Internet of Things system for flame glass fiber production

A networking system and glass fiber technology, applied in transmission systems, glass manufacturing equipment, general control systems, etc., can solve the problems of low input cost and rarely mentioned Internet of Things systems, and achieve the effect of simple use and normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

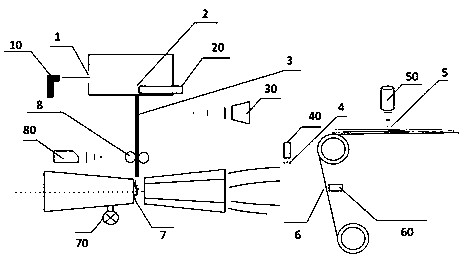

[0021] refer to figure 1 , is a schematic diagram of the monitoring signal of the flame glass fiber production Internet of Things system, in which 10 is a high-temperature thermometer, 1 is the entrance of the high-temperature furnace, 20 is an online viscometer, 2 is the glass liquid at the alloy drain plate of the high-temperature furnace, and 30 is a horizontal CCD camera, 3 is the flow stream at the drain plate of the high-temperature kiln, 40 is a liquid flow meter, 4 is a glue spraying device, 50 is a vertical CCD camera, 5 is a conveyor belt cotton felt, 60 is a pressure sensor, and 6 is a porous conveyor belt , 70 is the gas flow meter, 7 is the natural gas at the furnace head, 80 is the online speed measuring instrument, and 8 is the rubber roller, which consists of the raw material homogenization Internet of Things subsystem, flame injection Internet of Things subsystem and glue spraying and cotton collection Internet of Things subsystem It is composed of three major...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com