Nonclay one-way plugging drilling fluid

A drilling fluid and clay-free technology, which is applied in the field of oil drilling, can solve the problems of no plugging agent, high fluid loss, poor temperature resistance, etc., and achieve low friction and torque, excellent lubricating performance, and low overall cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

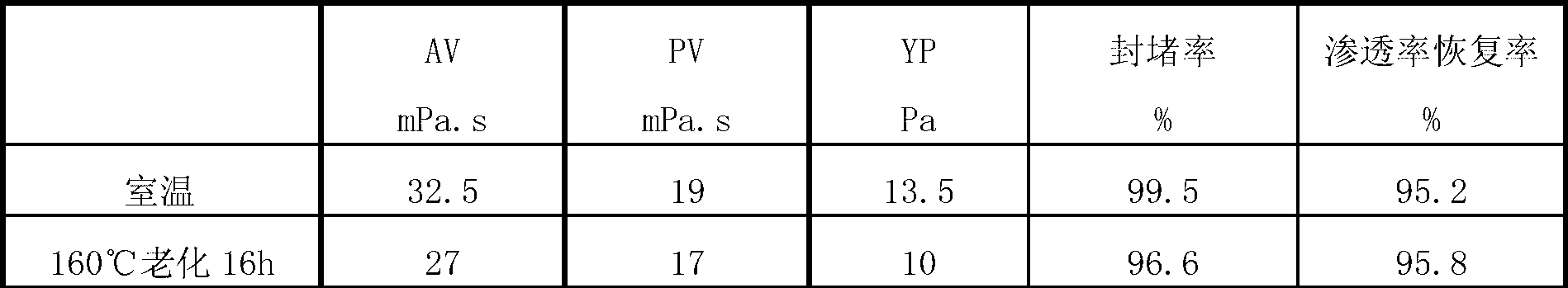

[0046]Add 1000 parts of clear water to the mixing tank, add 15 parts of sulfonate copolymer fluid loss reducer DSP-2 and 2 parts of xanthan gum FT into the clear water in turn, stir to fully dissolve; add 10 parts of amino polyol AP-1, 50 parts of polymer elastic microspheres SFH-1 and 10 parts of FYR lubricant, stir evenly; add 100 parts of potassium formate, stir well to dissolve it, and then it becomes clay-free one-way plugging drilling fluid. The clay-free unidirectional plugging drilling fluid prepared by the method in Example 1 was taken to investigate its performance, and the results are shown in Table 1.

[0047] Table 1

[0048]

Embodiment 2

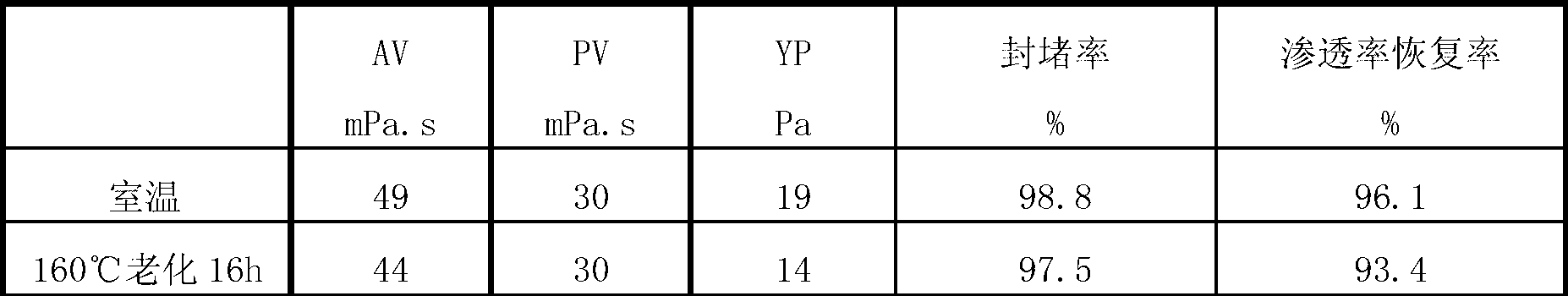

[0050] Add 1000 parts of water to the mixing tank, add 20 parts of sulfonate copolymer fluid loss reducer DSP-2 and 3 parts of xanthan gum FT into the water in turn, stir to fully dissolve; add 5 parts of amino polyol AP-1, 70 parts of polymer elastic microspheres SFH-1 and 15 parts of FYR lubricant, stir evenly; add 200 parts of sodium formate, stir well to dissolve it, and then it becomes clay-free one-way plugging drilling fluid. The clay-free unidirectional plugging drilling fluid prepared by the method in Example 2 was used to investigate its performance, and the results are shown in Table 2.

[0051] Table 2

[0052]

Embodiment 3

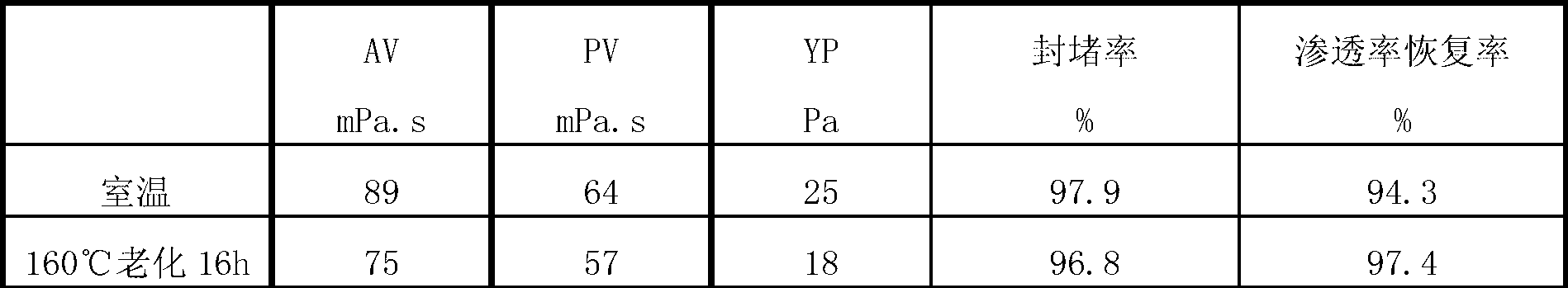

[0054] Add 1000 parts of clear water to the mixing tank, add 30 parts of sulfonate copolymer fluid loss reducer DSP-2 and 2 parts of xanthan gum FT into the clear water in turn, stir to fully dissolve; add 15 parts of amino polyol AP-1, 60 parts of polymer elastic microspheres SFH-1 and 20 parts of FYR lubricant, stir evenly; add 150 parts of sodium formate and 50 parts of potassium formate, stir well to dissolve it, and it becomes the clay-free one-way plugging drilling fluid. Get the clay-free unidirectional plugging drilling fluid prepared by the method of Example 3, investigate its performance, and the results are shown in Table 3:

[0055] table 3

[0056]

[0057] As can be seen from the above experimental results, the clay-free unidirectional plugging drilling fluid of the present invention has higher viscosity and shear force at room temperature and high temperature conditions, which meets the requirements of operation and construction, and the plugging rate and per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com