Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

A technology for lithium iron phosphate and power batteries, which is applied in the field of large-capacity and high-power polymer lithium iron phosphate power batteries and its preparation, can solve the problems of lithium iron phosphate positive electrode slurry preparation and coating difficulties, and solve the problems of preparation and coating Difficult deployment, improved safety, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

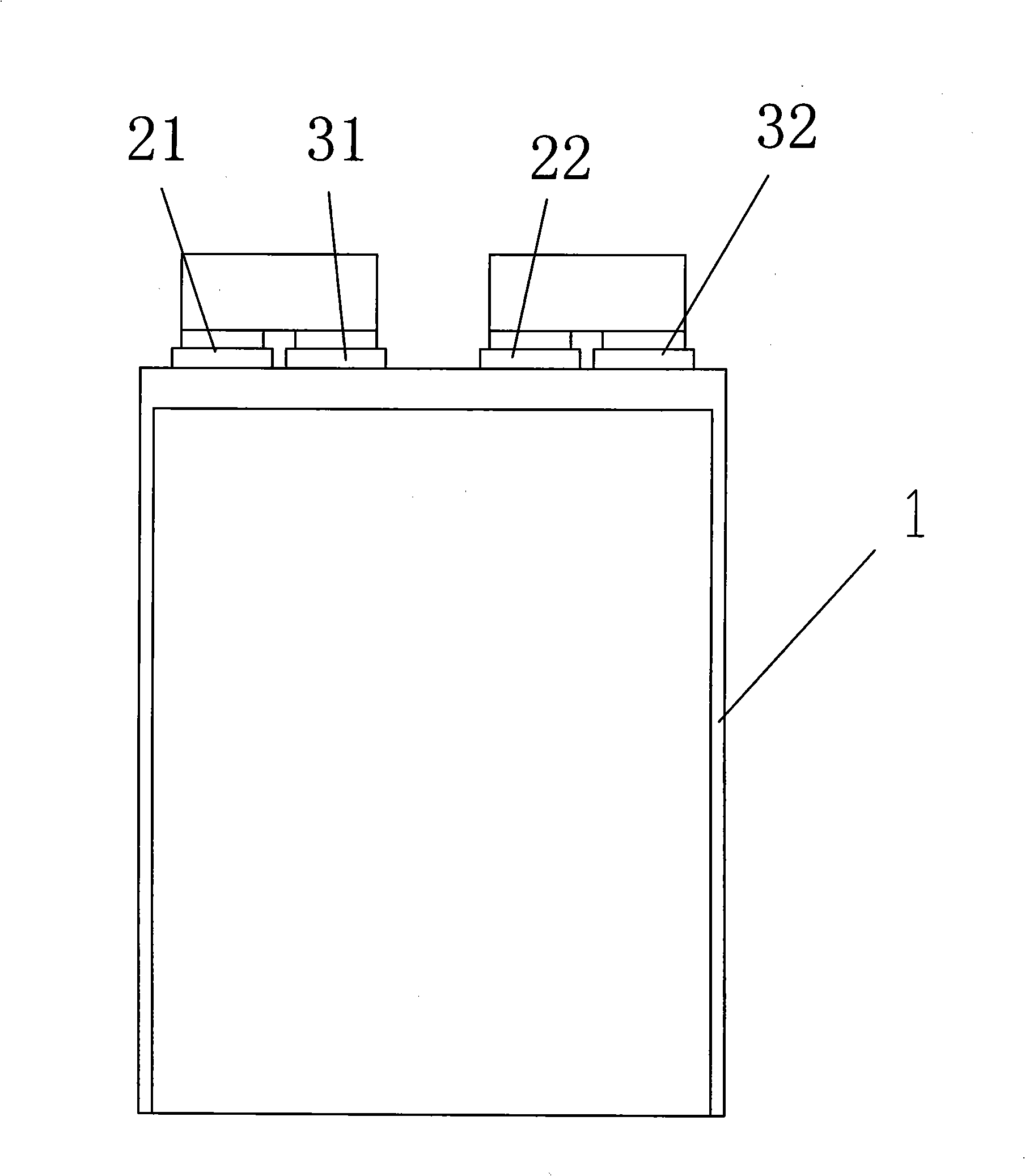

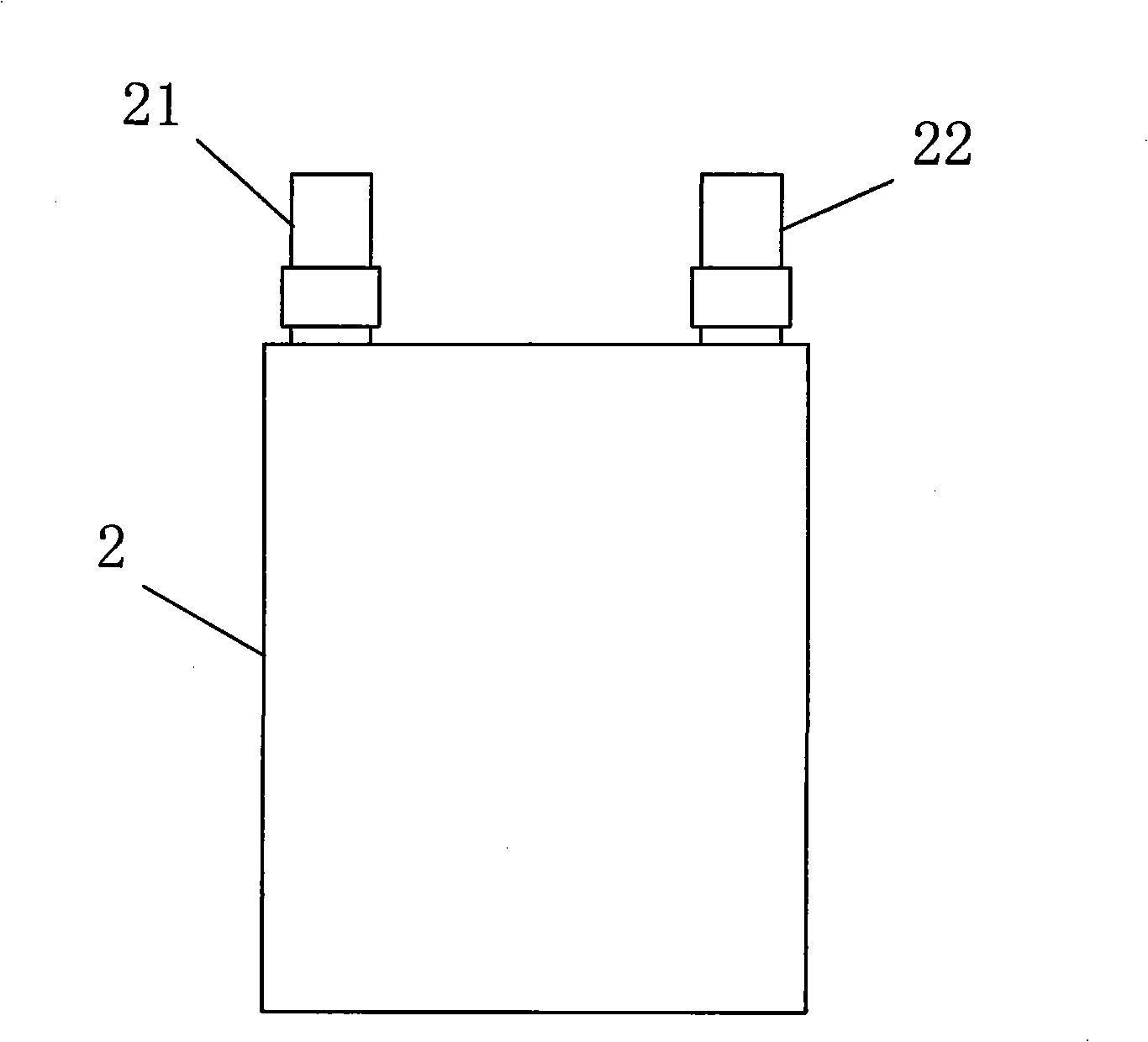

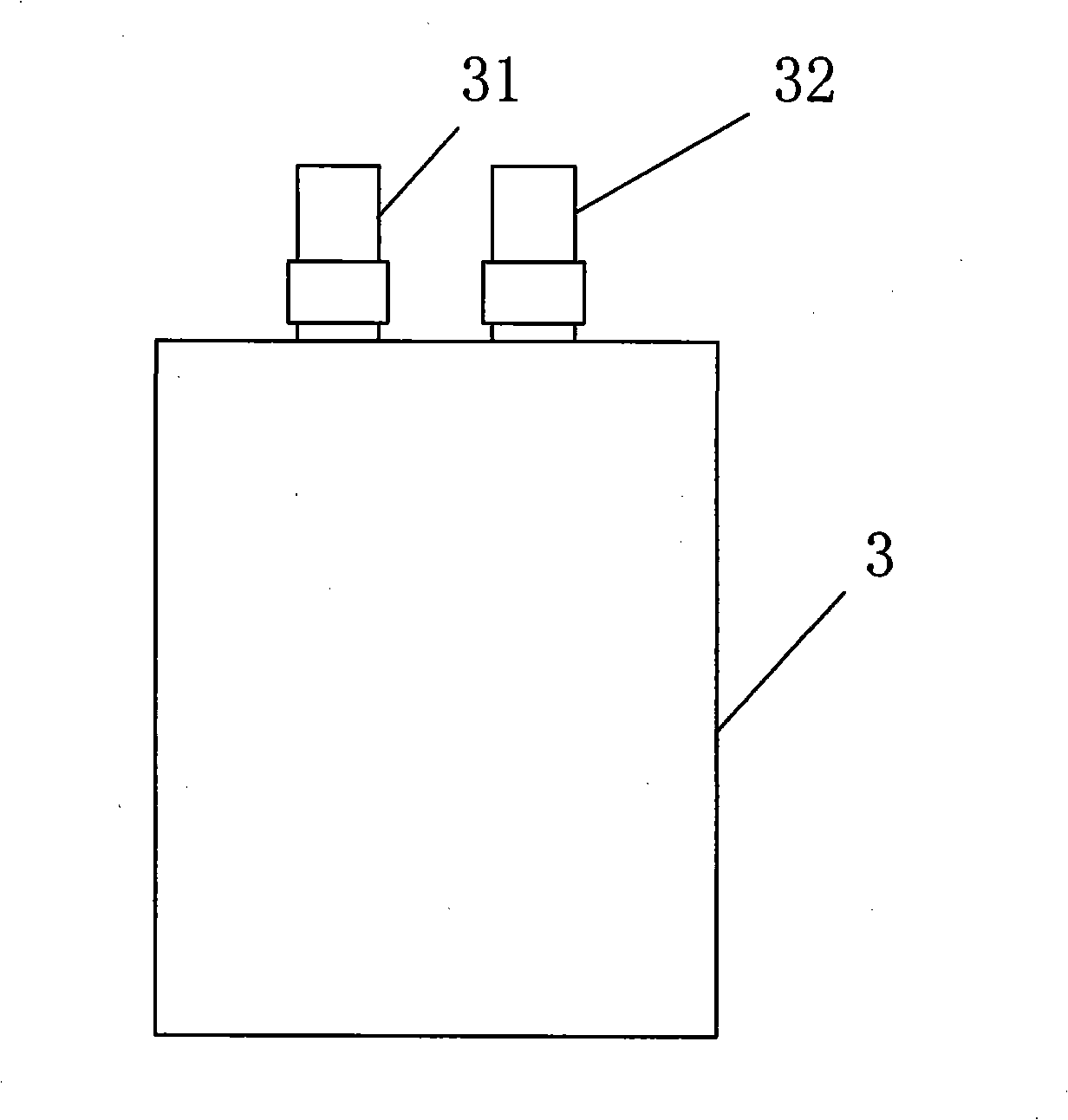

[0045] Embodiment 1, a high-capacity and high-power polymer lithium iron phosphate power battery described in this embodiment includes a positive electrode, a negative electrode, a diaphragm, a polymer gel electrolyte and a battery case 1, and the battery case 1 is made of aluminum plastic The positive electrode includes a positive electrode active material, a binder, a conductive agent, and a positive electrode current collector; the positive electrode active material is lithium iron phosphate (LiFePO 4 ) material; the negative electrode includes negative electrode material, conductive agent, thickener, binder and negative electrode current collector; Weld the two positive tabs and the negative tabs together; if it is multi-cell stacking, connect the tabs at the bottom of the cell, and expose two pairs of positive and negative tabs, and connect them separately; in order to prepare Convenient, the single cell adopts a winding structure; this embodiment uses two cells, which ar...

Embodiment 2

[0079] Embodiment 2. Compared with Embodiment 1, this embodiment differs in that the materials used in the positive electrode slurry and their weight percentage ratios are: 83% lithium iron phosphate, 4% superconducting carbon (Super-P), Conductive carbon black 2.5%, conductive graphite (KS-6) 2%, carbon nanotube 2%, polyvinylidene fluoride 6.5%; positive electrode coating surface density 9.5mg / cm 2 , positive electrode compaction density 1.95g / cm 3 ; The material used in the negative electrode slurry and its weight percentage ratio are: negative electrode material 90%, superconducting carbon (Super-P) 3%, conductive carbon black 2%, styrene-butadiene rubber (SBR) 3%, carboxymethyl fiber Plain sodium (CMC) 2%; Negative electrode coating surface density 3.8mg / cm 2, , negative electrode compacted density 1.45g / cm 3 ; The composition, structure and product preparation method of the product of this embodiment are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0080] Embodiment 3, compared with Embodiment 1, the difference of this embodiment is: the material used in the positive electrode slurry and its weight percentage ratio are: lithium iron phosphate 85%, superconducting carbon (Super-P) 5.5%, Conductive carbon black 2%, conductive graphite (KS-15) 1.5%, polyvinylidene fluoride 6%; positive electrode coating surface density 9mg / cm 2 , positive compaction density 2g / cm 3 The material used in the negative electrode slurry and its weight percentage ratio are: negative electrode material 91%, superconducting carbon (Super-P) 3%, conductive graphite (KS-15) 2%, styrene-butadiene rubber (SBR) 2.5%, Sodium carboxymethyl cellulose (CMC) 1.5%; Negative electrode coating surface density 3.8mg / cm 2 , negative electrode compacted density 1.4g / cm 3 ; The composition, structure and product preparation method of the product of this embodiment are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com