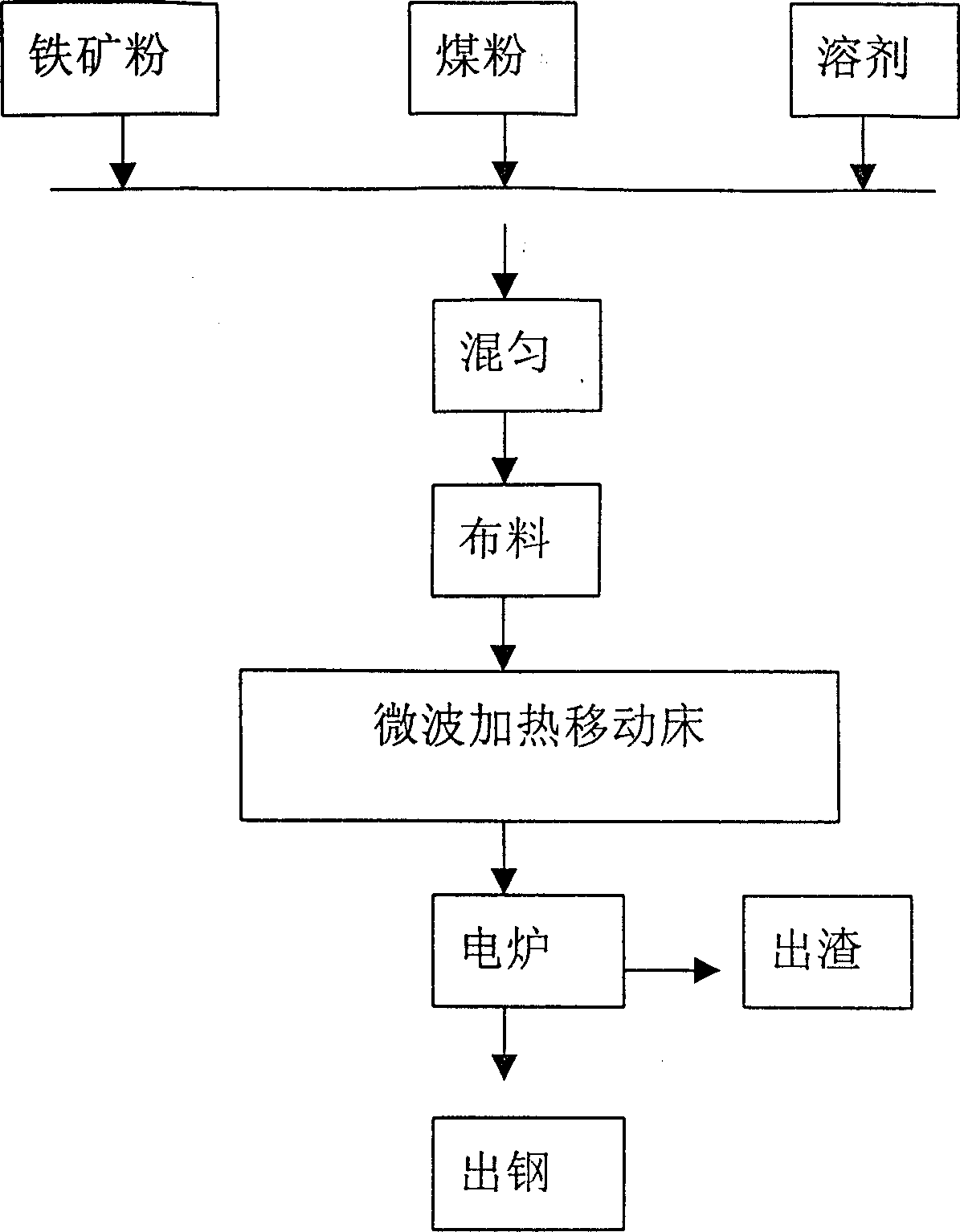

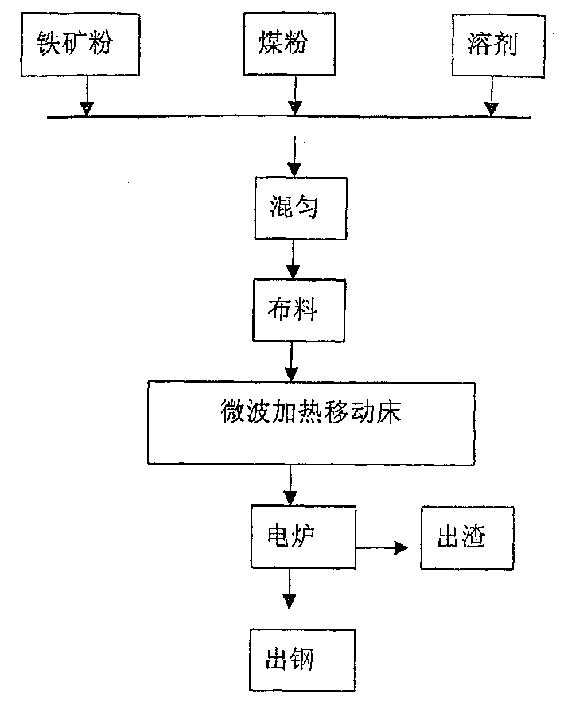

Coal-iron ore microwave reduction and electric furnace steel-making method and equipment

An iron ore and microwave technology, applied in the field of direct reduction short-process steel production, can solve problems such as pollution and scrap steel will not be alleviated, and achieve the effects of simple process, high practical value, and rational use of natural resources and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

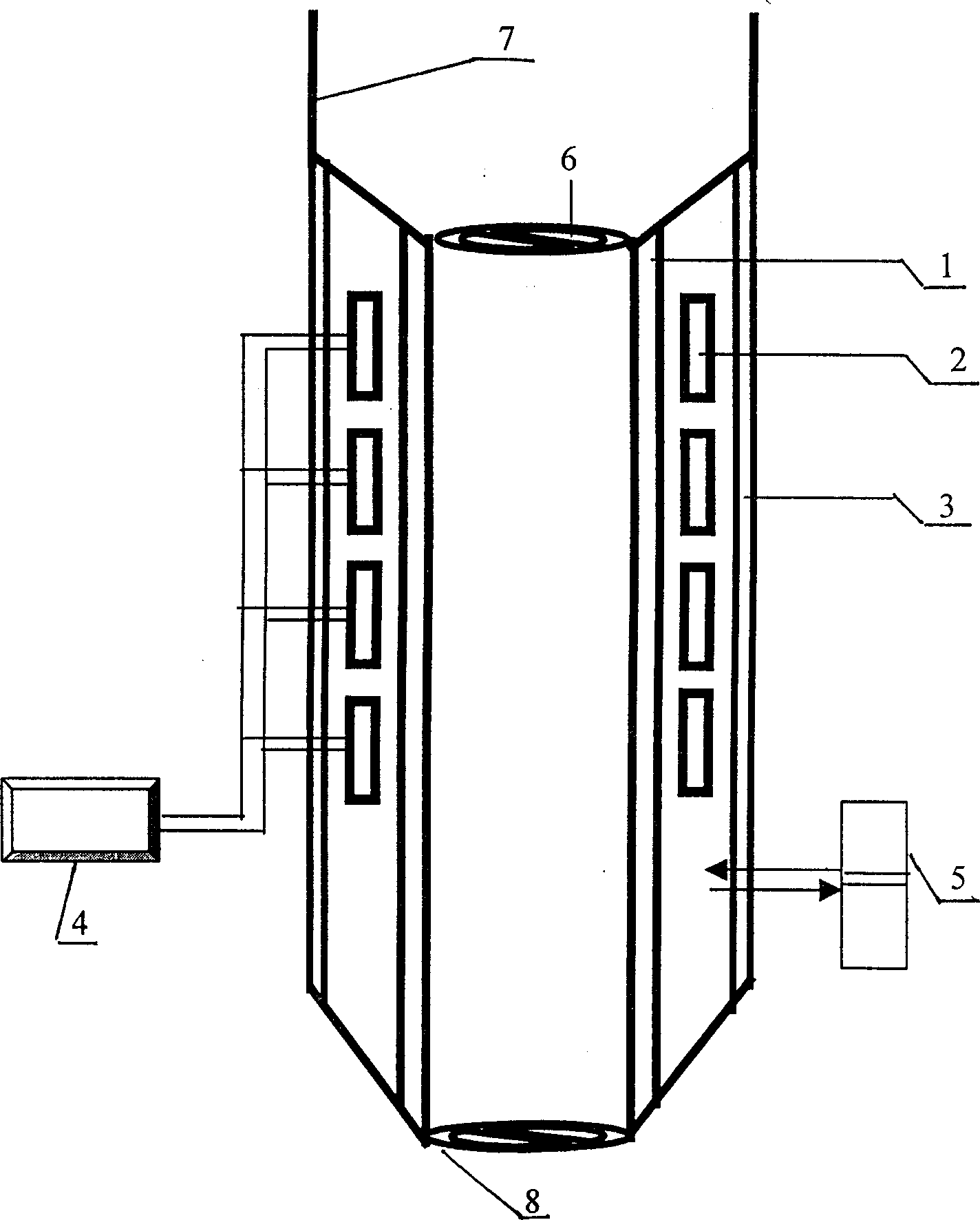

[0024] To make one ton of steel, weigh 470 kg of standard coal, 1540 kg of magnetite powder, and 225 kg of lime powder. Crush the coal and lime to a particle size of ≤3mm and mix them with powdered magnetite, then densely distribute them in the microwave heating reaction moving bed , energized and microwave-heated to 1200°C for 20 minutes, the magnetite is reduced to a reduced iron material with a metallization rate of 95%, and it is pushed into the electric arc furnace and 70 kg of standard coal is added, heated to 1500°C, smelted for 1.5 hours, Separation of steel slag to obtain 1 ton of qualified steel, water-quenched steel slag can be used as cement raw material or additive. Steel is sent to refining furnaces to smelt different steel grades.

[0025] Features of the present invention are as follows:

[0026] (1) In the smelting reduction process, it is very necessary to combine the use of primary energy and secondary energy effectively and rationally. The primary energy (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com