Semi-continuous production line of closed-cell aluminum foam

A closed-cell aluminum foam, semi-continuous technology, applied in the field of aluminum foam production line, can solve the problems of uneven distribution of foam, difficulty in precise operation, poor fluidity of aluminum liquid, etc., to achieve simple and controllable production process and consistent performance Good, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

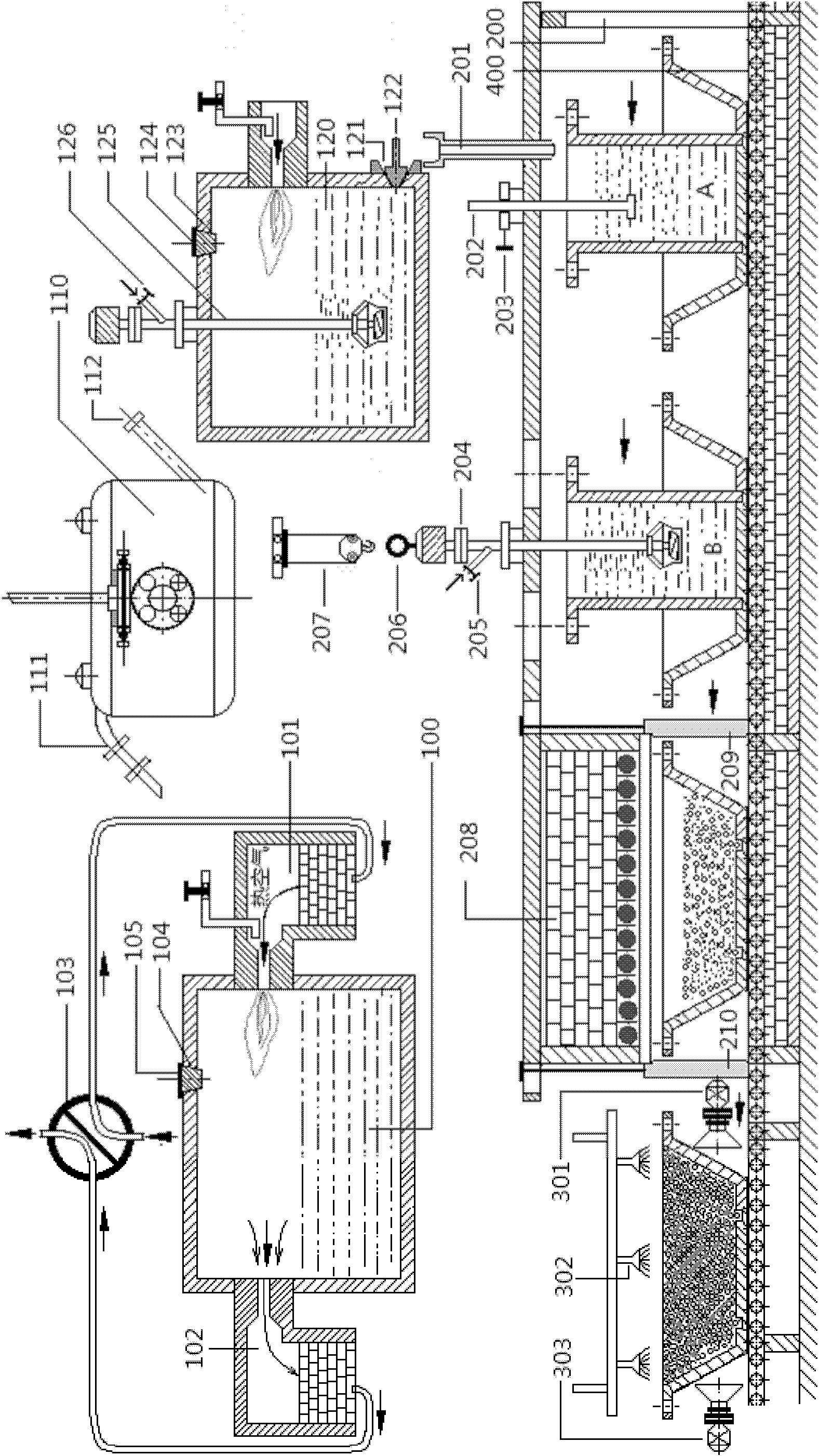

[0022] Example 1, using pure aluminum as a raw material to prepare a semi-continuous production process for closed-cell aluminum foam.

[0023] In this embodiment, calcium metal is used as a tackifier, and titanium hydride is used as a foaming agent.

[0024] The specific implementation of this embodiment includes the following steps:

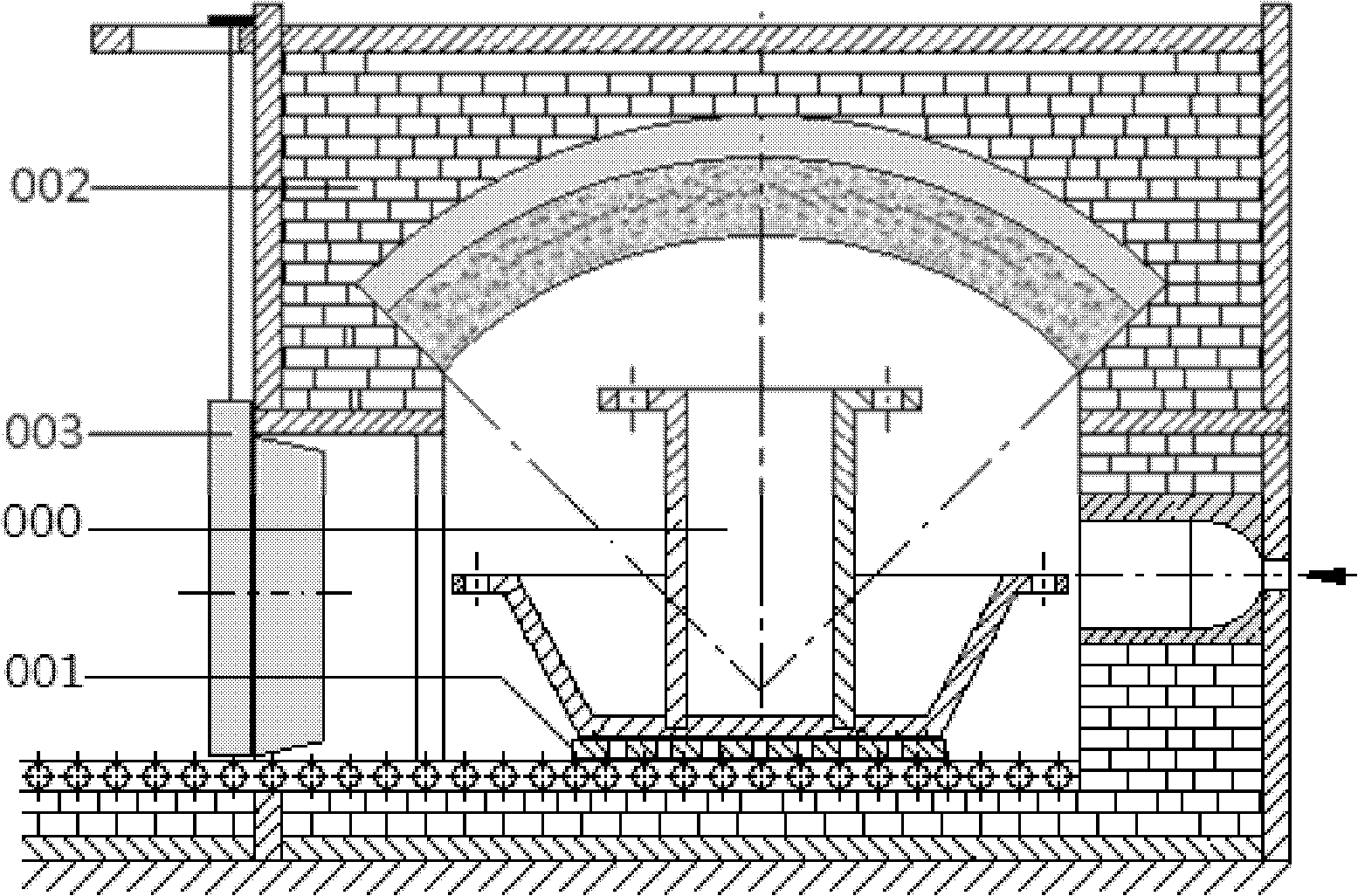

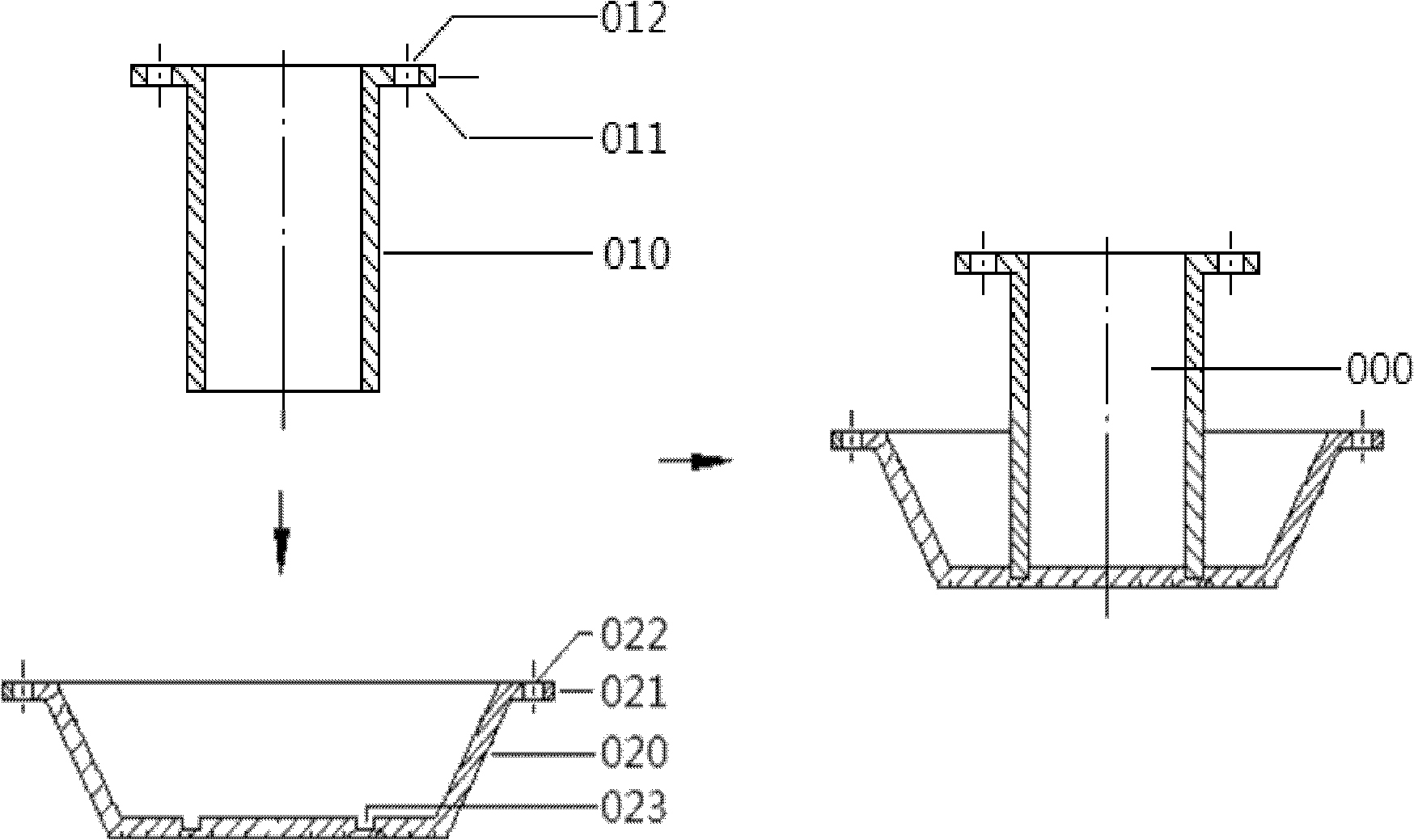

[0025] Step 1, assemble more than 000 composite molds. First place the asbestos rope soaked in high-temperature glue in the groove 023 on the bottom plate of the filling mold 020, then hoist the transition crucible 010 so that the bottom of the transition crucible 010 is embedded in the groove 023, and then, use high-temperature glue and asbestos powder The prepared paste fills the joint between the transition crucible 010 and the filling mold 020 to obtain a composite mold 000;

[0026] In the second step, preheat the composite mold 000, vacuum ladle 110, tundish 120 and foaming furnace 208. Their preheating temperatures are 680°C, 900°C, 900°...

Embodiment 2

[0036] Example 2, using ZL102 as a raw material to prepare a semi-continuous production process of closed-cell aluminum foam.

[0037] In this embodiment, calcium metal is used as a tackifier, and titanium hydride is used as a foaming agent.

[0038] The specific implementation of this embodiment is basically the same as that of Embodiment 1, the difference is the following process parameters.

[0039] ①. The preheating temperatures of composite mold 000, vacuum ladle 110, tundish 120 and foaming furnace 208 are 650°C, 900°C, 900°C, and 620°C respectively, and the preheating temperature is allowed to have a deviation of ±10°C.

[0040] ②. The melting temperature of ZL102 aluminum ingot is 780 in the melting furnace 100, and the melt is kept at this temperature. The melting and holding temperature are allowed to have a deviation of ±10°C.

[0041] 3., the tackifier calcium add-on of the present embodiment is 3%, and foaming agent add-on is 1.5%, and the time of stirring after ...

Embodiment 3

[0043] Example 3, using fly ash as a tackifier to prepare a semi-continuous production process of closed-cell aluminum foam.

[0044] In this embodiment, fly ash is used as a tackifier, zirconium hydride is used as a foaming agent, and pure aluminum is used as a raw material for production.

[0045] The specific implementation of this embodiment is basically the same as that of Embodiment 1, and the main difference with Embodiment 1 is as follows:

[0046] ①. The preheating temperature of the vacuum ladle 110 and the tundish 120 is the same as 780°C, and the preheating temperature is allowed to have a deviation of ±10°C.

[0047] ②. The melting temperature of pure aluminum ingots in the melting furnace 100 is 800, and the melt is kept warm at this temperature. The melting and holding temperatures are allowed to have a deviation of ±10°C.

[0048] 3. The amount of the tackifier fly ash added in the present embodiment is 5%; when the present embodiment proceeds to the "6th step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com