Four-directional grille

A grid and node technology, applied in the field of mesh plastic tensile structure, can solve problems such as easy to be damaged, not resistant to tangential force of soil layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

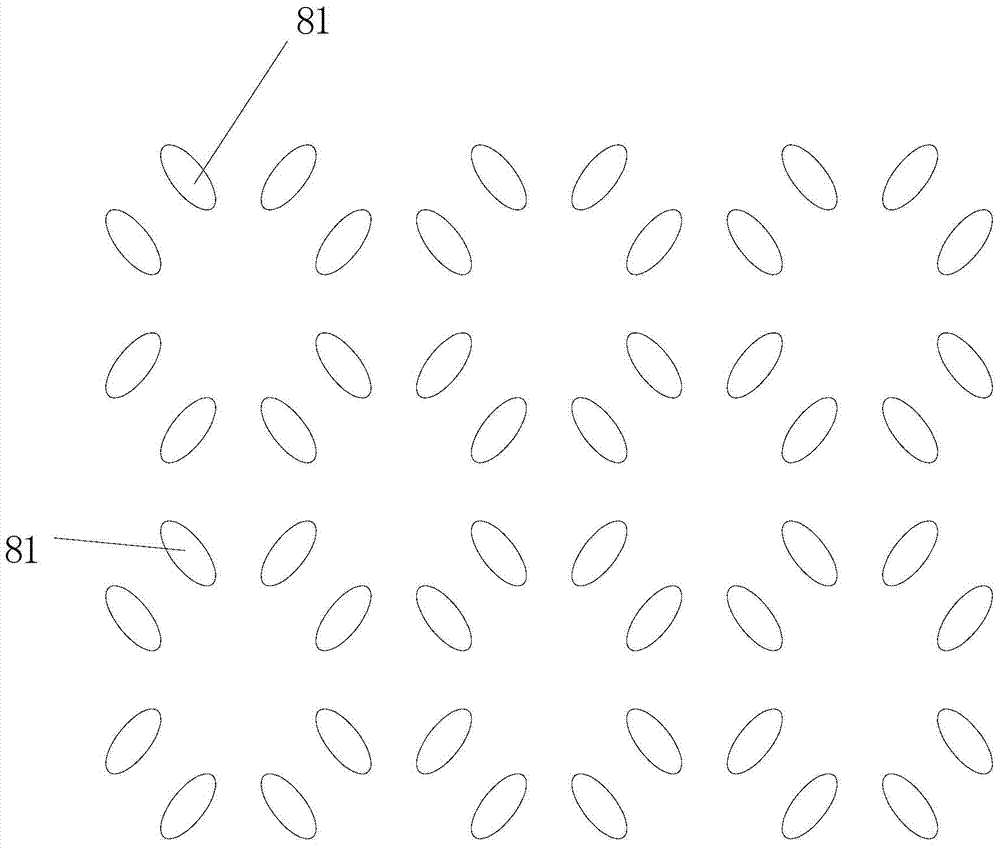

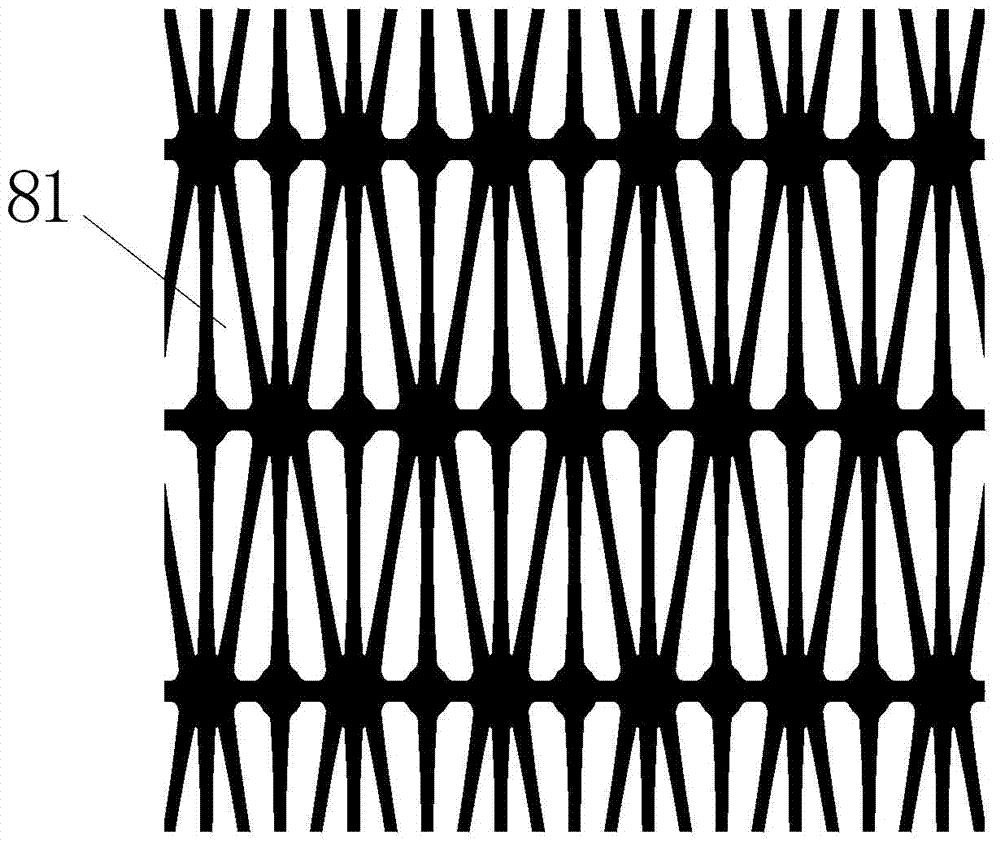

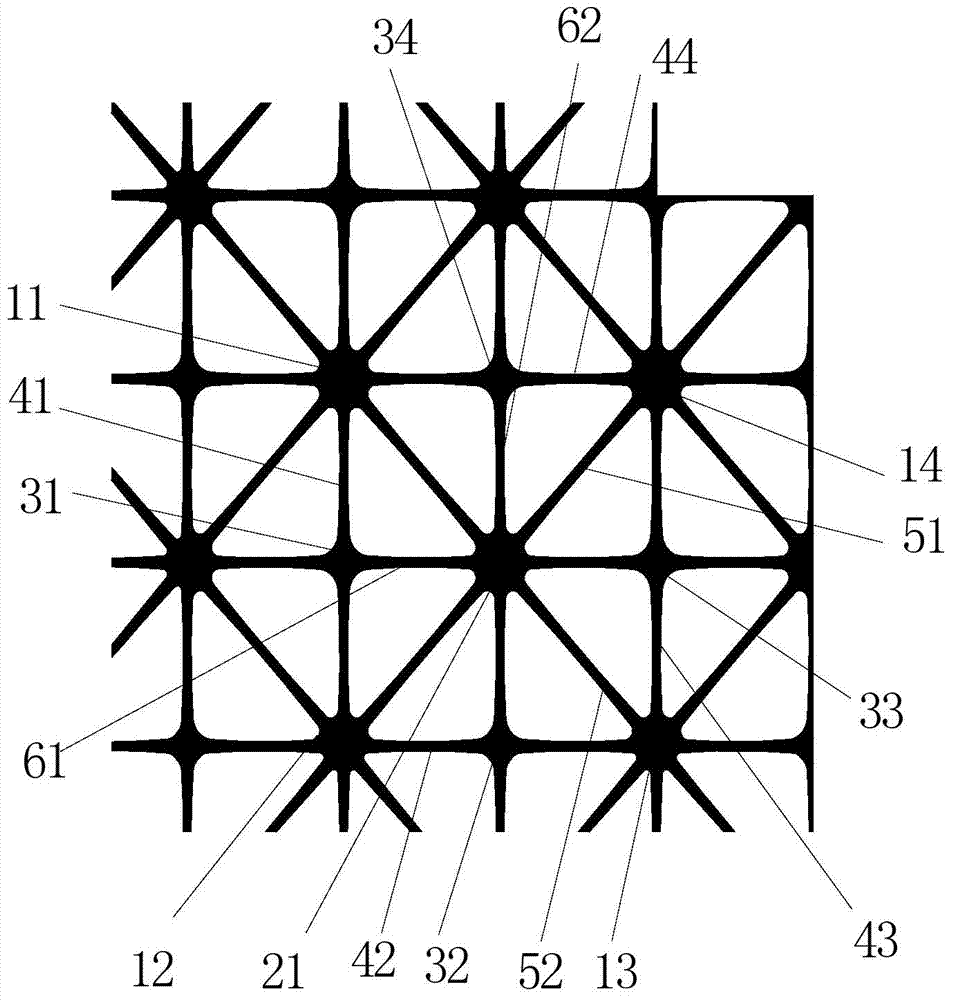

[0036] image 3 and Figure 6 Two types of four-way grids are shown respectively, and the main difference between the two types of four-way grids is that the angle of the ribs changes by 45 degrees, that is, image 3 After the four-way grille unit is rotated at an angle of 45 degrees on the plane, it forms a Figure 6 Two kinds of four-way grid units with different angles are the same or similar in structure, but in actual laying, due to the laying direction of the grid, after the four-way grid units with different angles are connected, It forms a certain position corresponding to the overall length direction or width direction of the grille, therefore, image 3 and Figure 6 The direction of the tensile force of the two kinds of four-way grilles may be different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com