Method for controlling wafer ion implantation dosage

A technology of ion implantation and control method, which is applied in the field of dose control of wafer ion implantation, and can solve problems such as linear motor speed error and ion source instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

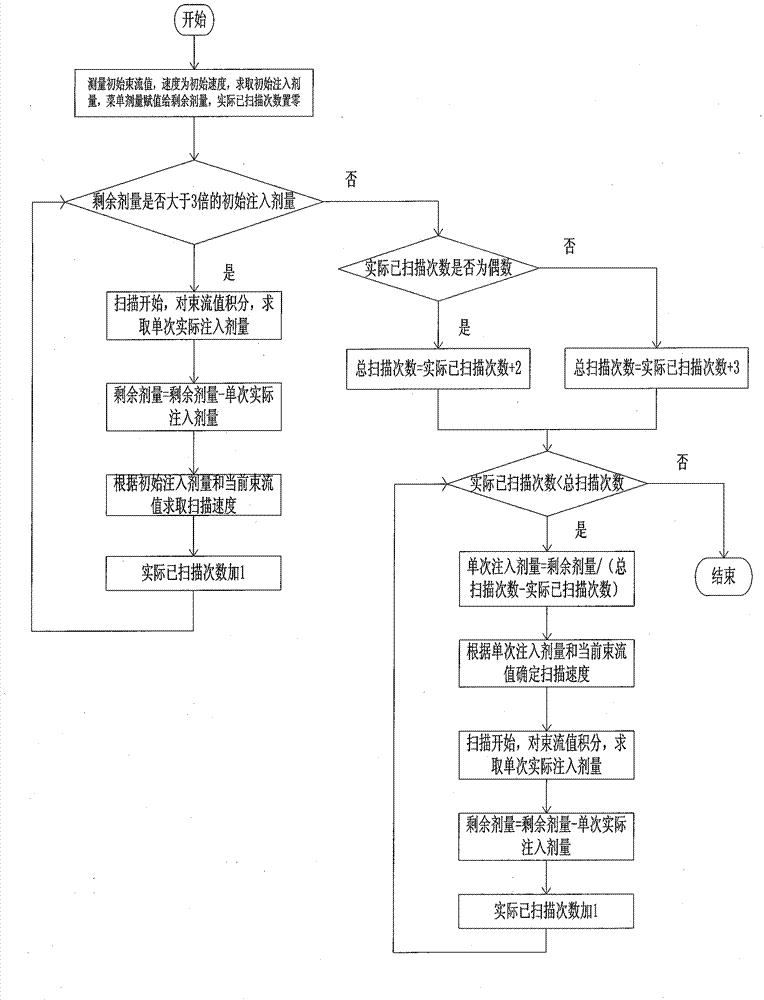

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

[0009] The present invention will be further introduced below according to the accompanying drawings and specific examples, but not as a limitation to the present invention.

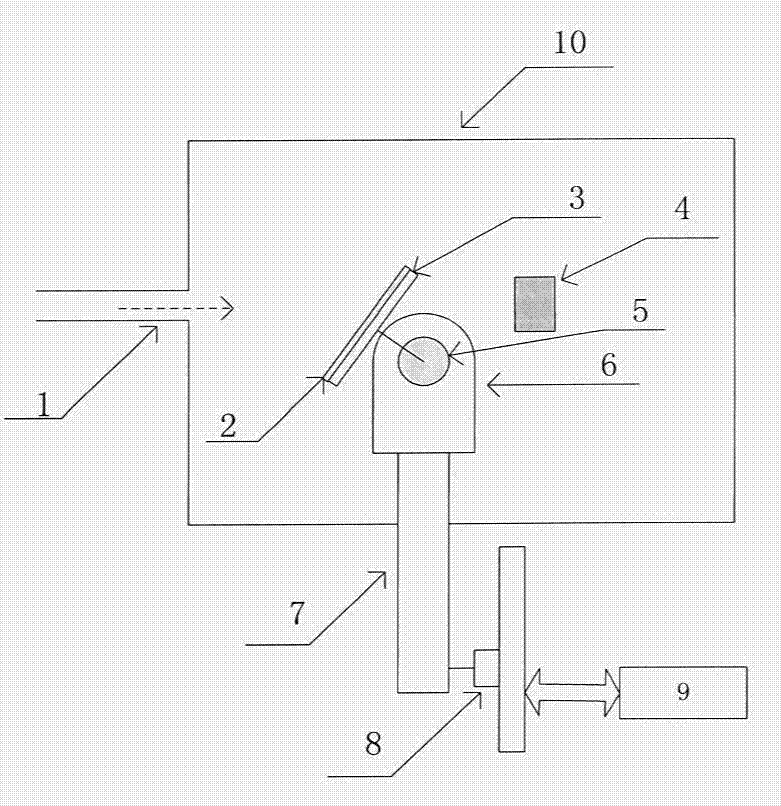

[0010] Such as figure 1 As shown, the hardware device for dose control of wafer ion implantation includes: ion beam current (1), wafer (2), target disc (3), closed-loop Faraday cup (4), X-Tilt motor (5), target stage (6 ), air bearing (7), linear motor (8), PMAC controller (9), target chamber (10). In order to ensure the purity of the ion beam, the environment for wafer implantation must be high vacuum, and the target chamber is a high vacuum environment. The ion beam current generated from the ion source is adjusted, and the ion beam current (1) reaching the target chamber meets the requirements for uniformity and parallelism before performing scanning implantation. The linear motor (8) is at the lowermost end of the motion stroke (loading position), and the targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com