Core-shell type polymer microspheres, preparation and applications thereof

A polymer, core-shell technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of great environmental differences, achieve simple preparation methods, facilitate micro-crack repair, and large volume expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

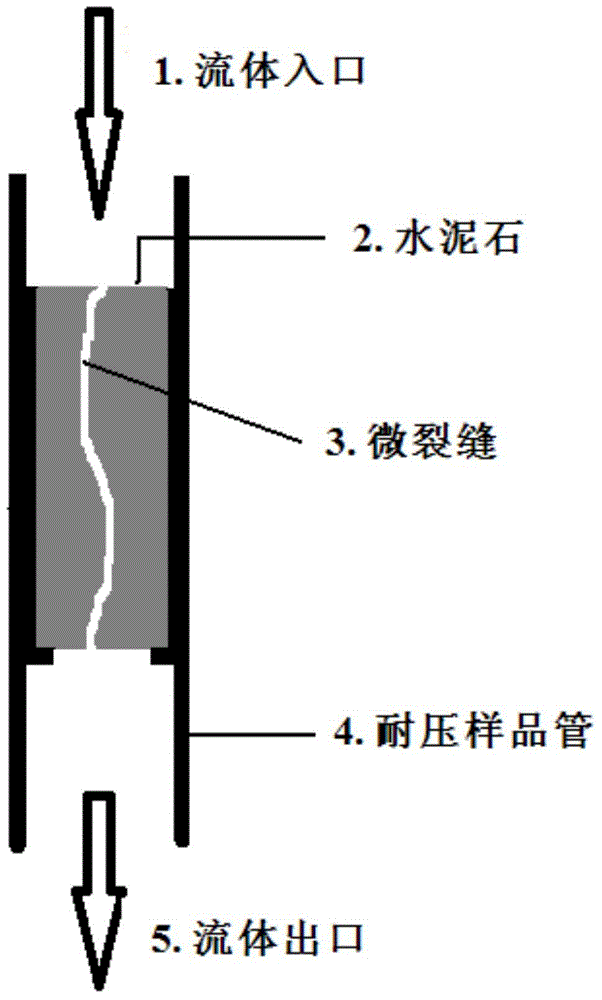

Image

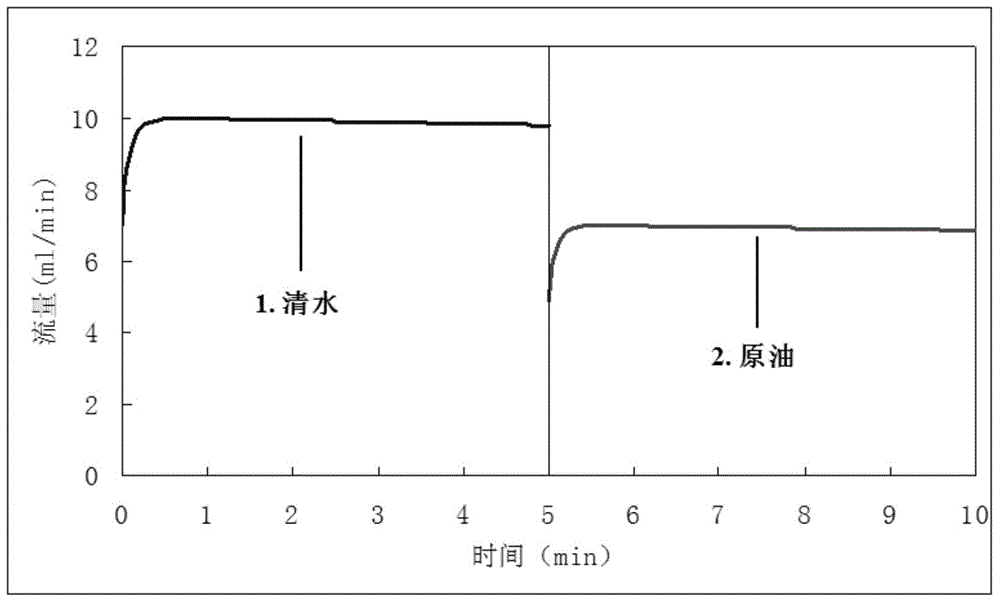

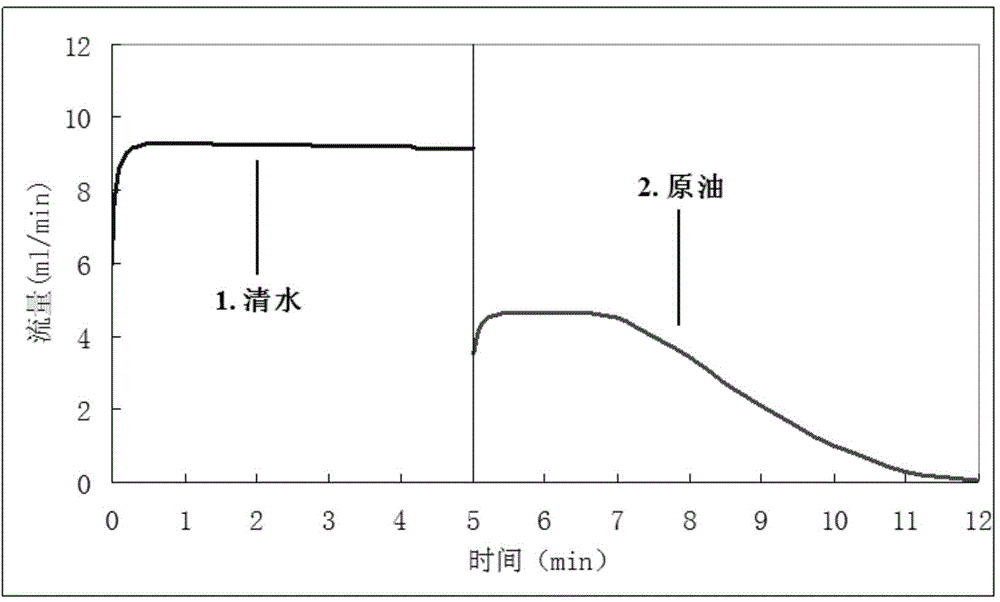

Examples

Embodiment 1

[0026] Add 900g of deionized water, 4.5g of sodium lauryl sulfate, and 9g of polyvinyl alcohol into a 3000ml reaction bottle, and stir slowly. After all the added materials are dissolved, add 100g of styrene, 30g of divinylbenzene, and Acyl 4g, then pass nitrogen to replace the air in the reactor, increase the stirring speed to 250r / min, stir for 30min, then raise the temperature to 80°C, and react for 4h; After the dropwise addition of the reaction solution of 5 g of benzoyl peroxide was completed, the reaction was continued for 4 h, cooled to room temperature, discharged, and filtered to obtain the product.

[0027] The product obtained above is subjected to a performance test, and cement slurry is prepared according to the GB / T19139-2003 standard. The cement slurry formula is as follows:

[0028] ①The cement stone formula with self-healing microspheres is: Shengwei G grade oil well cement 100g+polyvinyl alcohol 2g+self-healing microspheres 5g+fresh water 42.8g

[0029] ②Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com