Halogen-free flame-retardant polypropylene master batch and preparation method thereof

A flame retardant masterbatch and polypropylene technology, which is applied in the field of polymer material processing aids and their preparation, can solve the problems of low flexibility and high production cost of polypropylene products, achieve good water resistance and desorption performance, and improve the flame retardant effect. , the effect that the flame retardant performance is not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The polypropylene halogen-free flame retardant masterbatch of this embodiment is made of the following components by weight:

[0027] 20.72kg of polypropylene resin, 74kg of halogen-free composite flame retardant (composed of 40kg of piperazine diphosphate, 20kg of pentaerythritol diphosphate melamine salt, 10kg of melamine cyanurate, 4kg of triphenyl phosphate), dispersed Antioxidant 5kg, compound antioxidant 0.28kg (made up of the antioxidant DLTDP of the antioxidant 1076 of 0.2kg and 0.08kg);

[0028] The preparation method of the above-mentioned polypropylene halogen-free flame retardant masterbatch has the following steps:

[0029] (1) The above-mentioned components will be weighed according to the formula, and mixed in a high-speed mixer until the friction heat generated by the mixing makes the temperature of the material rise to 80 ° C ~ 90 ° C, and the material is discharged to cool;

[0030] (2) Feed the cooled mixed material into the twin-screw extruder for m...

Embodiment 2~ Embodiment 6

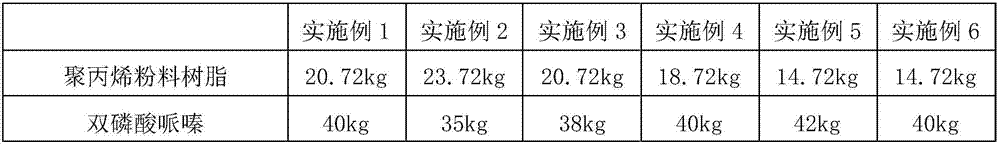

[0032] The preparation method of the halogen-free flame-retardant polypropylene material of each example is the same as that of Example 1, the difference lies in the weight ratio of each component, see Table 1 for details.

[0033] Table 1: each component formula of embodiment

[0034]

[0035]

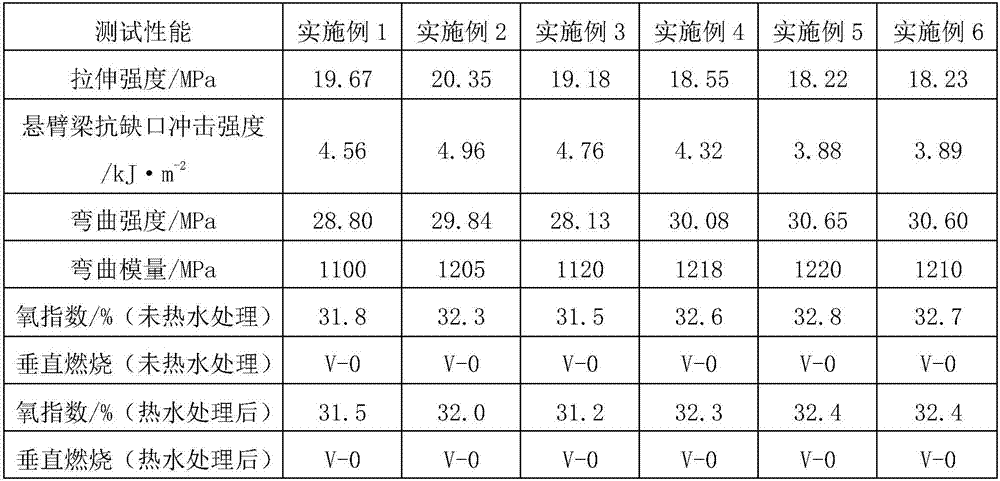

[0036] Mix the polypropylene halogen-free flame retardant masterbatch prepared in Examples 1 to 6 with the copolymerized polypropylene resin in a ratio of 35:65, and use an injection molding machine to inject a standard sample, and the standard sample according to the national standard The mechanical properties and flame retardant properties were tested, and the test results are shown in Table 2.

[0037] Table 2: Test results of mechanical properties and flame retardant properties of Examples 1 to 6

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com