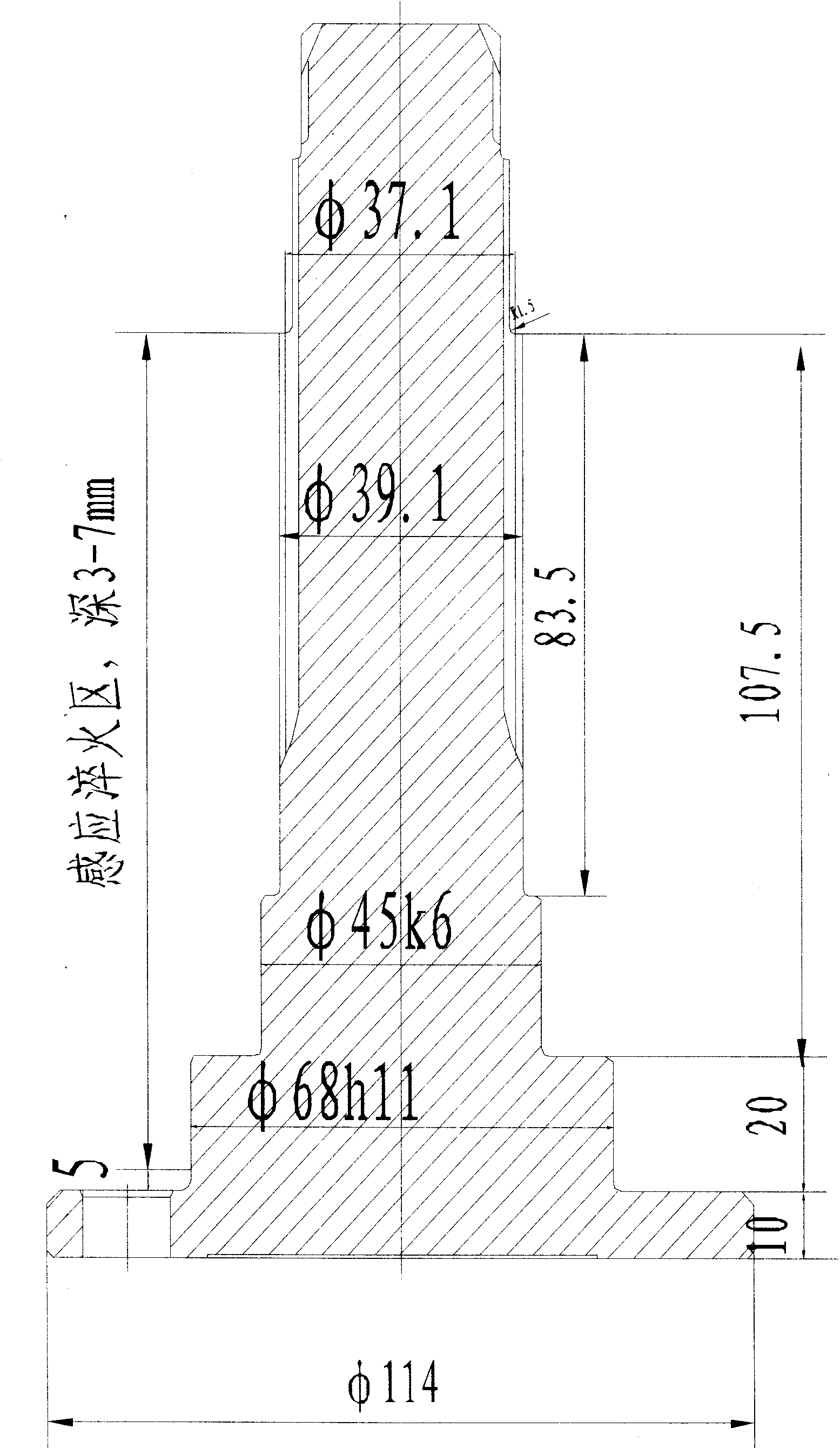

Large variable diameter shaft part induction heat-treatment and quenching technical method

A technology of induction heat treatment and process method, used in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve problems such as difficulty in meeting quenching requirements, difficulty in processing and manufacturing, and difficulty in induction heating, saving equipment investment and achieving good hardening effect. , The effect of improving static torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

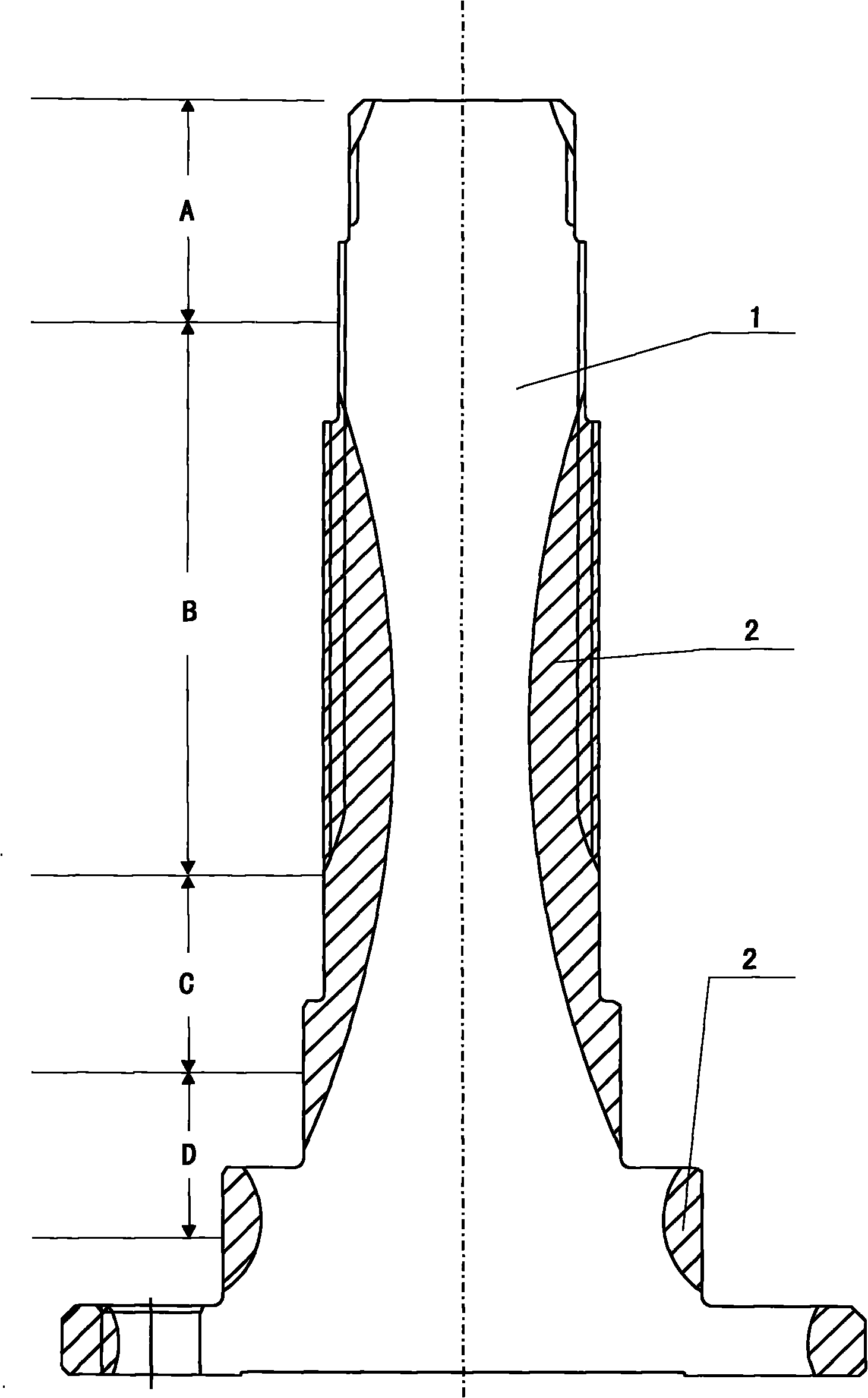

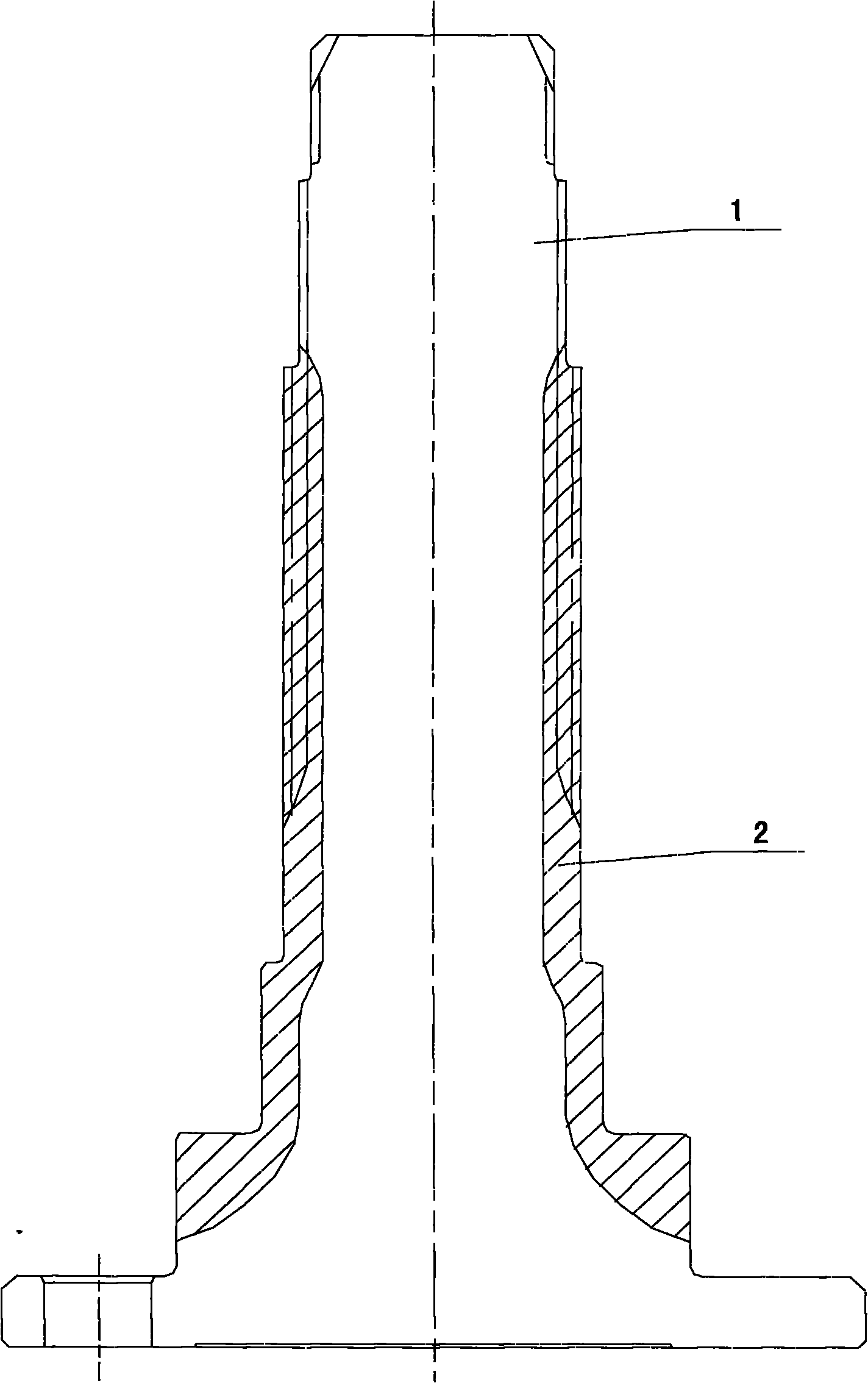

[0074] exist figure 2 Or in 3, an induction heat treatment and quenching process method for large variable diameter shaft parts, taking the driven shaft of power output as an example: the quenching method of continuous heating and quenching and liquid spray cooling is selected, and the machine tool action program is: first start with the spline Preheating at the upper end and continuously shifting to the Ф45 journal → preheating, stagnation, heating for a few seconds "should be determined according to the actual situation" → heating → stop heating → move to Ф68 for heating → lagging → heating → spray liquid → move to 45 for continuous Heat to 3~5mm above the spline "where the moving speeds of Ф45 and Ф37.1 are different, which should be reflected in the NC programming" → move to a certain position at the top of Ф37.1 "X = -53 in NC" → spray liquid for a few seconds "Experiment confirmed" → return to zero.

[0075] The above-mentioned induction heat treatment and quenching pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com