An automatic manufacturing machine for building sewage tank cement partitions

A technology for automatic manufacturing and sewage tanks, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of reduced strength of partitions, reduce workload and avoid troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

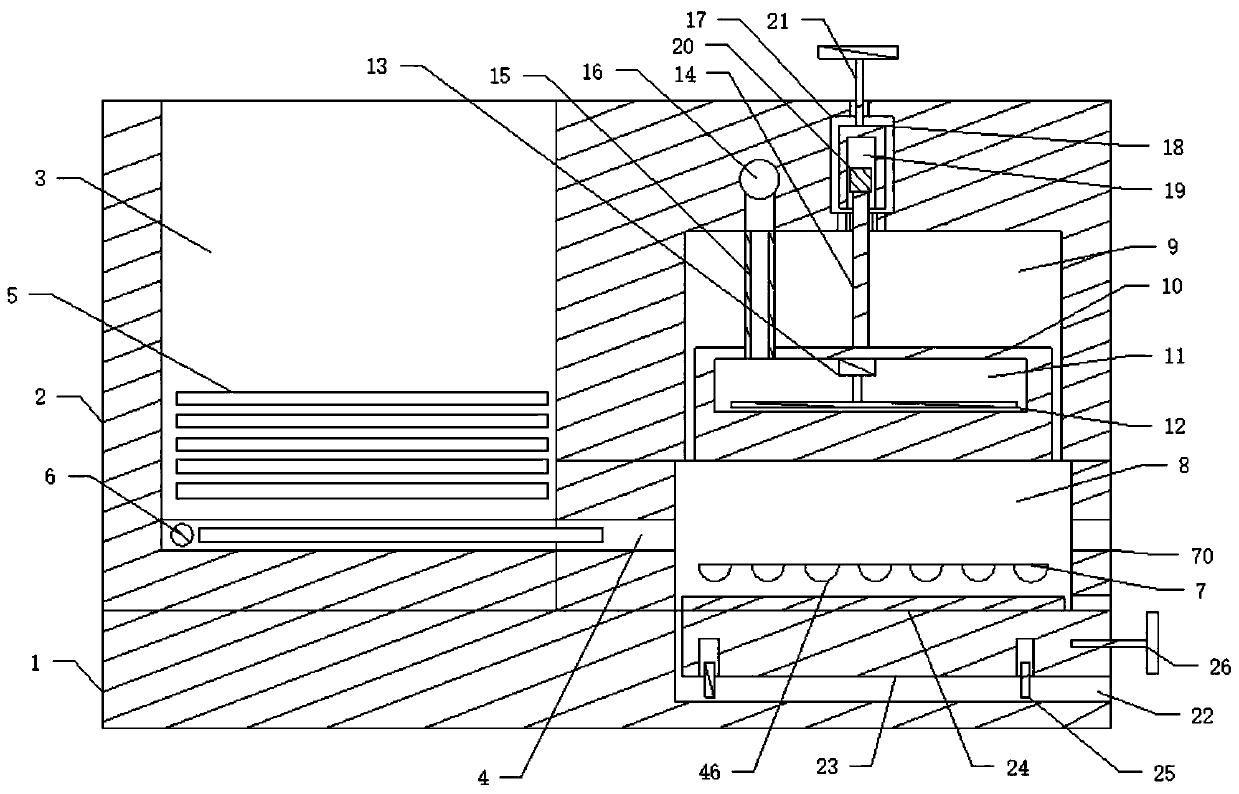

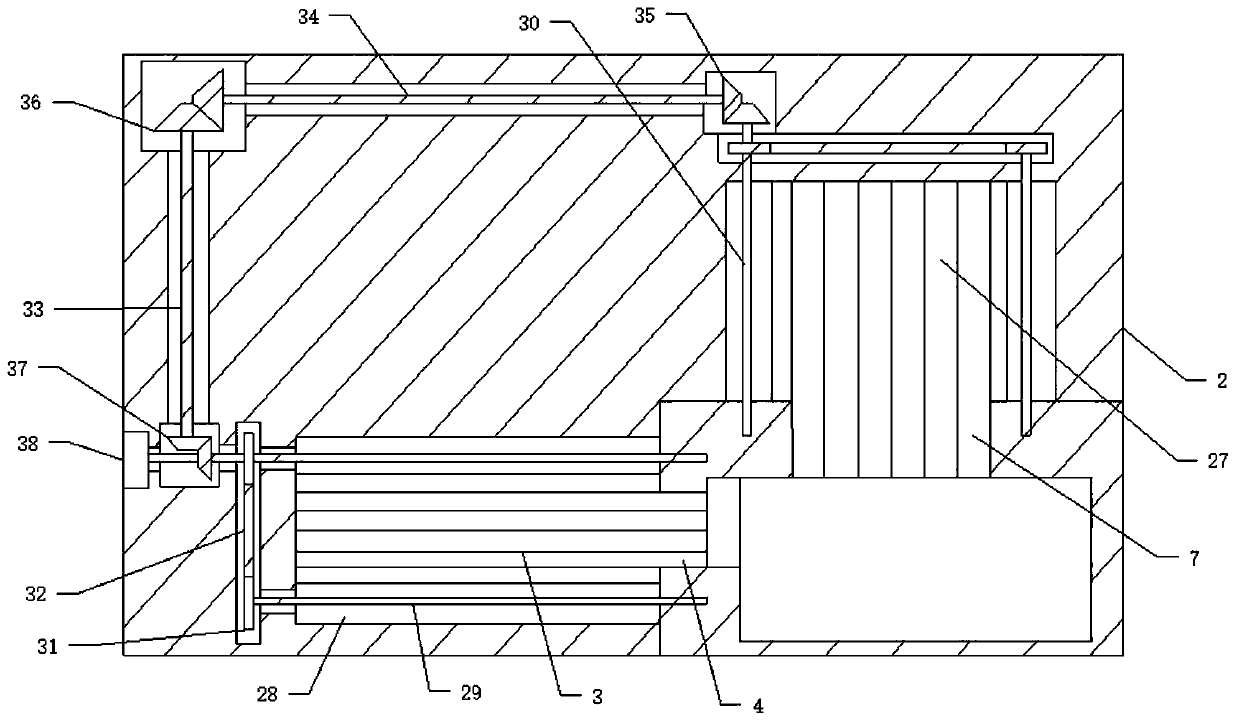

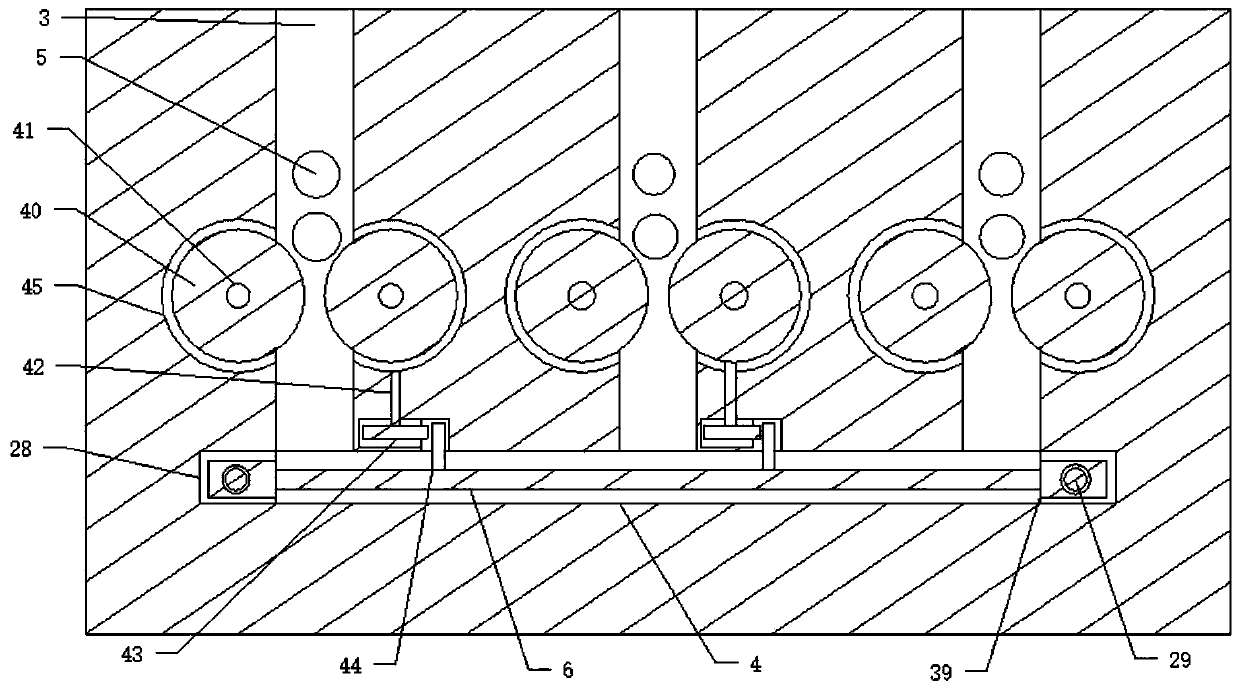

[0031] Such as Figure 1 to Figure 10 As shown, an automatic manufacturing machine for cement partitions of building sewage tanks includes a fixed base 1, and a body 2 is arranged on the fixed base 1, and a board-making groove 8 arranged in a square shape is arranged in the body 2 The body 2 is also provided with a first conveying trough 3 and a second conveying trough 27 corresponding to the plate-making trough 8, and the first conveying trough 3 and the second conveying trough 27 are respectively provided with multiple and arranged side by side, and respectively arranged on the side of the plate-making trough 8, the first conveying trough 3 and the second conveying trough 27 are respectively provided with supporting steel bars 5 stacked side by side, and in the body 2 A first chute 4 corresponding to the first delivery trough 3 is provided, and a second chute 7 corresponding to the second delivery trough 27 is provided in the body 2 . A chute 4 and the second chute 7 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com