Wharf ship loader telescoping mechanism rail production process and special rail butt joint tool thereof

A technology of telescopic mechanism and manufacturing process, which is applied in the direction of manufacturing tools, auxiliary devices, welding equipment, etc., can solve the problems of easy corrosion, reduced track life, and easy cracks in the gaps, so as to reduce production costs and extend track life , the effect of not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific process steps are:

[0032] First make the track segment: place the thickness, width, and length allowance when cutting the track segment, and use the milling machine to process the track segment thickness and width to remove the surface decarburization layer. The purpose is to prevent the track surface from not meeting the hardness requirements after quenching. And the quenching surface of the track segment is processed to remove the sharp angle of the track, so as to avoid the stress concentration after quenching and cracks at the sharp angle.

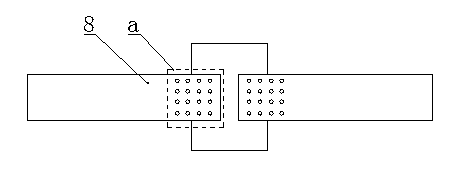

[0033] Then quench the track in sections and perform hardness testing: use an intermediate frequency furnace to quench the track in sections; figure 1 As shown, the hardness test is performed on the track surface of the track segment 8, and the multi-point hardness test is performed on the end of the track segment 8. The multi-point hardness test area a at the end of the track segment 8 includes the welding heat-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com