A kind of ionic liquid base drilling fluid and its preparation method

A technology of ionic liquid and preparation method, which is applied in the field of drilling fluid to achieve excellent suspension stability and rock-carrying performance, easy on-site application, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

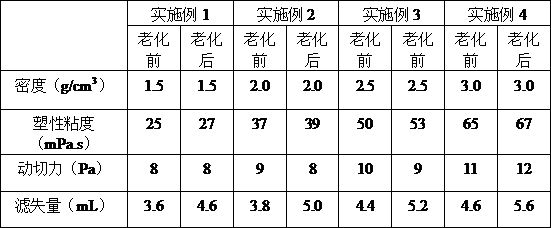

Embodiment 1

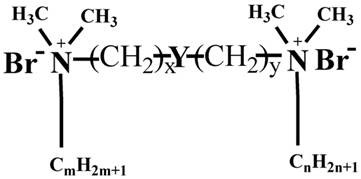

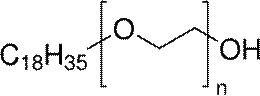

[0029] (1) 3 parts of flow regulator SL-KDPR, composed of Gemini type surfactant: polyoxyethylene surfactant = 2:3; (2) 3 parts of fluid loss reducer SL-KJL, composed of lignite Resin SPNH: sulfomethyl phenolic resin SMP-II = 3:2 ratio composition; (3) The weighting material is barite, and the weighting material is added so that the density of the drilling fluid is 1.5g / cm 3 ; (4) The base liquid is ethyl ammonium nitrate, 100 parts.

[0030] The above-mentioned components (1)-(3) are added to the component (4) sequentially in a conventional manner under the conditions of normal temperature and pressure and mechanical stirring according to the above-mentioned content, and then stirred for 2 hours after all the addition.

Embodiment 2

[0032] (1) 4 parts of flow regulator SL-KDPR, composed of Gemini surfactant: polyoxyethylene surfactant = 2:5; (2) 4 parts of fluid loss reducer SL-KJL, composed of lignite Resin SPNH: sulfomethyl phenolic resin SMP-II=5:2 ratio composition; (3) The weighting material is barite, and the weighting material is added so that the density of the drilling fluid is 2.0g / cm 3 ; (4) The base liquid is ethyl ammonium nitrate, 100 parts.

[0033] The above-mentioned components (1)-(3) are added to the component (4) sequentially in a conventional manner under the conditions of normal temperature and pressure and mechanical stirring according to the above-mentioned content, and then stirred for 2 hours after all the addition.

Embodiment 3

[0035] (1) 4 parts of flow regulator SL-KDPR, composed of Gemini surfactant: polyoxyethylene surfactant = 3:5; (2) 4 parts of fluid loss reducer SL-KJL, composed of lignite Resin SPNH: sulfomethyl phenolic resin SMP-II=3:1 ratio composition; (3) The weighting material is barite, and the weighting material is added so that the density of the drilling fluid is 2.5g / cm 3 ; (4) The base liquid is ethyl ammonium nitrate, 100 parts.

[0036] The above-mentioned components (1)-(3) are added to the component (4) sequentially in a conventional manner under the conditions of normal temperature and pressure and mechanical stirring according to the above-mentioned content, and then stirred for 2 hours after all the addition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com