An ultra-fine high-density drilling and completion working fluid for protecting ultra-deep tight sandstone gas reservoirs and its preparation method

A tight sandstone gas reservoir, high-density technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of tight sandstone gas reservoirs such as reduced effective permeability, difficult filtration loss control, and high solid content. Achieve the effect of improving suspension stability and thermal stability, overcoming coalescence tendency, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

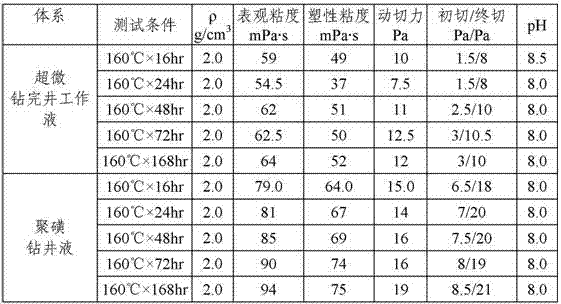

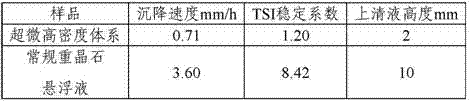

Examples

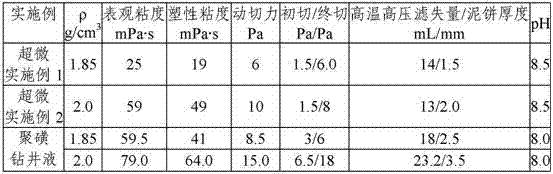

example 1

[0022] This embodiment provides a density of 1.85g / cm 3 Ultrafine high-density drilling and completion working fluid, which is prepared by the following steps:

[0023] Put 300 parts by weight of tap water in a beaker, add 455 parts by weight of API barite powder and 12 parts by weight of dispersant, stir the three fully and pour them into a grinder to grind until the particle size distribution of the mixed liquid is about 1-3 Micron, D90 is about 4-8 micron.

[0024] Add 21 parts by weight of potassium formate, 6 parts by weight of nitrile silicon fluid loss reducer, and 4 parts by weight of terpolymer fluid loss reducer in the above-mentioned base slurry in order (the effect of mixing the two kinds of fluid loss reducers will be better, there is synergistic effect), 0.3 parts by weight of xanthan gum, 16 parts by weight of sulfonated pitch, 0.8 parts by weight of micro silicon, 12 parts by weight of ultrafine CaCO 3 , at a stirring speed of 12,000 rpm for 30 minutes to obt...

example 2

[0026] This embodiment provides a density of 2.0g / cm 3 The ultra-fine high-density drilling and completion working fluid, which is prepared by the following steps:

[0027] Put 300 parts by weight of tap water in a beaker, add 600 parts by weight of API barite powder and 17.5 parts by weight of dispersant, stir the three fully and pour them into a grinder to grind until the particle size distribution of the mixed liquid is about 1-3 microns in D50 and about 1-3 microns in D90 About 4-8 microns.

[0028] Add 21 parts by weight of potassium formate, 4.5 parts by weight of nitrile silicon fluid loss reducer, and 4 parts by weight of terpolymer fluid loss reducer in the above-mentioned base slurry in order (the effect of mixing the two kinds of fluid loss reducers will be better, there is synergistic effect), 16 parts by weight of sulfonated pitch, 2.0 parts by weight of micro silicon, 12 parts by weight of ultrafine CaCO 3 , at a stirring speed of 12,000 rpm for 30 minutes to o...

example 3

[0030] This embodiment provides a density of 2.3g / cm 3 The ultra-fine high-density drilling and completion working fluid, which is prepared by the following steps:

[0031] Put 300 parts by weight of tap water in a beaker, add 860 parts by weight of API barite powder and 26 parts by weight of dispersant, stir the three fully and pour them into a grinder to grind until the particle size distribution of the mixed liquid is about 1-3 microns in D50 and about 1-3 microns in D90 About 4-8 microns.

[0032] Add 21 parts by weight of potassium formate, 6 parts by weight of nitrile silicon fluid loss reducer, and 4 parts by weight of terpolymer fluid loss reducer in the above-mentioned base slurry in order (the effect of mixing the two kinds of fluid loss reducers will be better, there is synergistic effect), 12 parts by weight of sulfonated pitch, 1.2 parts by weight of micro silicon, 12 parts by weight of ultrafine CaCO 3 , at a stirring speed of 12,000 rpm for 30 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com