Method for preparing nanosilver powder in batches

A technology of nano-silver powder and mass production, which is applied in the direction of nano-technology, can solve the problems of nano-silver agglomeration, agglomeration, and uneven particle size of nano-silver, and achieve the effect of increased surface area, uniform distribution of crystal seeds, and controllable quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

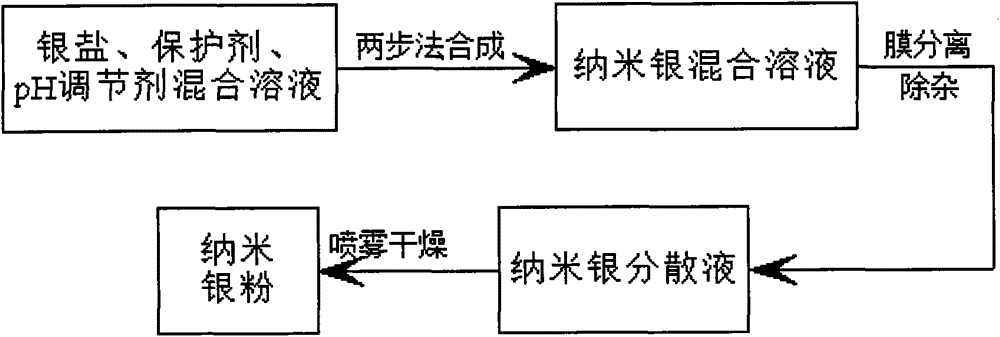

[0037] The preparation flow chart of nano-silver powder is attached figure 1 :

[0038] (1) Weigh 150g of dimethylaminomethacrylamide / acrylic acid copolymer and dissolve it in 40L of dewatered water, then add 1020g of silver nitrate to dissolve, adjust pH=9 with 4% mass fraction of dilute ammonia water, and use a metering pump to add to the above solution Slowly add 8L dropwise to the concentration of 5×10 -3 mol / L ascorbic acid aqueous solution, the dropping rate is 0.2mL / min; then, quickly add 15L of 0.2mol / L ascorbic acid aqueous solution dropwise to the above solution with a metering pump, the dropping rate is 10mL / min, continue to stir for 0.5h after dropping, Obtain nano-silver mixed solution;

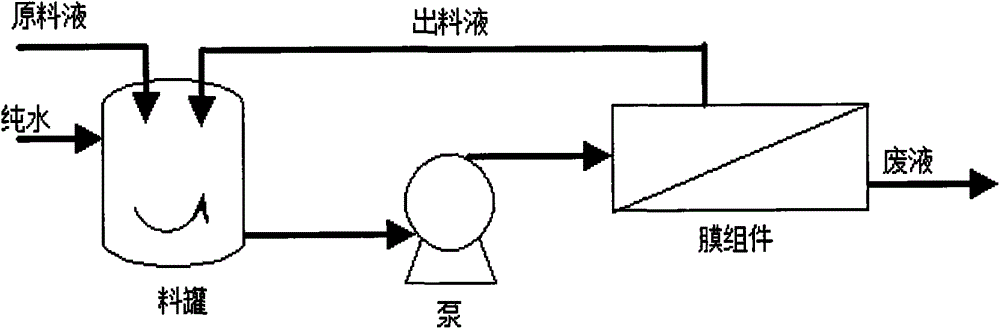

[0039] (2) the nano-silver mixed solution that step (1) obtains is passed through membrane separation equipment (see attached figure 2) for membrane separation, the ultrafiltration membrane material is polyacrylonitrile, and the membrane pore size is 30nm. Pour the mixed sol...

Embodiment 2

[0043] The preparation flow chart of nano-silver powder is attached figure 1 :

[0044] (1) Weigh 150g of polyacrylic acid (PAA) and dissolve it in 50L of deionized water, then add 340g of silver nitrate and stir until dissolved, and slowly inject 80mL of it into the above solution with a micropipette at a concentration of 8×10 -3 mol / L maltose aqueous solution at a rate of 0.05mL / min; then, quickly inject 8.75L of maltose aqueous solution with a concentration of 0.12mol / L at a rate of 60mL / min with a micropipette, and continue stirring for 1h to obtain nano-silver mixture;

[0045] (2) the nano-silver mixed solution that step (1) obtains is passed through membrane separation equipment (see attached figure 2 ) for membrane separation, the ultrafiltration membrane material is polystyrene, and the membrane pore size is 50nm. Pour the mixed solution into the material tank, then add deionized water, turn on the circulation pump and pipeline valve, the nano-silver mixed solutio...

Embodiment 3

[0049] The preparation flow chart of nano-silver powder is attached figure 1 :

[0050] (1) Weigh 300g polyvinyl alcohol and dissolve it in 20L deionized water, then add 340g silver sulfate and stir until dissolved, slowly add 0.5L dropwise to the solution with a metering pump at a concentration of 1×10 -3 mol / L aqueous solution of sodium hypophosphite at a rate of 0.4mL / min; then, use a metering pump to quickly add 4.17L aqueous solution of sodium hypophosphite with a concentration of 0.12mol / L at a rate of 20mL / min, and continue stirring for 1.5h , to obtain nano-silver mixed solution;

[0051] (2) the nano-silver mixed solution that step (1) obtains is passed through membrane separation equipment (see attached figure 2 ) for membrane separation, the ultrafiltration membrane material is polyvinyl chloride, and the ultrafiltration membrane pore size is 40nm; pour the mixed solution into the material tank, then add deionized water, open the circulating pump and pipeline val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com