Patents

Literature

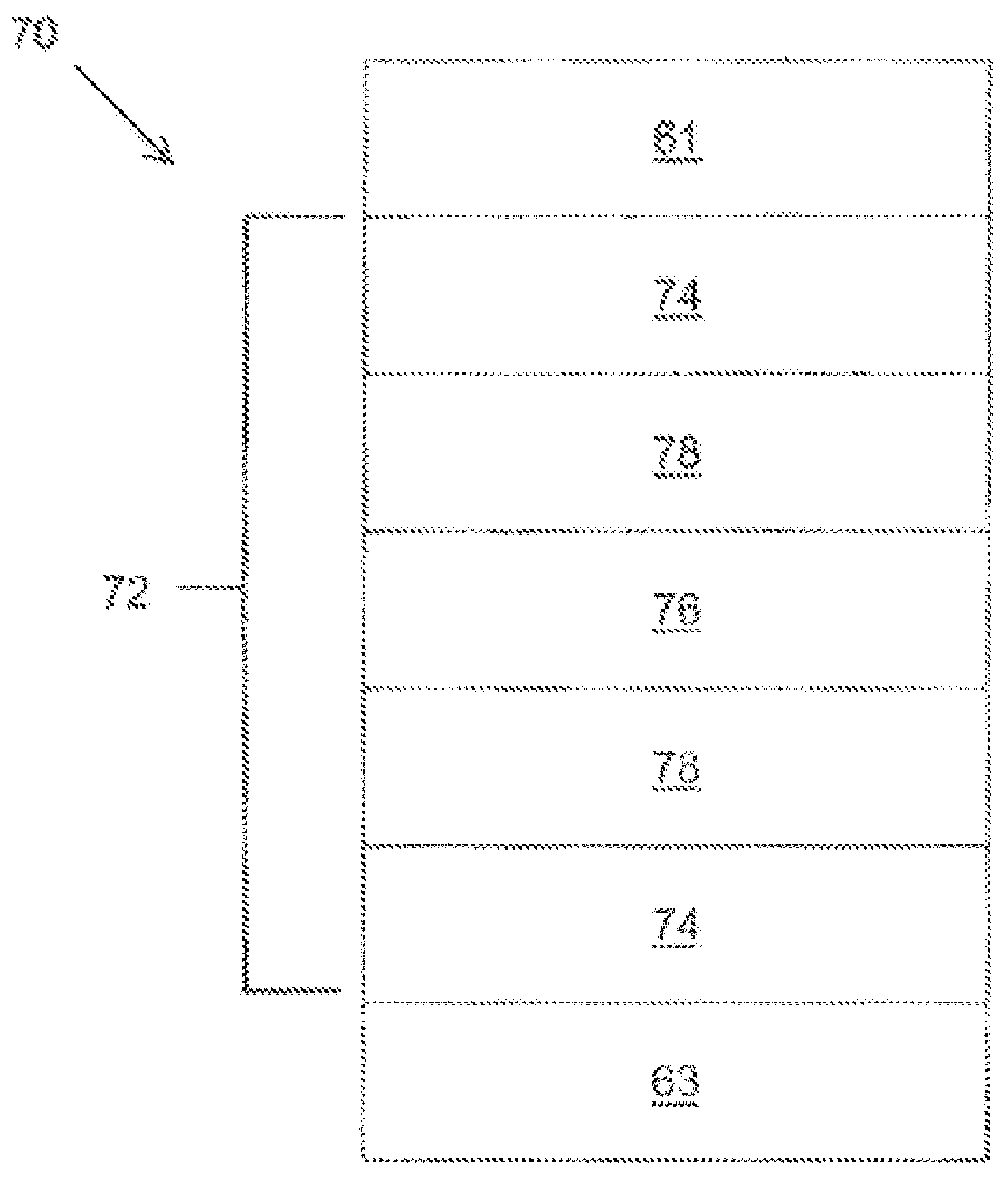

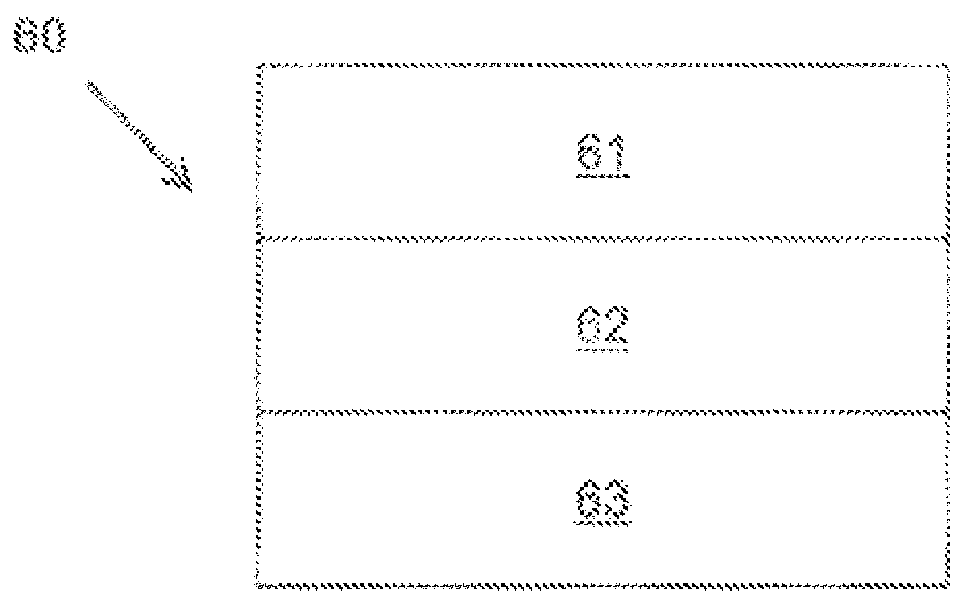

163 results about "Moisture vapor transmission rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moisture vapor transmission rate (MVTR), also water vapor transmission rate (WVTR), is a measure of the passage of water vapor through a substance. It is a measure of the permeability for vapor barriers.

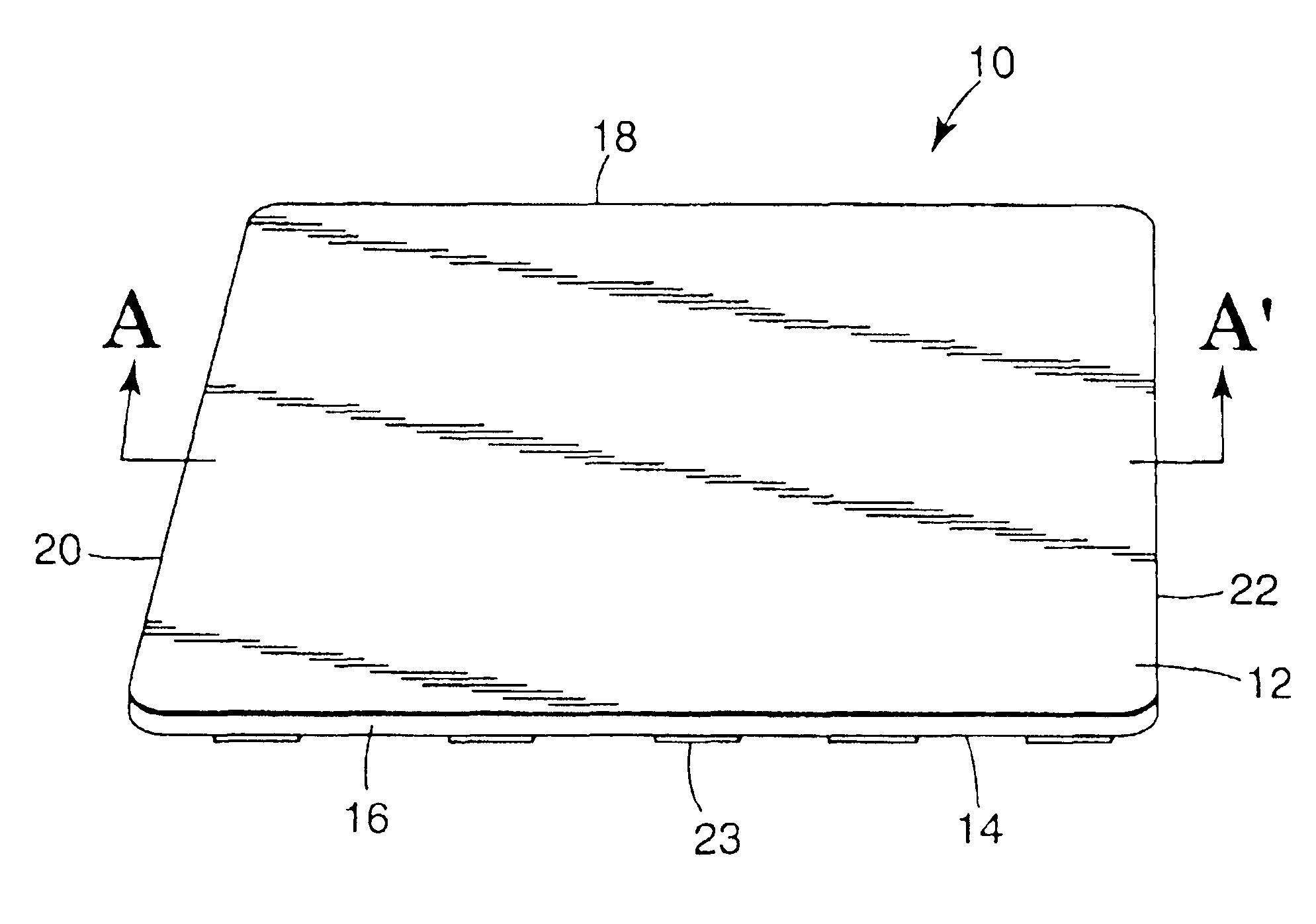

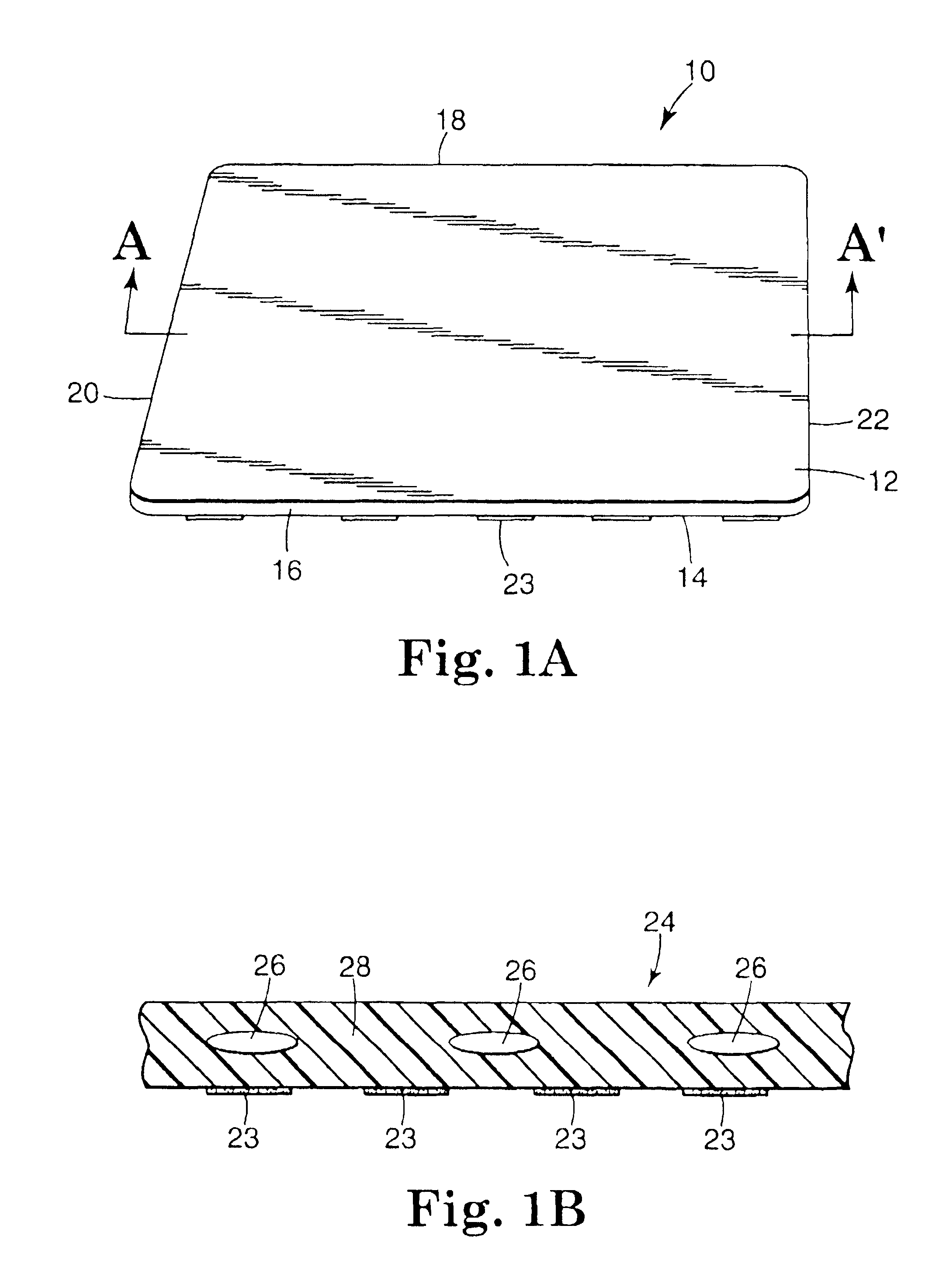

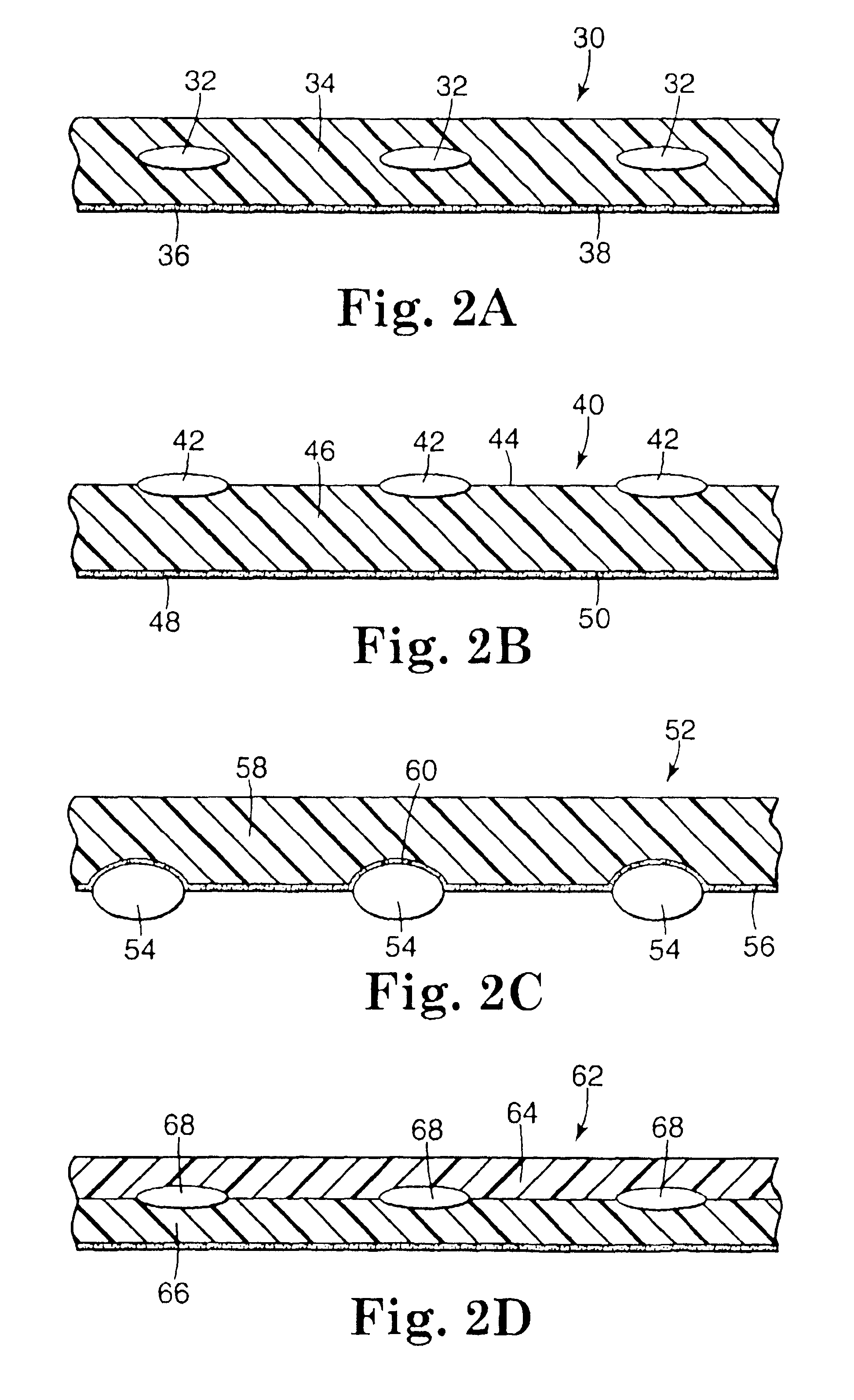

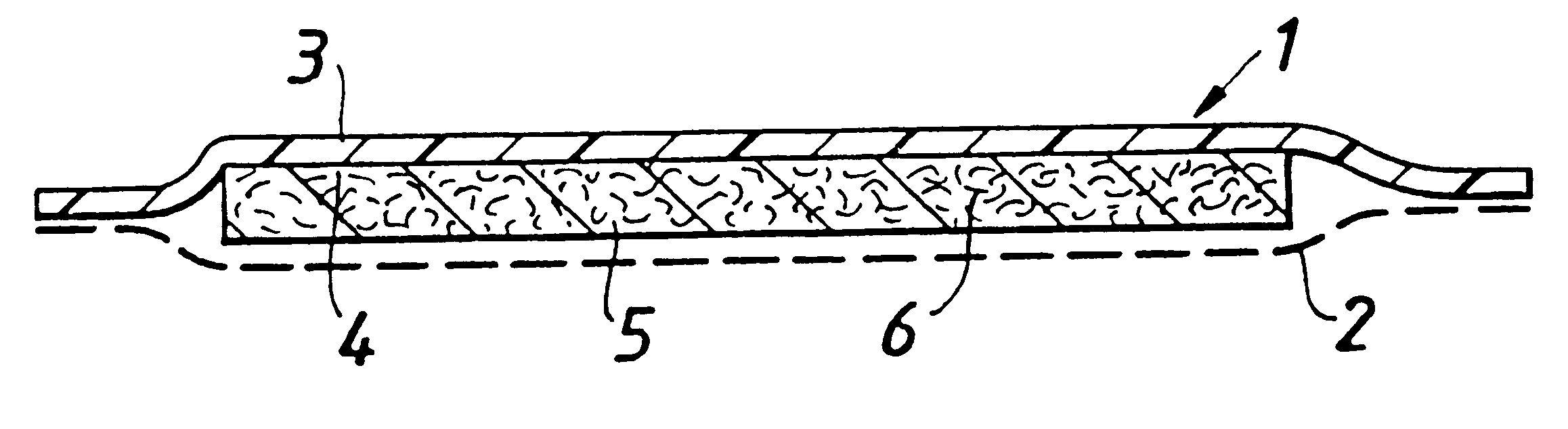

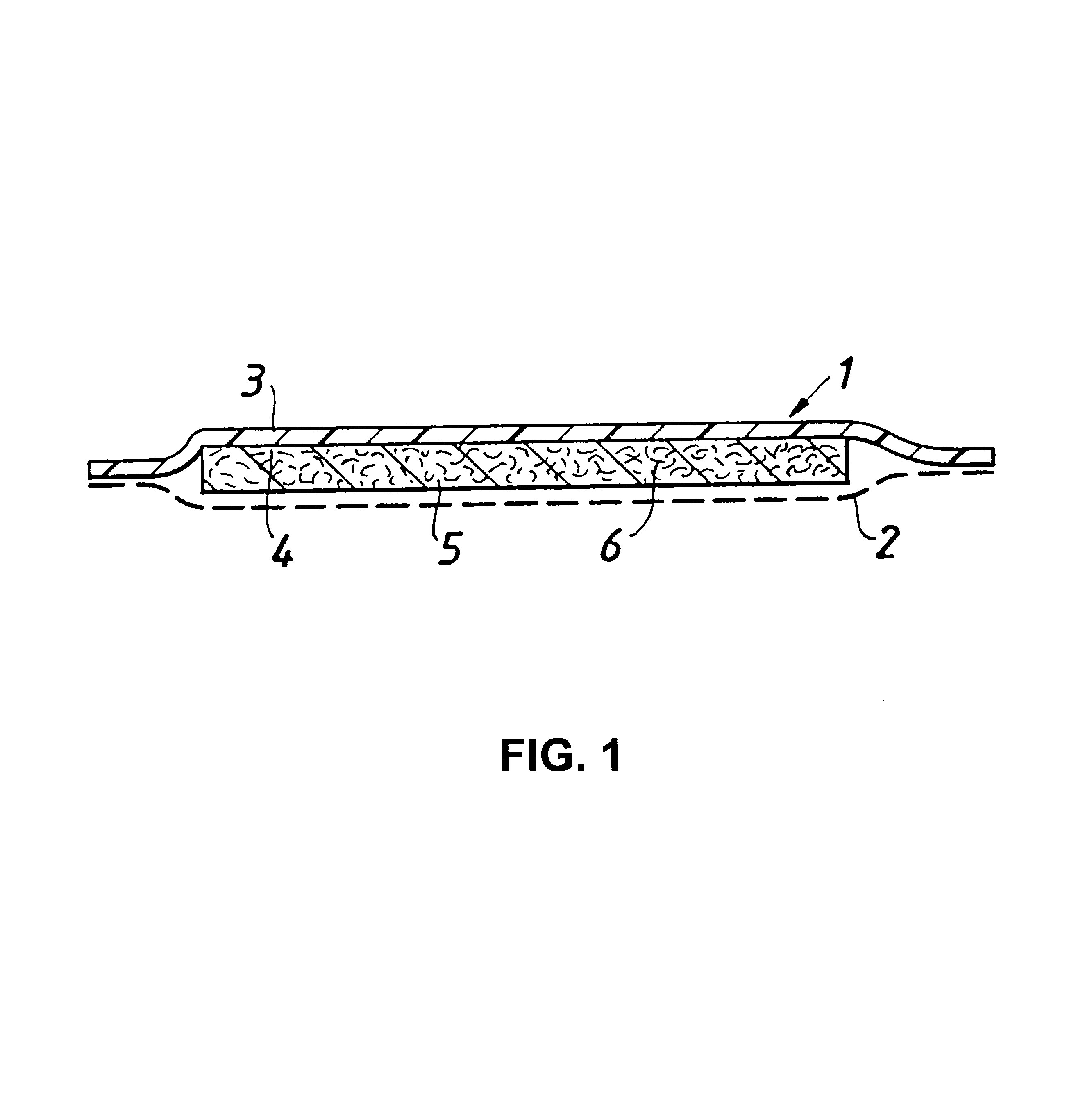

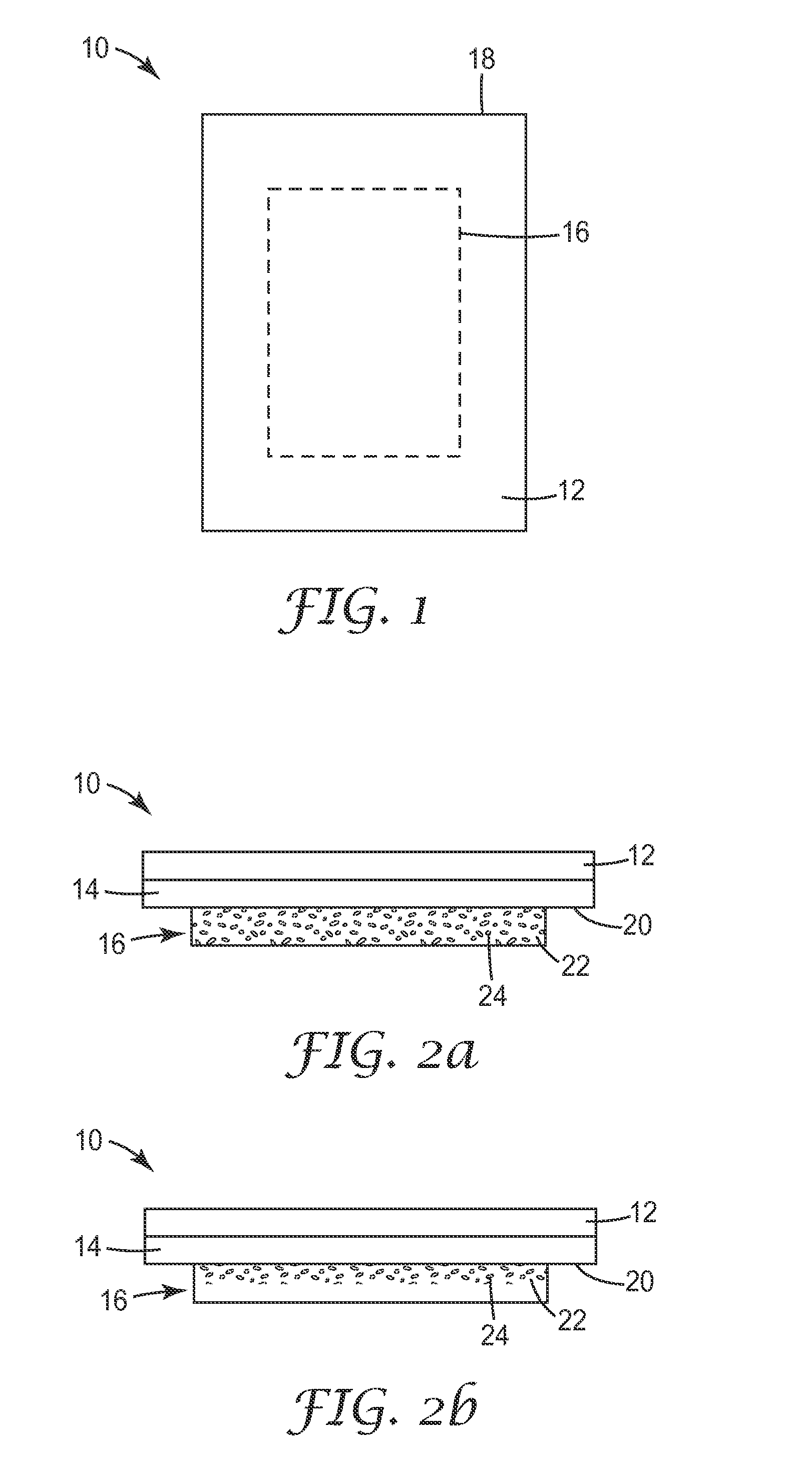

Adhesive composite having distinct phases

InactiveUS6927315B1Increase stiffnessHigh tensile strengthPlastersAdhesive dressingsMoisture vapor transmission rateEngineering

A conformable adhesive article for use as a sterile medical dressing is described. The article includes a breathable polymeric matrix, a plurality of phases, and an adhesive composition positioned on the polymeric matrix. The plurality of phases preferably provide reinforcement and stiffness to the article. The article permits transport of moisture across the breathable polymeric matrix, preferably at an Inverted water moisture vapor transmission rate of at least 300 g / m2 / 24 hours.

Owner:3M INNOVATIVE PROPERTIES CO

Breathable polyurethanes, blends, and articles

InactiveUS6897281B2Improve breathabilityImprove moisture vapor transmission rateSynthetic resin layered productsPolyurea/polyurethane coatingsGramSide chain

A breathable polyurethane having an upright moisture vapor transmission rate (MVTR) of more than about 500 gms / m2 / 24 hr comprises:(a) poly(alkylene oxide) side-chain units in an amount comprising about 12 wt. % to about 80 wt. % of said polyurethane, wherein (i) alkylene oxide groups in said poly(alkylene oxide) side-chain units have from 2 to 10 carbon atoms and are unsubstituted, substituted, or both unsubstituted and substituted, (ii) at least about 50 wt. % of said alkylene oxide groups are ethylene oxide, and (iii) said amount of said side-chain units is (i) at least about 30 wt. % when the molecular weight of said side-chain units is less than about 600 grams / mole, (ii) at least about 15 wt. % when the molecular weight of said side-chain units is from about 600 to about 1,000 grams / mole, and at least about 12 wt. % when the molecular weight of said side-chain units is more than about 1,000 grams / mole, and(b) poly(ethylene oxide) main-chain units in an amount comprising less than about 25 wt. % of said polyurethane.Coatings and films for textiles and other articles and applications using such polyurethanes have excellent breathability, i.e., high moisture vapor transmission rates (MVTR).

Owner:LUBRIZOL ADVANCED MATERIALS INC

Breathable composite sheet structure and absorbent articles utilizing same

A breathable composite sheet material, a method for making such a sheet material, and an absorbent article utilizing the sheet material are provided. The composite sheet material is comprised of a thermoplastic film adhered directly to a fibrous substrate. The thermoplastic film comprises at least 50% by weight of a polymer material from the group of block copolyether esters, block copolyether amides and polyurethanes. The substrate comprises a fibrous web of at least 50% by weight of polyolefin polymer synthetic fibers. The composite sheet exhibits a peel strength of at least 0.1 N / cm, a dynamic fluid transmission of less than about 0.75 g / m2 when subjected to an impact energy of about 2400 joules / m2, and a moisture vapor transmission rate, according to the desiccant method, of at least 1500 g / m2 / 24 hr. The absorbent article comprises (a) a topsheet; (b) a backsheet; and (c) an absorbent core located between the topsheet and the backsheet; wherein the backsheet comprises the non-porous, substantially fluid impermeable, moisture vapor permeable composite sheet material described above. The composite sheet material is oriented such that the film layer of the composite sheet material faces toward the absorbent core. The absorbent article may comprise a disposable diaper.

Owner:THE PROCTER & GAMBLE COMPANY

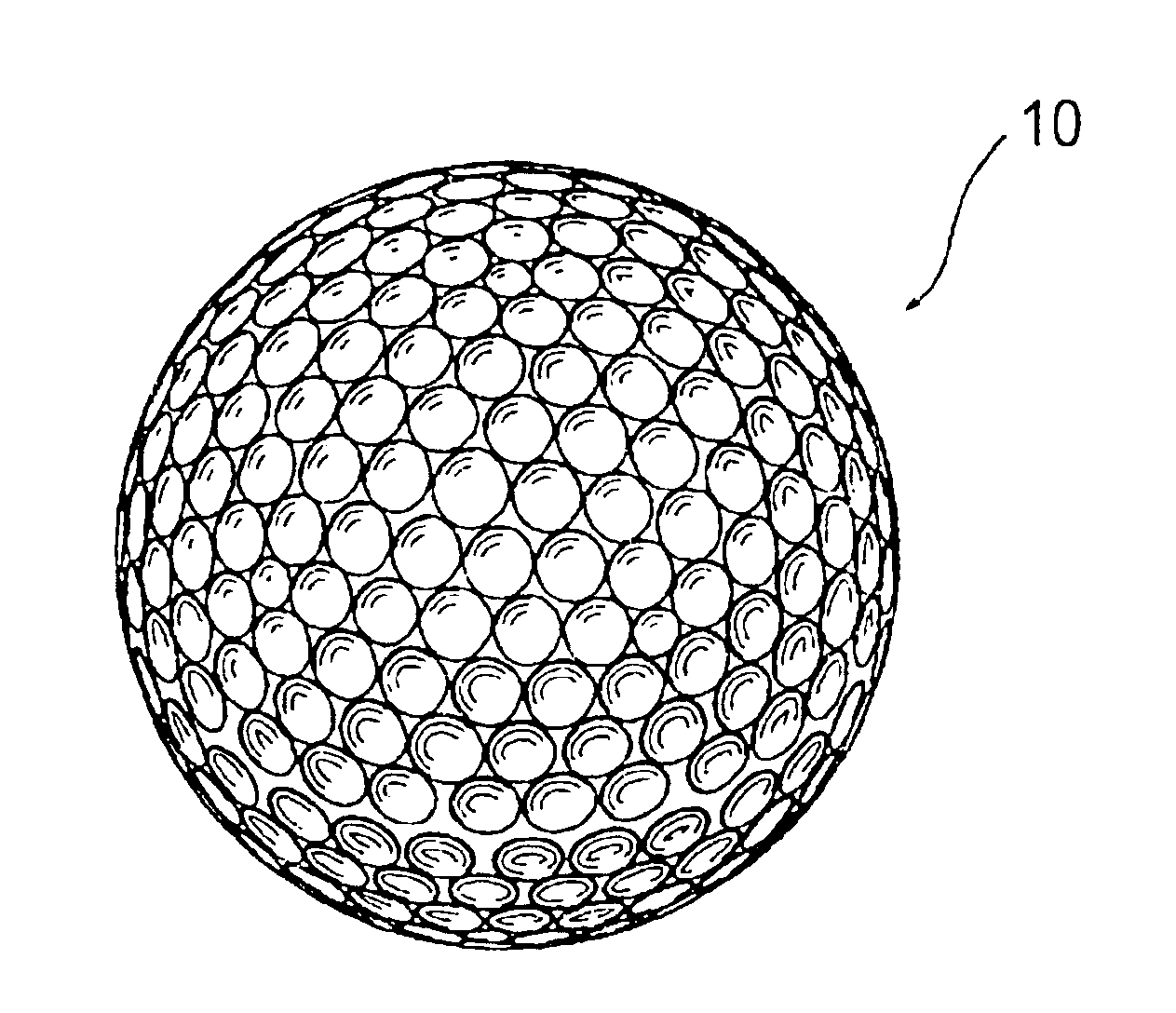

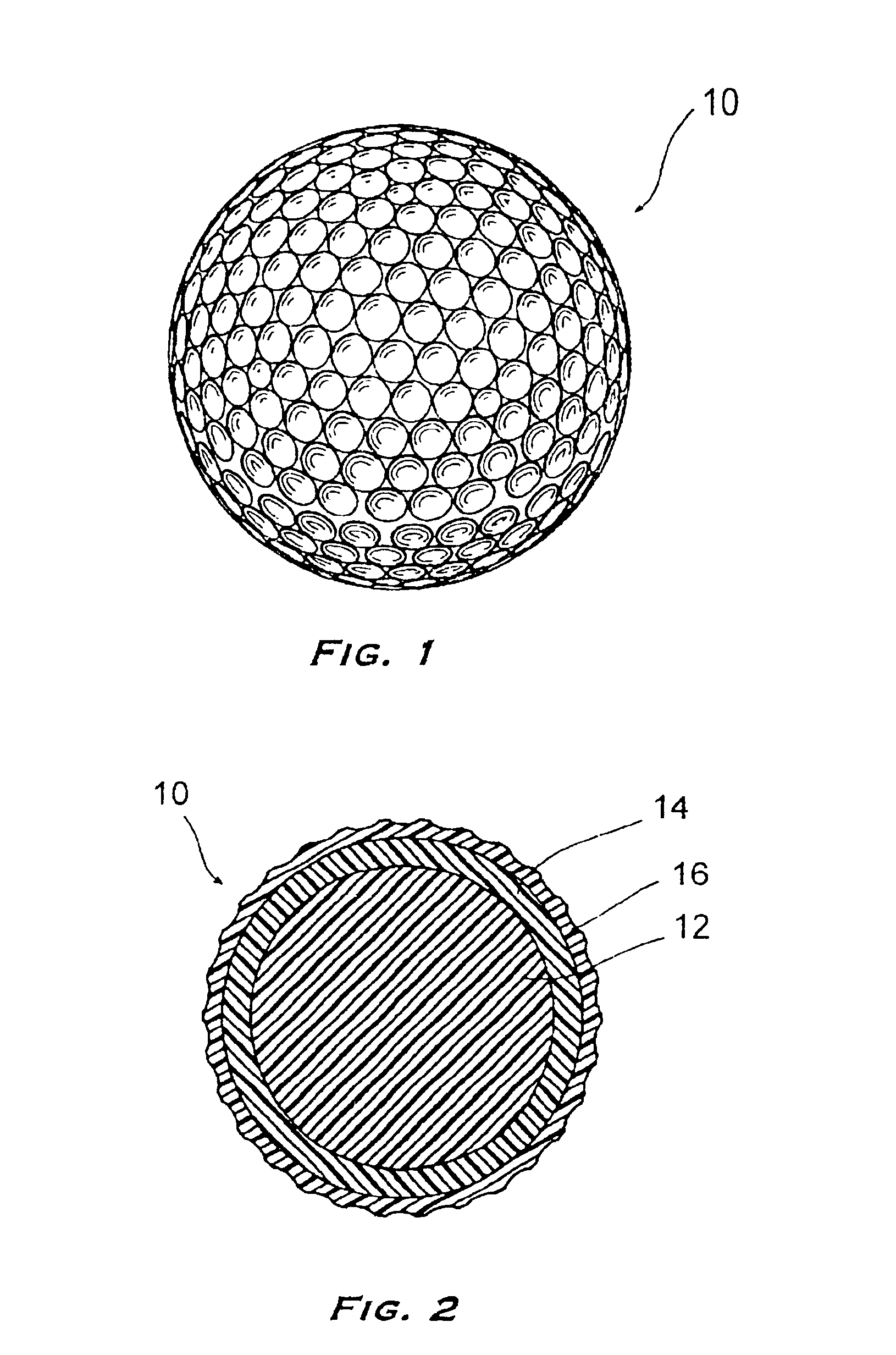

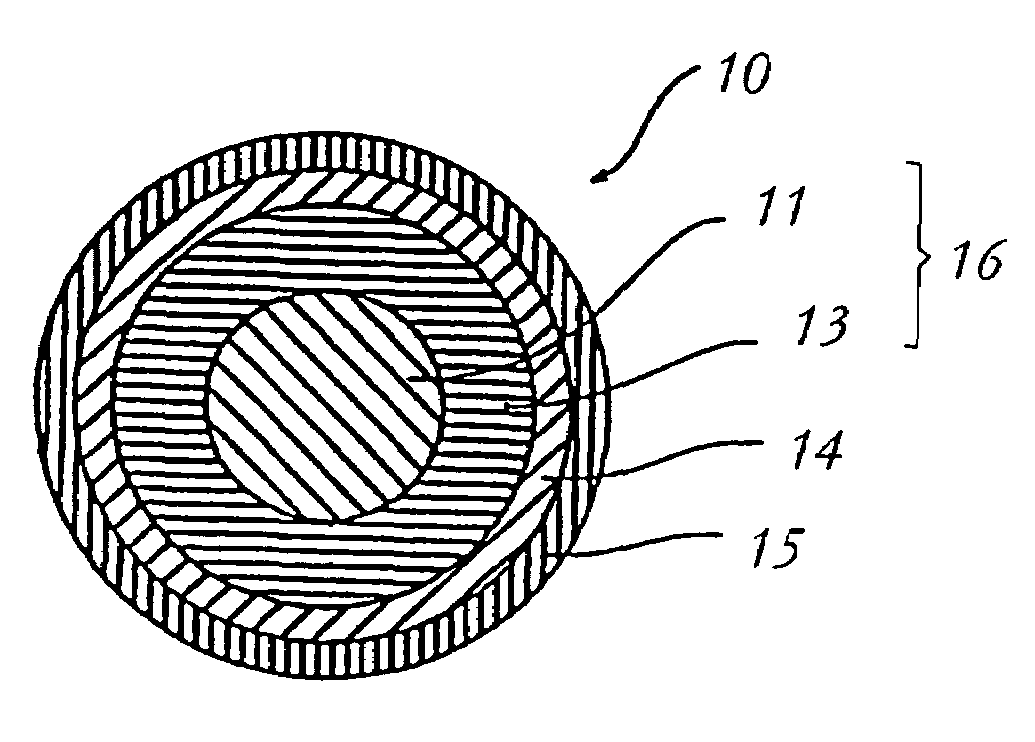

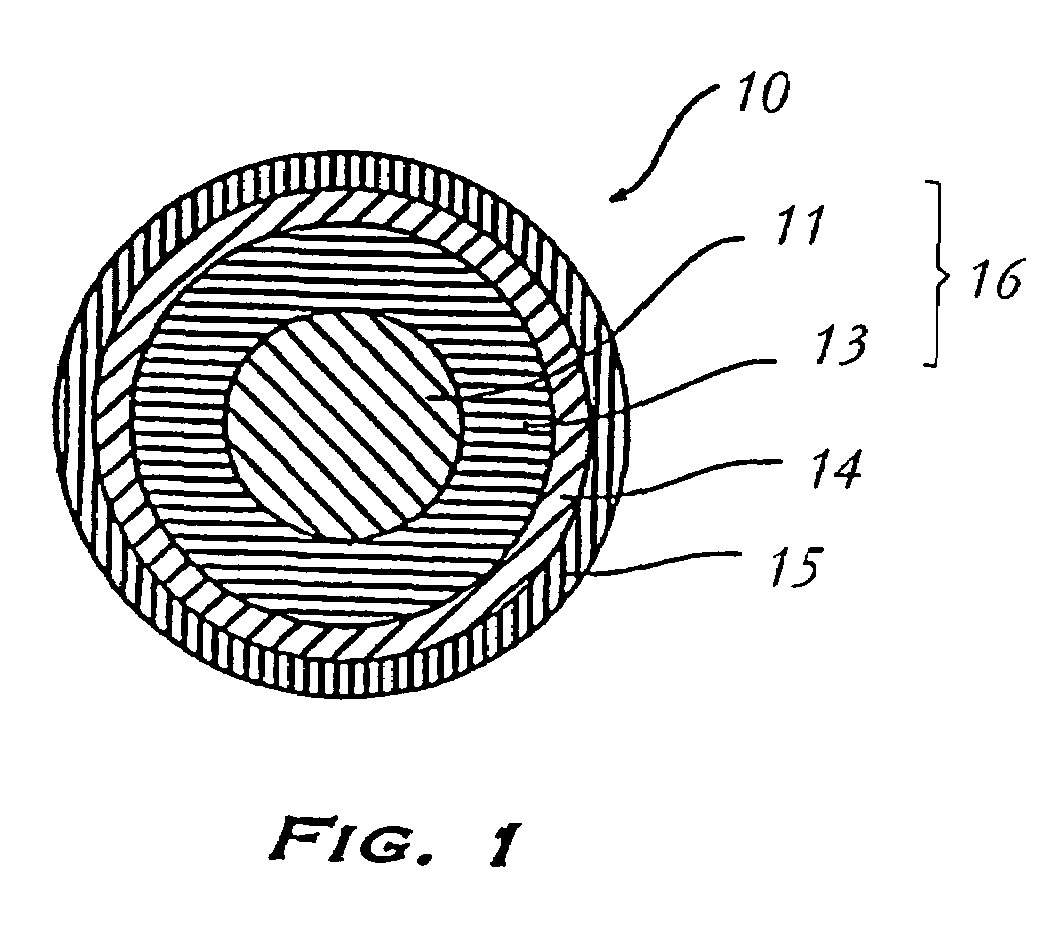

Golf ball with vapor barrier layer and method of making same

A golf ball comprising a core, a barrier layer enveloping the core, and a cover enveloping the barrier layer, wherein the barrier layer has a moisture vapor transmission rate less than that of the cover, and the barrier layer comprises a thermoplastic or thermoset composition of microparticles dispersed in a binder.

Owner:ACUSHNET CO

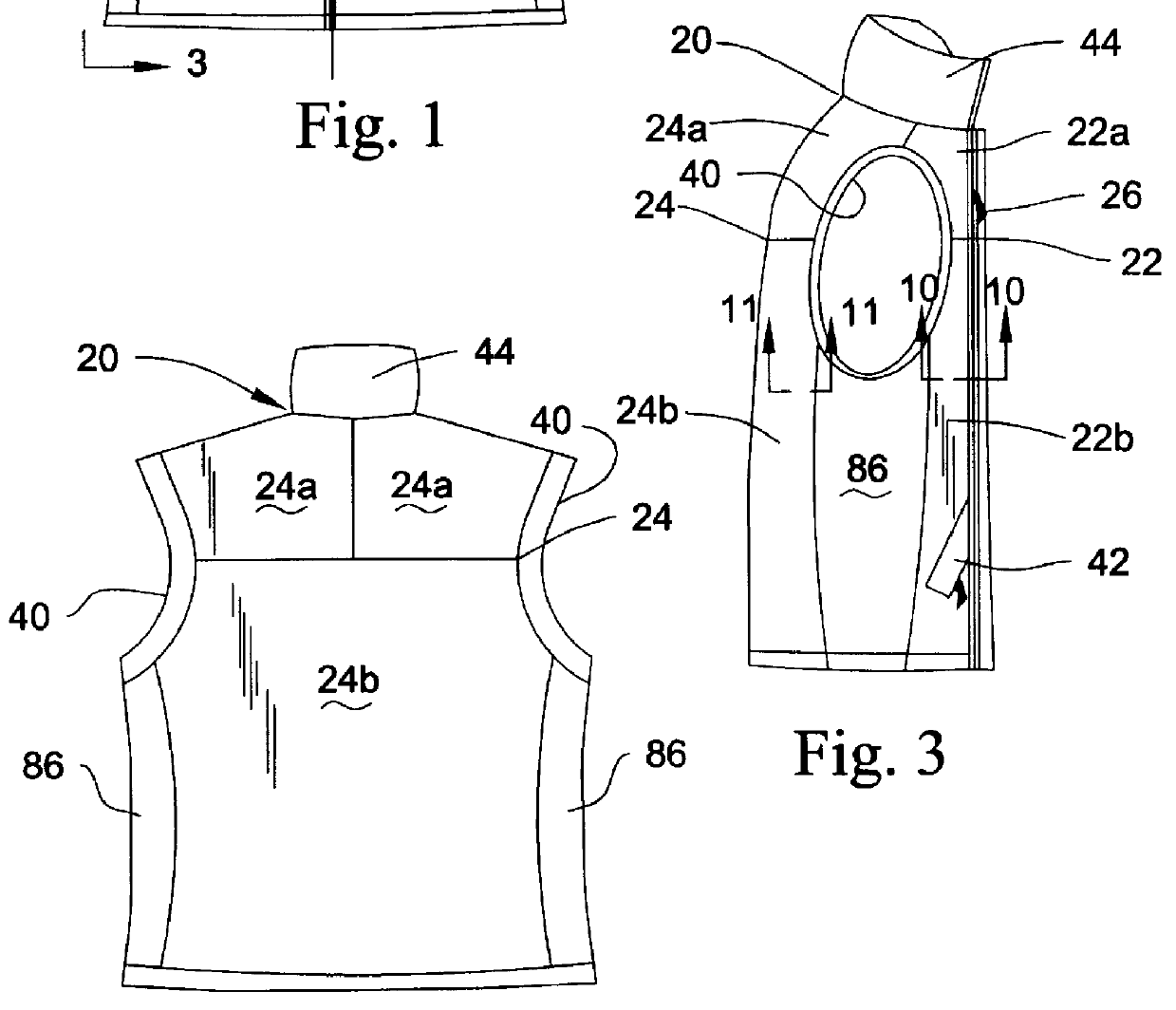

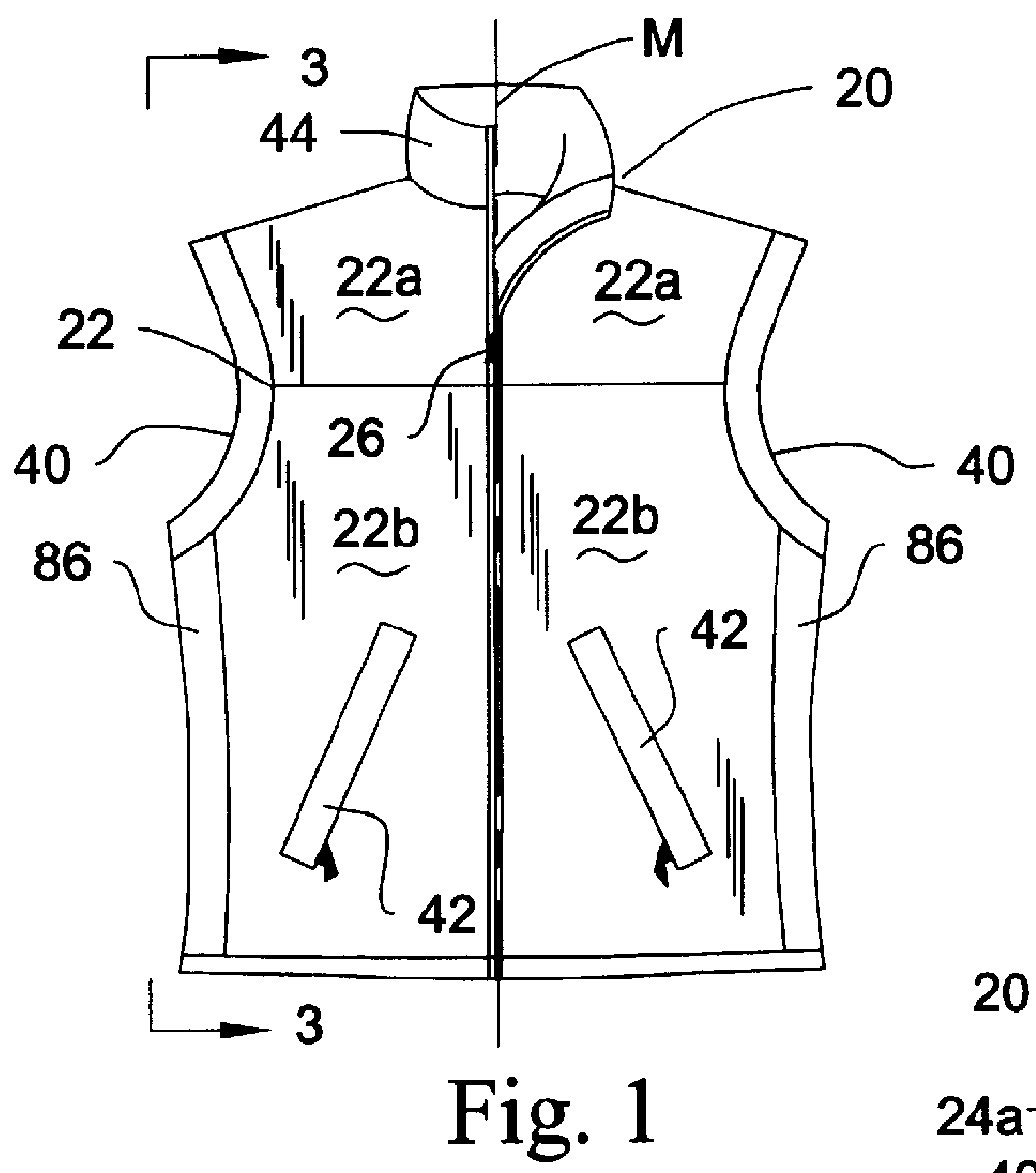

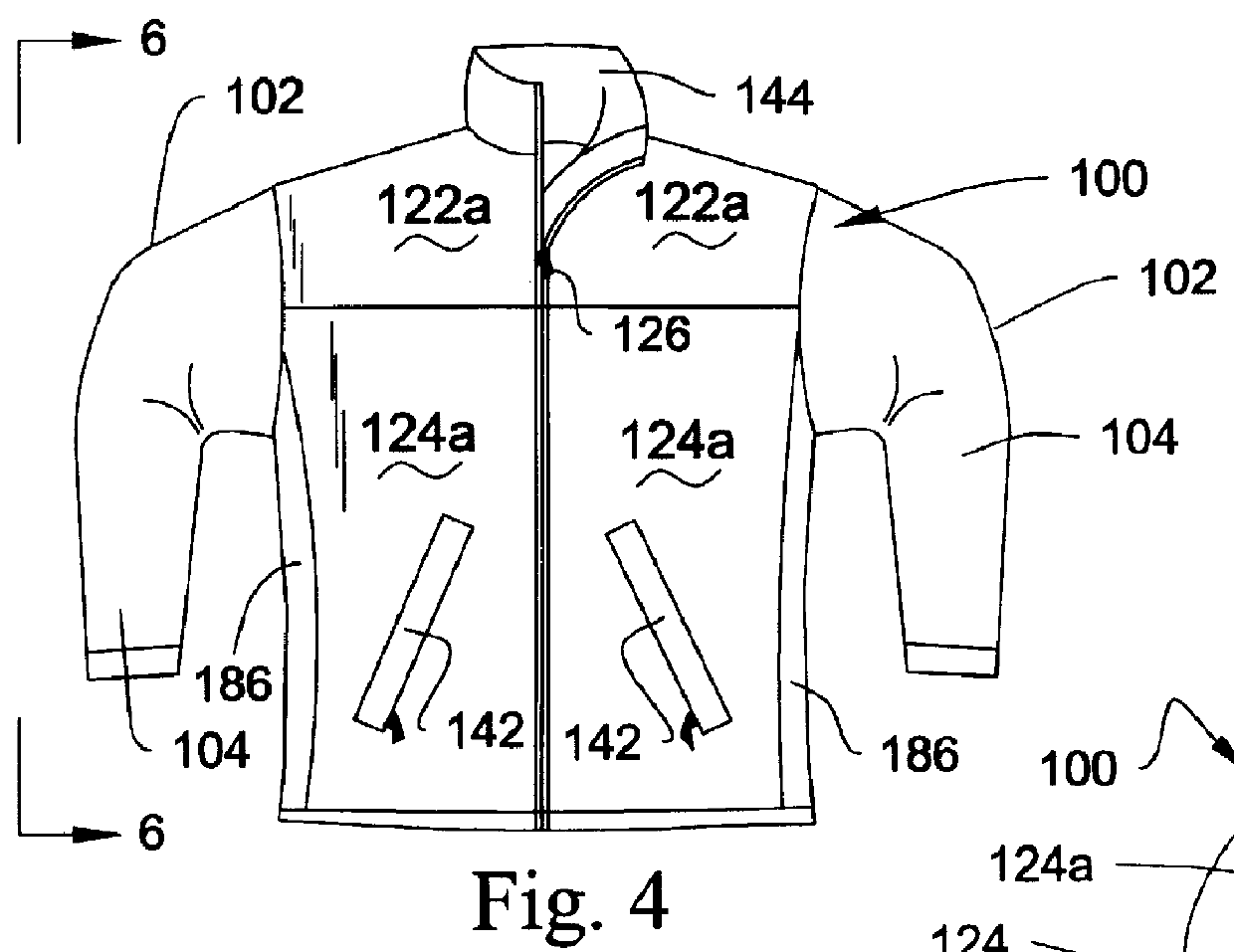

Garment with moisture vapor transmissive wind barrier panels

A garment (20) for inhibiting relatively moving air from contacting a portion of a person wearing the garment. The garment (20) comprises a first panel (22) for inhibiting relative air movement contact against a portion of the body of the person. The first panel (22) includes a first fabric layer (62), a second fabric layer (64) and a first membrane (66) located between the first and second the first fabric layers. The first membrane (66) is water-resistant. The first panel (22) has an air permeability of not more than 3 CFM / ft2 and a moisture vapor transmission rate of at least 800 gm / m2xday. The garment (20) also comprises a second panel (24) connectable with the first panel (22). The second panel (24) includes a third fabric layer (62a), a fourth fabric layer (64a) and a second membrane (66a) located between the third and fourth fabric layers. The second membrane (66a) is water-resistant. The second panel (24) has an air permeability of at least 6 CFM / f2 and a moisture vapor transmission rate of at least 1000 gm / m2xday.

Owner:BHA GROUP HLDG

Golf ball with vapor barrier layer and method of making same

A golf ball with at least one moisture vapor barrier layer is disclosed. The moisture vapor barrier layer comprises an elastomer, and has a moisture vapor transmission rate of less than about 0.6 grams·mm / m2·day.

Owner:ACUSHNET CO

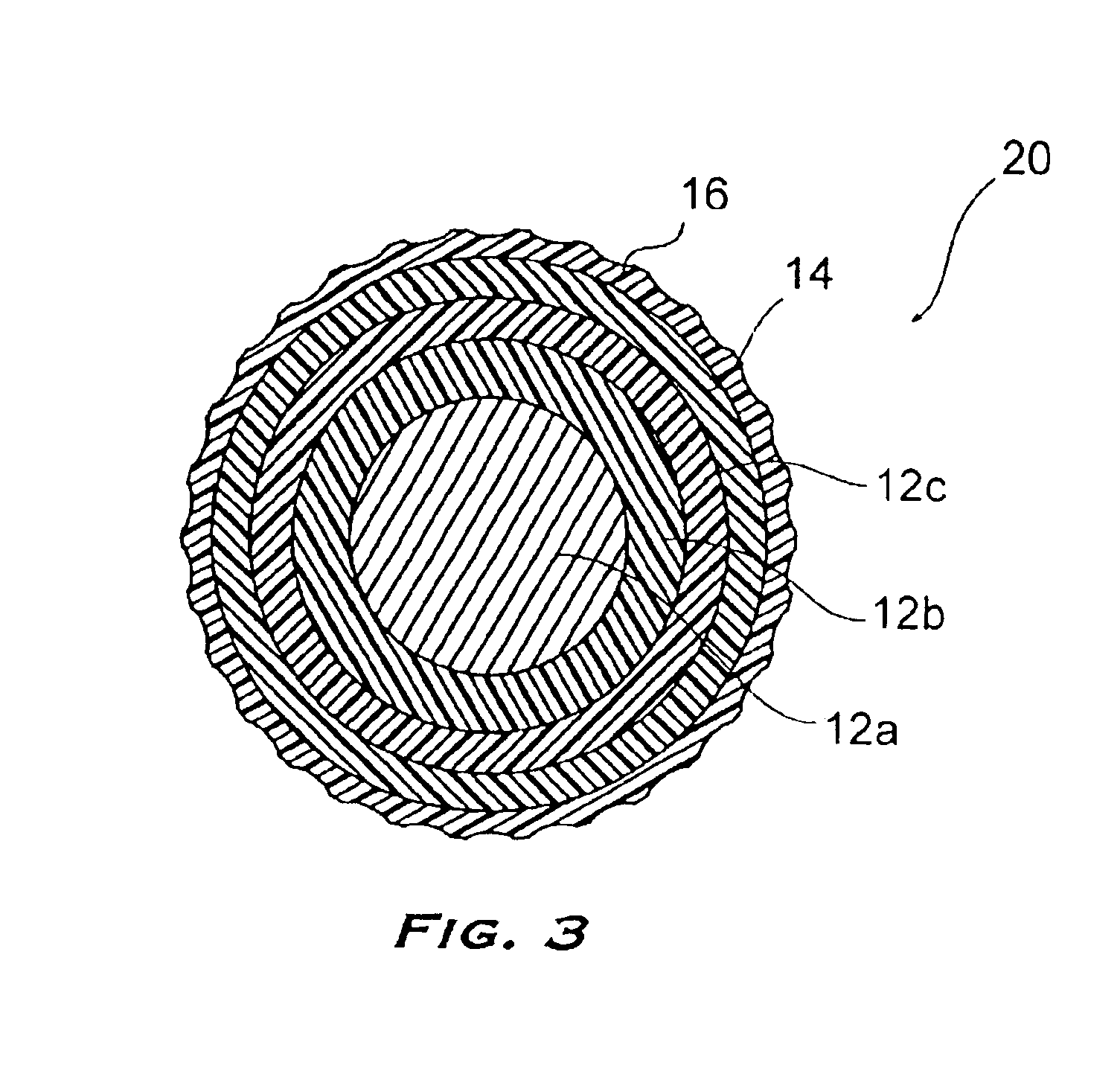

Multi-layer core golf ball

InactiveUS7255656B2Extended service lifeGolf ballsDomestic articlesMoisture vapor transmission rateEngineering

The present invention is directed to an improved golf ball displaying the desired spin profile and having a generally rigid, thermoset polybutadiene outer core surrounding a relatively soft, low compression inner core. In general, this golf ball has an inner core and at least one outer core layer surrounding the inner core. The inner core has a hardness less than a hardness of the outer core and a specific gravity less than or equal to the outer core specific gravity. Overall the inner core compression and outer core are formulated to provide a combined overall core compression of greater than about 50, preferably greater than about 70. A cover layer is provided to surround and to cover the outer core layer. A moisture barrier layer is provided between the outer core layer and the cover layer to protect the inner and outer cores from degradation due to exposure to water. The moisture vapor transmission rate of the moisture barrier layer is selected to be less than the moisture vapor transmission rate of the cover layer.

Owner:ACUSHNET CO

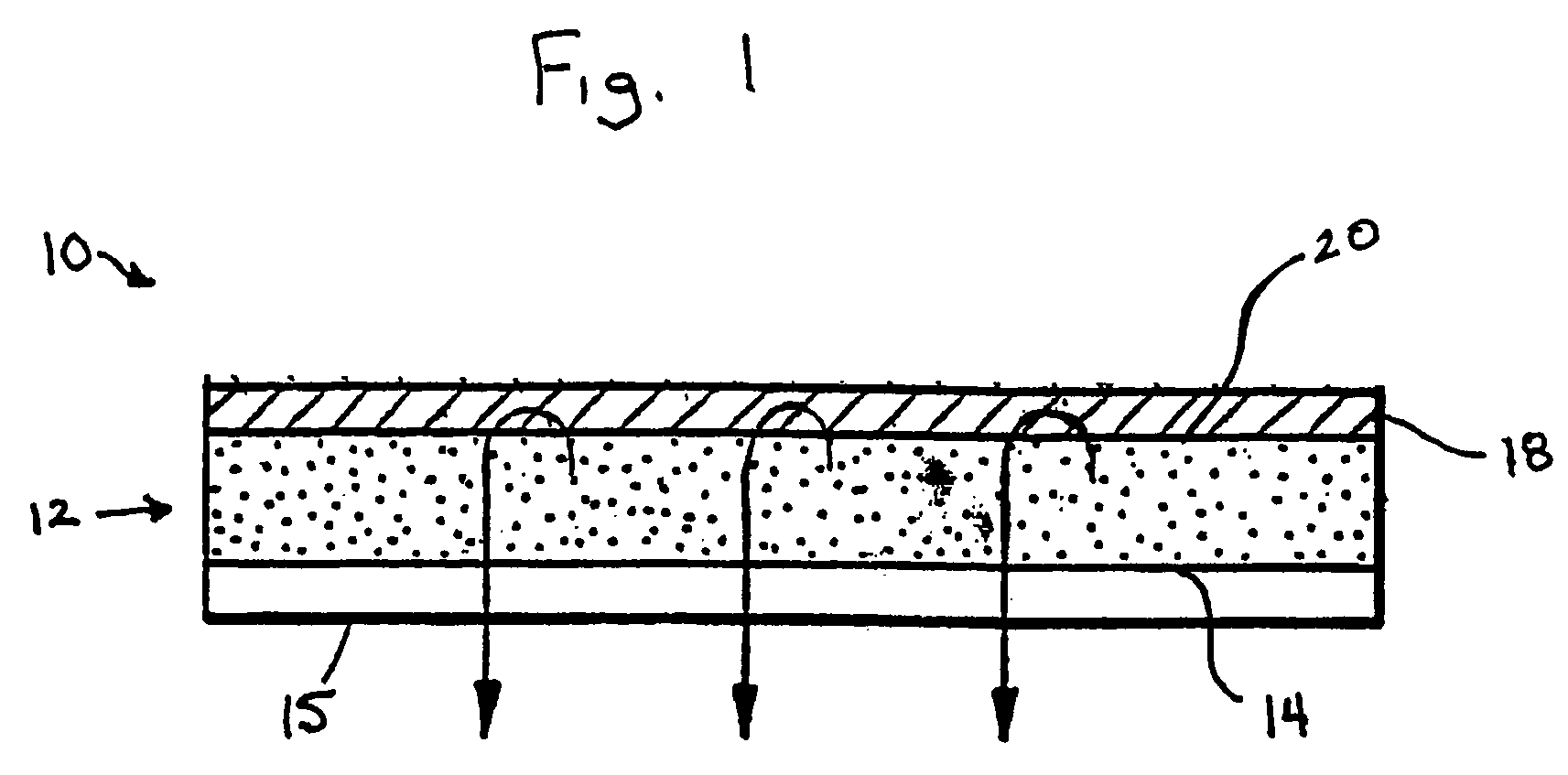

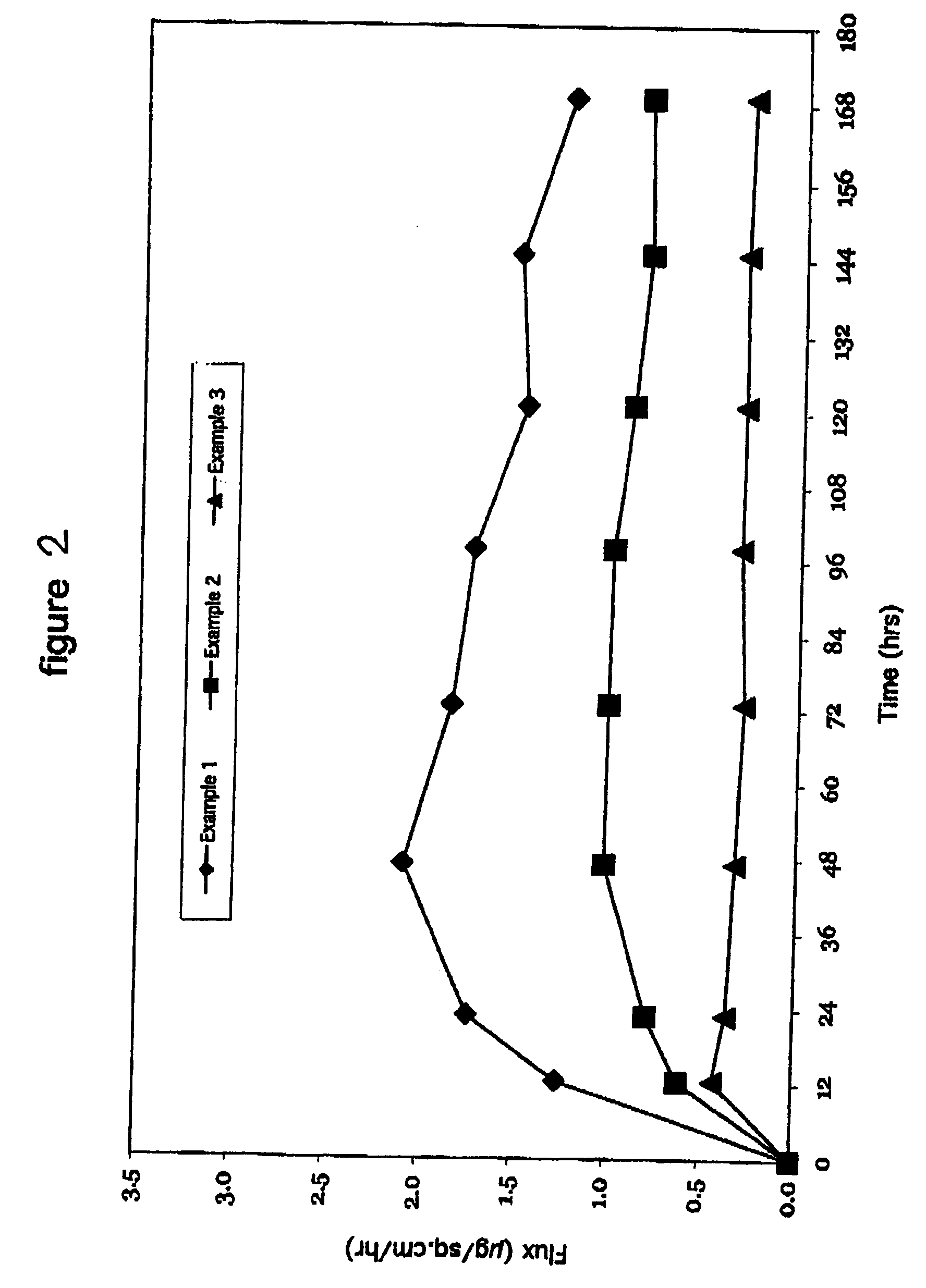

Transdermal drug delivery device including an occlusive backing

InactiveUS20060078604A1Simple and inexpensive to manufactureDesirable in adhesiveOrganic active ingredientsNervous disorderActive agentMoisture vapor transmission rate

A transdermal drug delivery system for the topical application of one or more active agents contained in one or more polymeric and / or adhesive carrier layers, proximate to a non-drug containing polymeric backing layer which can control the delivery rate and profile of the transdermal drug delivery system by adjusting the moisture vapor transmission rate of the polymeric backing layer.

Owner:NOVEN PHARMA

Dressings

A wound dressing is provided which is made up of a backing layer, an apertured wound facing layer and an intermediate absorbent layer comprising fibers of material which upon contact with moisture will form a gel. The intermediate layer also includes a non-gel forming component, e.g., another fibrous material which can support the formed gels. The backing layer also has a water transmission rate which is greater than its moisture vapor transmission rate.

Owner:SMITH & NEPHEW INC

Medical articles and methods of making using miscible composition

ActiveUS20110112458A1Facilitate transmissionHigh MVTRPretreated surfacesAdhesive dressingsChemical compositionMoisture vapor transmission rate

Provided are methods of improving the moisture vapor transmission rate of a pressure sensitive adhesive layer in a medical article with a miscible composition, as well as medical articles including the improved pressure sensitive adhesive layer.

Owner:3M INNOVATIVE PROPERTIES CO

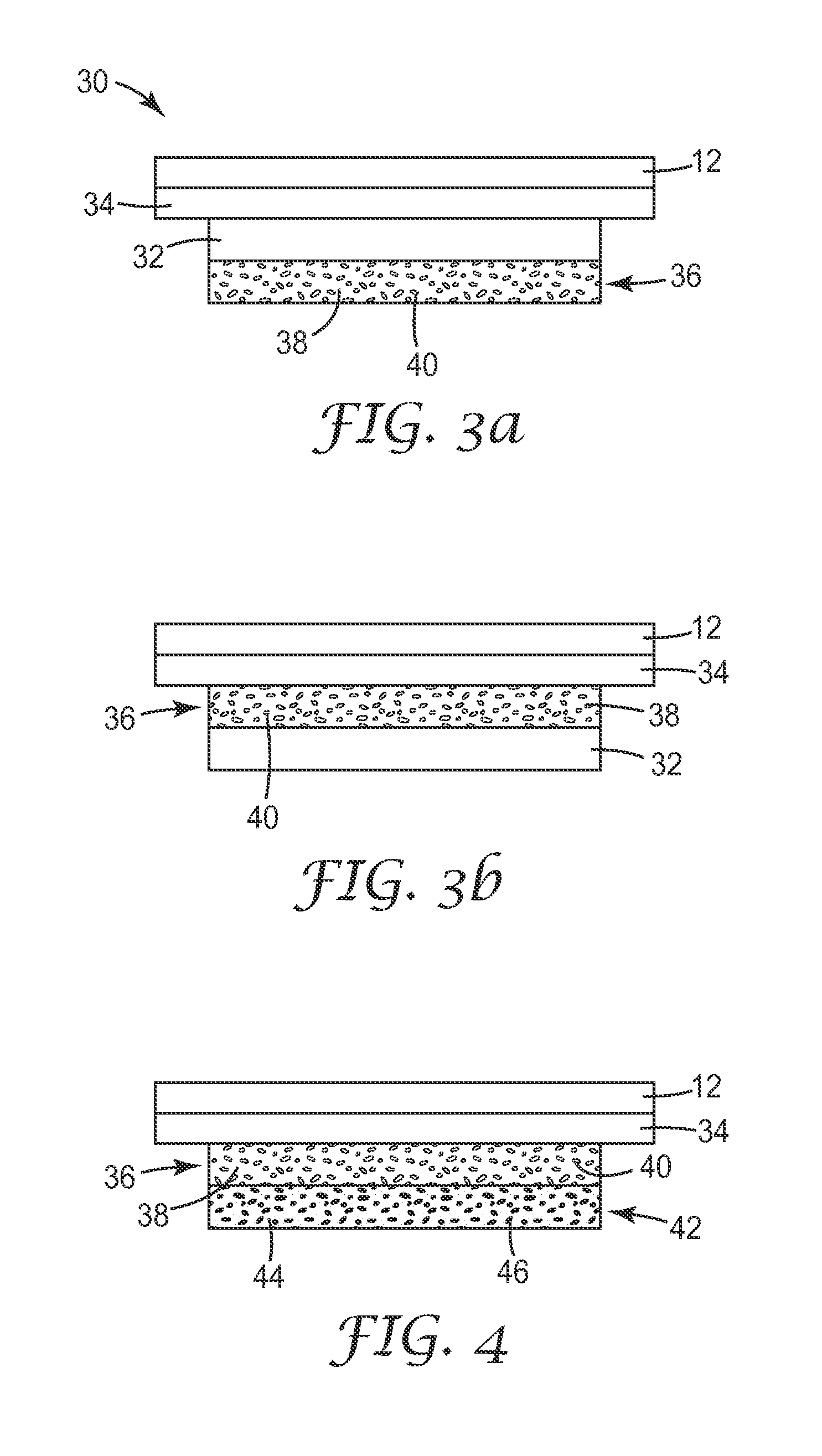

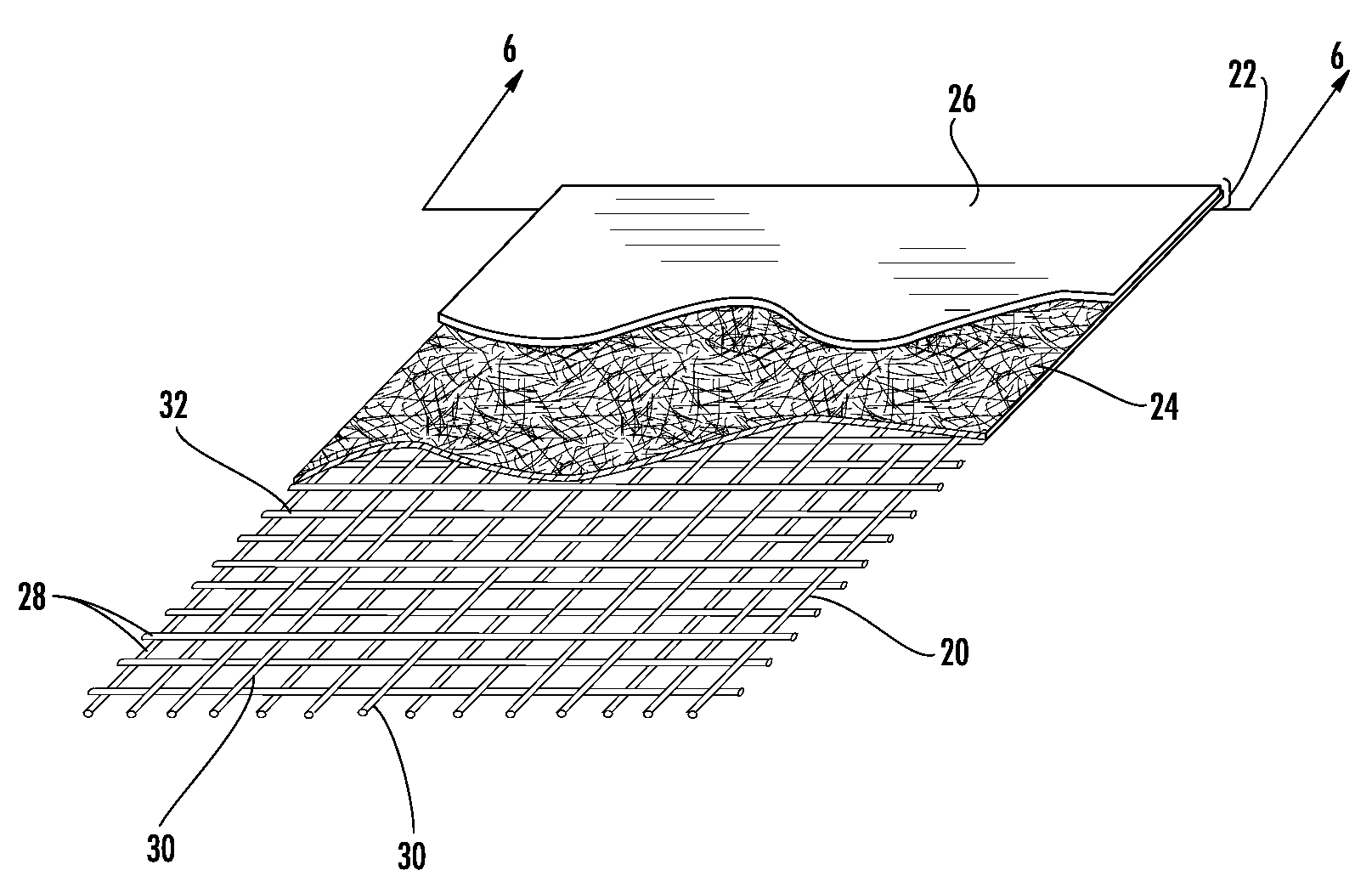

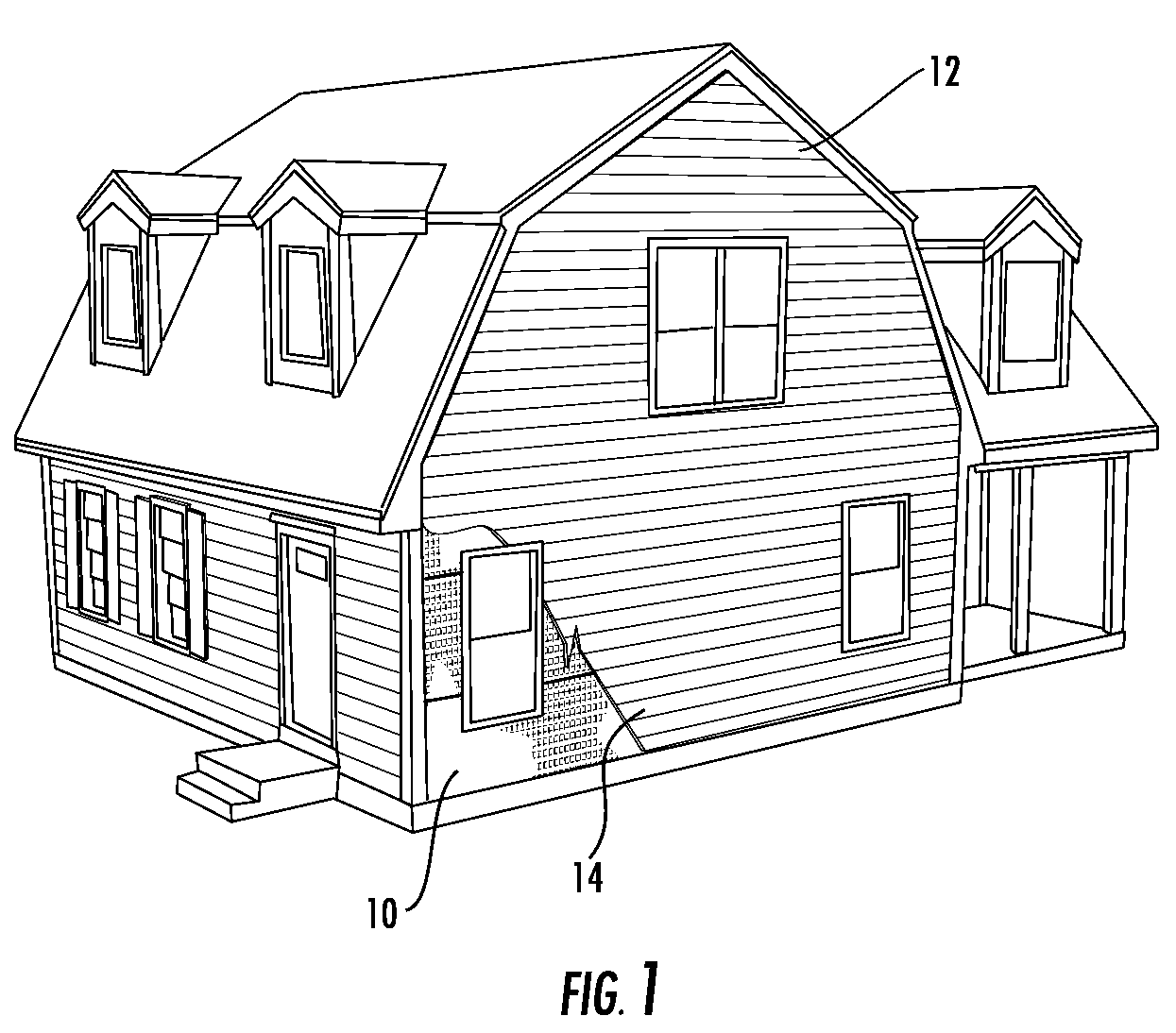

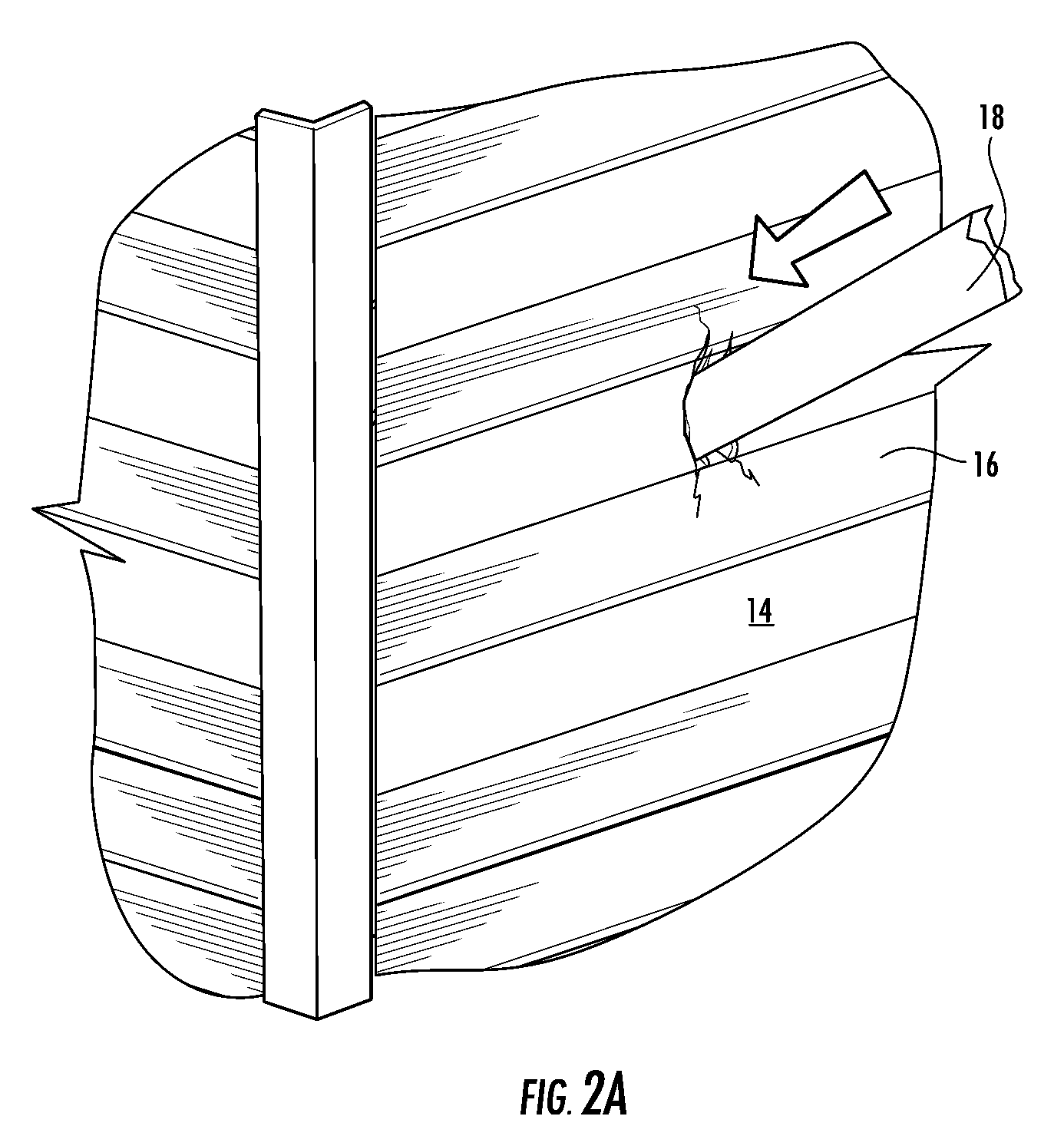

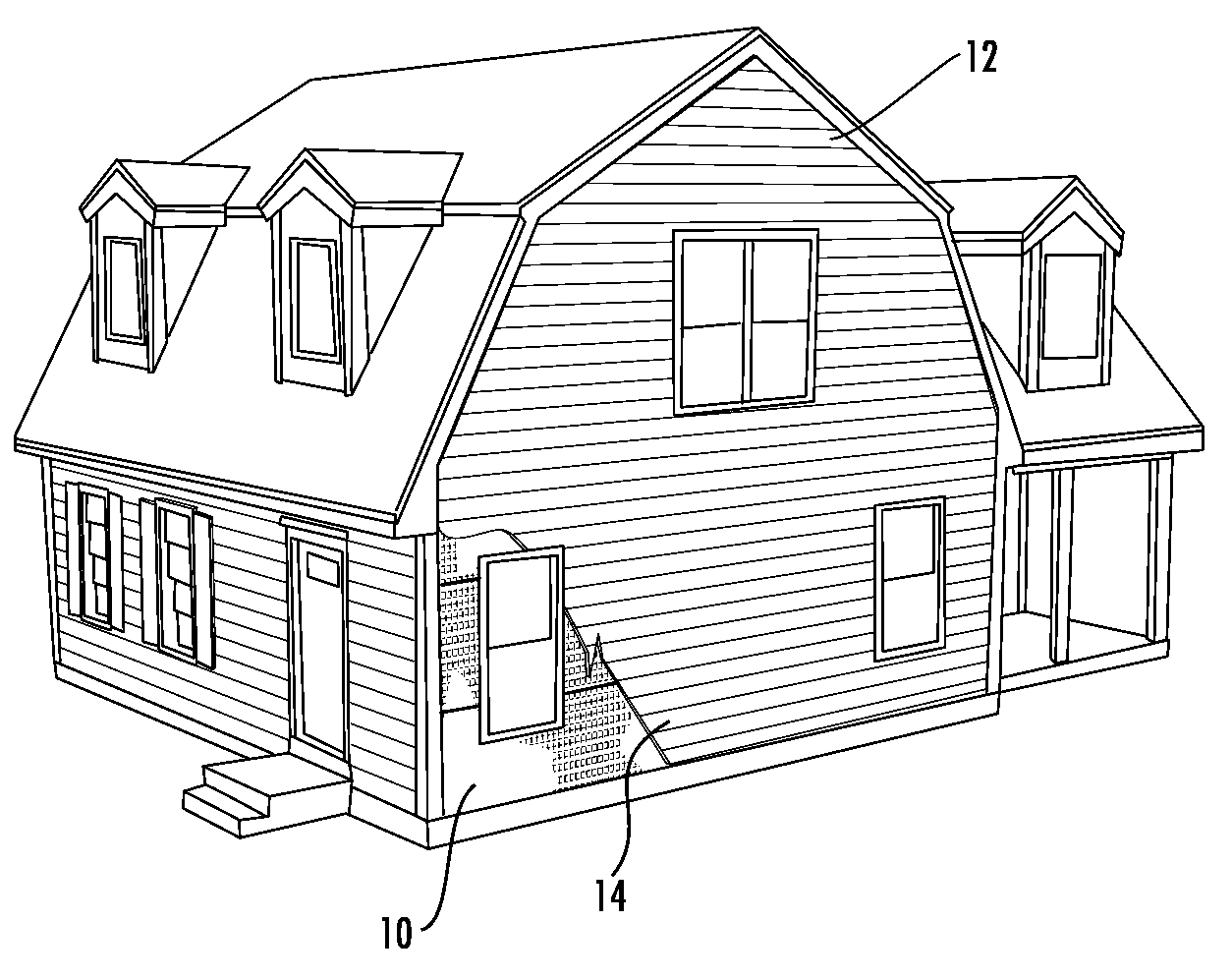

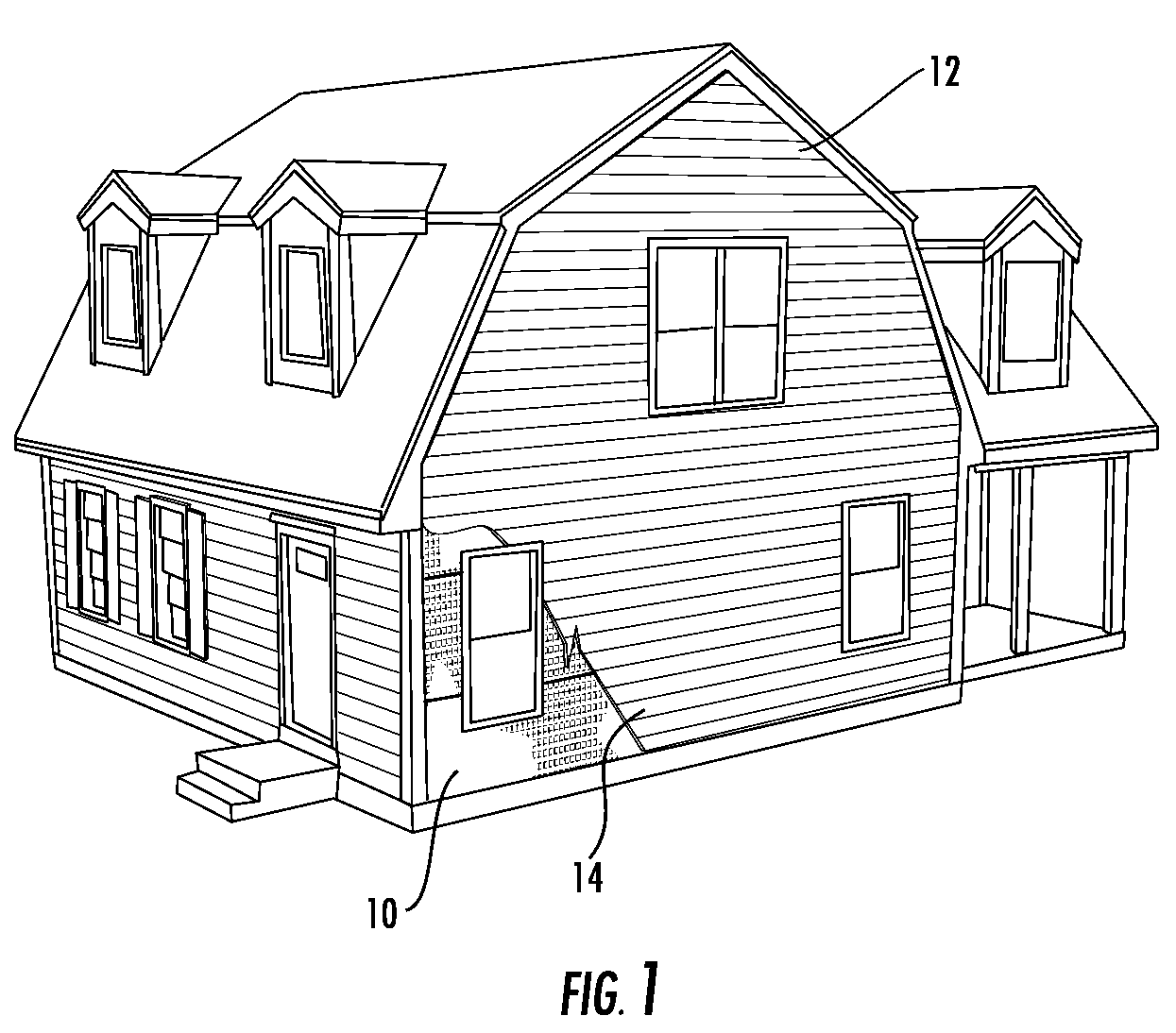

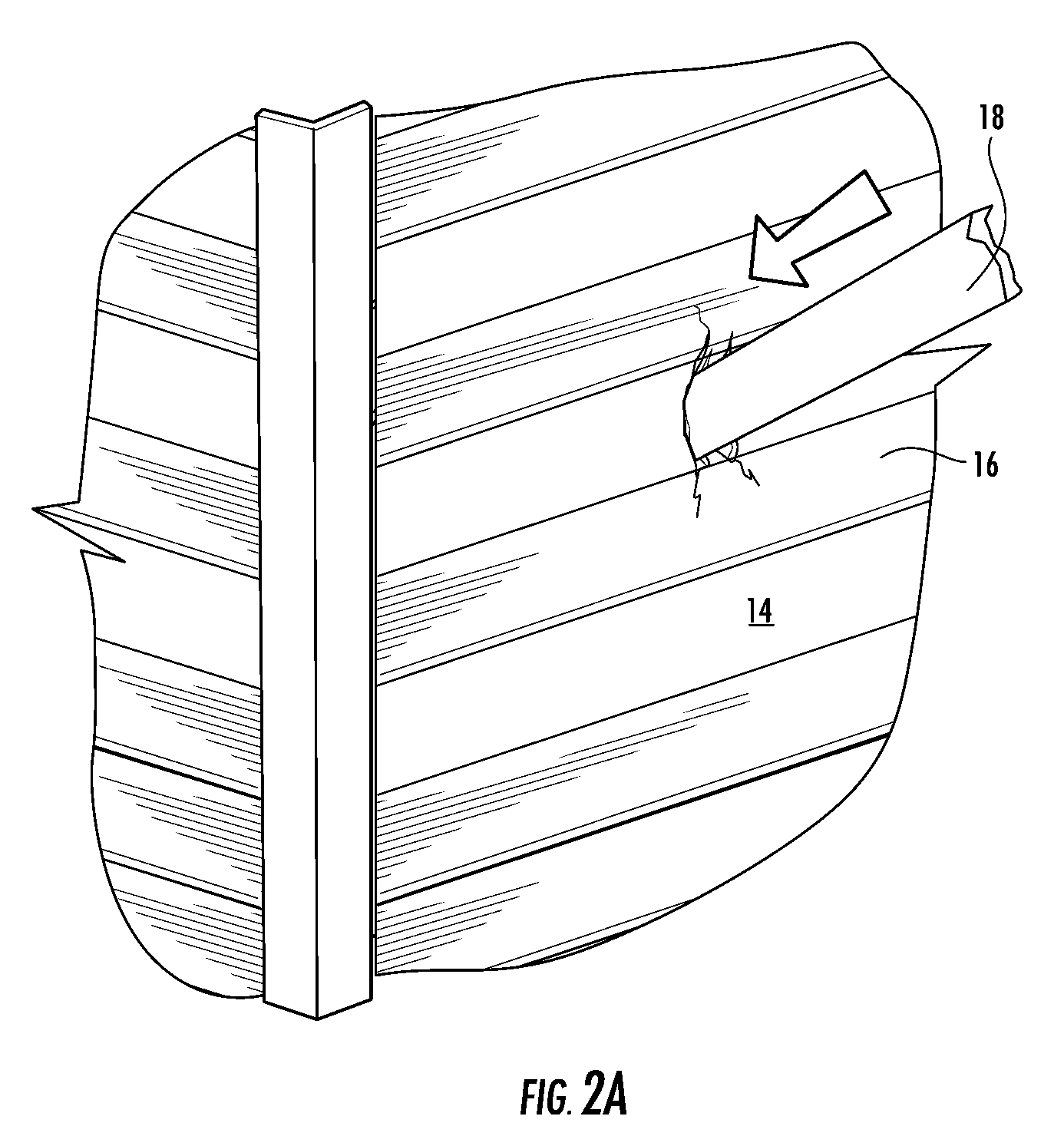

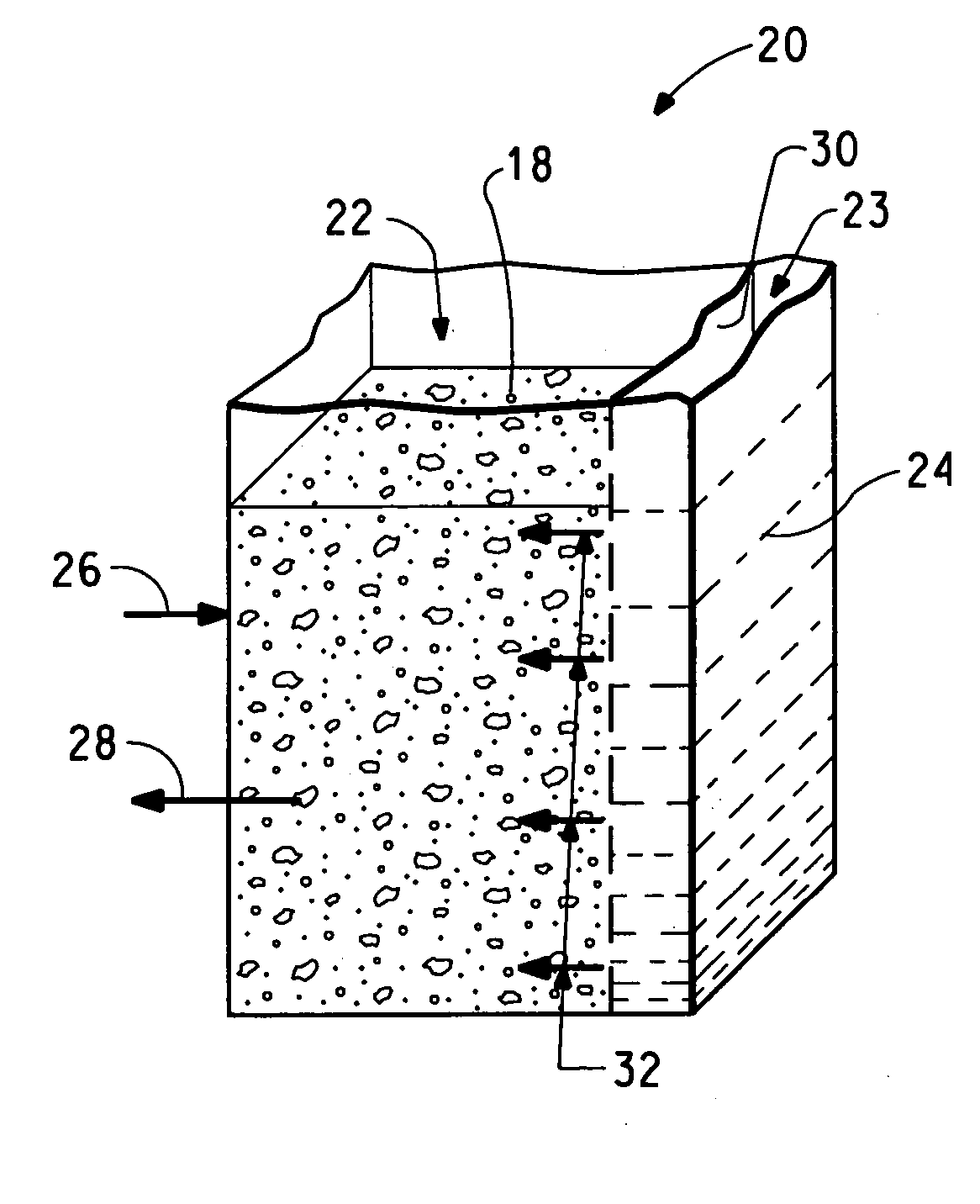

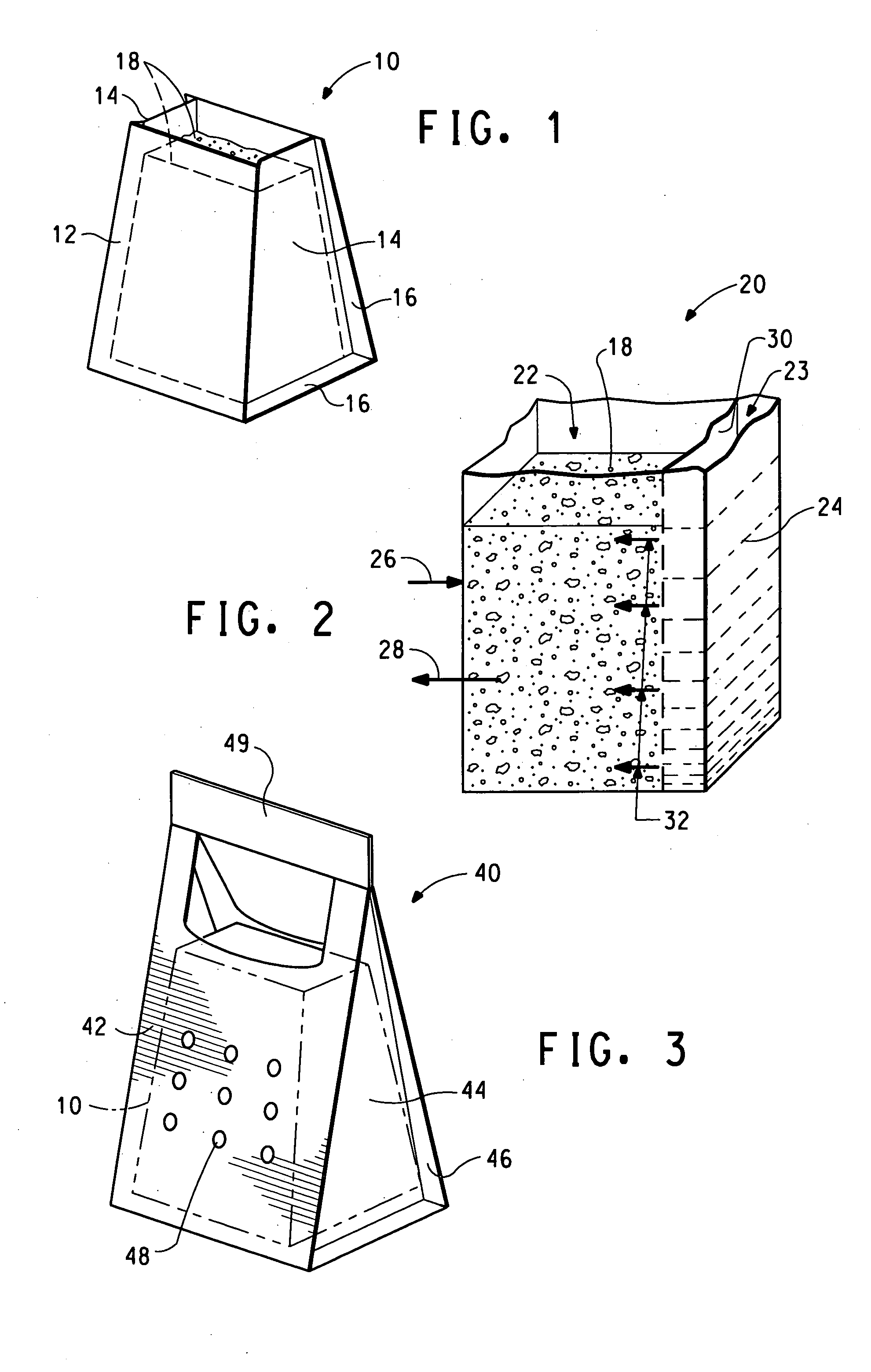

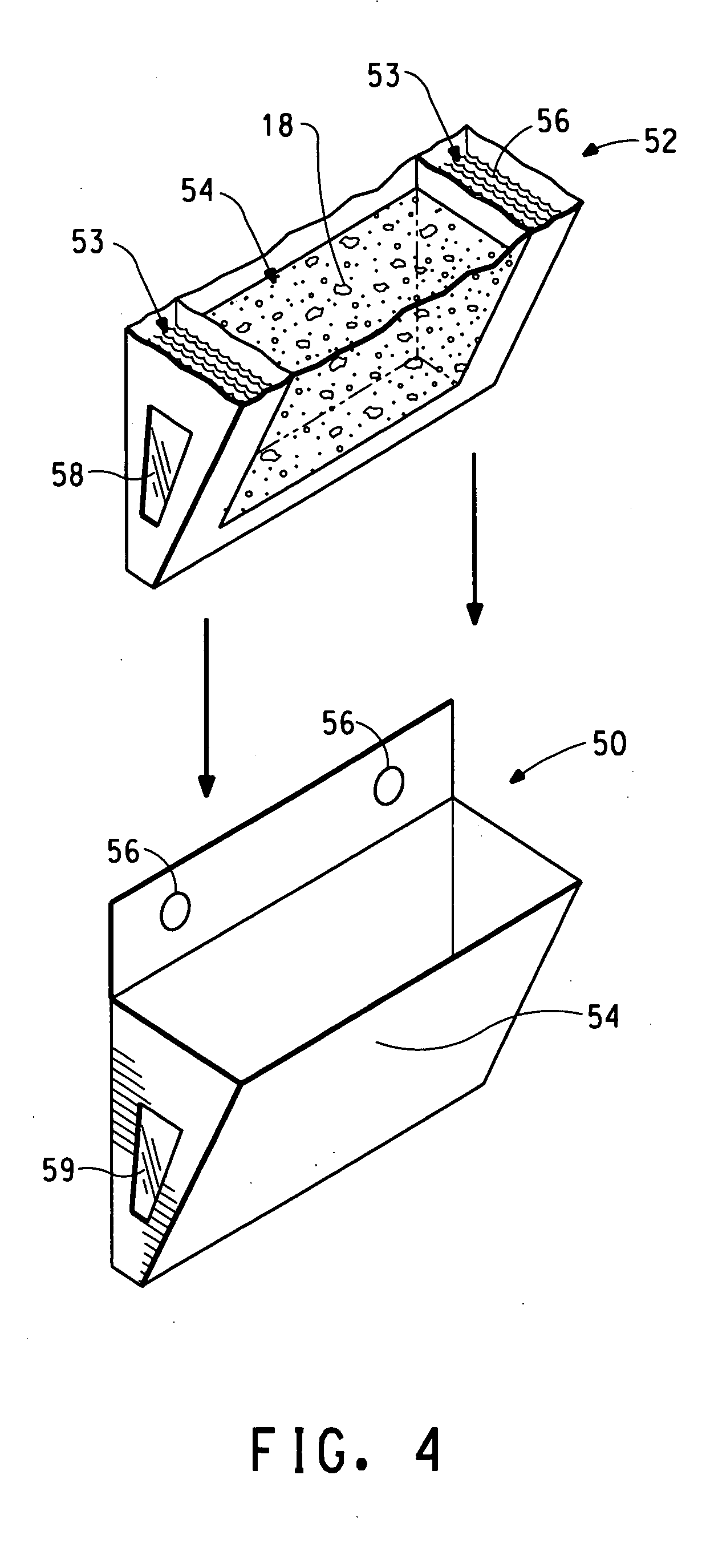

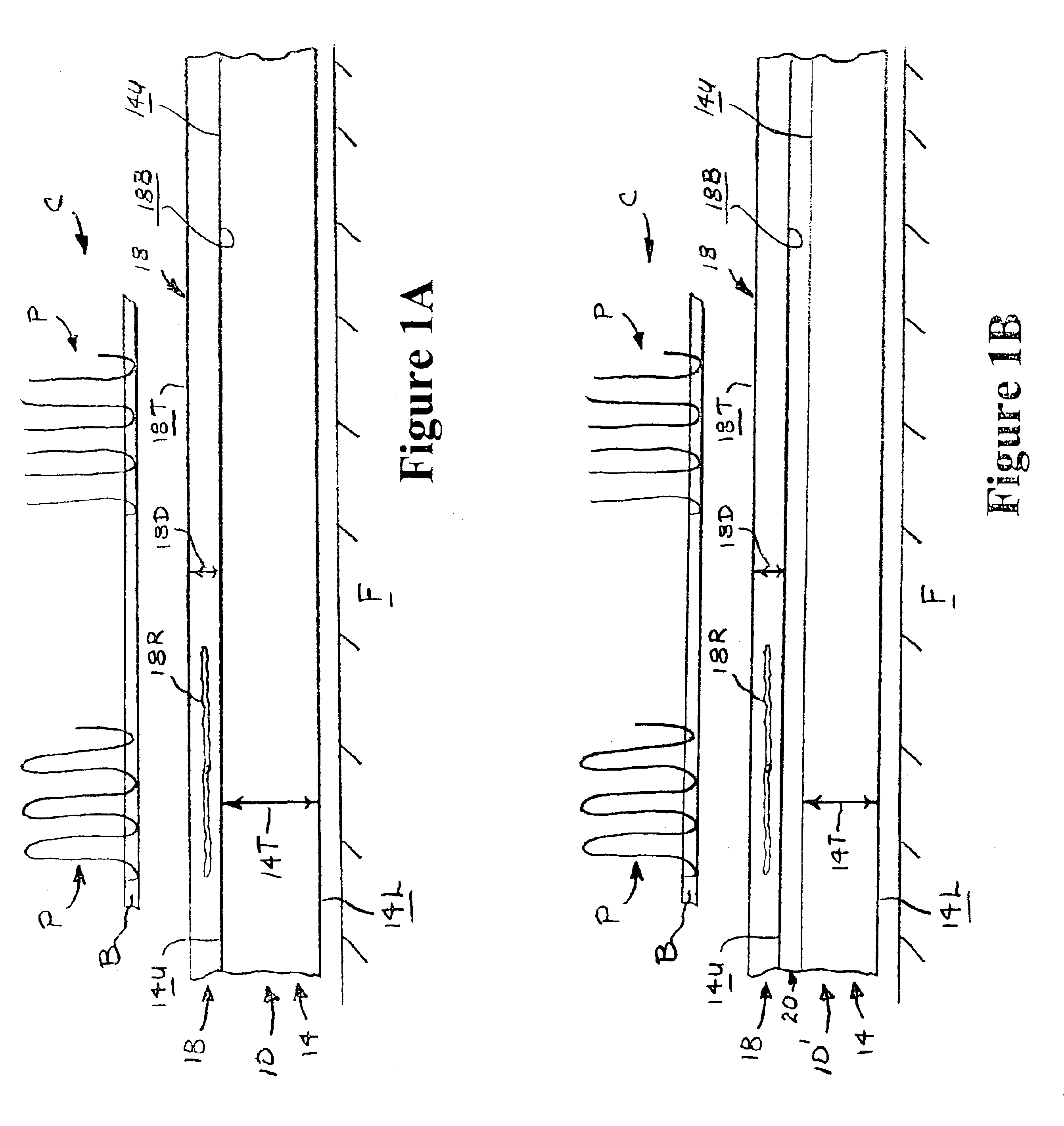

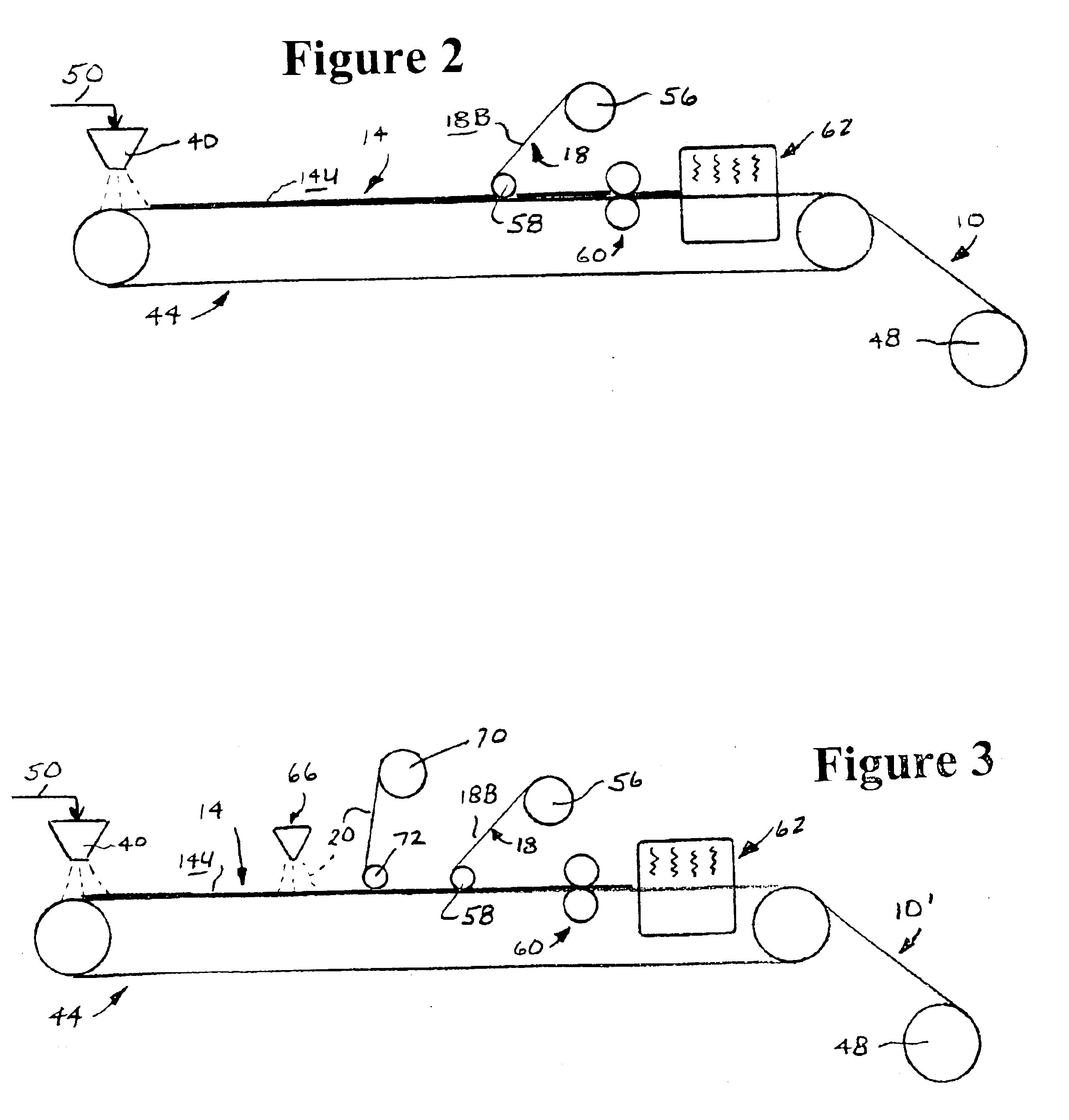

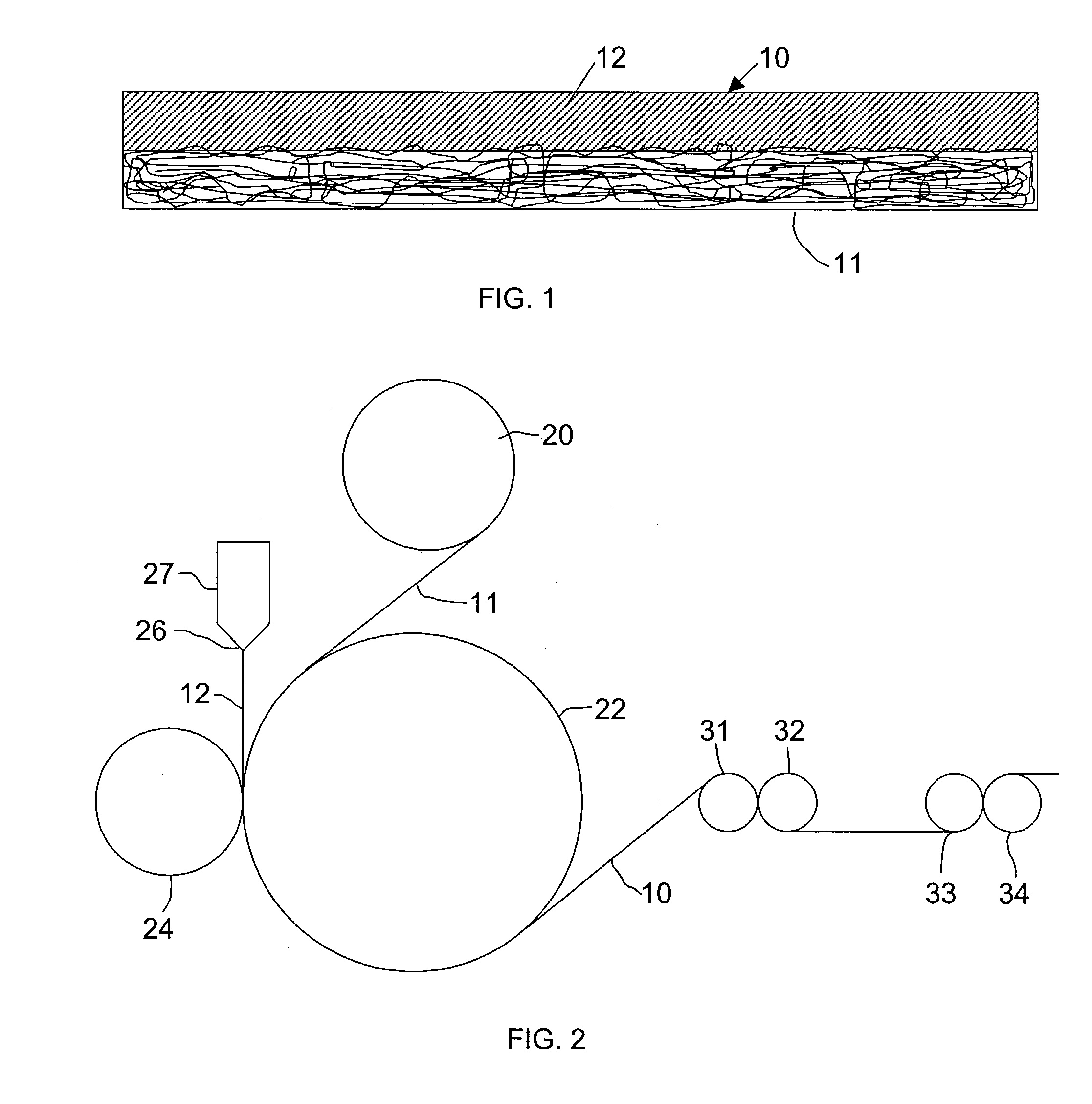

Impact Resistant Sheet Material

The present invention provides an impact resistant sheet material that helps provide exterior walls of a building with resistance to impacts so that the building structure can meet building standards, such as the Miami-Dade County Large Missile Impact Test, for resisting impacts in high wind areas. In one embodiment, sheet material comprises an impact resistant layer that attached to fibrous substrate. The impact resistant layer provides impact resistance to the sheet material so that a wall structure employing the sheet material is able to successfully withstand an impact from a projectile comprising a 9 pound, 7 foot two-by-four (“2×4”) traveling at a speed of at least 34 miles per hour. The impact resistant sheet material may comprise a moisture vapor permeable, water-impermeable barrier layer having a hydrohead of at least 55 cm and a moisture vapor transmission rate of at least 35 g / m2 / day. Such a sheet material is particularly useful in barrier applications, such as a house wrap.

Owner:FIBERWEB LLC

Impact resistant sheet material

The present invention provides an impact resistant sheet material that helps provide exterior walls of a building with resistance to impacts so that the building structure can meet building standards, such as the Miami-Dade County Large Missile Impact Test, for resisting impacts in high wind areas. In one embodiment, sheet material comprises an impact resistant layer that attached to fibrous substrate. The impact resistant layer provides impact resistance to the sheet material so that a wall structure employing the sheet material is able to successfully withstand an impact from a projectile comprising a 9 pound, 7 foot two-by-four (“2×4”) traveling at a speed of at least 34 miles per hour. The impact resistant sheet material may comprise a moisture vapor permeable, water-impermeable barrier layer having a hydrohead of at least 55 cm and a moisture vapor transmission rate of at least 35 g / m2 / day. Such a sheet material is particularly useful in barrier applications, such as a house wrap.

Owner:FIBERWEB LLC

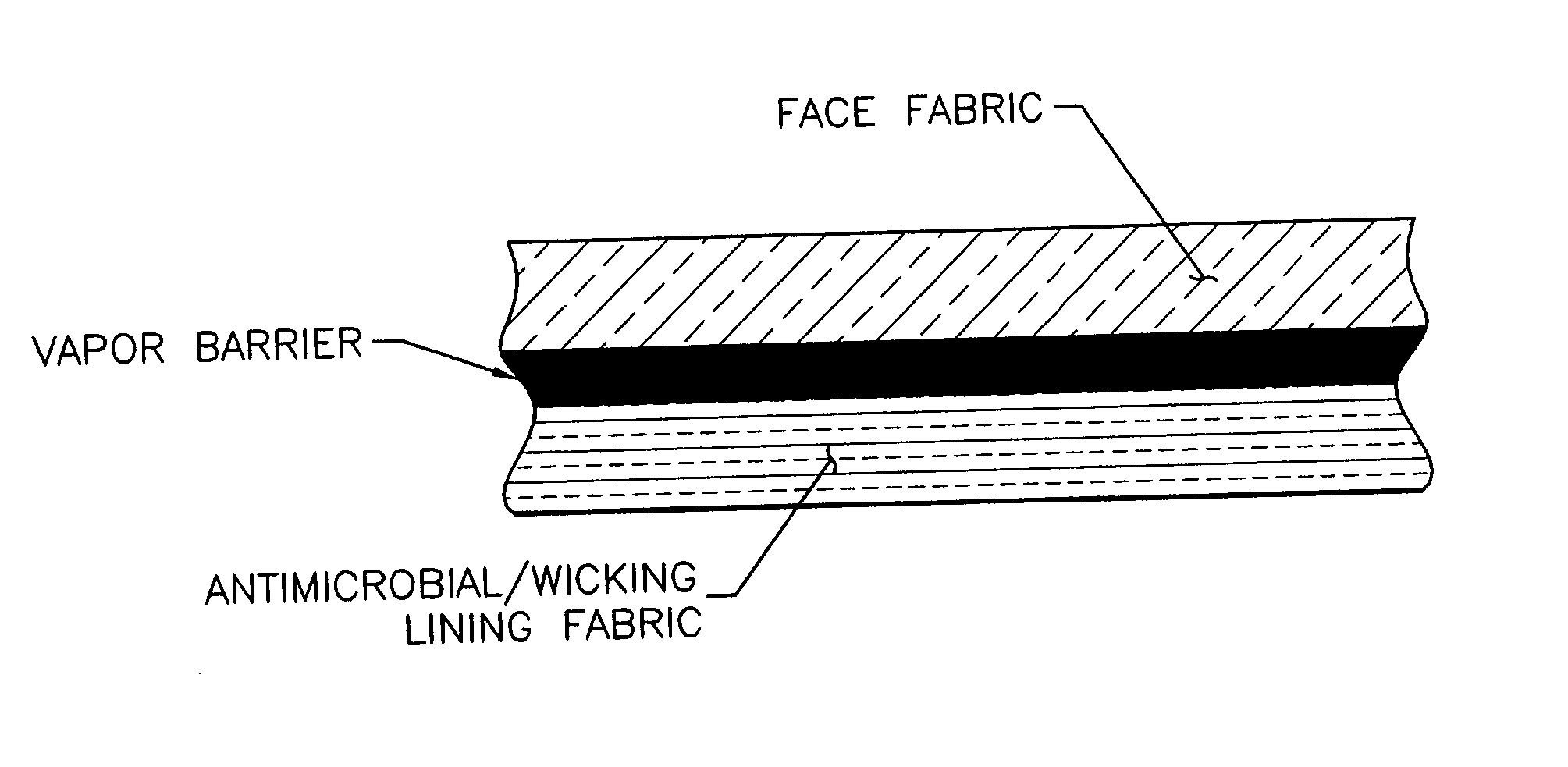

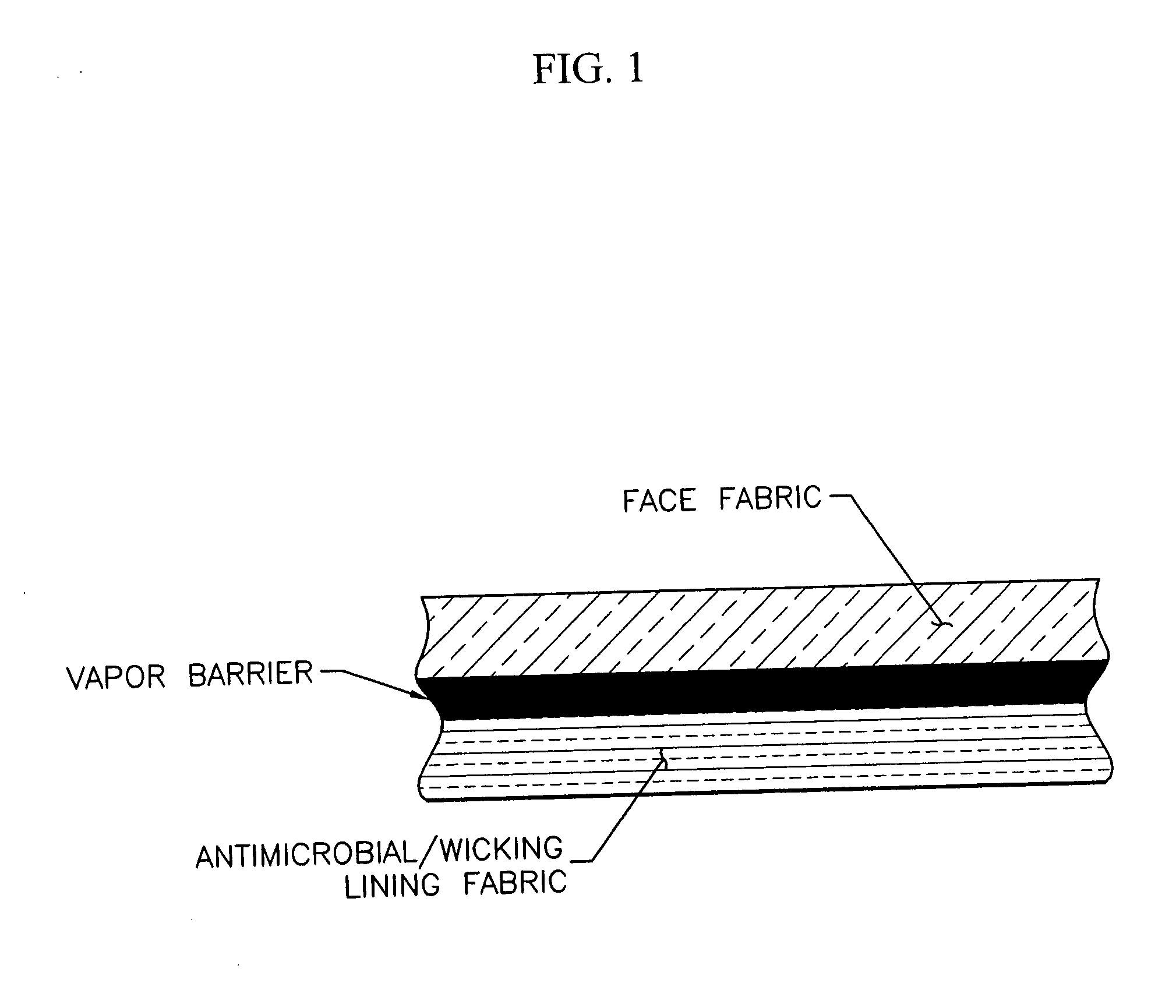

Multifunctional composite vapor barrier textile

InactiveUS20070166503A1Relieve overheatingAdd to comfort and aesthetic propertyGarment special featuresSynthetic resin layered productsVapor barrierAdhesive

The present invention is directed to a multifunctional waterproof / vapor barrier fabric for use in industrial, medical, outdoor apparel (hunting, fishing, skiing, mountaineering, etc.) and military applications. The invention combines functional elements that are especially suited for the above applications. The fabric comprises a lining with wicking and antimicrobial properties, a vapor barrier film or coating with low Moisture Vapor Transmission Rate (M.V.T.R.), and a woven or knit face fabric enhanced with a hydrophobic face coating. The fabric performs admirably in various uses due in part to the use of hydrophobic adhesive, film and coatings, which renders the fabric subject to negligible moisture gain. The durability and water proof properties of the fabric are enhanced due to the impermeable low M.V.T.R design. The fabric of the present invention incorporates a unique combination of properties that addresses issues commonly associated with vapor barrier fabrics. The invention provides a waterproof / barrier fabric that is desirable to wear in direct contact with the skin to prevent evaporative heat loss in cool or cold conditions. The fabric is also effective when worn over one or more layers of other clothing. The fabric is particularly effective because it is capable of use as a base layer and waterproof shell, which helps to minimize the number of layers of clothing needed in cold weather.

Owner:HANNIGAN RYAN B

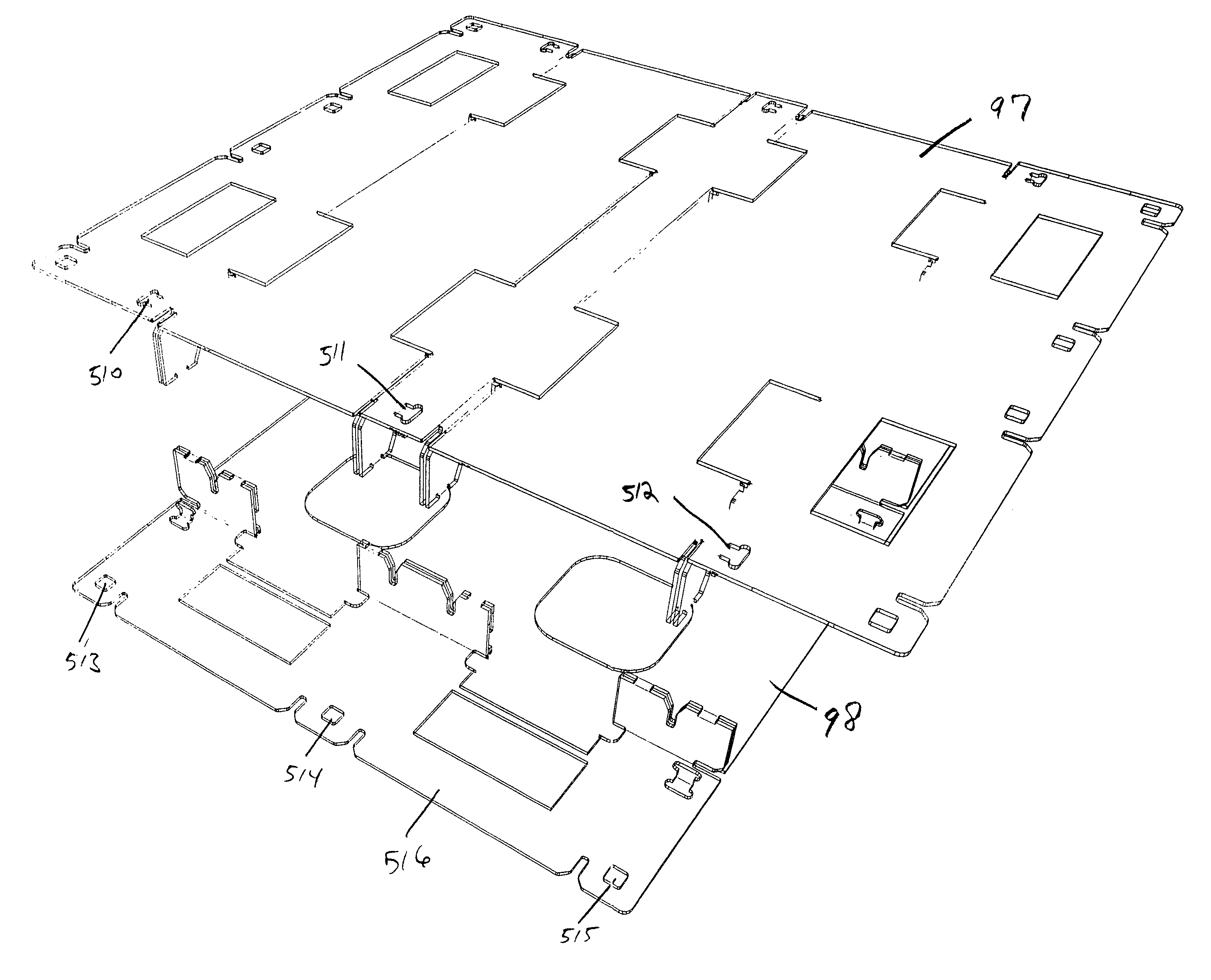

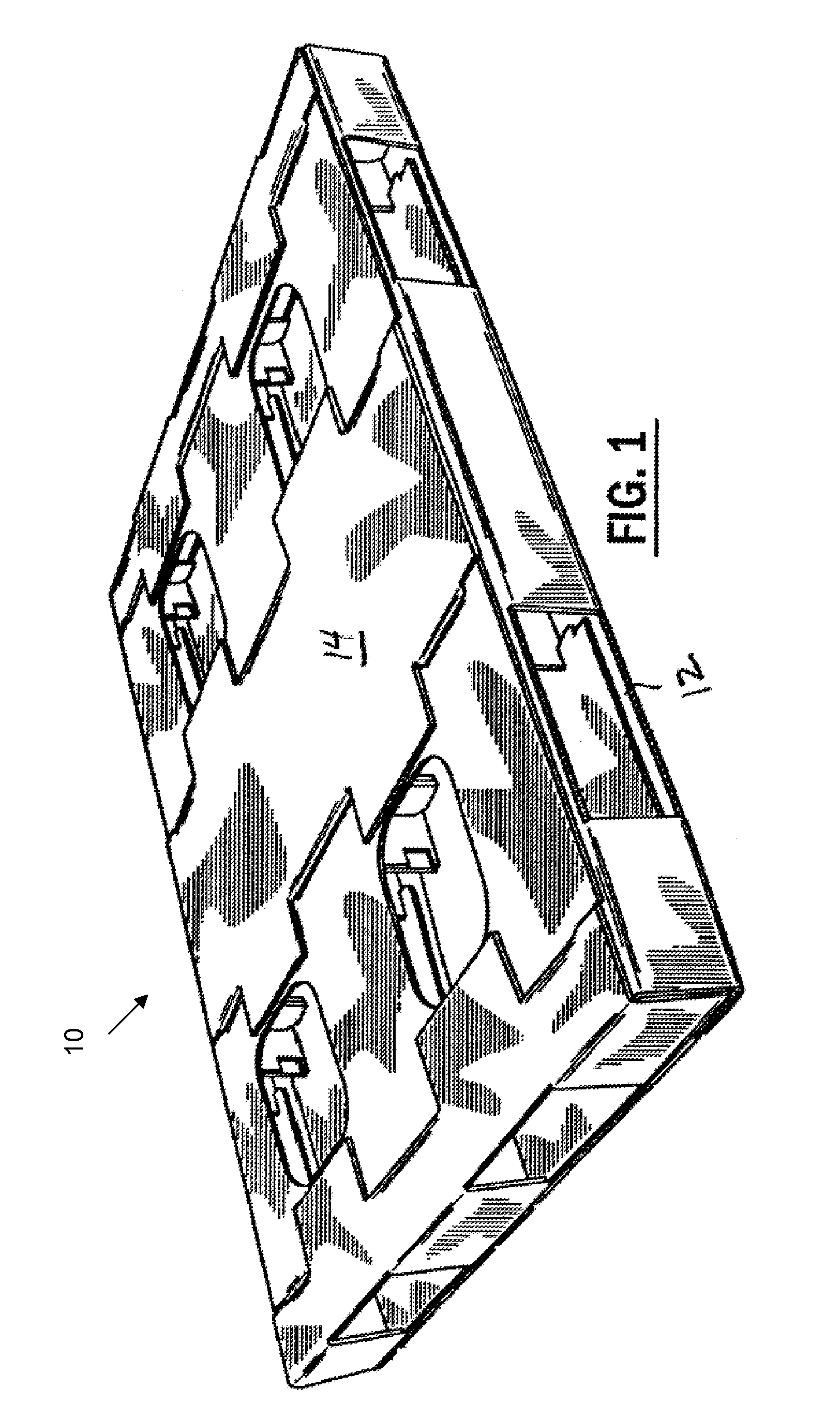

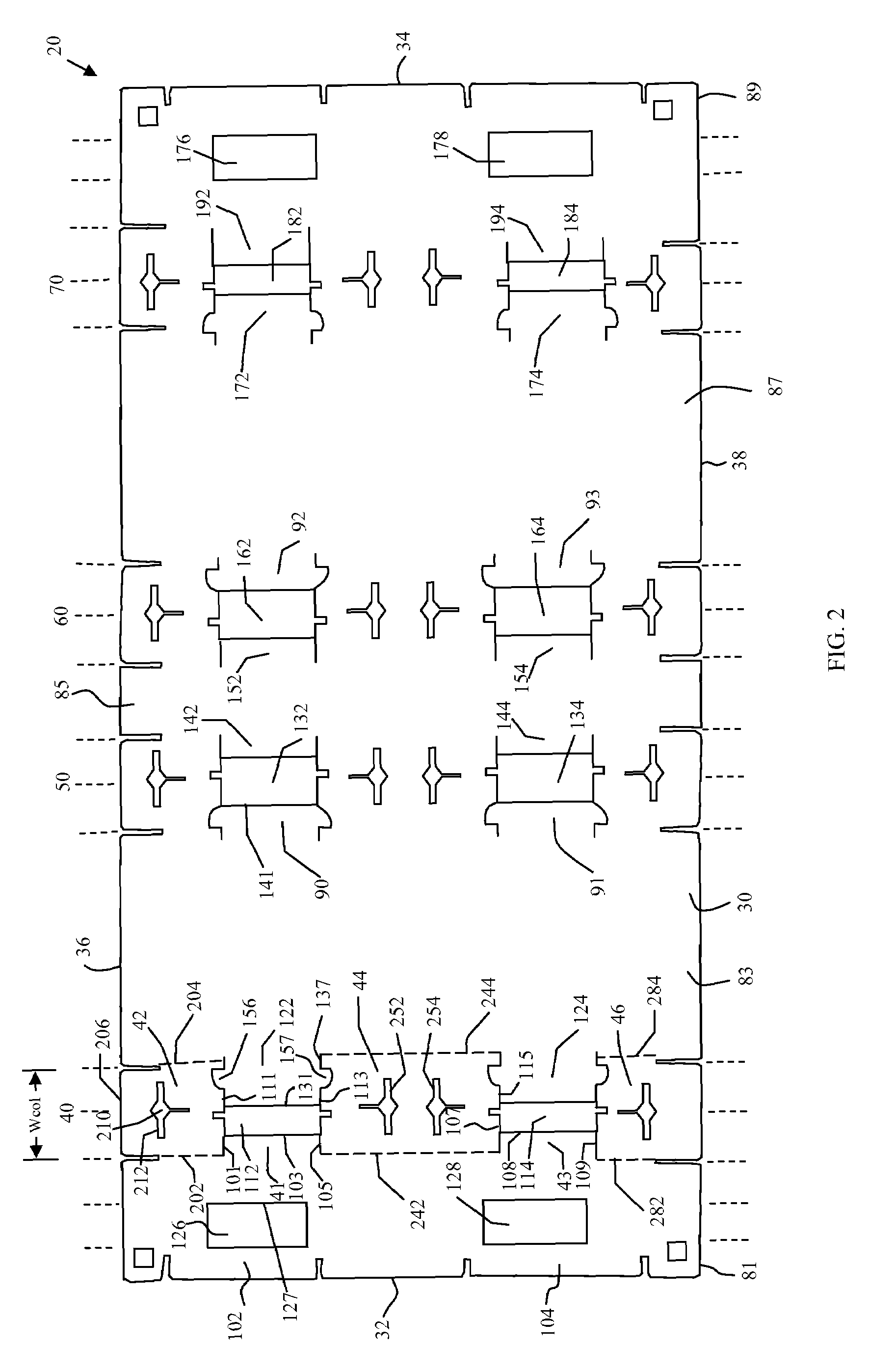

Force-resisting support assembly

InactiveUS7426890B2Solve the complicated productionSimple stepsStands/trestlesKitchen equipmentCardboardEnvironment effect

The present invention is a force resisting assembly, and can be constructed into a pallet or dunnage support made from paperboard that minimizes adverse environmental impact, occupies little space before it is configured, and effectively saves production, storage and transportation costs. The present paperboard assembly can be shipped and stored as either one or more die-cut and scored paperboard pieces, thereby eliminating excess volume, with the pieces being readily interconnectable to form a complete pallet or dunnage support assembly. Preferably, the paperboard of the present invention further has a low moisture vapor transmission rate (MVTR), excellent glueability and recyclability.

Owner:OLVEY SUSAN

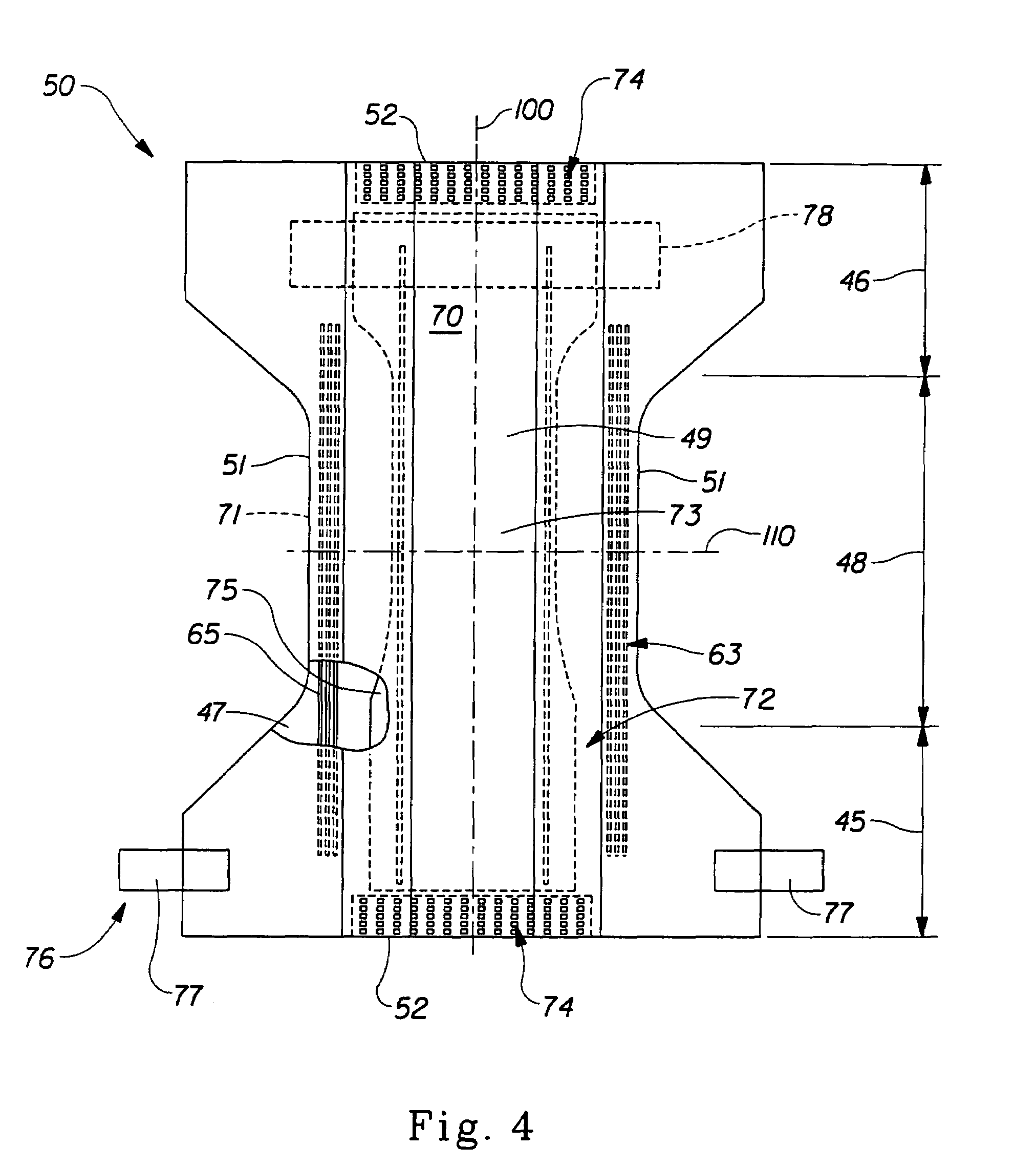

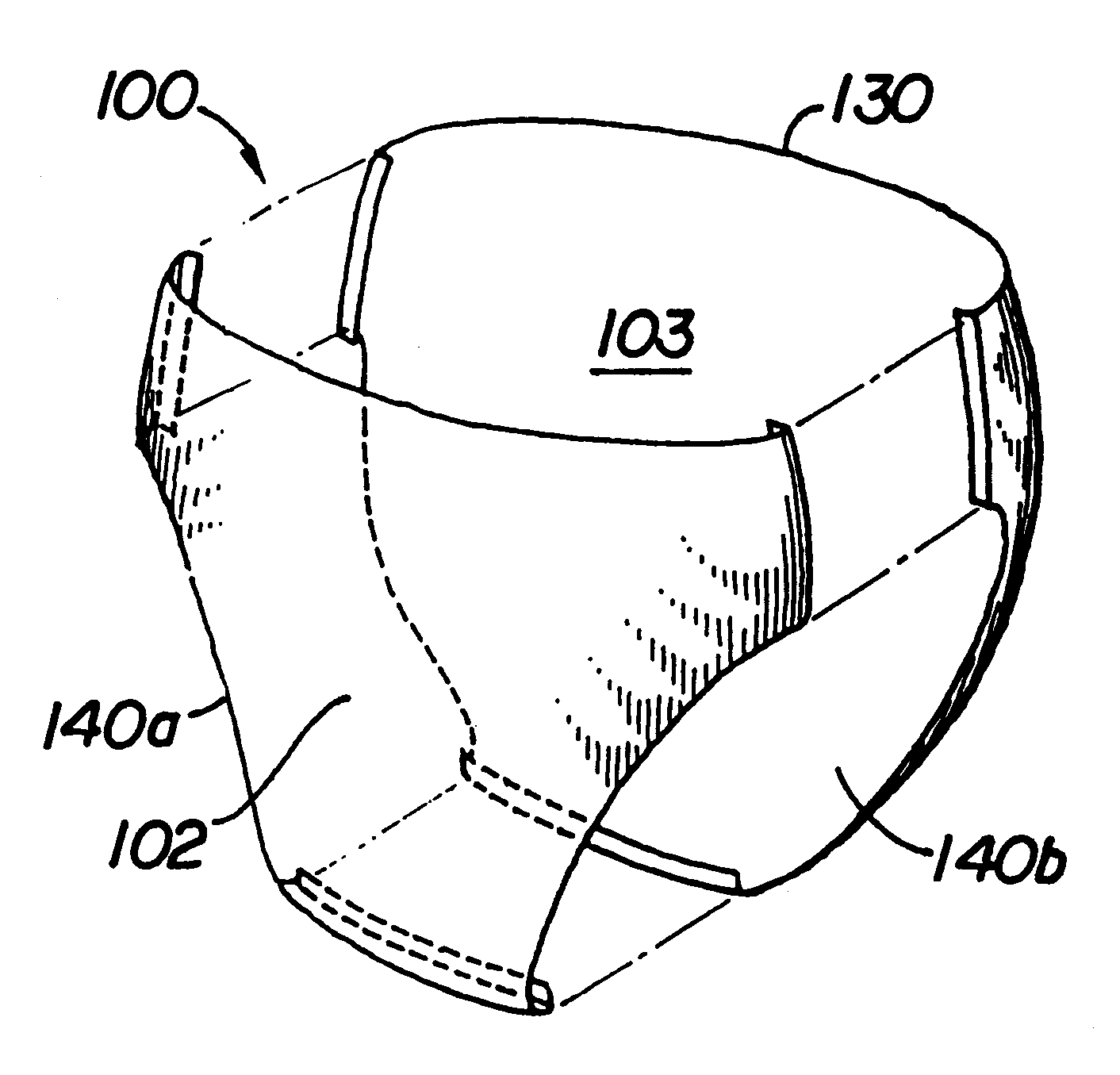

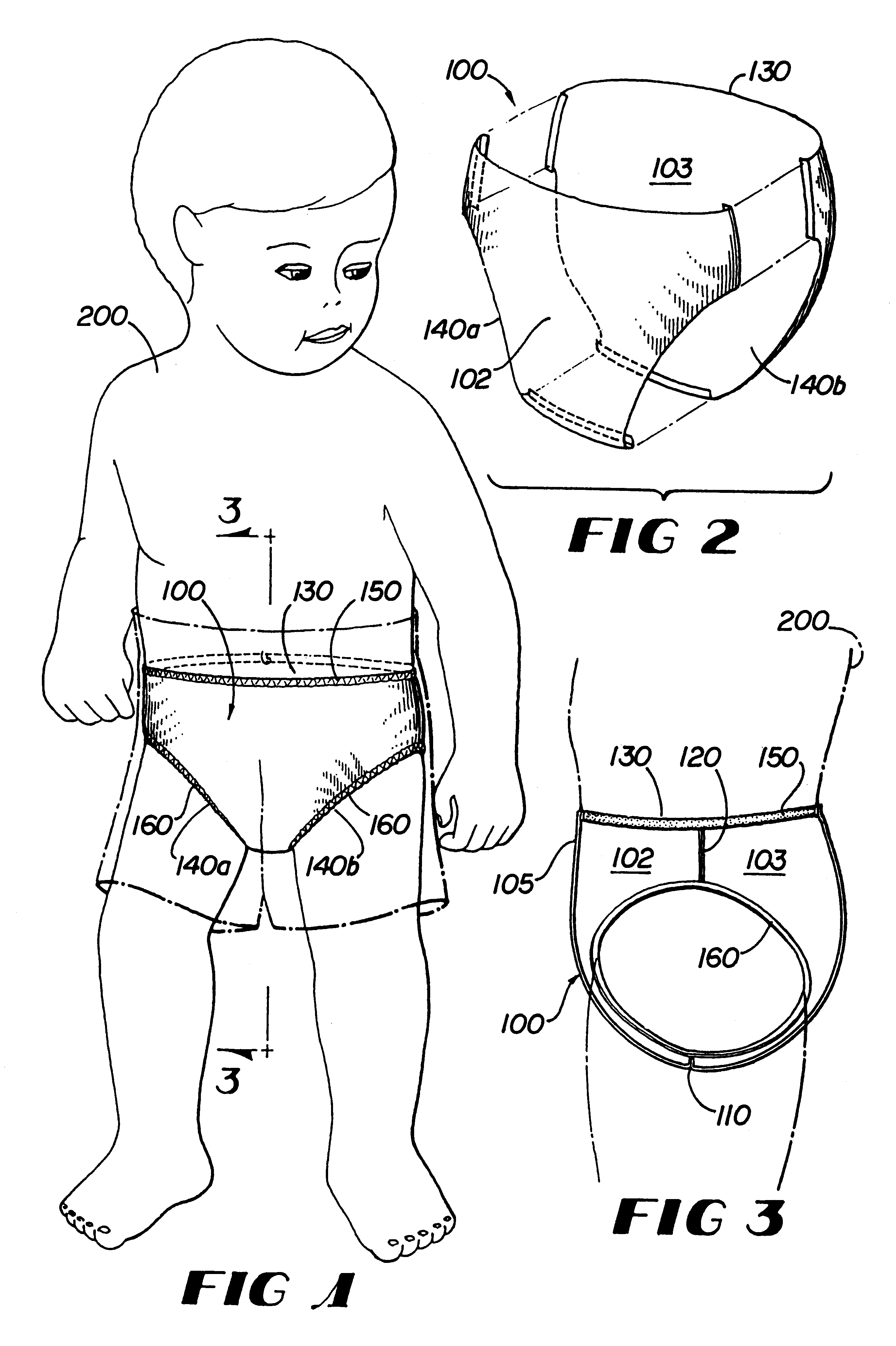

Breathable, waterproof swim diaper and method of manufacture

InactiveUS6195800B1Comfortable to wearTrousersBaby linensMoisture vapor transmission rateEngineering

A swim diaper for use by a child while swimming, bathing or otherwise exposed to an aqueous environment includes a main torso section formed from a sheet of breathable, waterproof material of sufficient thickness to retain solid waste and having a moisture vapor transmission rate of at least 200 g / m2 / day. The main torso section has a torso receiving aperture at the upper end of the main torso section for receiving a torso and leg receiving apertures located in the lower portion of the main torso section for receiving a child's legs.

Owner:FUTURE PROD

High moisture vapor transmission hot melt moisture cure polyurethane adhesive with excellent hydrolysis resistance

InactiveUS6133400AGood moisture permeabilityImprove washabilityAdhesive articlesSynthetic resin layered productsPolyesterMoisture cure polyurethane

This invention relates to a hot melt moisture cure polyurethane composition which is the reaction product of a polyether polyol formed from a compound selected from the group consisting of ethylene oxide, propylene oxide, 1,2-butylene oxide, 1,4-butylene oxide and mixtures thereof; a low molecular weight polyalkylene glycol having from 3 to 7 carbon atoms; a crystalline polyester polyol having a melting point from about 40 DEG C. to about 120 DEG C.; and at least one polyfinctional isocyanate component wherein said composition has a moisture vapor transmission rate of greater than about 100 g / m2 / day film thickness of from about 450 to about 500 g / m2, and hydrolysis resistance.

Owner:HB FULLER CO

Highly neutralized acid polymer compositions having a low moisture vapor transmission rate and their use in golf balls

The present invention is directed to a golf ball having at least one layer formed from a moisture resistant composition having a moisture vapor transmission rate of 12.5 g·mil / 100 in2 / day or less, a melt flow index of 1.0 g / 10 min or higher, and comprising a highly neutralized acid polymer. Golf balls of the present invention include one-piece, two-piece, multi-layer, and wound golf balls. The composition may be present in any one or more of a core layer, a cover layer, or an intermediate layer.

Owner:ACUSHNET CO

Breathable plant container

InactiveUS20050166451A1Easy to controlHigh tensile strengthFlower holdersAgriculture gas emission reductionPorosityHydrostatic head

A breathable plant container is provided that includes a hollow vessel having an opening through which planting soil can be inserted into the hollow portion of the vessel and through which a plant growing in the soil can grow out of the vessel. The hollow vessel has a wall comprised of a synthetic microporous sheet material selected from the group of flash-spun plexifilamentary fabrics, spunbonded / meltblown / spunbonded (“SMS”) fabrics, and microporous film laminates. The wall of the hollow vessel preferably has an air porosity less than 200 seconds / 100 cm3, a moisture vapor transmission rate of at least 300 g / m2 / day, and a hydrostatic head of at least 20 cm. The hollow vessel may have a first compartment separated from a second compartment by a synthetic, moisture vapor permeable membrane that resists the passage of water such that water added to the second compartment can keep moist soil added to the first compartment.

Owner:EI DU PONT DE NEMOURS & CO

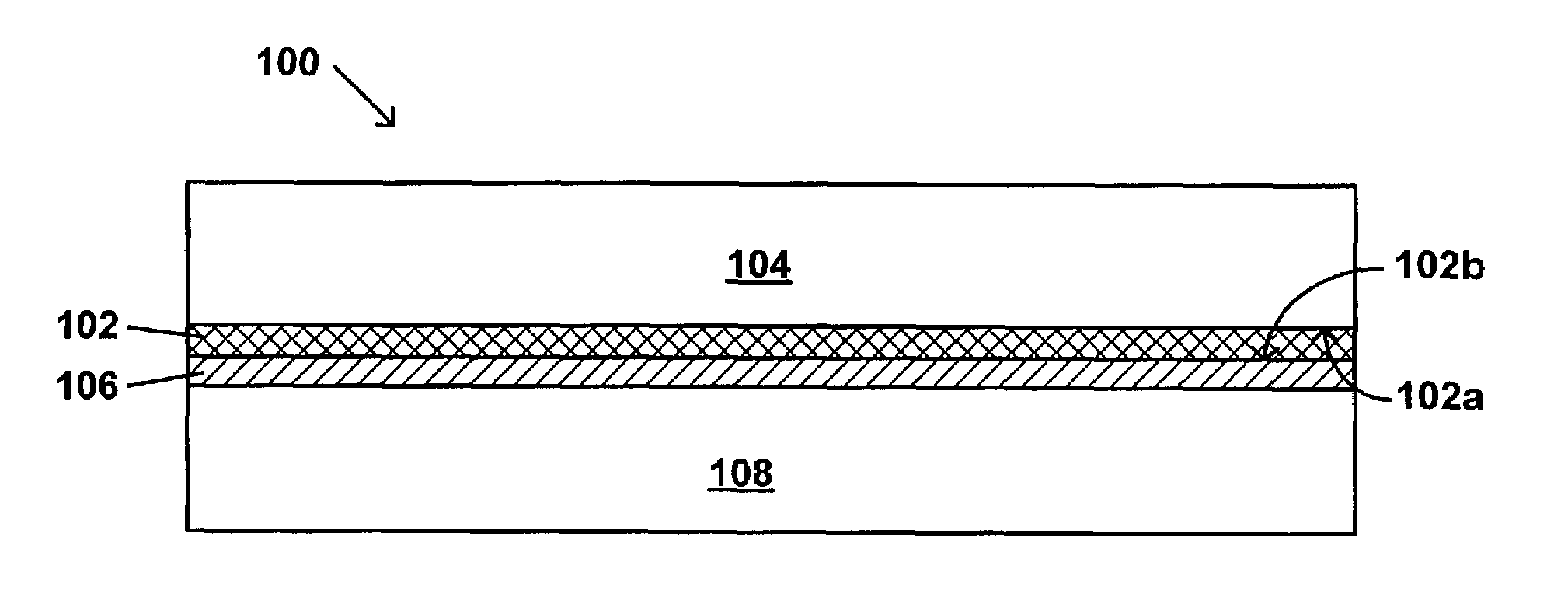

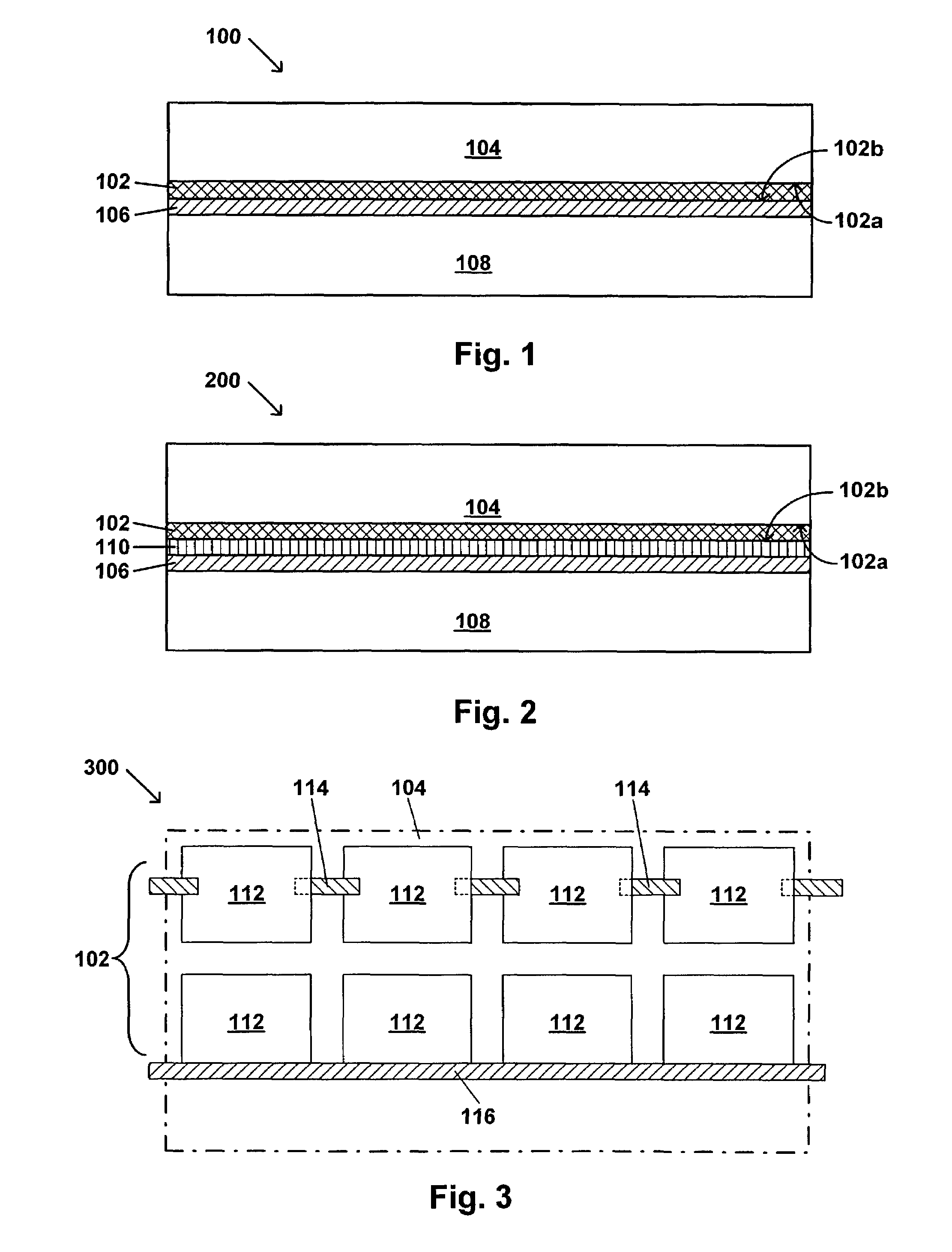

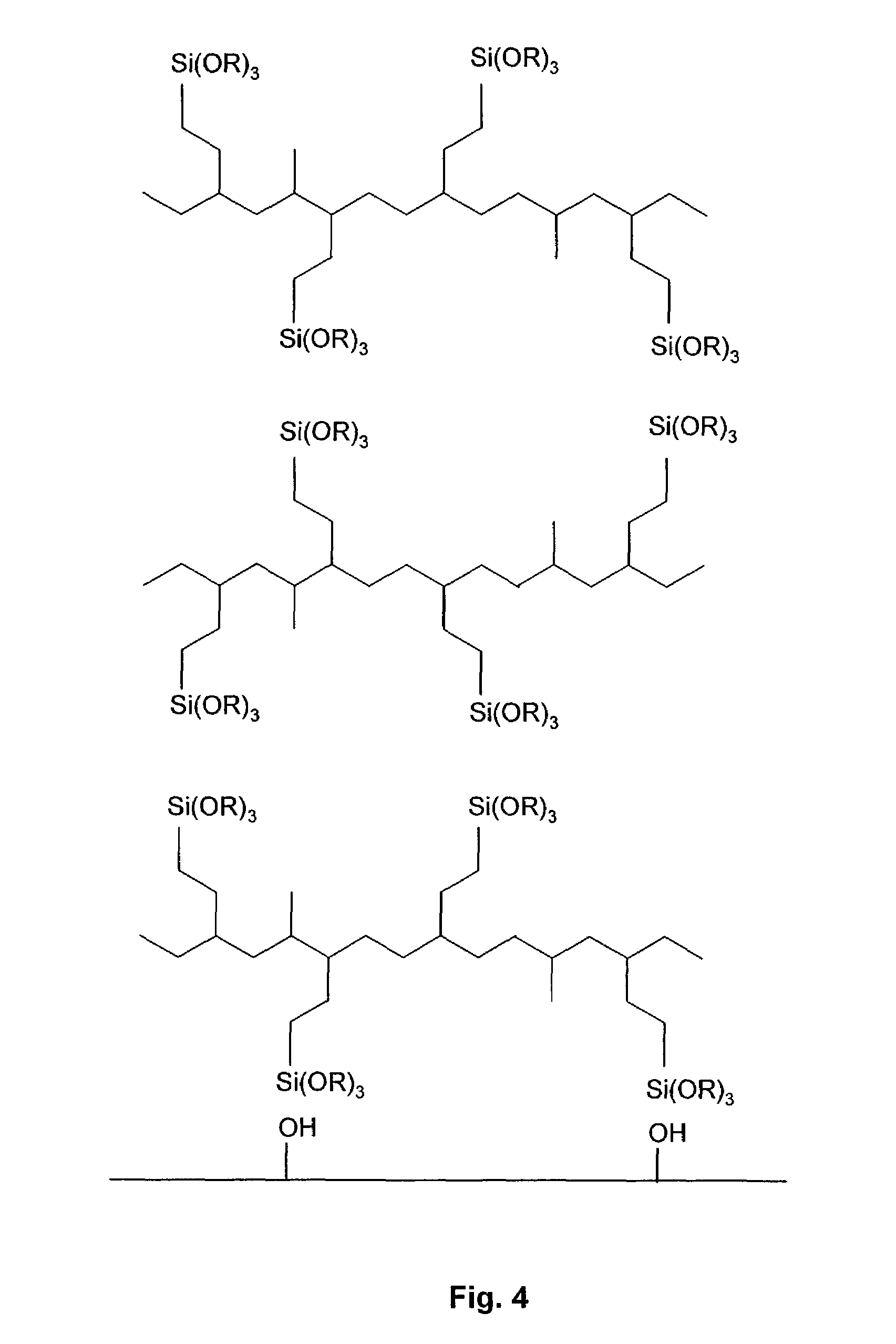

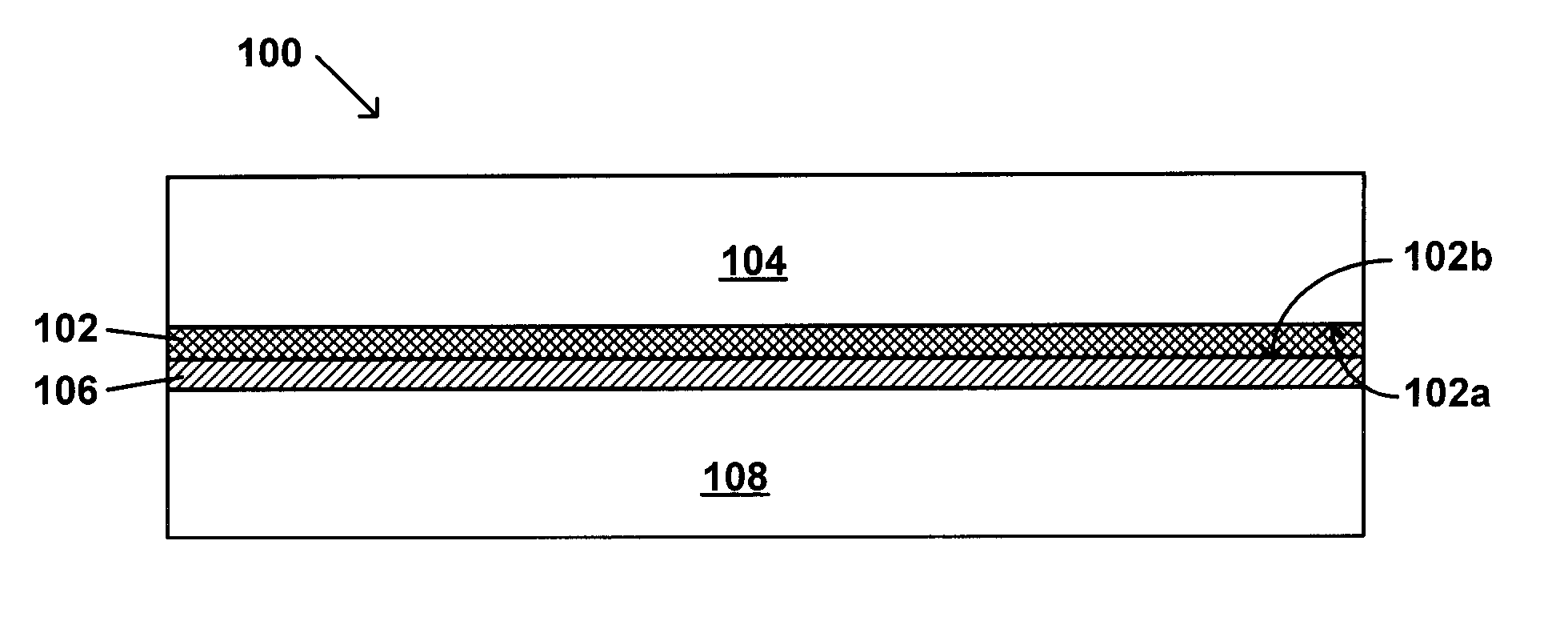

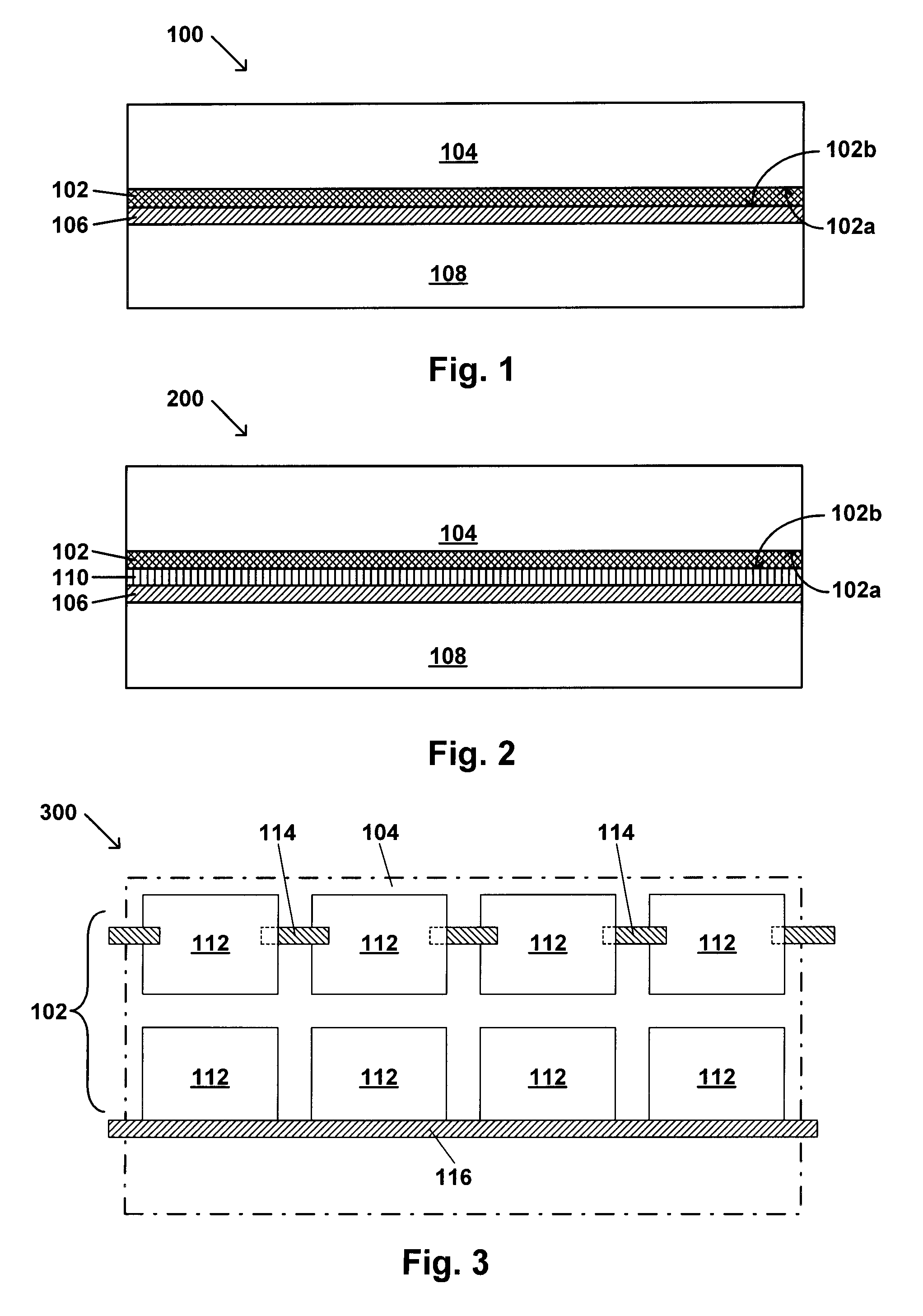

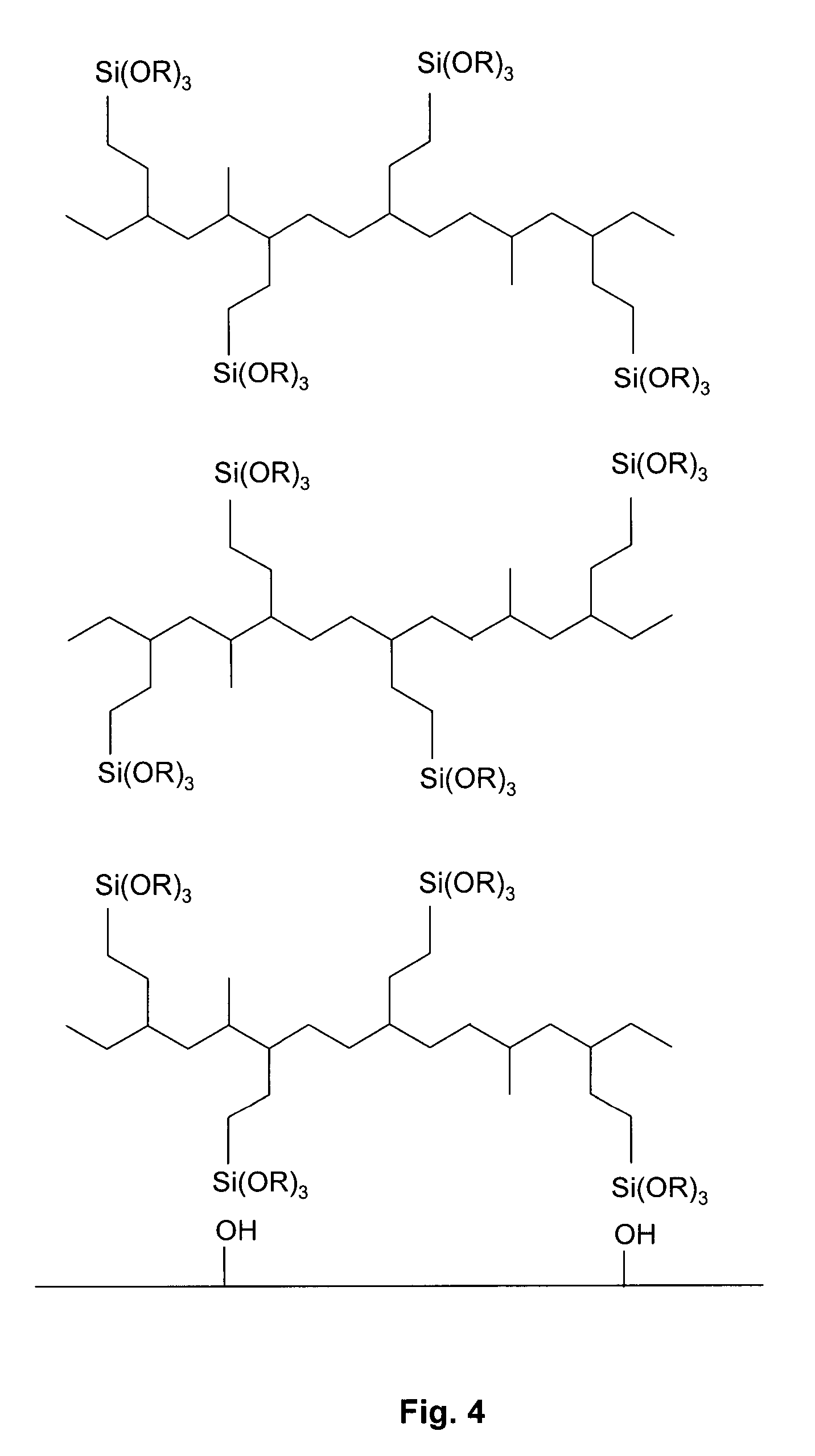

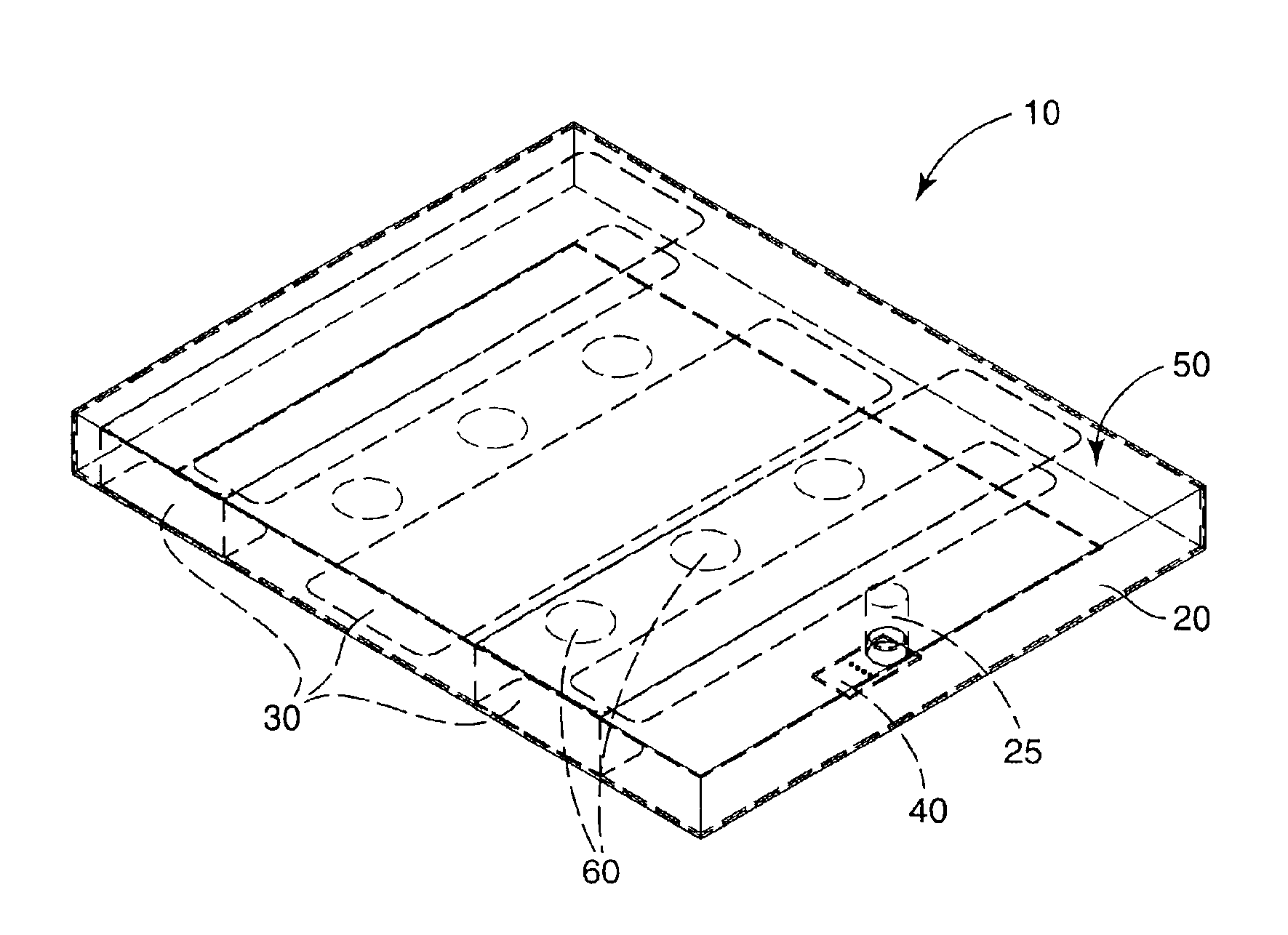

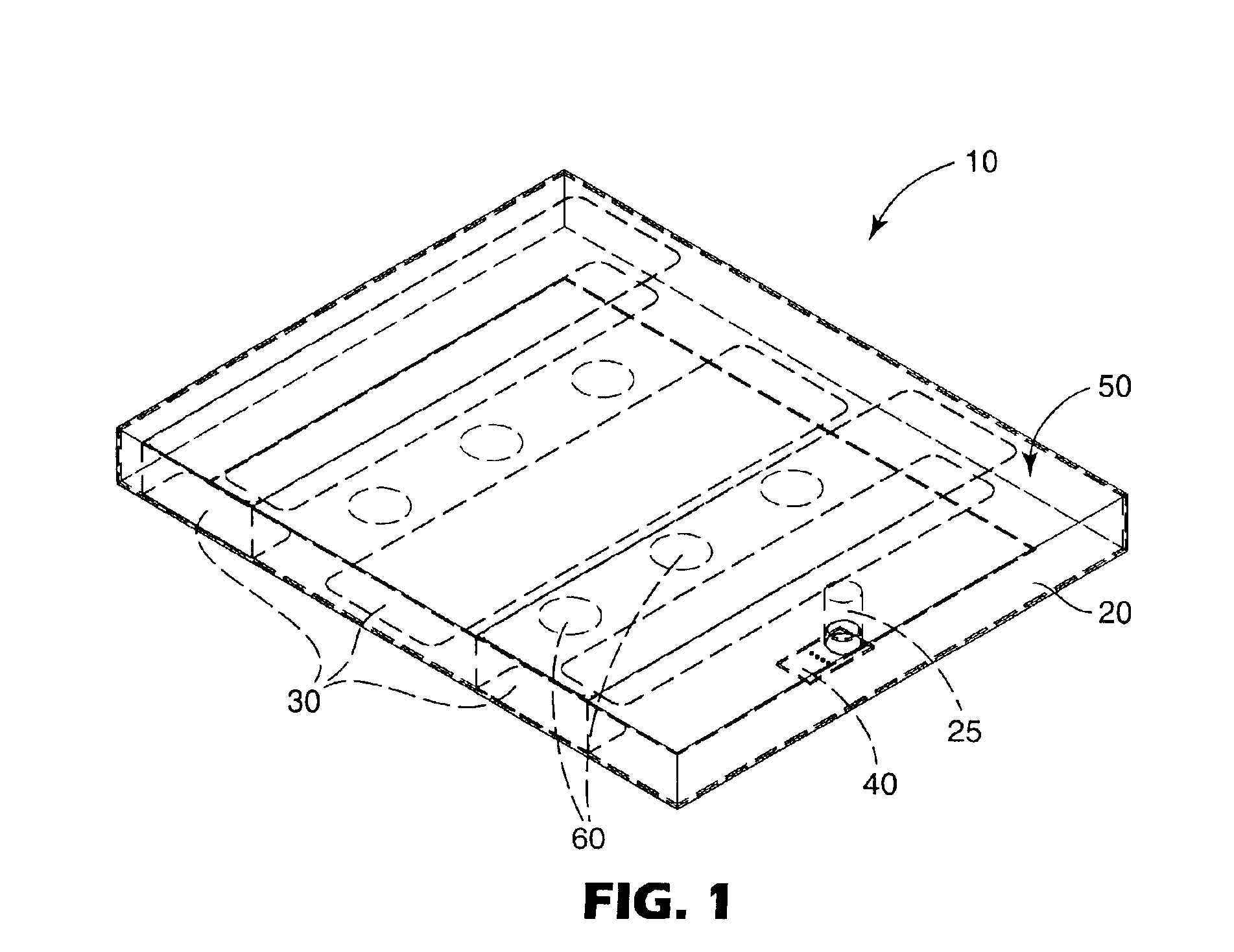

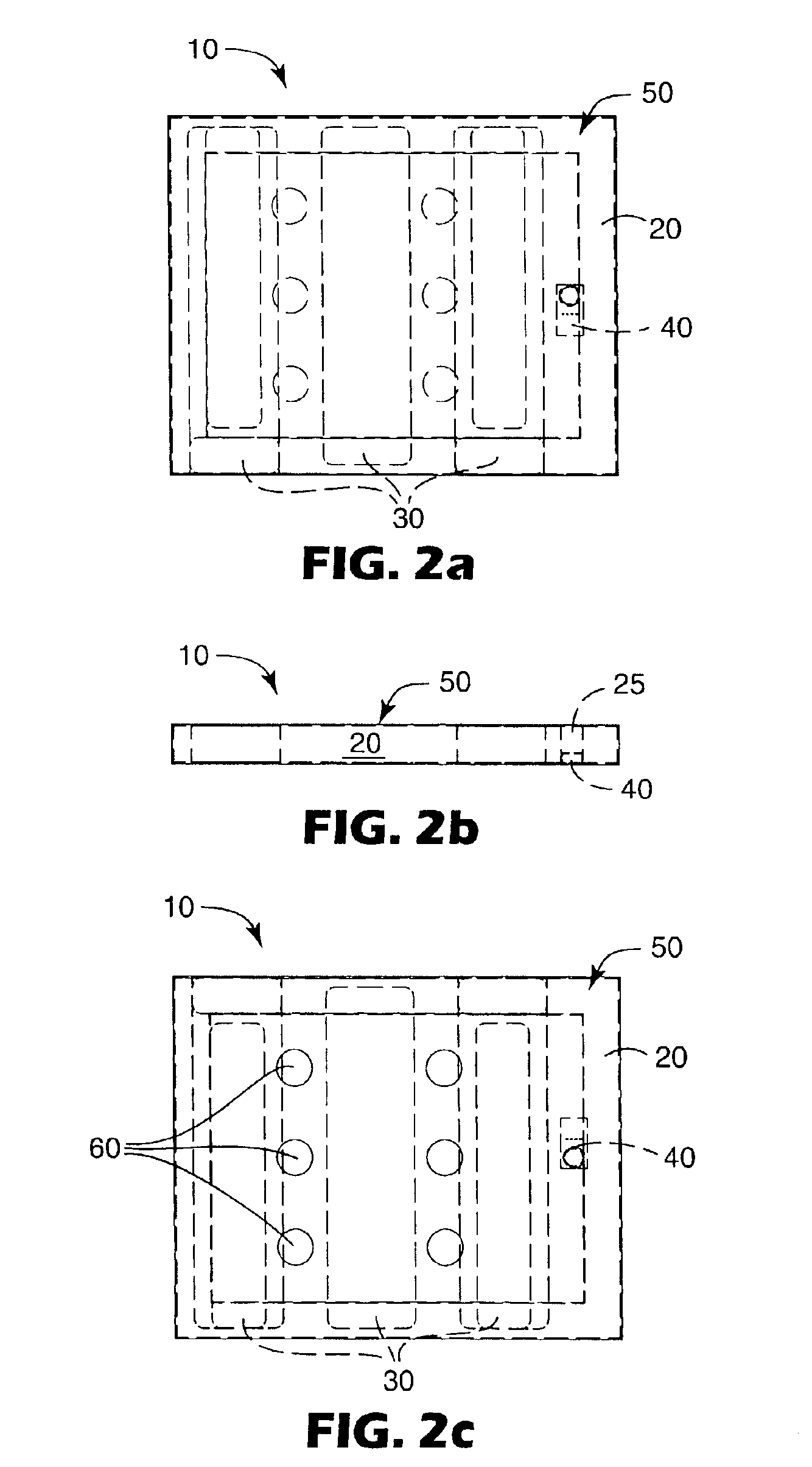

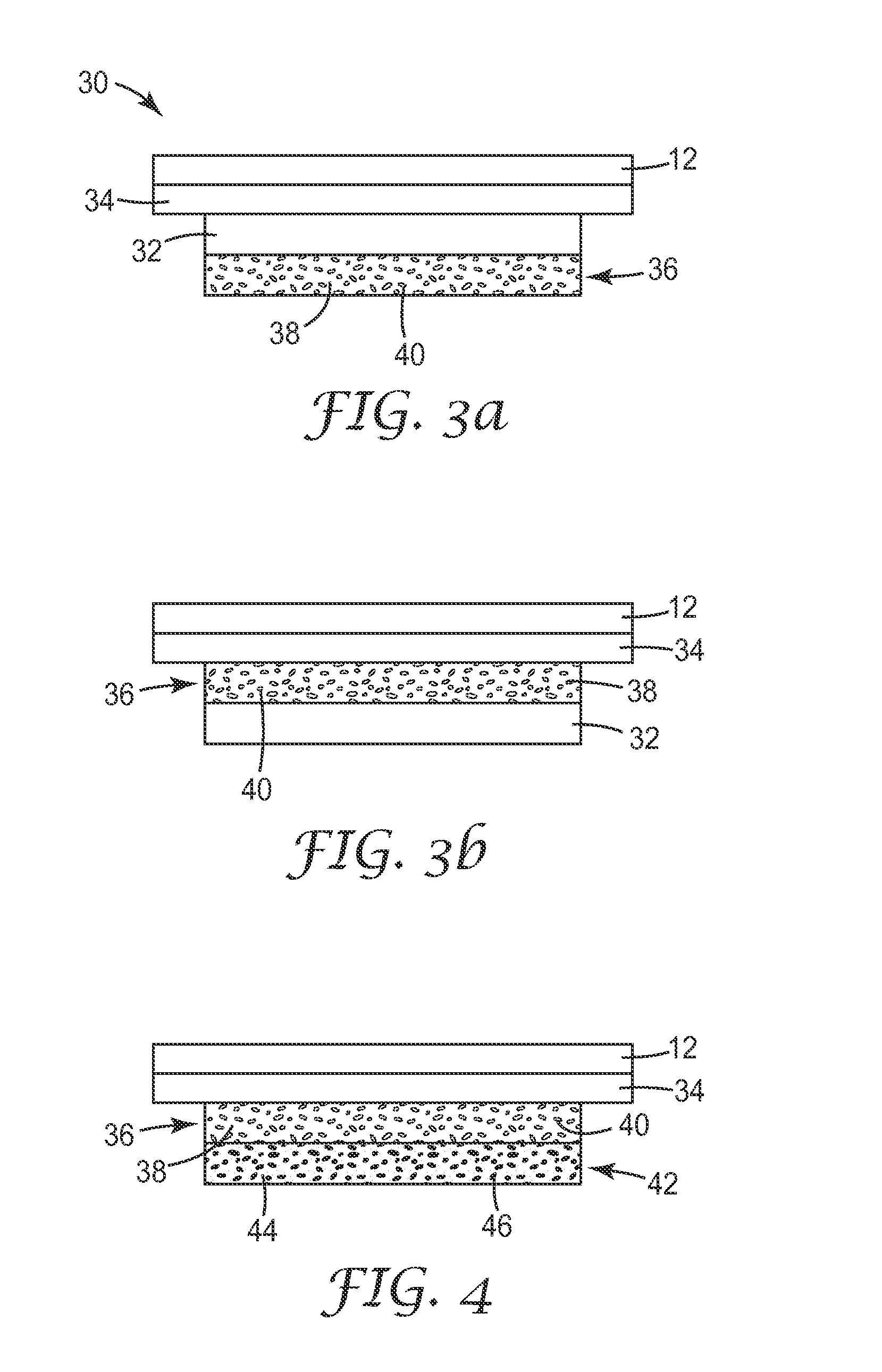

Solar panel including a low moisture vapor transmission rate adhesive composition

InactiveUS7449629B2Improve protectionImprove adhesionNon-macromolecular adhesive additivesPV power plantsMoisture vapor transmission rateCopolymer

A solar panel including a photovoltaic material layer; a backing panel; and an adhesive layer disposed between and adhering together the photovoltaic material layer and the backing panel, in which the adhesive layer comprises an adhesive composition, the adhesive composition comprising a low MVTR polymer or copolymer and a silane-modified polymer or copolymer. In another embodiment, the solar panel includes module wire openings which are filled by an adhesive composition comprising a low MVTR polymer or copolymer and a silane-modified polymer or copolymer. A method of making the solar panel is provided.

Owner:QUANEX IG SYST INC

Solar panel including a low moisture vapor transmission rate adhesive composition

InactiveUS20070062573A1High strengthImprove substrate adhesionNon-macromolecular adhesive additivesPV power plantsAnti-reflective coatingEngineering

A solar panel including a front panel; a photovoltaic material layer deposited either directly on the front panel or directly on an anti-reflective coating formed between the front panel and the photovoltaic material layer; a backing panel; and an adhesive layer disposed between and adhering together the photovoltaic material layer and the backing panel, in which the adhesive layer comprises an adhesive composition, the adhesive composition comprising a low MVTR polymer or copolymer and a silane-modified polymer or copolymer. In another embodiment, the solar panel includes module wire openings which are filled by an adhesive composition comprising a low MVTR polymer or copolymer and a silane-modified polymer or copolymer. A method of making the solar panel is provided.

Owner:FERRI LOUIS ANTHONY +1

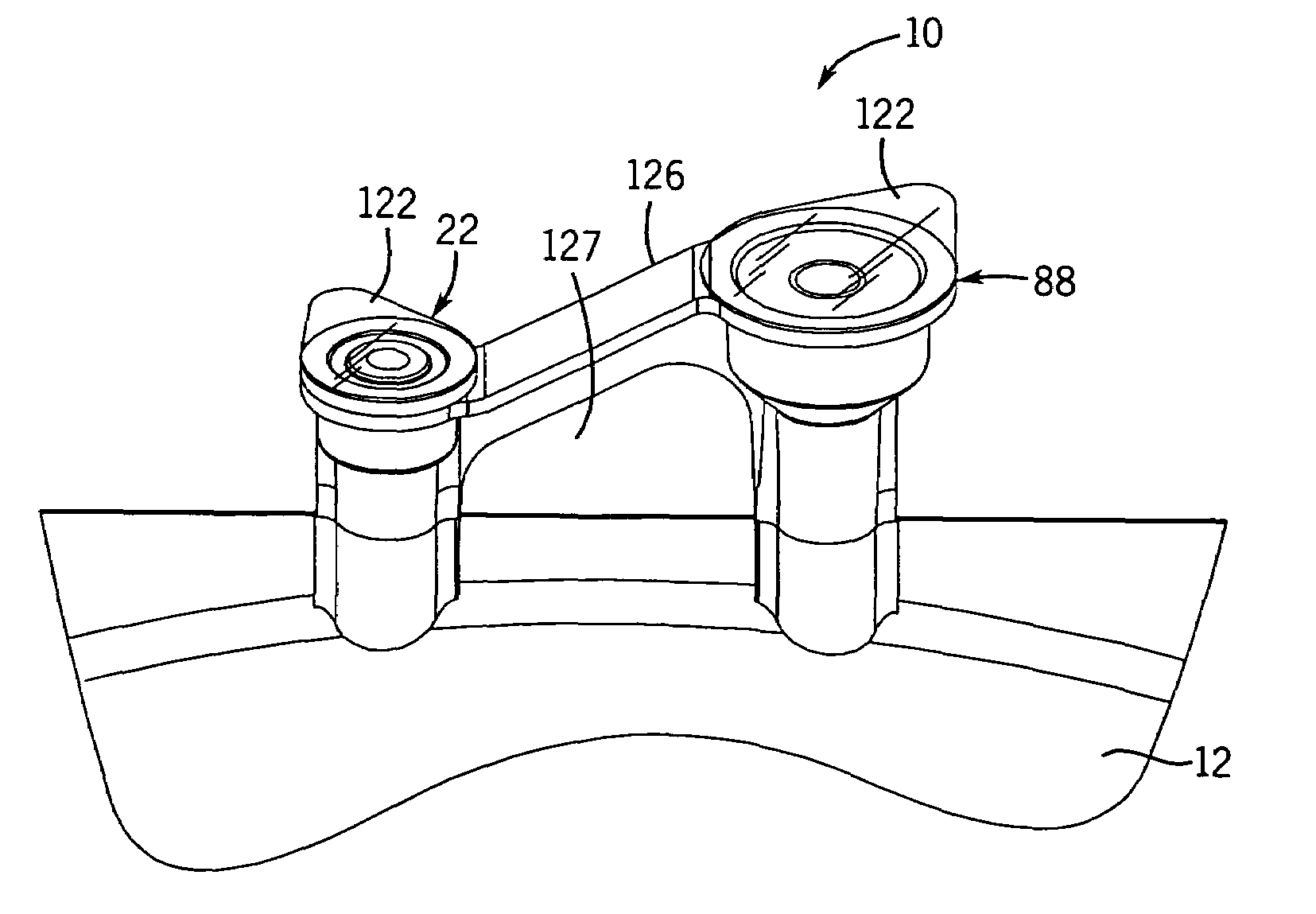

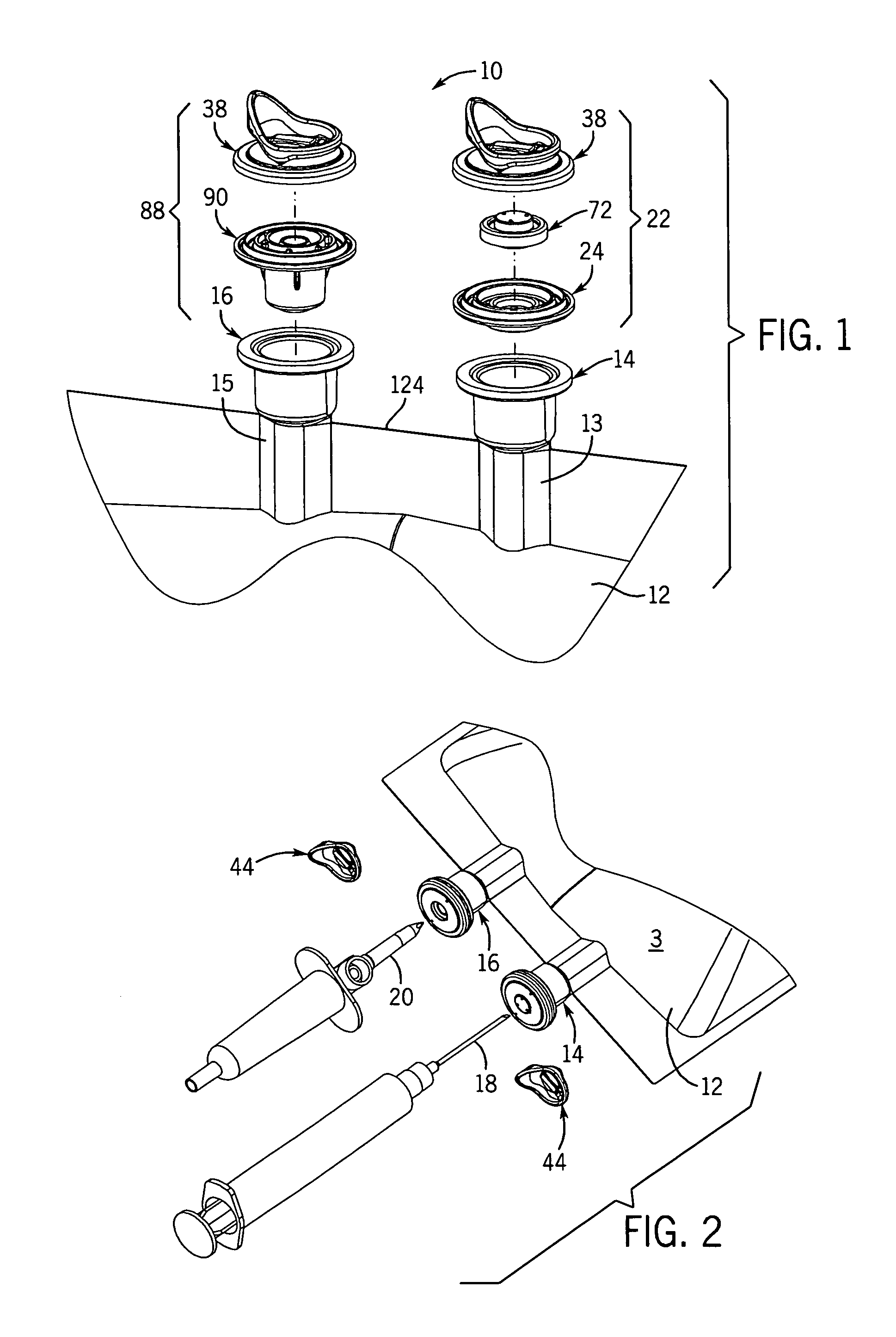

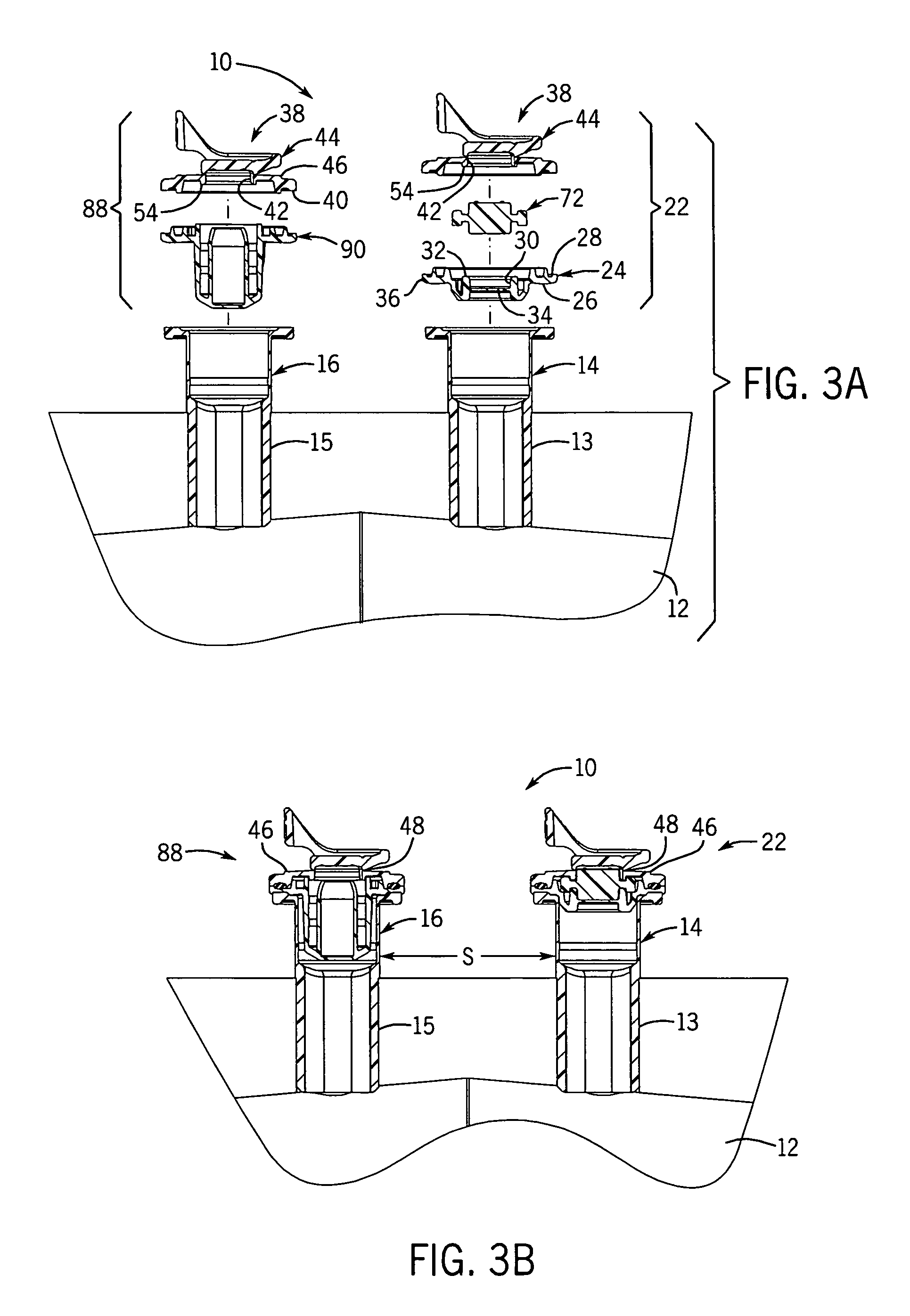

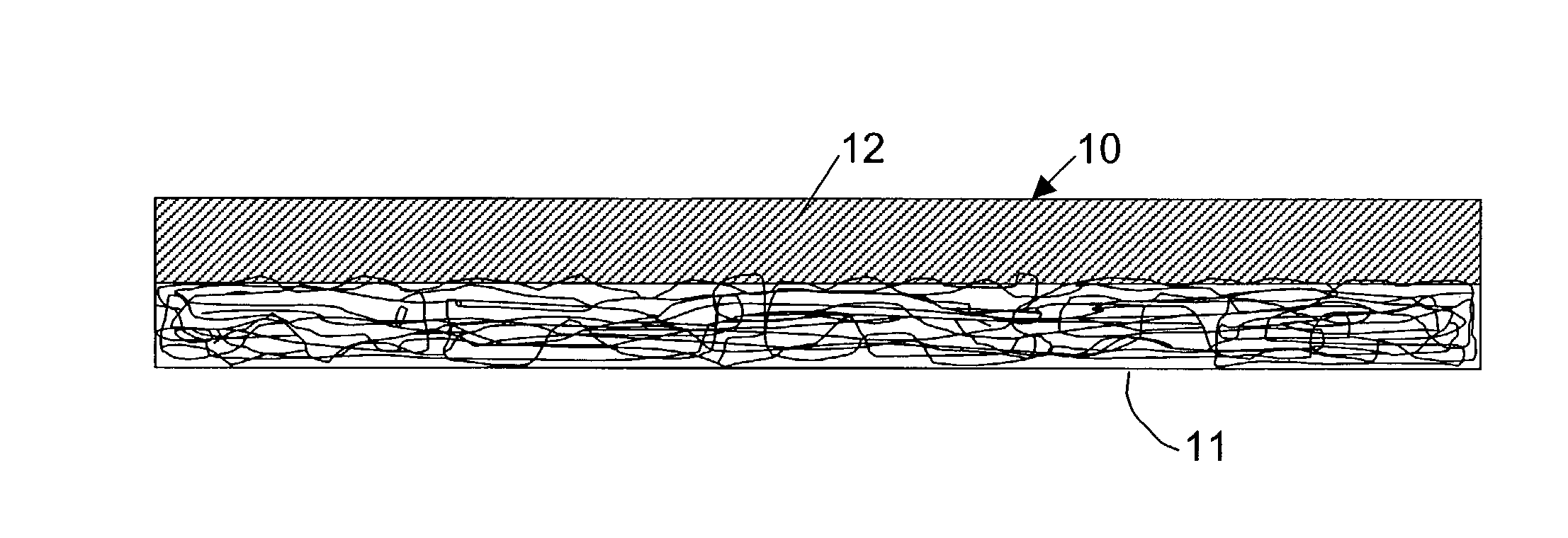

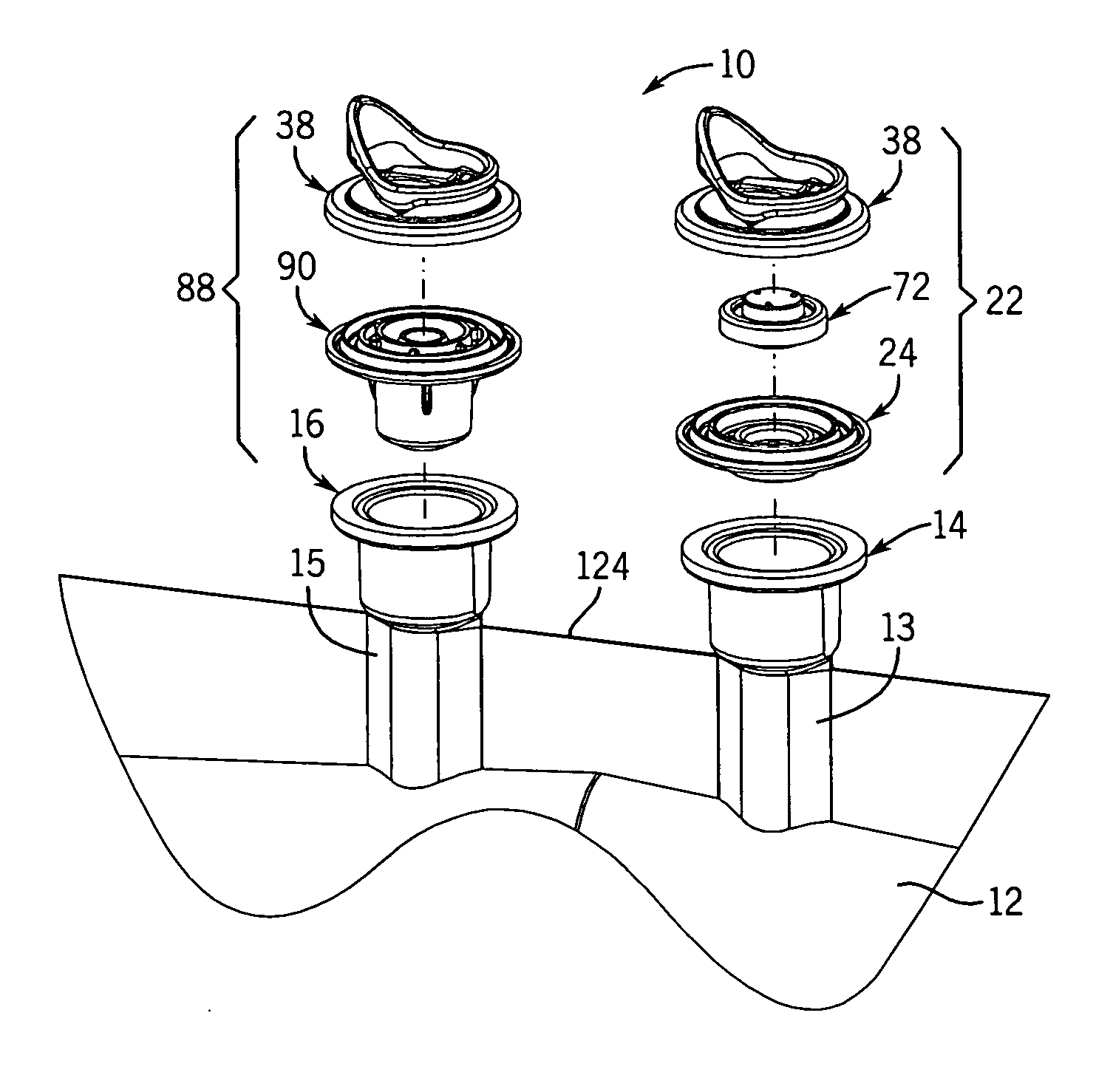

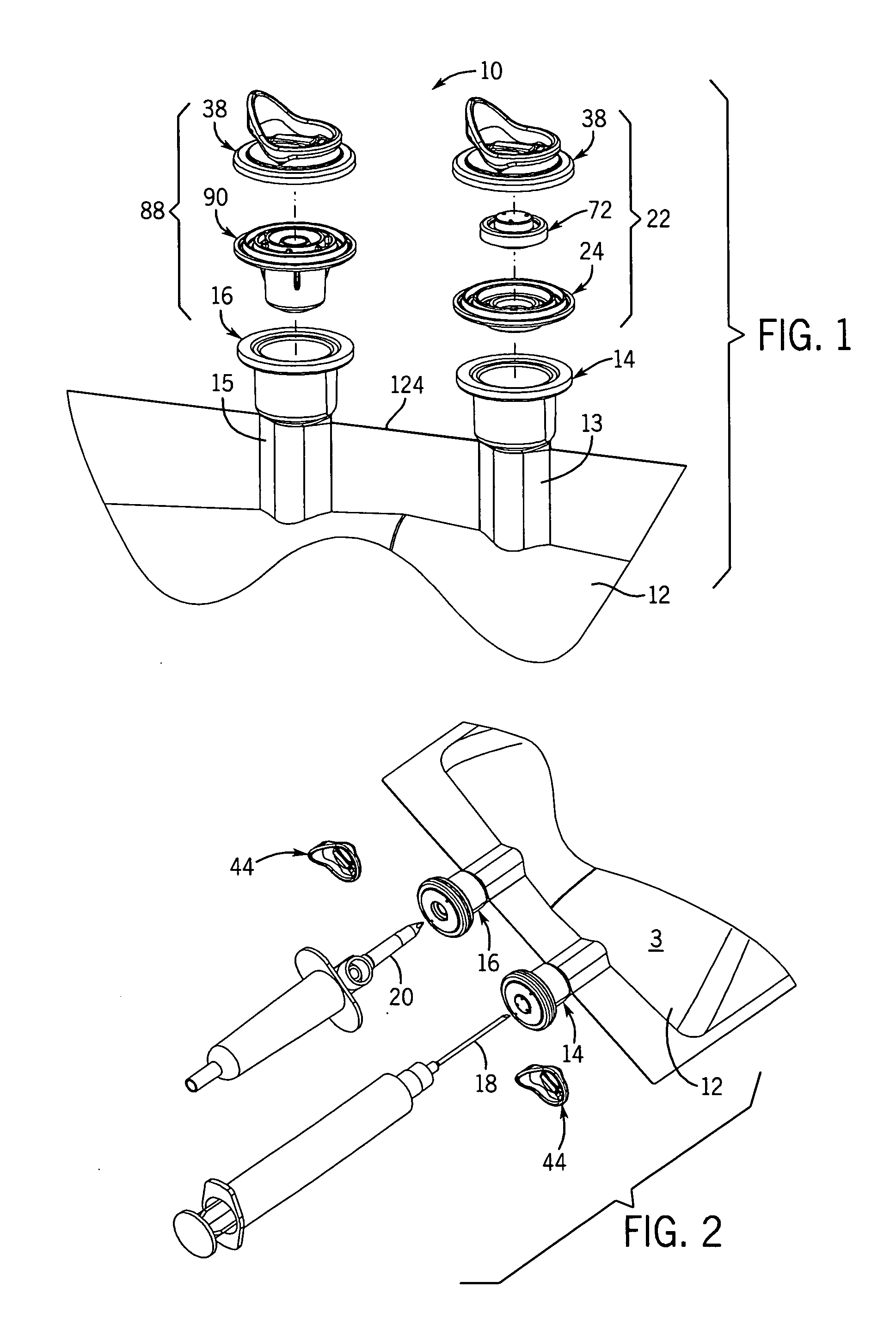

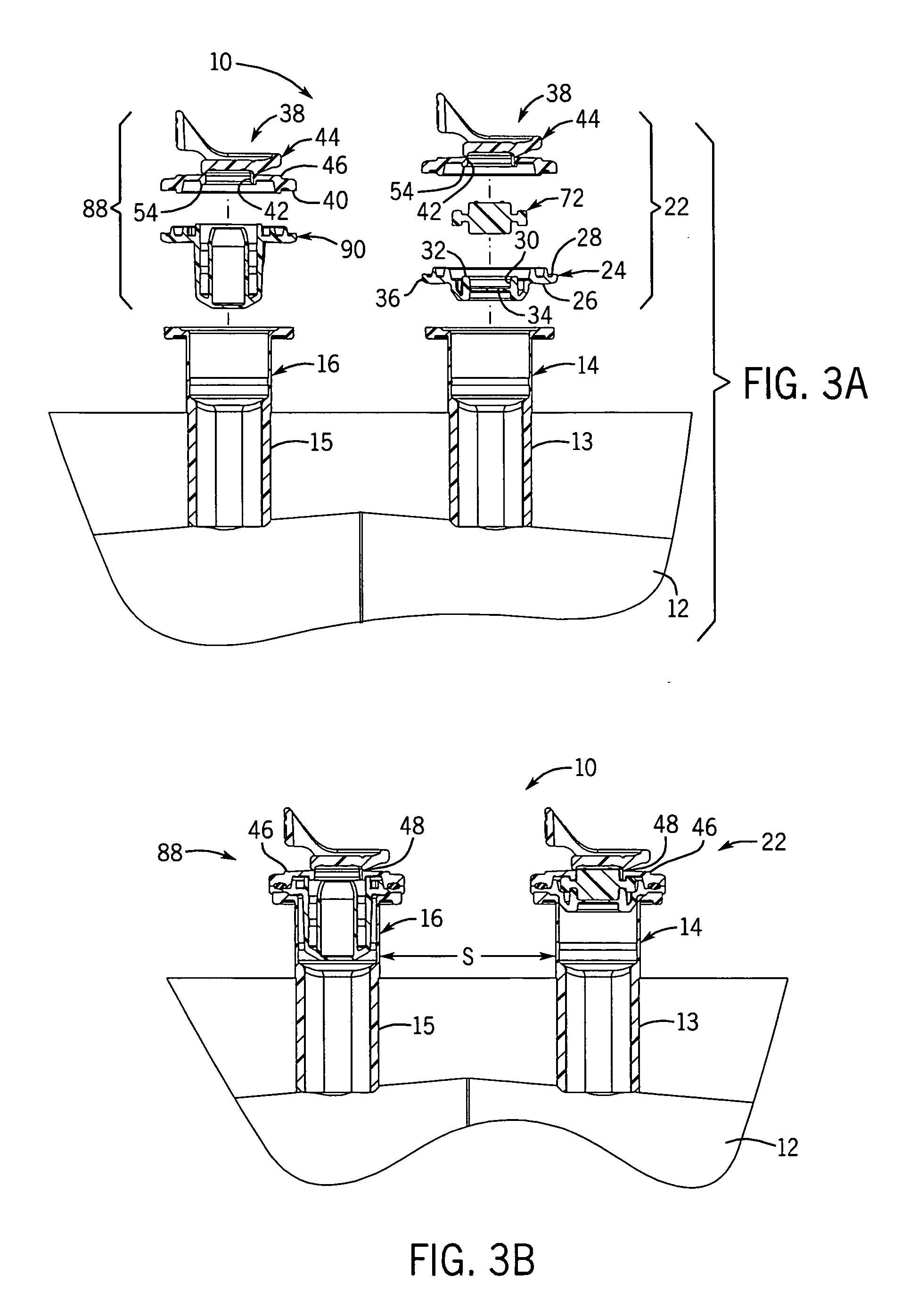

Medical fluid container

ActiveUS7527619B2Facilitate reliable fabrication and useLow moisture vapor transmission rateDiagnosticsSurgeryPolyolefinMoisture vapor transmission rate

A flexible non-PVC, non-DEHP container or bag for medical fluids has a container body formed of a multiple layer polyolefin film. The container has one or more ports equipped with a polyolefin fill tube and port closure assembly. The container has a low moisture vapor transmission rate.

Owner:HOSPIRA

Selectively permeable protective structure and articles therefrom

An article comprising a selectively permeable membrane supported on a support is disclosed wherein the article has moisture vapor transmission rate of at least 1800 g / m2 / 24 h and the selectively permeable membrane comprises a composition comprising an organic acid-modified ionomer.

Owner:DOW GLOBAL TECH LLC

Durable, liquid impermeable and moisture vapor permeable carpet pad

A carpet pad comprises a two-layer structure of a cushion and a barrier film formed of a synthetic polymeric material free of any fibrous substrate laminated thereto. The barrier film may be directly bonded to the cushion or bonded thereto using a layer of adhesive. The carpet pad is simultaneously impermeable to liquid deposited onto the pad from above the barrier film and permeable to moisture vapor at a moisture vapor transmission rate of at least 14.6 grams per square meter per twenty-four hours (14.6 g / m2 / 24 hours). The carpet pad is sufficiently durable to maintain liquid impermeability as measured by a Vetterman Drum Wear Test / Staining / Stain Cleaning Test after at least ten thousand cycles or under a pressure of at least eight pounds per square inch (0.56 kg per square meter) as measured by a Modified Mullen Bursting Strength Test.

Owner:LOWES CO INC

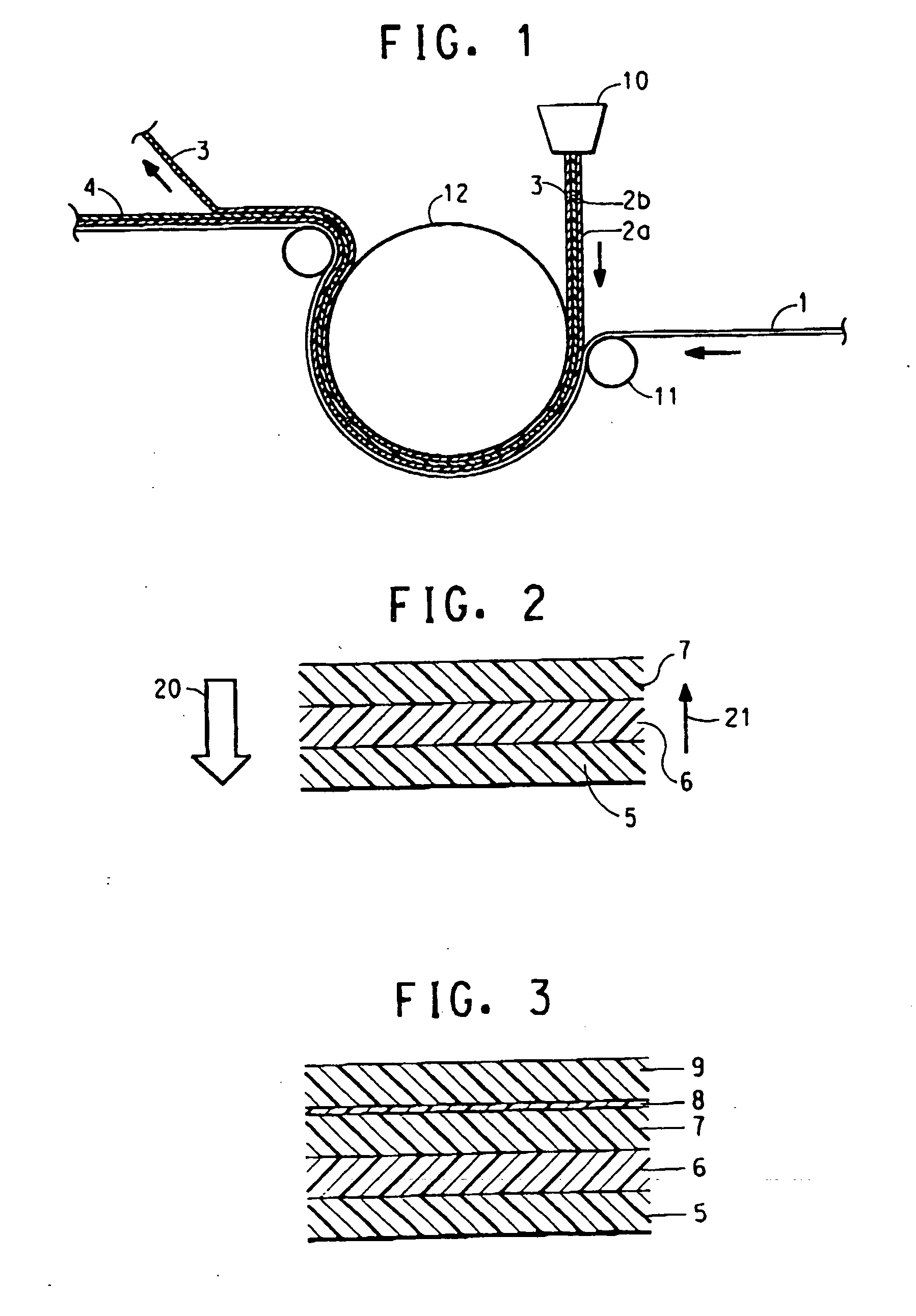

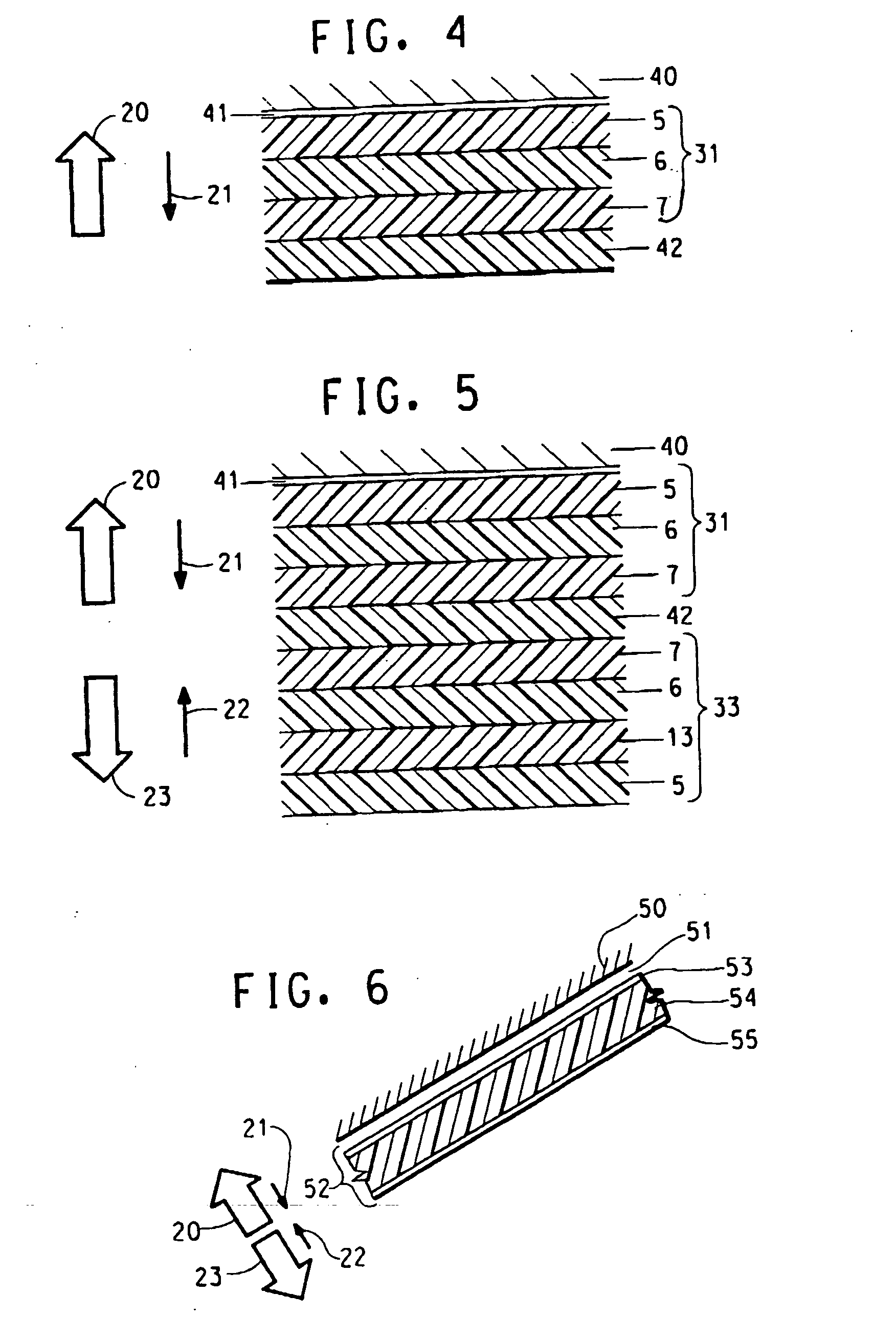

Laminate structure

InactiveUS20070087640A1Synthetic resin layered productsConstructions elementsControl layerMoisture vapor transmission rate

A substantially liquid impermeable moisture vapor permeable laminate structure comprising: (i) a substrate layer comprising a woven or non-woven material, (ii) a moisture vapor control layer attached to said substrate, (iii) a tie layer comprising one or more copolymers comprising from about 30 to about 90 weight percent ethylene co-monomer units and from about 10 to about 70 weight percent vinyl acetate co-monomer units, and (iv) a layer comprising one or more copolyetherester(s) in an amount of at least 50 weight percent based on the total amount of polymer in the layer. The moisture vapor transmission rate (MVTR) in the direction away from the copolyetherester-containing layer and tie layer and towards the substrate is preferably greater than the MVTR in the direction away from the substrate layer and towards the tie layer and copolyetherester-containing layer.

Owner:ALBERTONE YANNICK +3

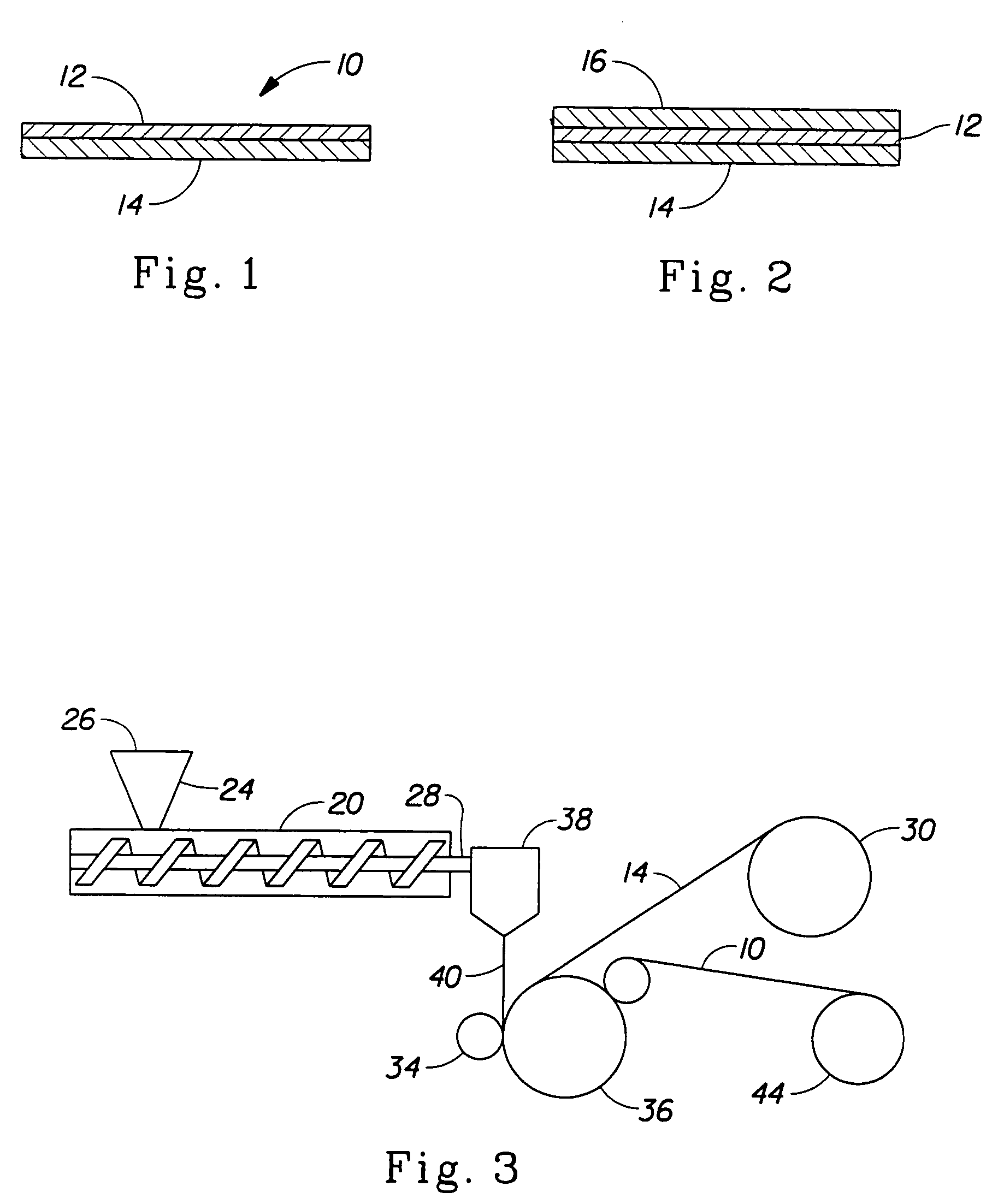

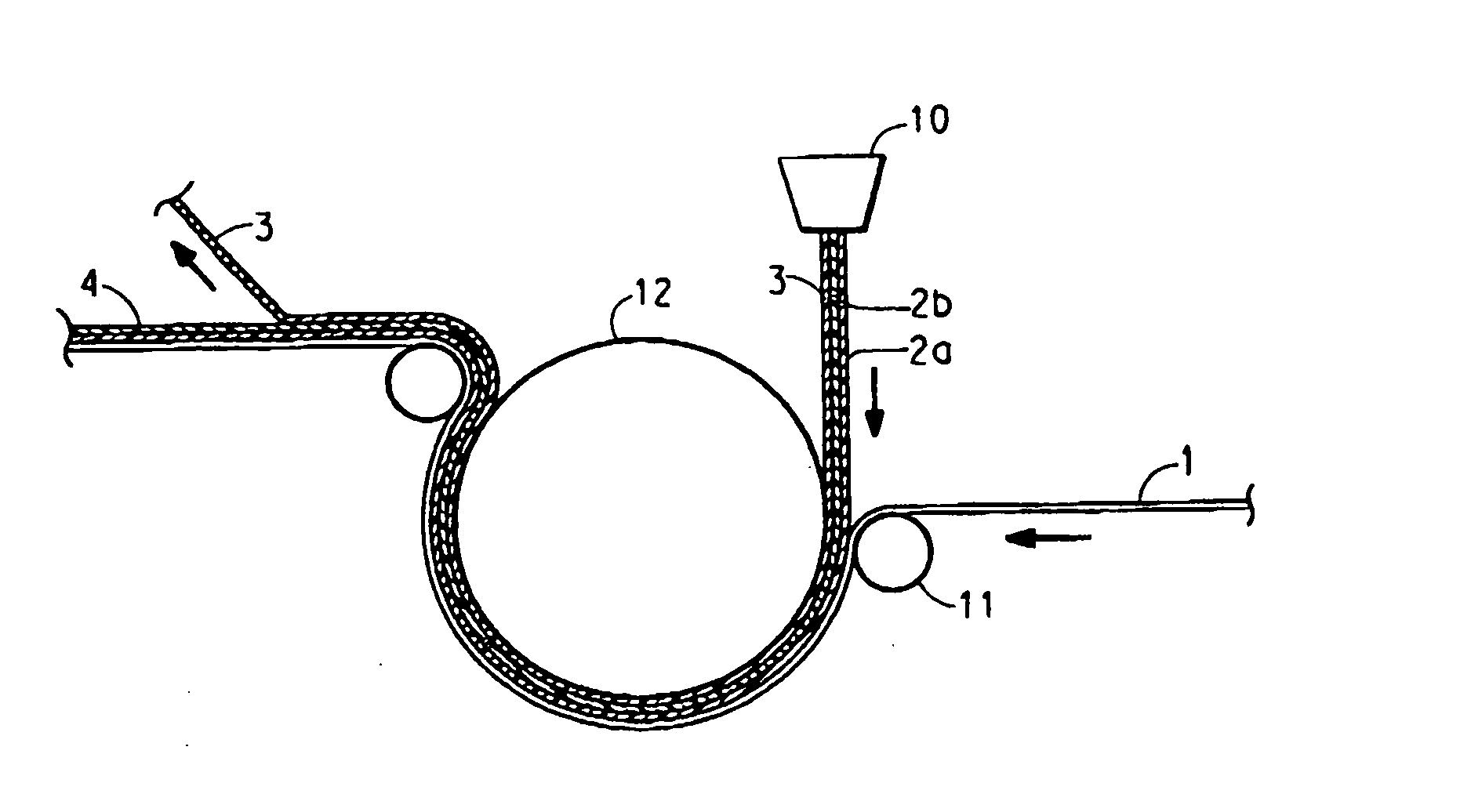

Microporous composite sheet material

InactiveUS7972981B2High strengthImprove barrier propertiesFilament/thread formingMonocomponent polypropylene artificial filamentPolymer sciencePolyolefin

A moisture vapor permeable, water impermeable composite sheet material is provided which is suitable for use as a housewrap material, and is also useful for other applications such as tarpaulins, or as covers for automobile, boats, patio furniture or the like. The composite sheet material includes a nonwoven substrate and an extrusion-coated polyolefin film layer overlying one surface of the substrate. The nonwoven substrate is comprised of polymeric fibers randomly disposed and bonded to one another to form a high tenacity nonwoven web. The nonwoven substrate has a grab tensile strength of at least 178 Newtons (40 pounds) in at least one of the machine direction (MD) or the cross-machine direction (CD). The extrusion coated polyolefin film layer is intimately bonded to the nonwoven substrate. The film layer has micropores formed therein to impart to the composite sheet material a moisture vapor transmission rate (MVTR) of at least 35 g / m2 / 24 hr. at 50% relative humidity and 23° C. and a hydrostatic head of at least 55 cm. In one embodiment, the nonwoven substrate comprises a spunbonded nonwoven fabric formed of randomly disposed substantially continuous polypropylene filaments. The spunbonded nonwoven fabric is an area bonded fabric in which the filaments are bonded to one another throughout the fabric at locations where the randomly disposed filaments overlie or cross one another.

Owner:FIBERWEB LLC

High Density Polyethylene Blend Films

InactiveUS20120107542A1Lower the resistance valueBottlesSynthetic resin layered productsLow-density polyethyleneMoisture vapor transmission rate

A polymer blend comprising high density polyethylene, hydrocarbon resin and nucleating agent; non-oriented film layers and non-oriented films comprising the blend; and packaging articles comprising the non-oriented film are provided. The non-oriented film has normalized moisture vapor transmission rate of no greater than 0.30 g-mil / 100 in2 / day measured at about 100° F. and 90% external relative humidity. The polymer blend comprises from about 69% by weight to about 90% by weight high density polyethylene, wherein the high density polyethylene has a melt index of at least 1.0 g / 10 min and a density greater than 0.958 g / cc; from about 5% by weight to about 30% by weight hydrocarbon resin; and from about 0.01% by weight to about 1% by weight nucleating agent.

Owner:BEMIS COMPANY INC

Breathable moisture barrier for an occupant sensing system

InactiveUS6906534B2Track rapid changeBreathableVehicle seatsResistance/reactance/impedenceElectricityWater vapor

A breathable moisture barrier suitable for use in enclosing flexible electrodes, foam substrate and other electrical components within a substantially liquid impervious environment without significantly impairing the ability of electrical sensors to accurately measure temperature and humidity variations within the surrounding environment such as the seating compartment of an automobile. It is further disclosed that a breathable polymeric material having a sufficiently high moisture vapor transmission rate (MVTR) will permit water vapor to be transported across the barrier and quickly reach equilibrium within the enclosed seat sensor mat assembly and to allow the humidity compensation of the occupant sensing system to function correctly. The breathable moisture barrier of the present invention provides a sufficiently high MVTR to allow rapid humidity equilibration within the sensor mat so as to better track rapid changes in the passenger compartment environmental conditions upon starting the car and applying either air conditioning or heating.

Owner:3M INNOVATIVE PROPERTIES CO

Medical fluid container

ActiveUS20060282061A1Facilitate reliable fabrication and useLow moisture vapor transmission rateDiagnosticsSurgeryPolyolefinMoisture vapor transmission rate

A flexible non-PVC, non-DEHP container or bag for medical fluids has a container body formed of a multiple layer polyolefin film. The container has one or more ports equipped with a polyolefin fill tube and port closure assembly. The container has a low moisture vapor transmission rate.

Owner:HOSPIRA

Thick inner cover multi-layer golf ball

A golf ball including a core having a diameter of 0.5 inches to 1.4 inches, a compression of about 45 or less; and a coefficient of restitution of from 0.730 to 0.810; a cast polyurea cover; and an intermediate layer disposed between the core and the cover, the intermediate layer having a thickness of 0.11 inches or greater and being formed from a composition including a highly-neutralized acid polymer having a moisture vapor transmission rate of 8 g·mil / 100 in2 / day or less; wherein a combination of the core and the intermediate layer results in a compression of from about 70 to about 100, and the golf ball has a coefficient of restitution of from 0.805 to 0.820 when measured at an incoming velocity of 125 ft / s and greater than 0.75 when measured at an incoming velocity of 160 ft / s, and a compression of from 75 to 105.

Owner:ACUSHNET CO

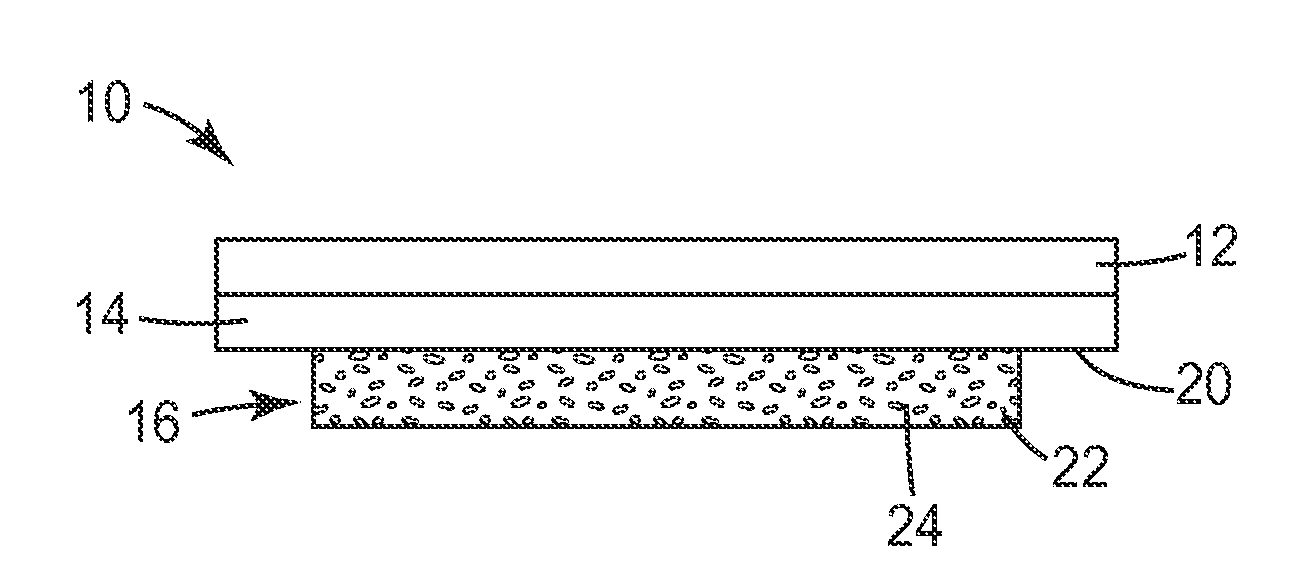

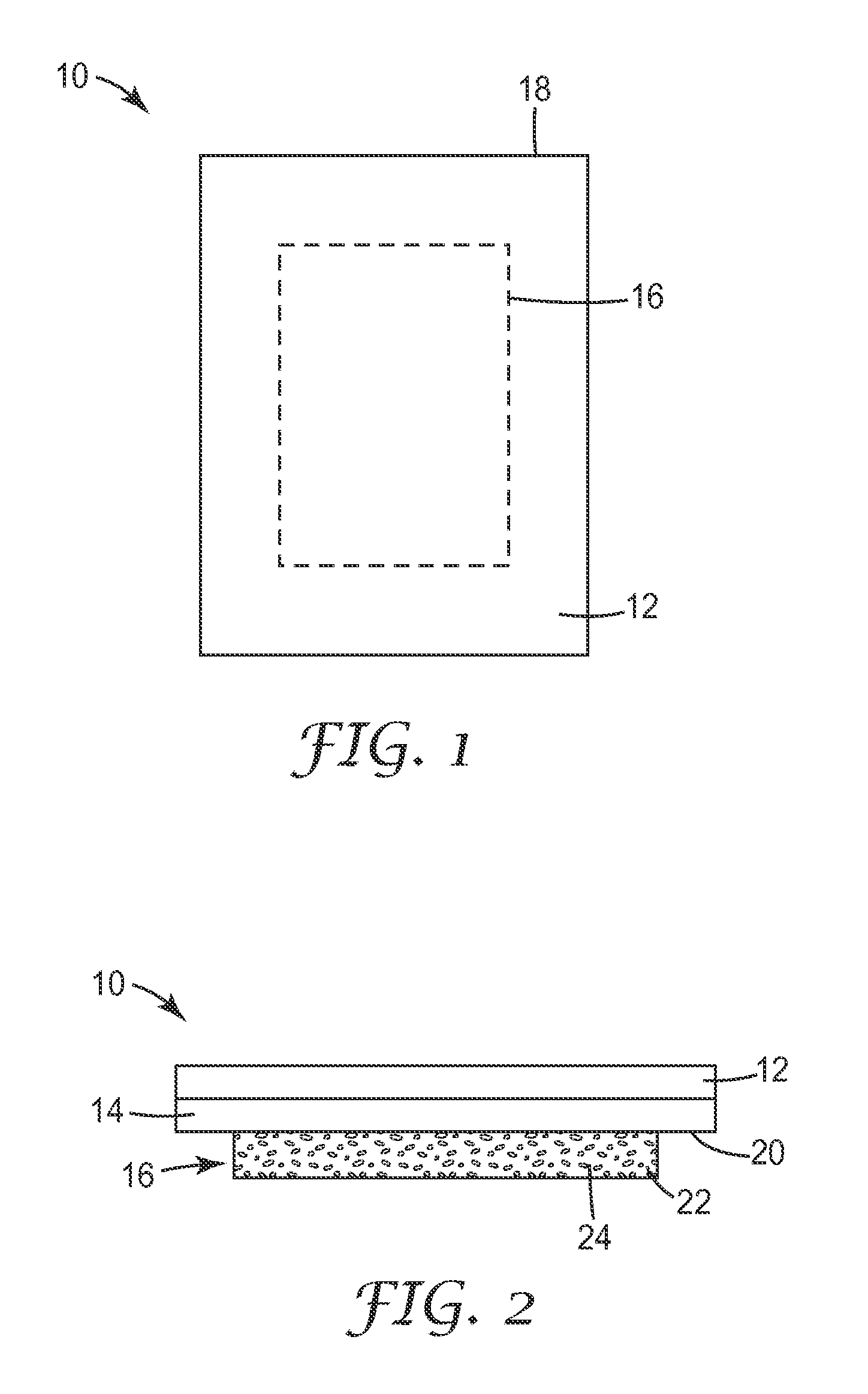

Medical articles and methods of making using immiscible material

ActiveUS20110112457A1Improve moisture vapor transmission rateHigh MVTRLamination ancillary operationsPolyureas/polyurethane adhesivesWound dressingMoisture vapor transmission rate

Provided are medical articles (e.g., wound dressings) that include a pressure sensitive adhesive layer and methods of making the medical articles using immiscible materials that increase moisture vapor transmission rates.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com