Self-healing material for well cementation and preparation method thereof

A healing material and cementing technology, which is applied in the field of polymer materials, can solve problems such as failure to meet the cementing requirements of high-pressure natural gas wells, failure to achieve cement sheath recovery, and weak natural gas response capabilities, so as to improve self-healing ability and large volume Expansion, strong mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

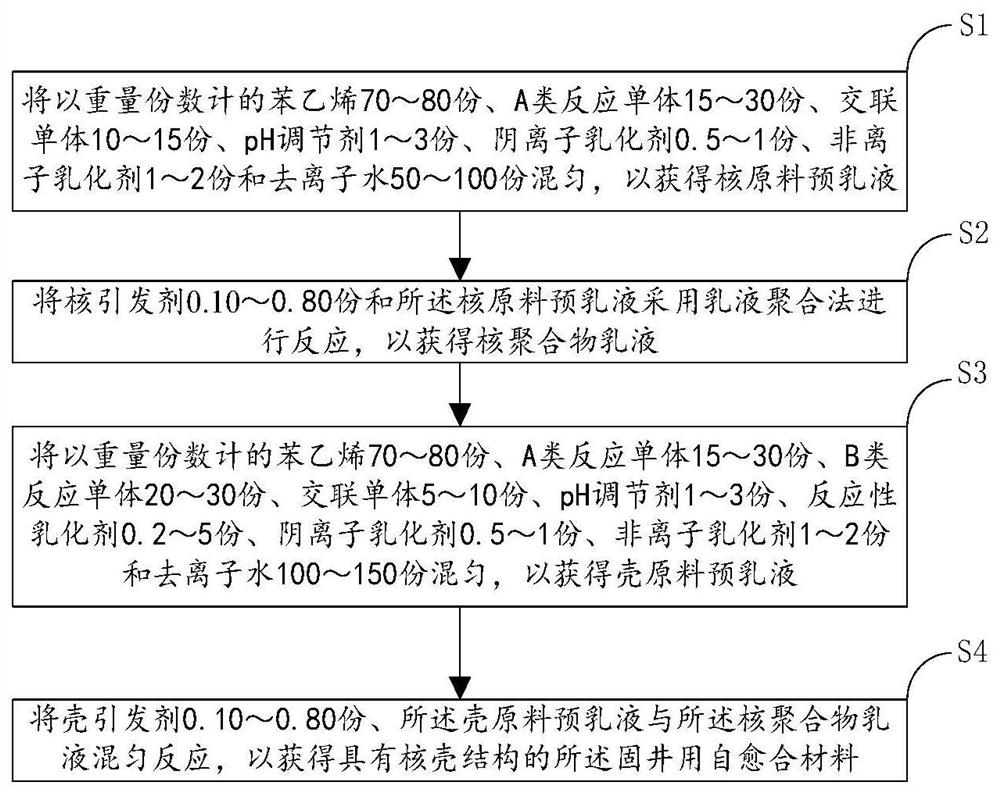

[0034] According to a typical embodiment of the present invention, a method for preparing a self-healing material for well cementing is provided, such as figure 1 As shown, the method includes:

[0035] S1. In parts by weight, 70-80 parts of styrene, 15-30 parts of A-type reactive monomer, 10-15 parts of cross-linking monomer, 1-3 parts of pH regulator, and 0.5-1 part of anionic emulsifier 1. Mix 1-2 parts of non-ionic emulsifier with 50-100 parts of deionized water to obtain pre-emulsion of nuclear raw materials;

[0036] S2. Reacting 0.10-0.80 parts of the nuclear initiator and the nuclear raw material pre-emulsion by emulsion polymerization to obtain a nuclear polymer emulsion;

[0037] S3, 70-80 parts by weight of styrene, 15-30 parts of A-type reactive monomers, 20-30 parts of B-type reactive monomers, 5-10 parts of cross-linking monomers, 1-30 parts of pH regulators 3 parts, 0.2-5 parts of reactive emulsifier, 0.5-1 part of anionic emulsifier, 1-2 parts of non-ionic em...

Embodiment 1

[0063] A self-healing material for well cementing provided in this embodiment is prepared through the following steps:

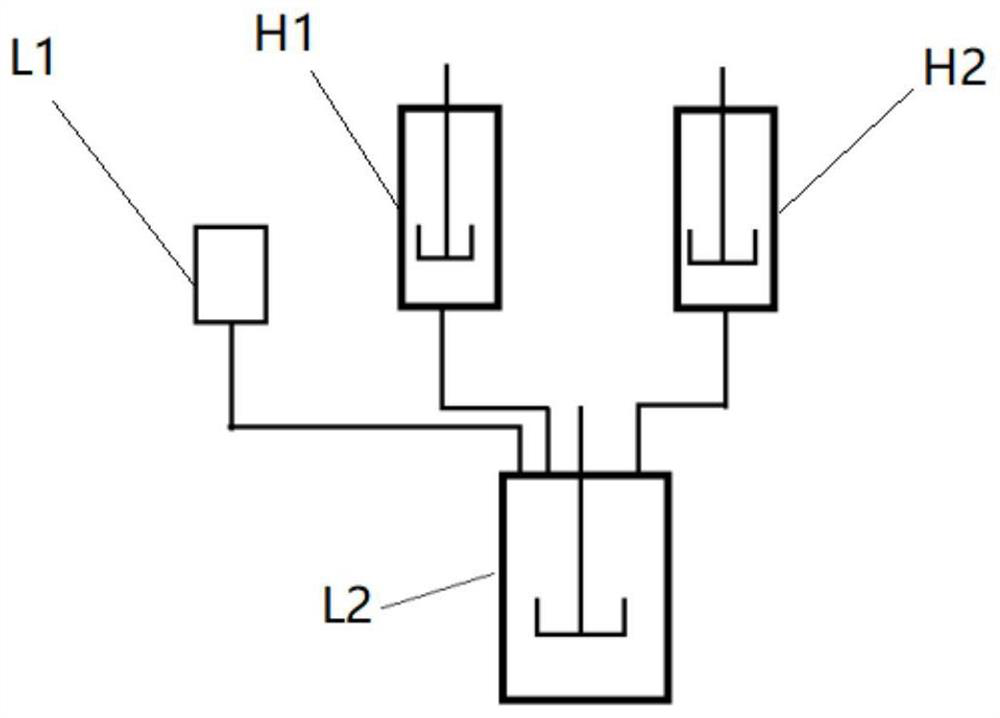

[0064] (1) Pre-emulsion preparation of nuclear raw materials: put 80 kg of styrene, 25 kg of butyl methacrylate, 10 kg of divinylbenzene, 1.5 kg of sodium dihydrogen phosphate, and 0.5 kg of sodium dodecylbenzenesulfonate into the mixing tank H1. kg, nonylphenol polyoxyethylene ether 1.2kg, deionized water 70kg, high-speed stirring for 60min to prepare the core part of the pre-emulsion, set aside;

[0065] (2) Pre-emulsion of raw materials for the shell part: put 70kg of styrene, 20kg of butyl acrylate, 30kg of isooctyl acrylate, 5kg of divinylbenzene, 1.5kg of sodium dihydrogen phosphate, and allyl polyoxyethylene into the mixing tank H2. Ether fatty alcohol 0.4kg, sodium dodecylbenzenesulfonate 0.6kg, nonylphenol polyoxyethylene ether 1.0kg, deionized water 120kg. Stir at high speed for 60 minutes to prepare the shell part pre-emulsion and set aside;

[...

Embodiment 2

[0071] (1) Pre-emulsion preparation of nuclear raw materials: 70kg of styrene, 30kg of methyl methacrylate, 15kg of divinylbenzene, 1.0kg of sodium dihydrogen phosphate, 0.7kg of sodium lauryl sulfate, Nonylphenol polyoxyethylene ether 1.4kg, deionized water 90kg, high-speed stirring for 60min to prepare the core part of the pre-emulsion, set aside;

[0072] (2) Raw material pre-emulsion for the shell part: put 70kg of styrene, 15kg of butyl methacrylate, 20kg of isooctyl acrylate, 6kg of divinylbenzene, 1.0kg of sodium dihydrogen phosphate, and allyl polyoxygen into the mixing tank H2. Vinyl ether fatty alcohol 0.4kg, sodium lauryl sulfate 0.6kg, nonylphenol polyoxyethylene ether 1.0kg, deionized water 120kg. Stir at high speed for 60 minutes to prepare the shell part pre-emulsion and set aside;

[0073](3) Initiator solution preparation: 0.5 kg of ammonium persulfate is dissolved in 4.5 kg of deionized water, marked as a nuclear initiator; 0.6 kg of ammonium persulfate is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com