Temperature control direct-writing nozzle of biological printer

A bioprinter and nozzle technology, which is applied in manufacturing auxiliary devices, processing heating elements, processing environment adjustment, etc., can solve the problems of low forming accuracy, inability to form in vitro tissue models, and difficult forming of hydrogel materials, so as to achieve easy three-dimensional forming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

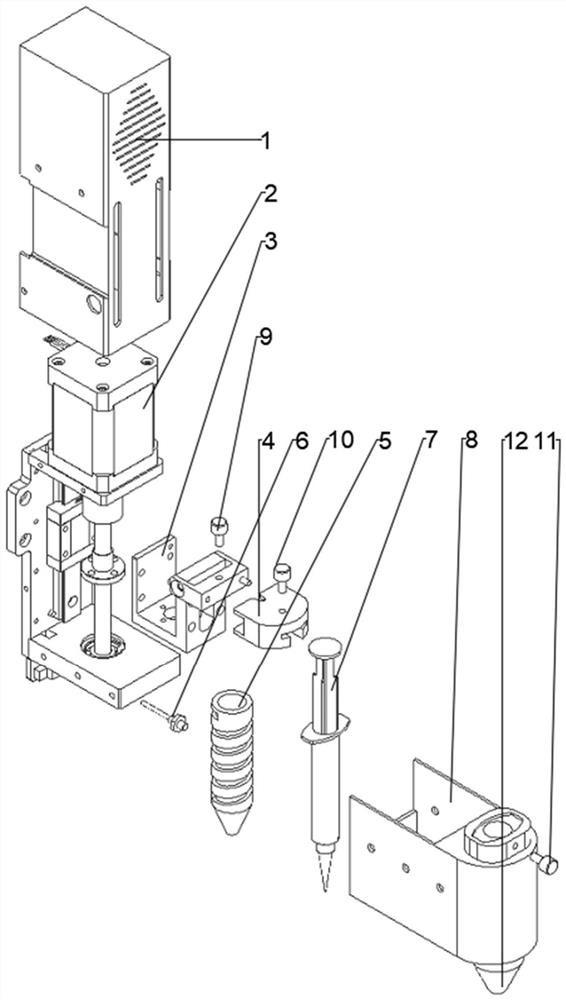

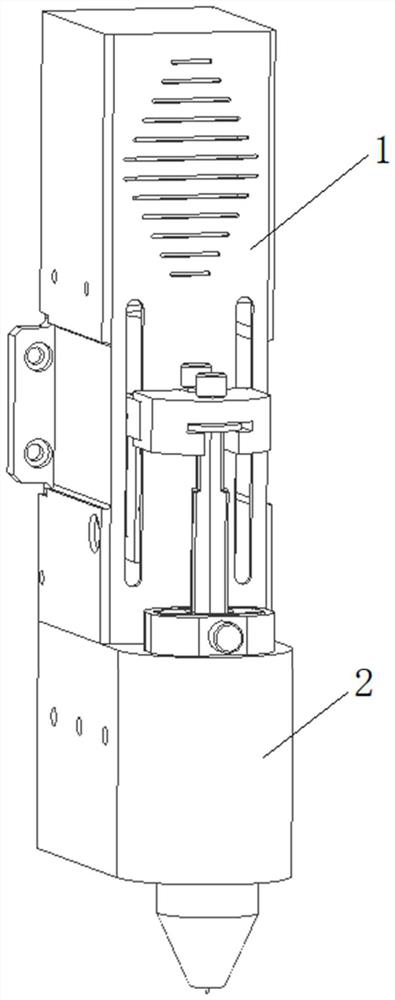

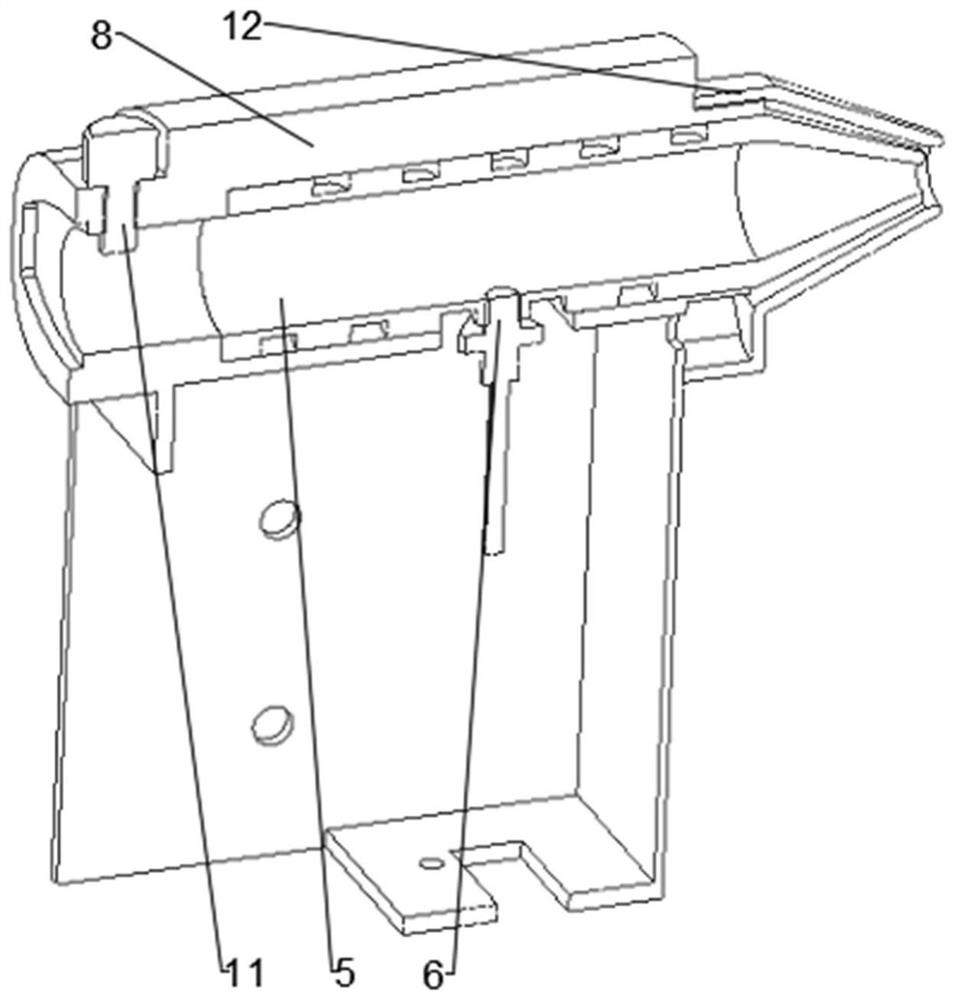

[0020] In order to more clearly illustrate the technical solutions in the specific embodiments of the present invention, the drawings that need to be used in the description of the specific embodiments will be briefly introduced below. Obviously, the accompanying drawings in the following description are some embodiments of the present invention , for those skilled in the art, other drawings can also be obtained according to these drawings on the premise of not paying creative work.

[0021] Such as Figure 1 to Figure 3 As shown, a bioprinter temperature-controlled direct-writing nozzle provided by the present invention includes a linear movement platform composed of a motor screw slider, a Z-shaped plate 3 fixedly connected to the screw slider, a quick plug-in terminal 4, Heating copper pipe 5, thermistor 6, syringe 7, syringe clamp 8, syringe clamp cap 12 and dustproof protective shell 1. In the process of in vitro tissue model processing, the extrusion flow rate of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com