Preparation method of nanometer molybdenum powder containing homodisperse carbon nano tubes

A carbon nanotube and nanomolybdenum powder technology, which is applied in the field of nanocomposite powder preparation, can solve the problem of less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

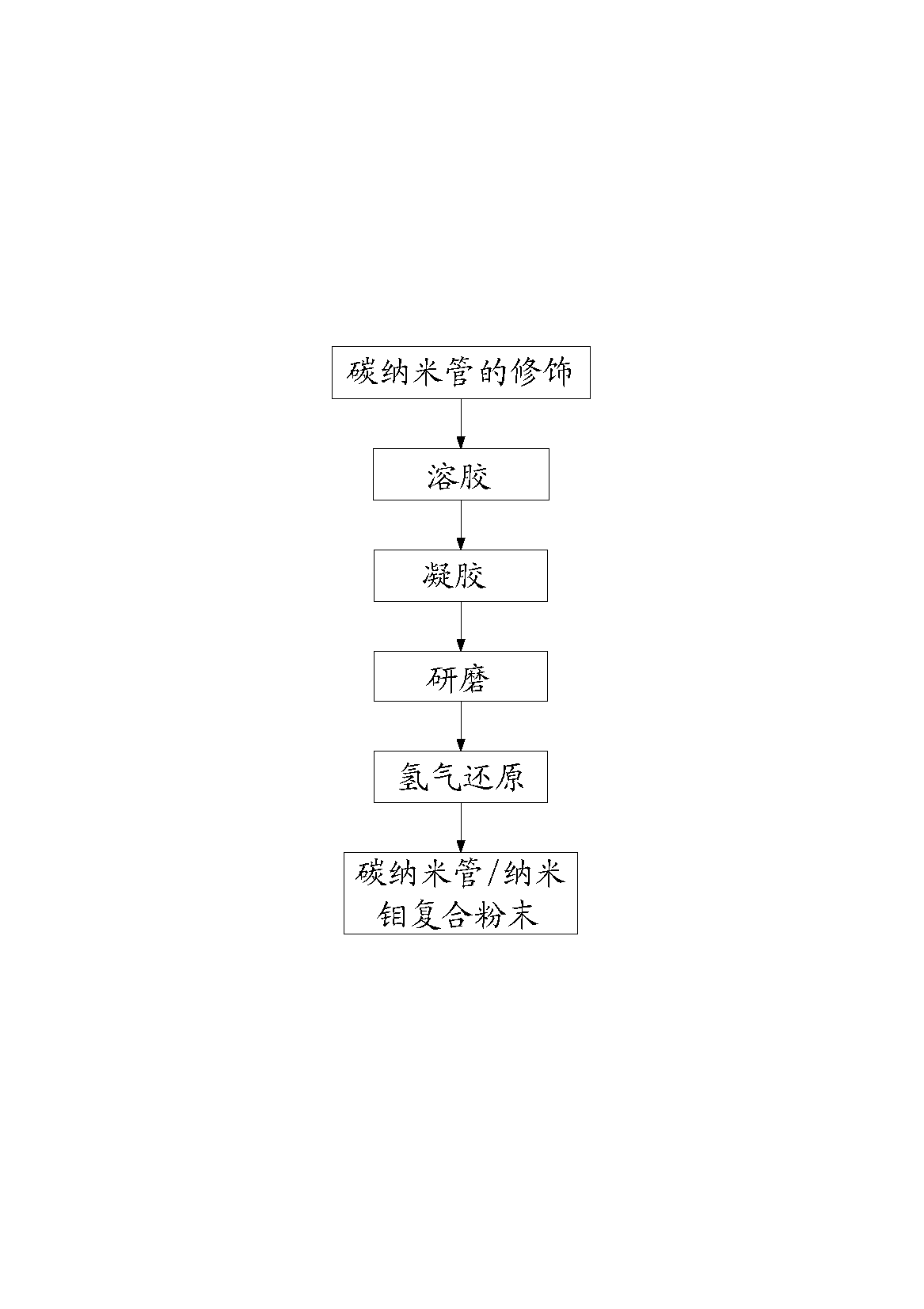

[0028] like figure 1 Shown, the preparation technological process of the preparation method of a kind of nano-molybdenum powder containing uniformly dispersed carbon nanotubes of the present invention is:

[0029] (1) Modification of carbon nanotubes: place carbon nanotubes in concentrated nitric acid (the content of carbon nanotubes relative to concentrated nitric acid is 5-15g / 100ml), ultrasonically disperse at a temperature of 60-80°C for 20-30min, and then in Reflux treatment at 70-90°C for 1-5h, after cooling to room temperature, dilute with deionized water and suction filter until neutral, then place the powder in a vacuum drying oven at 60-90°C for 2-5h to obtain modified carbon nanotubes. Through this step, the generation of agglomeration of carbon nanotubes can be reduced, and their dispersion and adsorption characteristics for nanometer molybdenum powder can be improved.

[0030](2) Preparation of sol: weigh a certain amount of carbon nanotubes and mix them with am...

Embodiment 2

[0036] A preparation process of nano-molybdenum powder containing uniformly dispersed carbon nanotubes is:

[0037] (1) Modification of carbon nanotubes: place carbon nanotubes in concentrated nitric acid (the content of carbon nanotubes relative to concentrated nitric acid is 5-15g / 100ml), ultrasonically disperse at a temperature of 60-80°C for 20-30min, and then in Reflux treatment at 70-90°C for 1-5h, after cooling to room temperature, dilute with deionized water and suction filter until neutral, then place the powder in a vacuum drying oven at 60-90°C for 2-5h to obtain modified carbon nanotubes.

[0038] (2) Preparation of sol: Weigh carbon nanotubes with a volume content of 12% (relative to the total content of carbon nanotubes plus ammonium paramolybdate solution) and mix them with ammonium paramolybdate solution, add citric acid monohydrate and polyethylene glycol reagent (The amount of both additions is 0.5-1.5% of the volume of the mixed solution). After fully stirr...

Embodiment 3

[0044] A preparation process of nano-molybdenum powder containing uniformly dispersed carbon nanotubes is:

[0045] (1) Modification of carbon nanotubes: place carbon nanotubes in concentrated nitric acid (the content of carbon nanotubes relative to concentrated nitric acid is 5-15g / 100ml), ultrasonically disperse at a temperature of 60-80°C for 20-30min, and then in Reflux treatment at 70-90°C for 1-5h, after cooling to room temperature, dilute with deionized water and suction filter until neutral, then place the powder in a vacuum drying oven at 60-90°C for 2-5h to obtain modified carbon nanotubes.

[0046] (2) Preparation of sol: Weigh carbon nanotubes with a volume content of 23% (relative to the total content of carbon nanotubes plus ammonium paramolybdate solution) and mix them with ammonium paramolybdate solution, add citric acid monohydrate and polyethylene glycol dropwise Reagents (the amount of both additions is 0.5-1.5% of the volume of the mixed solution). After f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com