Arm support type concrete mixing pump truck

A technology for concrete and pump trucks, which is applied in construction, building structure, construction material processing, etc., can solve the problems of difficult to accurately mix concrete raw materials, increase construction workload, environmental pollution, waste of manpower, etc. Large-scale concrete construction, simplified fabrication and pumping process, improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

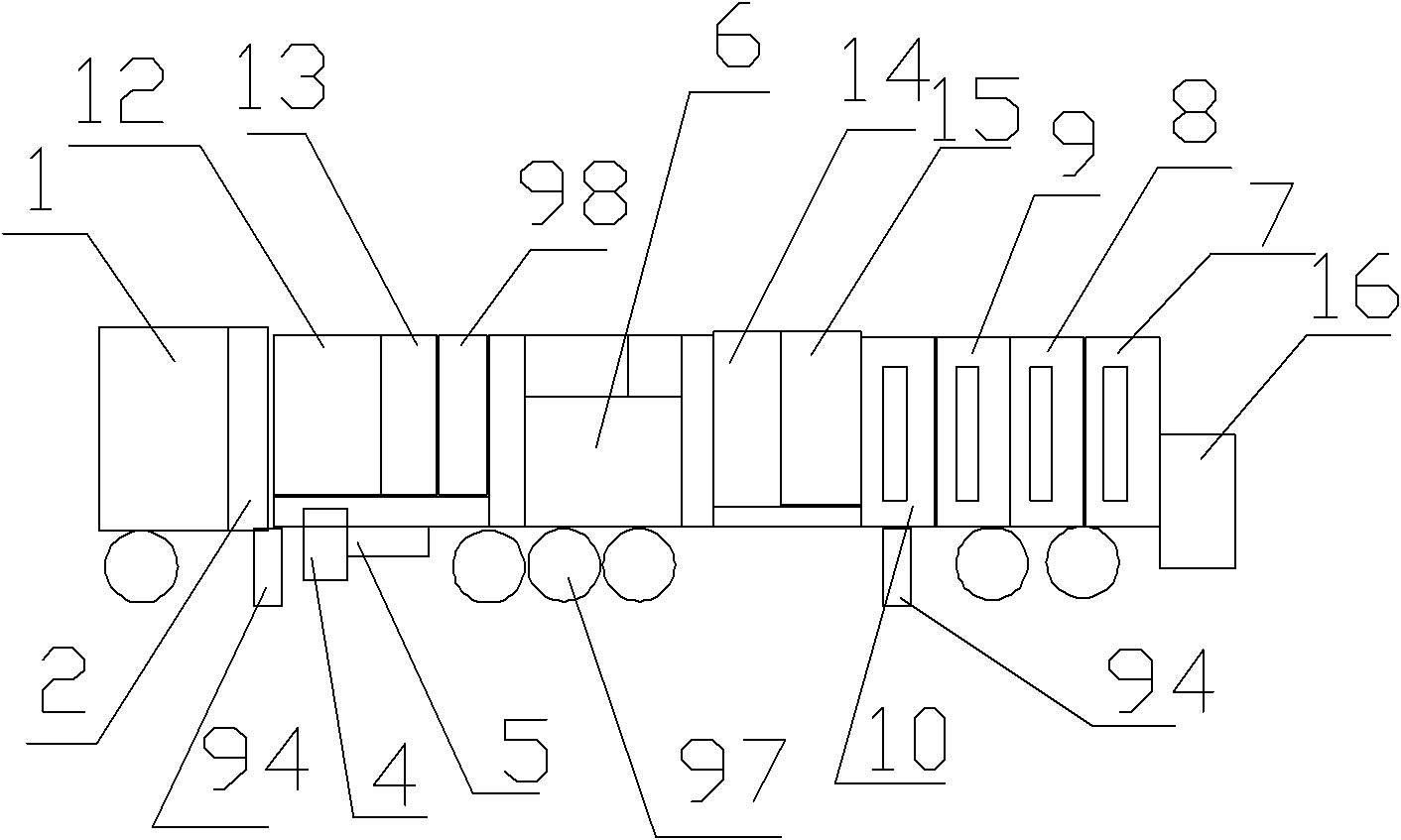

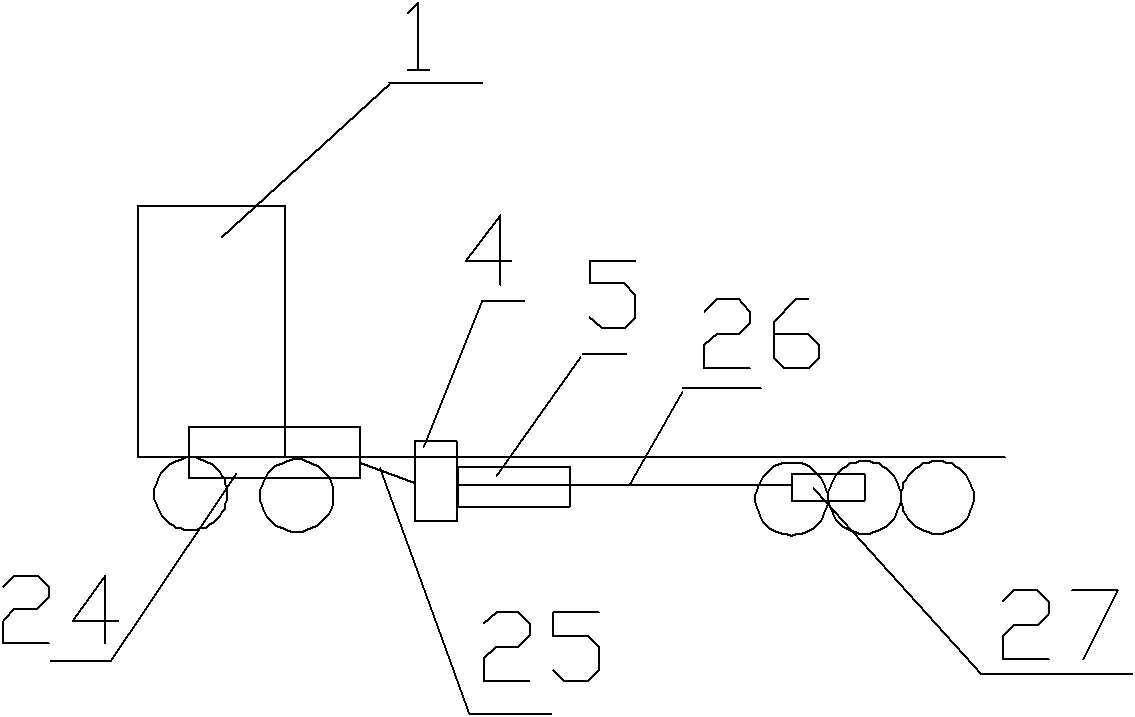

[0043] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 , a concrete mixing pump truck, including a cab 1 and a car body 97, a transfer case 4 is placed on the chassis of the car body 97, and the transfer case 4 obtains power from the chassis engine 24 through the transmission shaft 25, and then drives the generator 5, Sufficient power is provided for the whole system, and the transfer case 4 also drives the chassis traveling device 27 through the chassis transmission shaft 26, and the power switching between the generator 5 and the chassis traveling device 27 is controlled by the switch of the transfer case 4. An independent electronic control room 2 that can control continuous loading of concrete raw materials, raw material storage, weighing, concrete mixing and pumping is installed in the outflow space at the rear of the cab 1 . At the same time, a mo...

Embodiment 2

[0066] see figure 1 , Figure 10 , Figure 11 and Figure 14 , The difference between this device and the device in Embodiment 1 is: the boom system such as boom device, slewing support, slewing reducer, proportional distribution valve group, boom balance valve is installed at the front end of car body 97. The support system 3 that stretches out from the car body bottom both sides of car crane formula is installed at the front and rear ends of the car body 97 chassis. The boom device includes a boom 17 and a boom slewing support 18, the lower part of the boom slewing support 18 is connected with the vehicle body, and the upper part of the boom slewing support 18 is connected with the boom 17; The structural steel plate is welded, and the mesh structure includes honeycomb mesh structure, circular mesh structure, rectangular mesh structure, etc. Since the inner side of the boom steel plate adopts a mesh structure, this structure can greatly increase the strength of the steel...

Embodiment 3

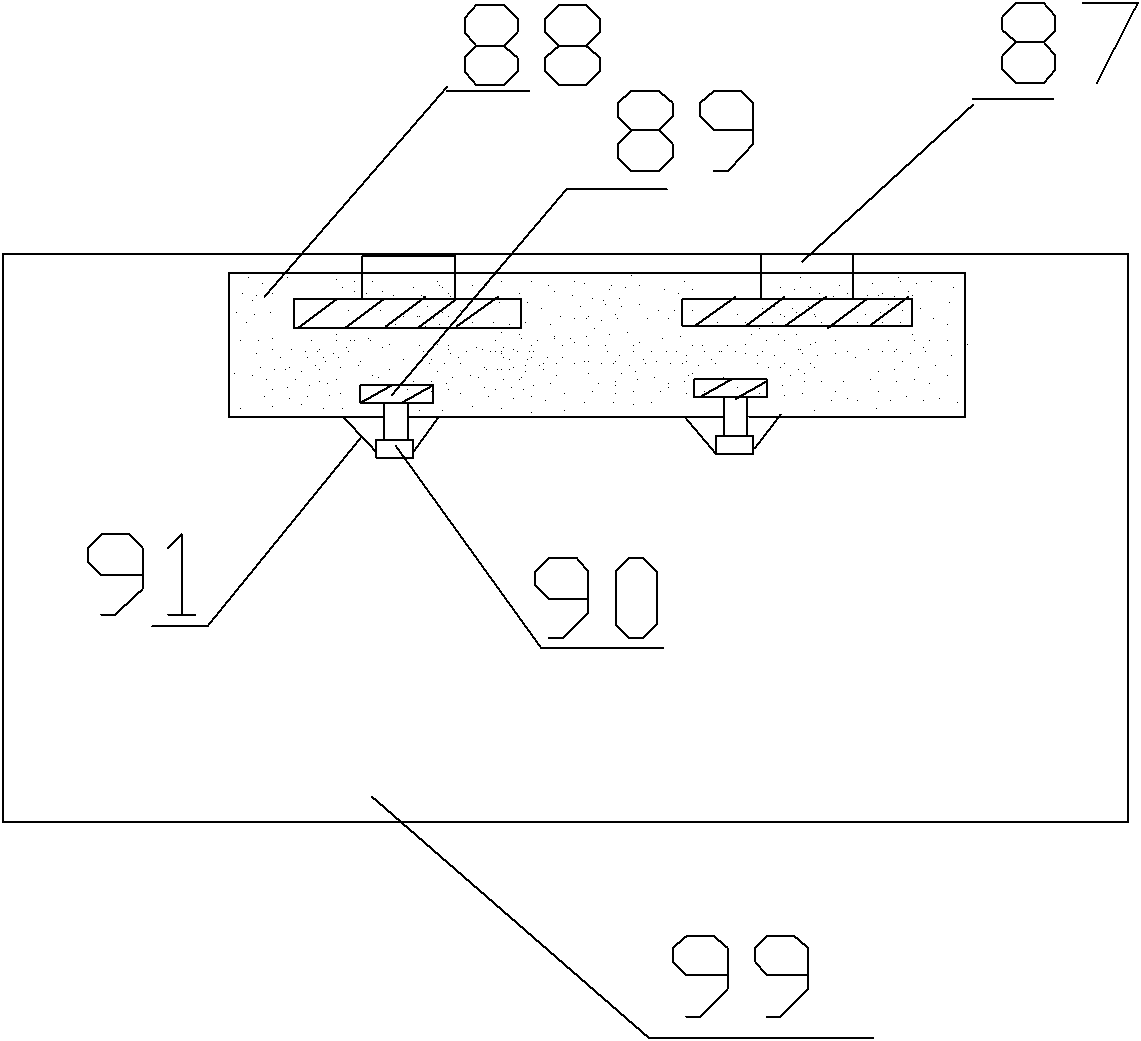

[0068] The difference between this example and example 1 and example 2 is that an independent diesel generator set 92 can also be installed on the car body 97, instead of driving the transfer case 4 through the vehicle chassis engine 24, and then driving the generator through the transfer case 4 5. The form of providing power for the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com