Tapping and pouring system for molten metals

a technology of molten metal and pouring system, which is applied in the direction of molten metal pouring equipment, molten metal conveying equipment, manufacturing converters, etc., can solve the problems of material loss and safety problems, and the tendency to cause important so as to improve the situation, less oxidation and contamination of molten metal, and less alteration of molten material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] According to a first aspect, the invention concerns a system (2) for tapping and pouring high-temperature molten material, for instance for tapping molten metal from a crucible (4) and pouring it into a mould.

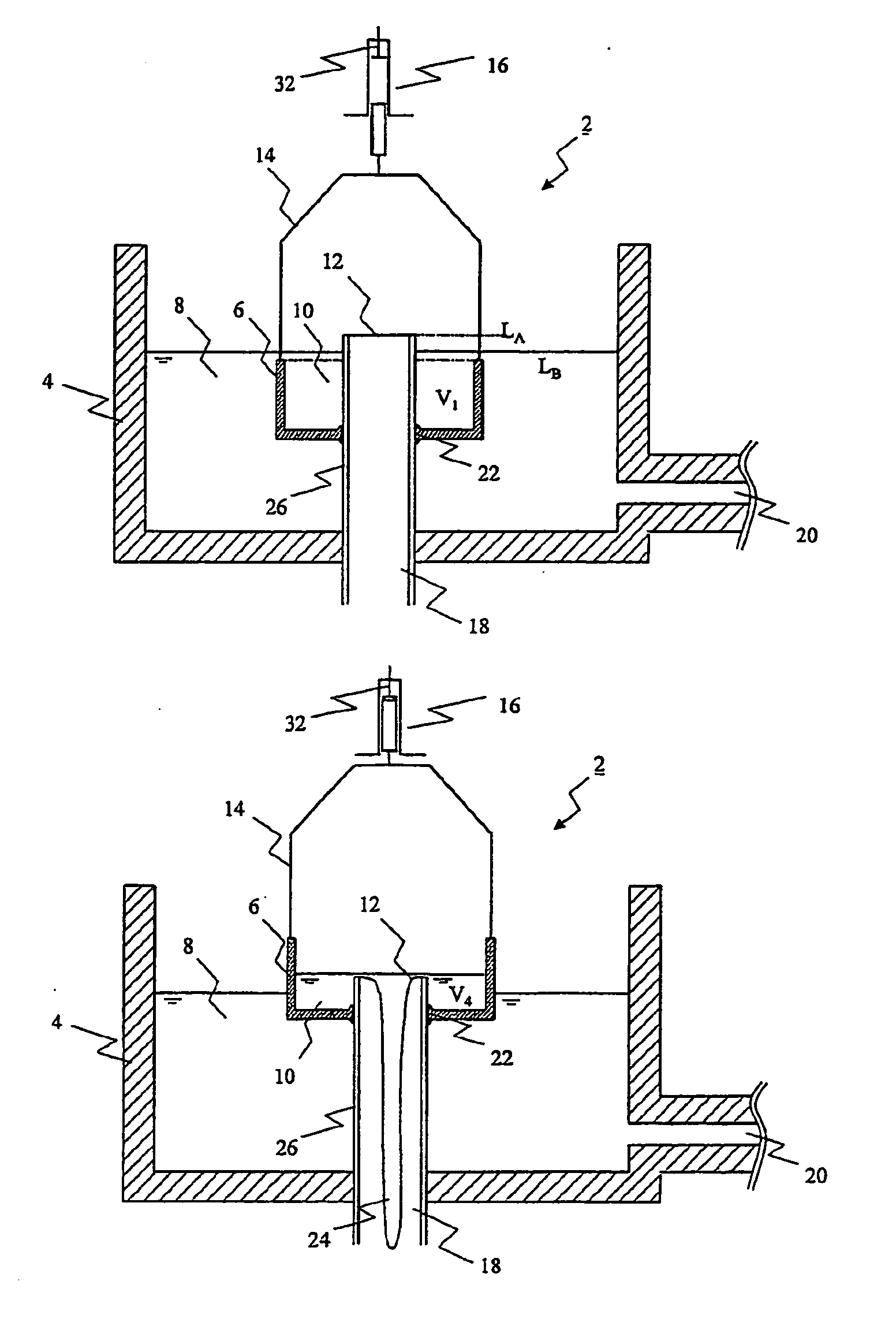

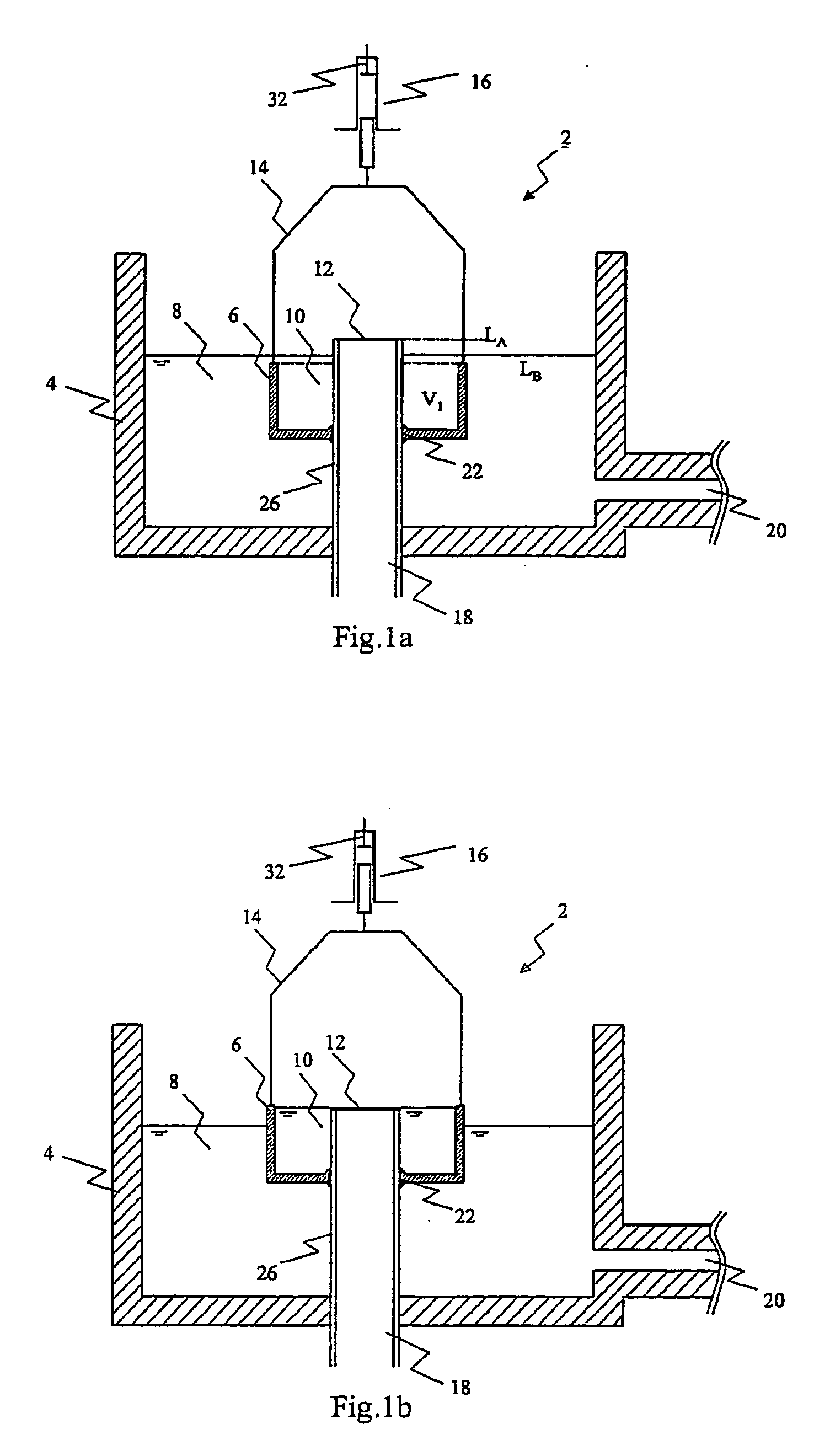

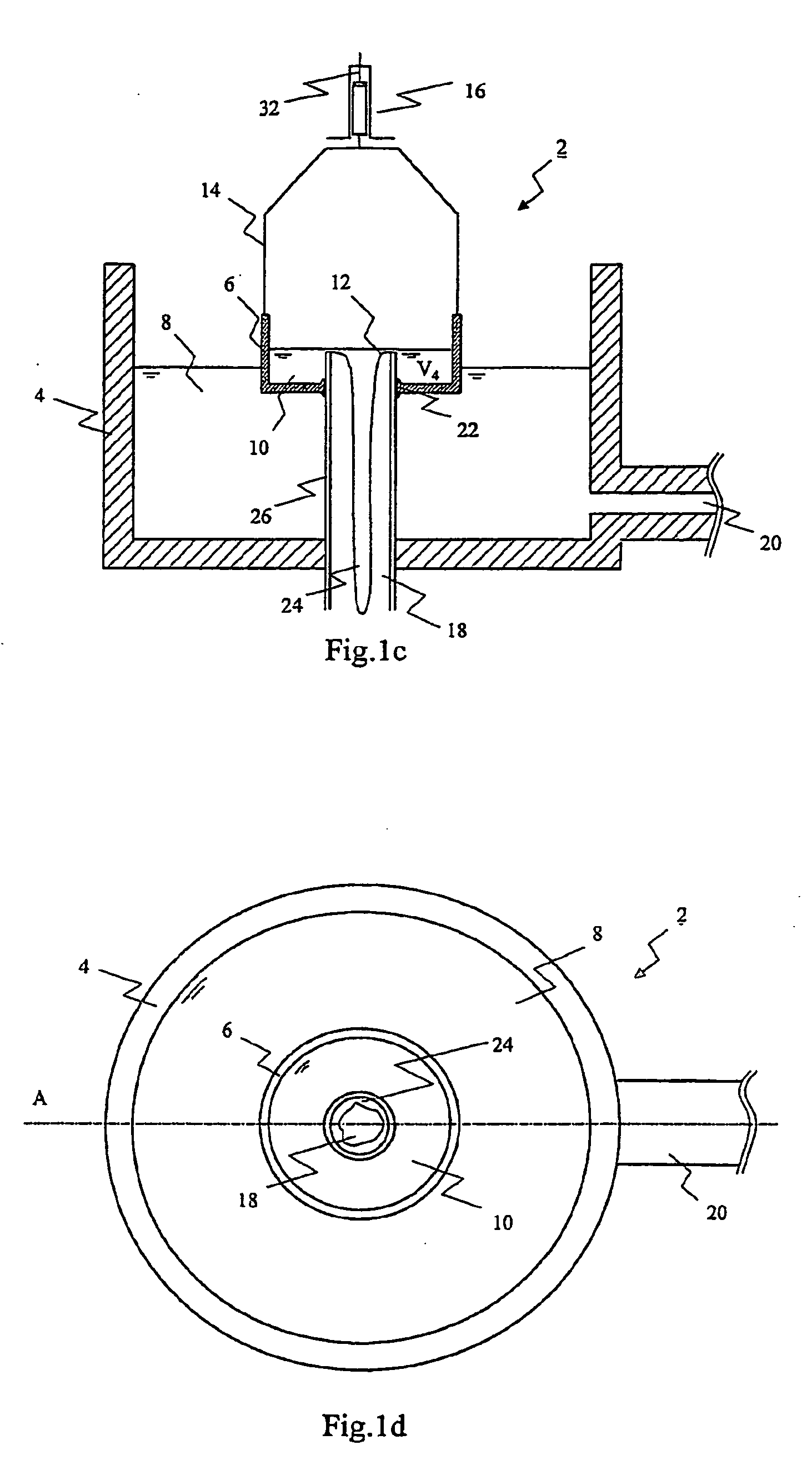

[0028]FIG. 1a shows a schematic cross-section representation of an example of the system (2) according to the invention, in operation, while the second container (6) is entirely plunged into the first container bath (8). In operation, the first container (4) or crucible contains indeed a bath (8) of molten material, for instance a molten metal, which communicates through a first channel (20) for instance with another crucible, although it will be clear for the person skilled in the art that such a communication channel (20) is neither essential nor compulsory to the invention.

[0029] A second channel (18) or hollow inner tube is located substantially inside the first container (4) and extends from above the level La of the first container bath (8) to below the bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com