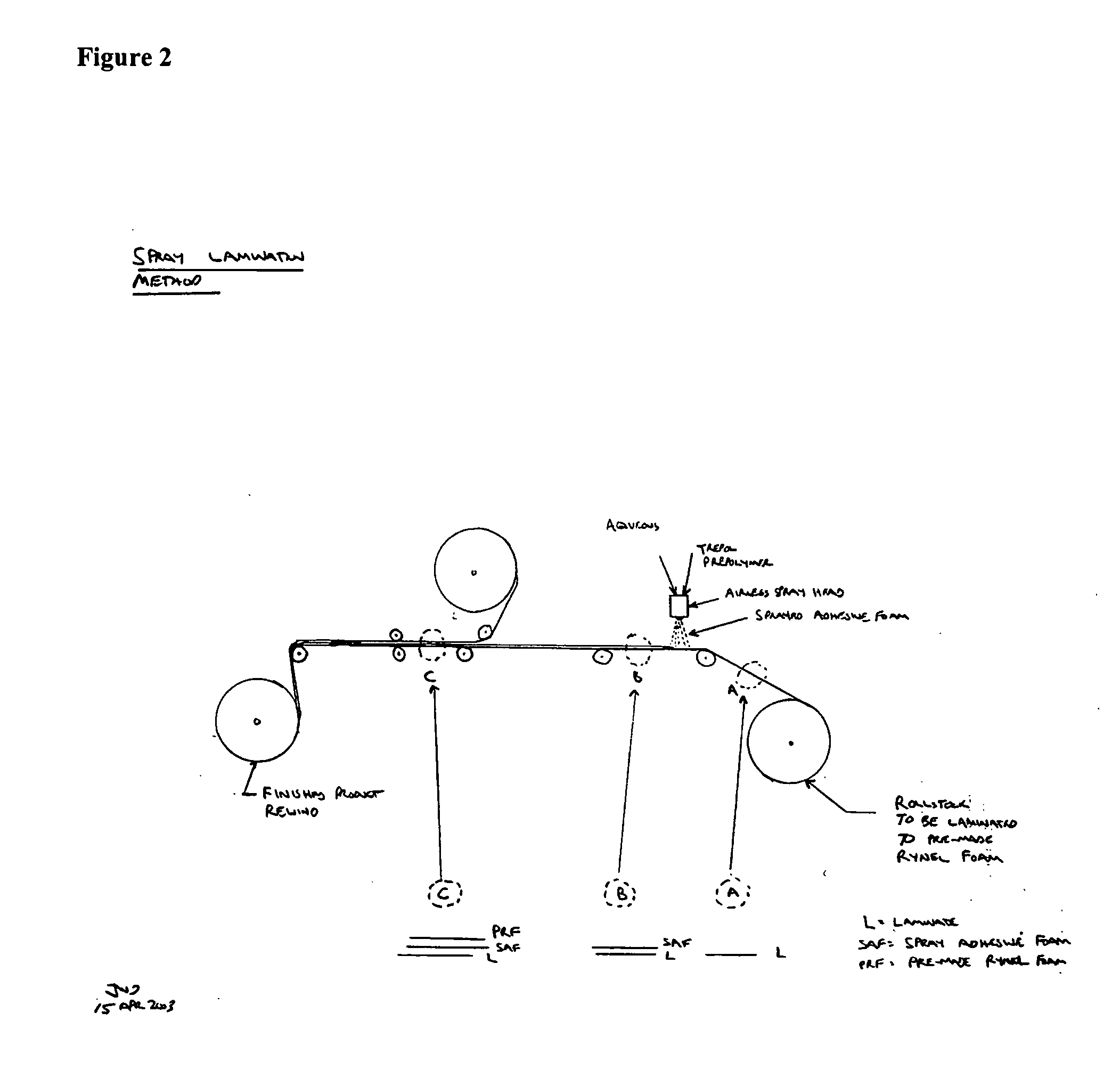

Spraying Method

As depicted in FIG. 2, the material to be laminated to the foam is orientated such that the “side-to-be-adhered-to” is facing upright. The Rynel medical prepolymer (Trepol®) is combined with an aqueous solution in the spray head in a predetermined ratio (typically 1:1 or 1:1.2) and dispensed onto the “upside” of the laminate material via a spray gun. The dispensed foam reacts and begins to cure. Next, the previously made foam material is laid down on top of the polymeric adhesive mixture and pressure is applied using a roller. The composite material continues down the length of the production line while the adhesive continues to cure and cross link thereby binding the laminate material to the pre-made foam. The pre-made foam is rolled up ready for slitting, die cutting etc.

example 3

The moisture vapor transmission rate (MVTR) of a sample of 4005 Polyurethane foam coated with a layer of Trepol® based foam was determined using the following method. The layer of 4005 Polyurethane foam obtained from Scapa UK Limited was approximately 0.4 mm thick.

A sample cut from a dressing was applied to the upper flange of a Paddington Cup and fixed securely in place with the retaining ring. A 0.9% saline solution is added to the cup, which is then securely sealed and weighed. The cup is then inverted onto a screen support in a tray containing silica gel absorbent and placed in a 37° C. incubator for 24 hours after which the cup is removed from the incubator and allowed to equilibrate to room temperature and re-weighed. The loss in weight due to moisture vapor transmission is used to calculate the MVTR. The MVTR data is presented below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com