Inner shuttle pressing plate and rotating shuttle

A pressing plate and inner shuttle technology, applied in textiles and papermaking, sewing equipment, sewing machine collar mechanism, etc., can solve the problems that the thickness of the ropes cannot be completely the same, loose stitches, stagnation, etc., to reduce looseness The probability of the occurrence of the phenomenon, the smoothness of the stitches, and the effect of reducing the loosening phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

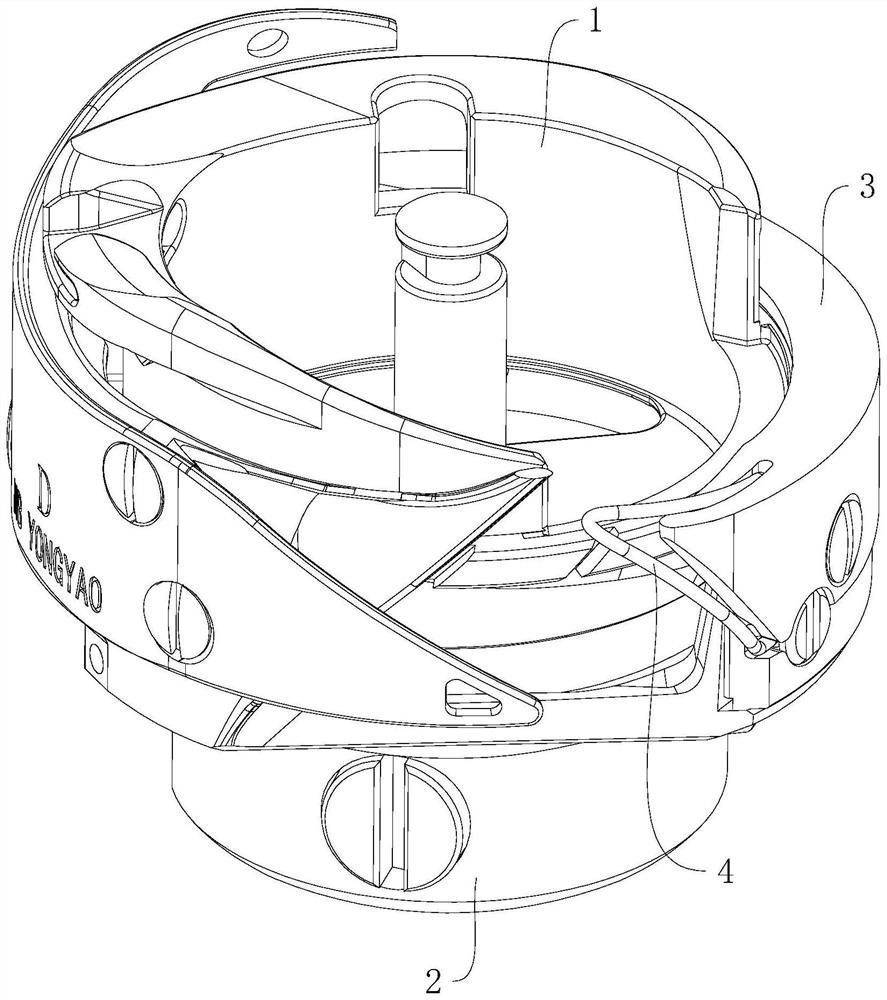

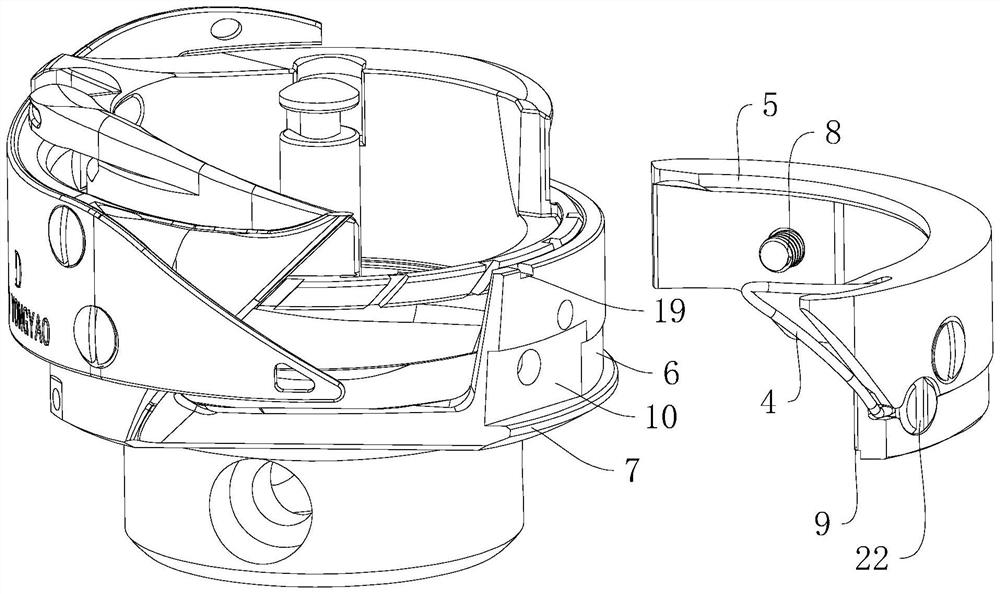

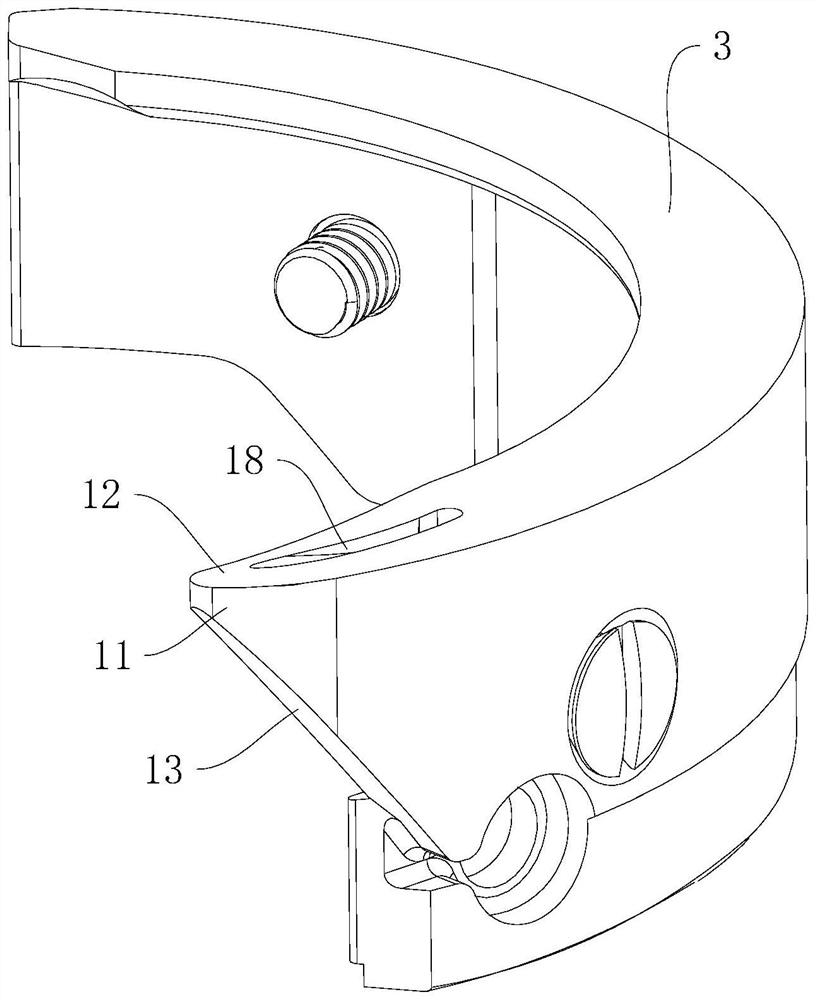

[0037] The following is attached Figure 1-4 The application is described in further detail.

[0038] see figure 1 , a rotary hook, including an inner shuttle 1, an outer shuttle 2 connected to the outer peripheral side of the inner shuttle 1 through a rotating shaft coaxially rotating, and an inner shuttle pressing plate fixed to the outer end of the outer shuttle 2 by bolts.

[0039] see figure 1 and figure 2 , the inner shuttle pressure plate includes a pressure plate body 3 and a wire spring 4, the pressure plate body 3 is in the shape of an arc plate as a whole, and the inner peripheral end surface of the pressure plate body 3 is integrally formed with a wrapping 5 on the side close to the side wall, and the wrapping 5 is perpendicular to The pressure plate body 3, when the pressure plate body 3 abuts against the outer peripheral surface of the outer shuttle 2, the wrapping 5 covers the upper end of the outer shuttle 2, the outer peripheral end surface of the outer sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com