Manufacture method of rock sample with random fractures

A technology of rock samples and production methods, which is applied in the field of geotechnical engineering, can solve the problems of difficult spatial cross arrangement, inability to cut built-in cracks, and inability to make built-in rock cracks, etc., achieving the effect of simple operation method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

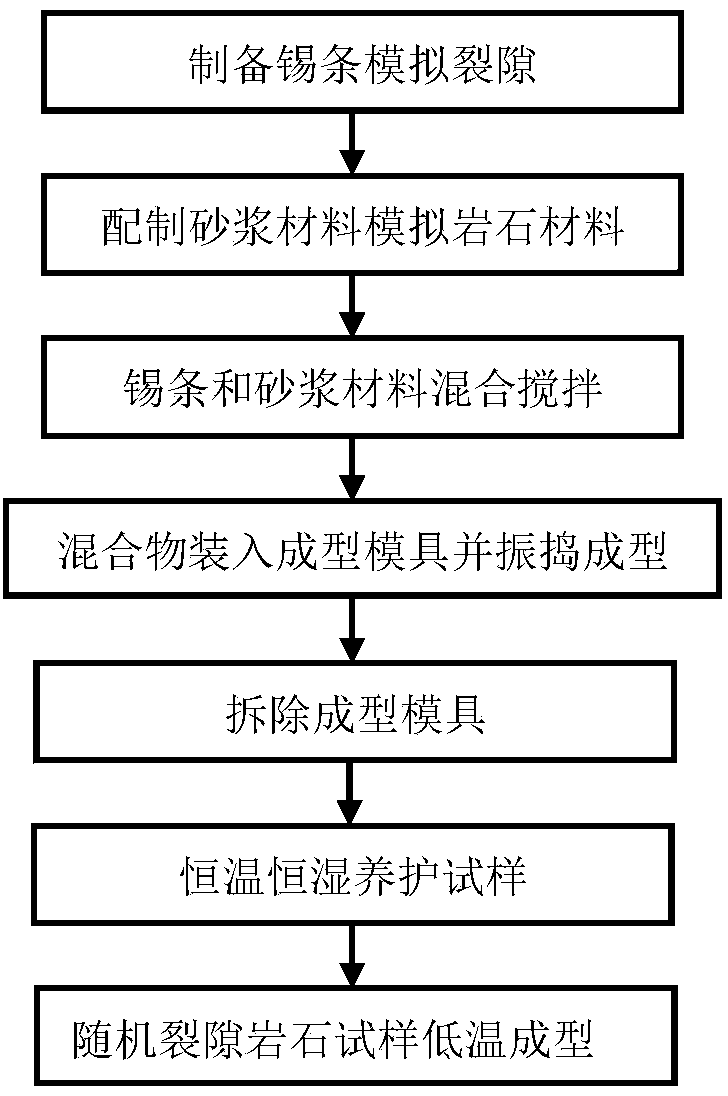

[0026] Such as figure 1 Shown, the preparation method of random fractured rock sample, the steps are as follows:

[0027] 1. Prepare tin bars to simulate cracks. The specific method is as follows:

[0028] Manually or mechanically cut metal tin at a specified temperature (temperature higher than 15°C and lower than 40°C), and process it into tin bars with a thickness of 0.5 mm, a width of 3 mm, and a length of 30 mm to 90 mm. The length distribution of the tin bars conforms to Weber Distribution (Weibull Distribution); the number of tin bars is determined according to the simulated rock fracture density;

[0029] For example: to make 100 tin strips, it is necessary to process 2 strips of 30mm and 90mm each, 6 strips of 40mm and 80mm each, 12 strips of 45mm and 75mm, 18 strips of 50mm and 80mm, and 24 strips of 60mm;

[0030] 2. Prepare mortar material to simulate rock material, the specific method is as follows:

[0031] The mortar material is prepared from 525# rapid harde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com