Solar panel including a low moisture vapor transmission rate adhesive composition

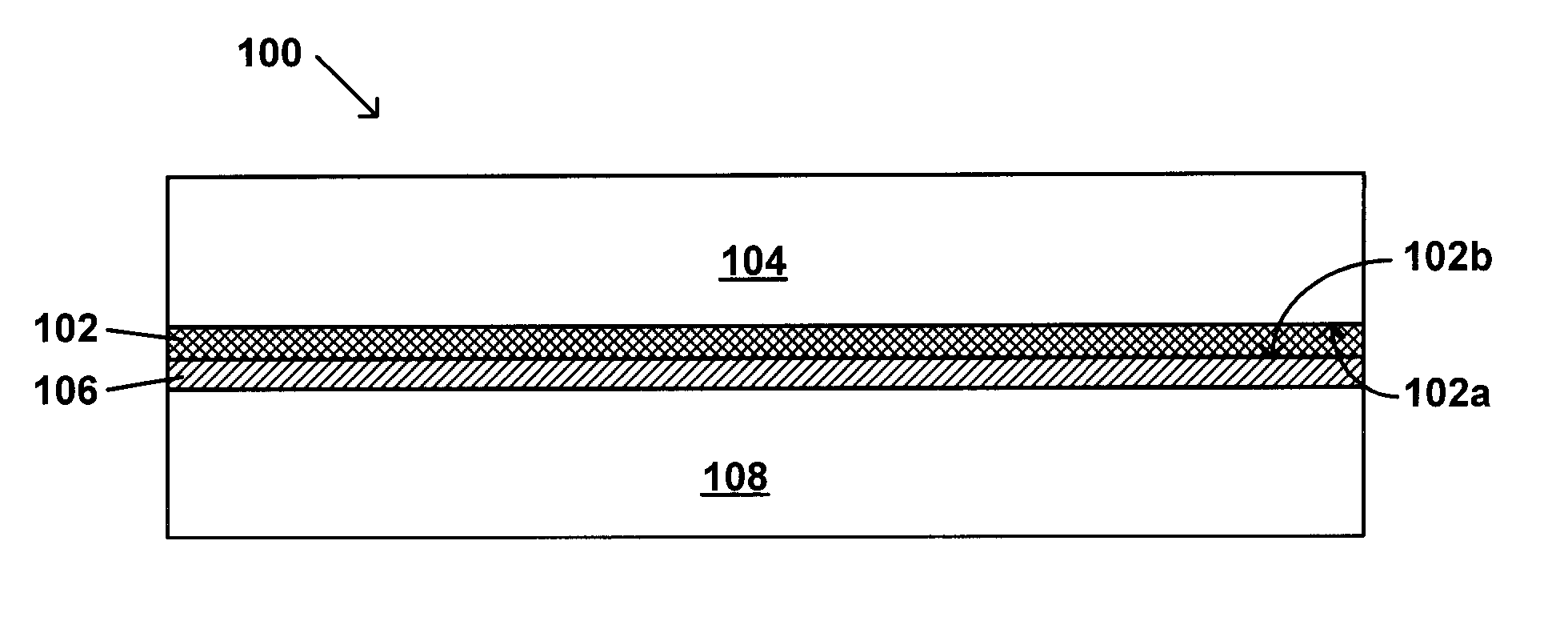

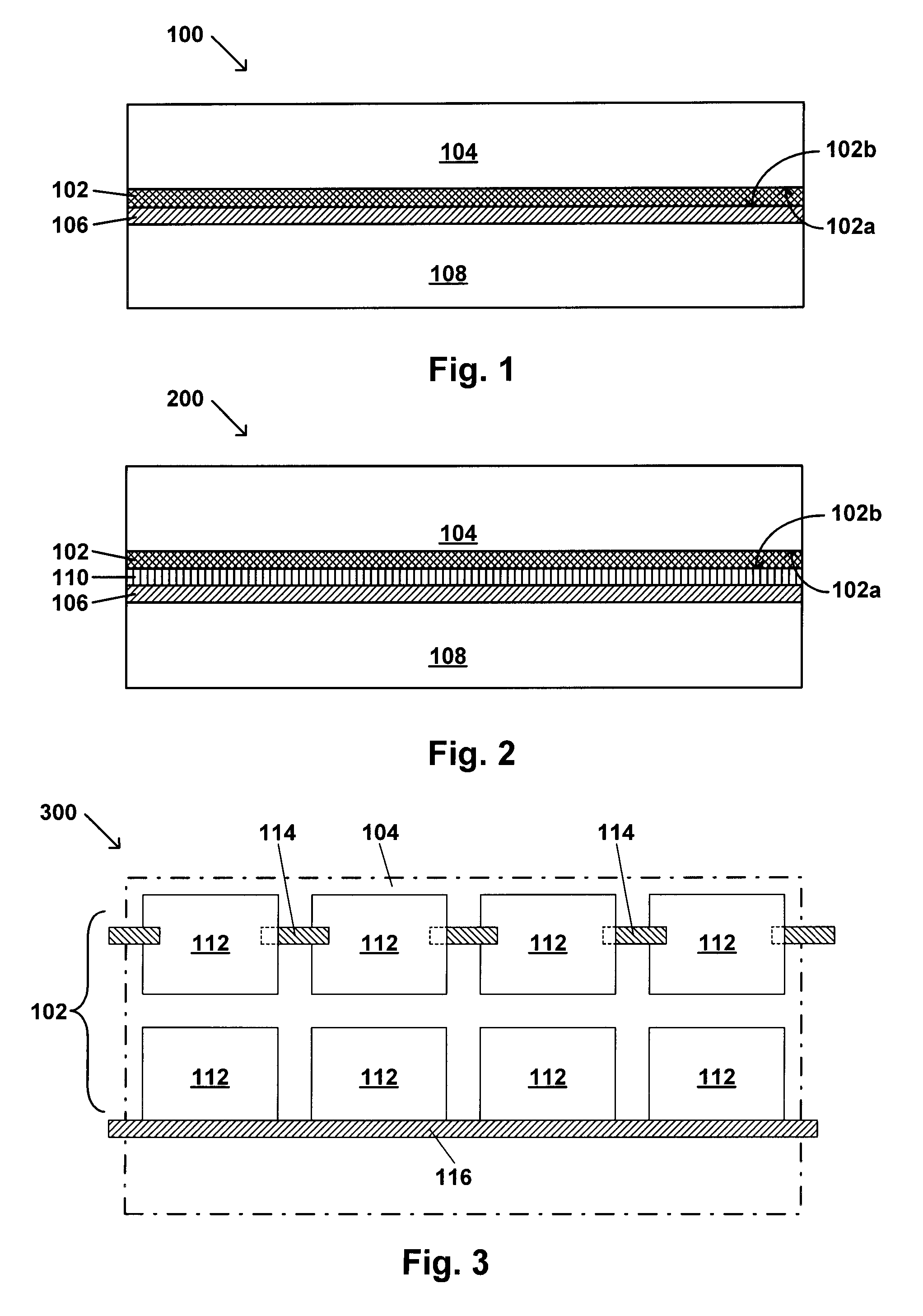

a technology of solar panels and adhesive layers, applied in the field of solar panels, can solve the problems of long-standing water penetration into solar panels, failure of the adhesive layer, deleterious effects of solar panels, etc., and achieve the effect of prolonging protection, strengthening strength and substrate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0098] The following examples relate to the adhesive compositions for use with the solar panels of the present invention, their formulation and testing. While the tests are applied to test panels, they are considered to be fully applicable to the solar panels described herein. In each case, the indicated formulations are prepared from the indicated source materials in the manner described above, that is, generally in the absence of moisture with appropriate mixing. These examples are illustrative and not intended to be limiting in scope.

formulation examples

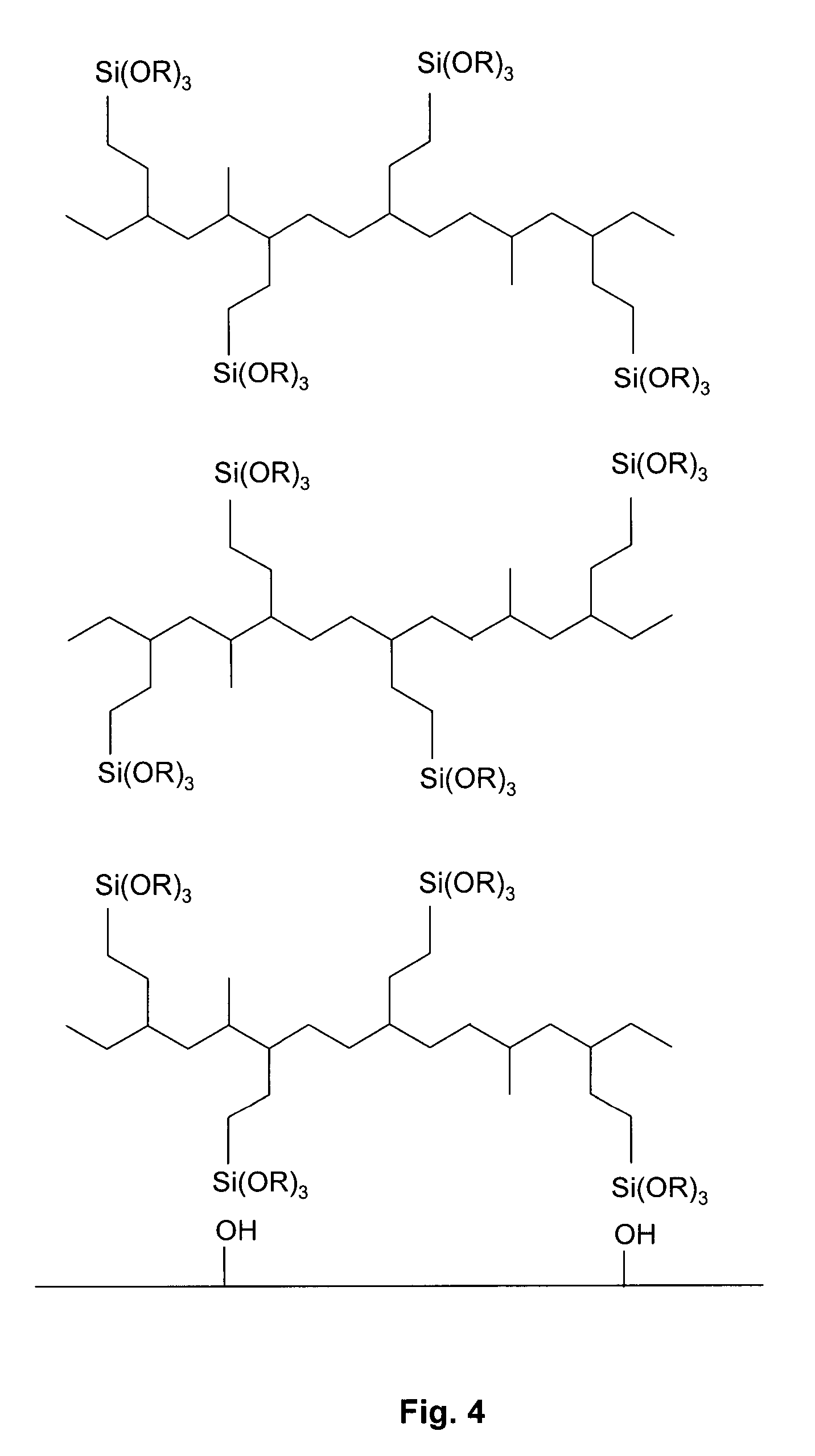

[0099] The following formulation examples include a low MVTR polymer and a silane-modified APAO in accordance with the present invention:

IngredientABCDEPolyisobutylene Rubber16.000.0010.0033.0010.00Filler34.000.000.0033.0080.00Hydrocarbon Resin10.000.000.000.000.00Semi-solid PIB6.0010.000.000.000.00Silane0.200.000.000.000.00Catalyst0.050.000.000.050.05Silane-modified APAO34.0090.0090.0034.0010.00TOTAL100.25100.00100.00100.05100.05IngredientFGHIJPolyisobutylene Rubber10.0010.000.0010.0010.00Filler30.0030.0033.0045.0040.00Hydrocarbon Resin5.0025.0015.00010.00Semi-solid PIB5.000.0018.000.005.00Silane0.200.000.000.000.20Catalyst0.050.050.050.050.05Silane-modified APAO50.0035.0034.0045.0035.00TOTAL100.25100.05100.05100.05100.00

[0100] The materials used in the foregoing Formulation Examples are the following:

Polyisobutylene RubberBUTYL ® 268(isobutylene-isoprene copolymer)FillerCaCO3Hydrocarbon ResinFORAL ® 85 orECR 158Semi-solid PIBOPPANOL ® B-12 (polyisobutylene)SilaneSILQUEST ® A11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elevated temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com