Method for preparing highly ordered aluminum oxide template by asymmetric two-step anodization

A technology of secondary anodization and alumina template, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of limiting and restricting the scope of application, and achieve the effect of realizing modulation and expanding the scope of selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

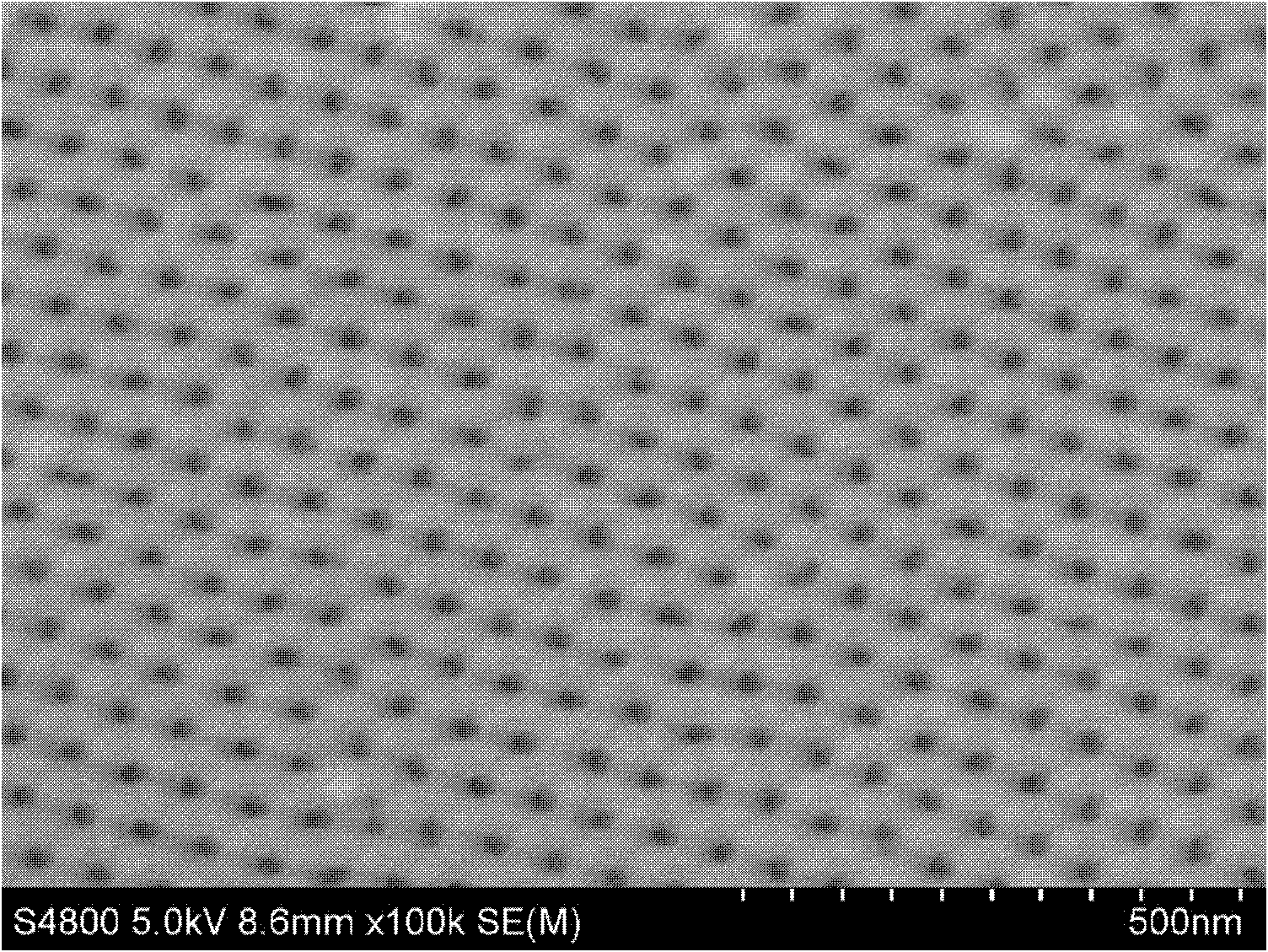

[0024] Under the protection of argon, 99.99wt% of the aluminum sheet was annealed at a high temperature, the annealing temperature was 500°C, and the annealing time was 3 hours; the surface oil was removed by ultrasonic cleaning in acetone for about 30 minutes, and then the Electrochemical polishing in absolute ethanol and perchloric acid for 5-8 minutes, the polishing voltage is 15-18V, and the temperature of the polishing solution is 20-25°C; the polished aluminum sheet is heated at a temperature of 5°C and a concentration of 4wt%. In sulfuric acid, carry out anodic oxidation for the first time with a voltage of 25V, and the oxidation time is 3 to 4 hours; soak the template oxidized for the first time in a mixed solution of 6wt% phosphoric acid and 1.8wt% chromic acid at room temperature for 24 hours , to completely remove the surface oxide film; in oxalic acid with a temperature of 5°C and a concentration of 0.4mol / L, the second anodic oxidation is performed at a voltage of ...

Embodiment 2

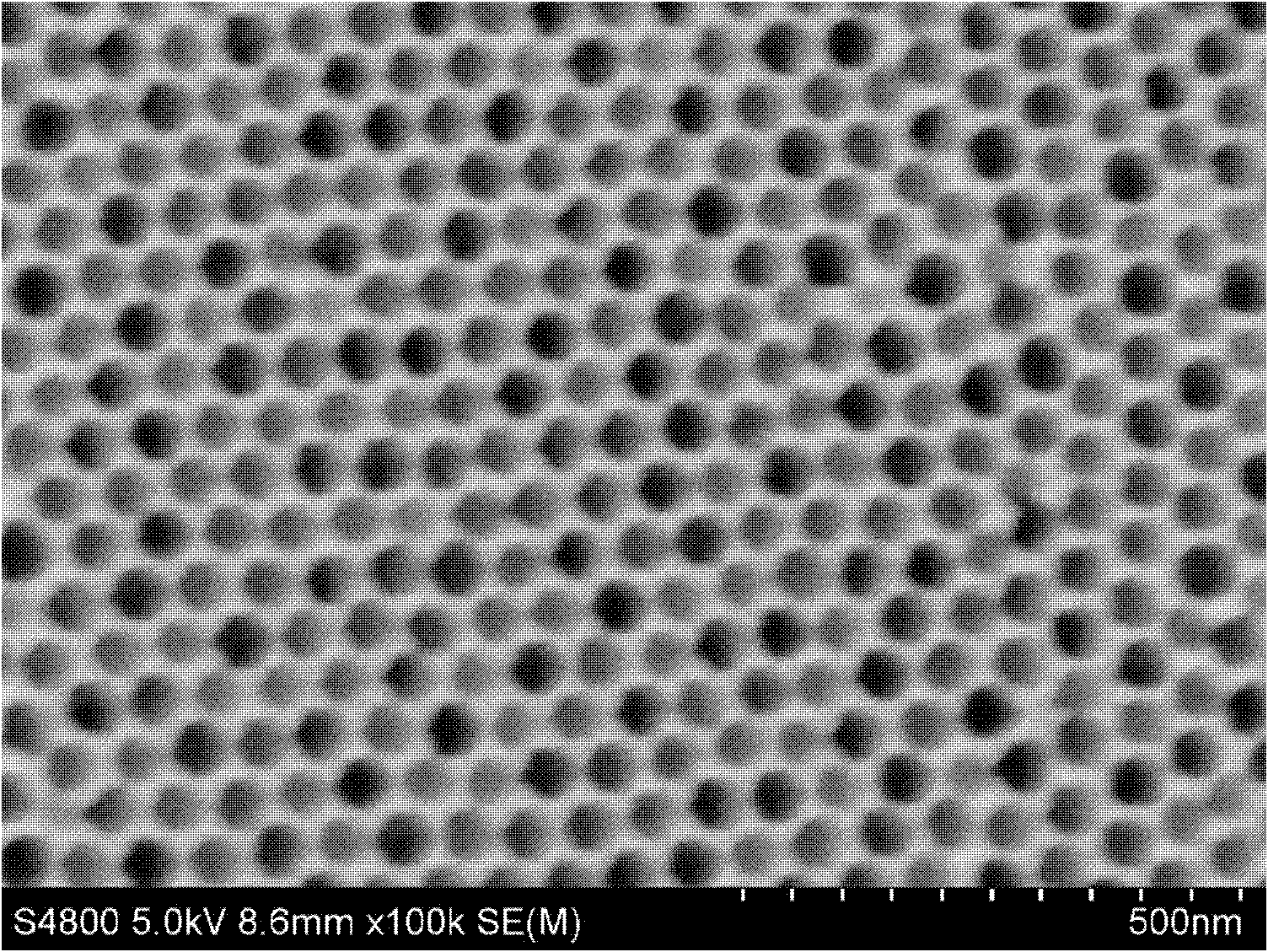

[0026] Under the protection of argon, 99.99wt% of the aluminum sheet was annealed at a high temperature, the annealing temperature was 500°C, and the annealing time was 3 hours; the surface oil was removed by ultrasonic cleaning in acetone for about 30 minutes, and then the Electrochemical polishing in absolute ethanol and perchloric acid for 5-8 minutes, the polishing voltage is 15-18V, and the temperature of the polishing solution is 20-25°C; the polished aluminum sheet is heated at a temperature of 5°C and a concentration of 4wt%. In sulfuric acid, carry out anodic oxidation for the first time with a voltage of 25V, and the oxidation time is 3 to 4 hours; soak the template oxidized for the first time in a mixed solution of 6wt% phosphoric acid and 1.8wt% chromic acid at room temperature for 24 hours , to completely remove the surface oxide film; in phosphoric acid with a temperature of 5°C and a concentration of 4wt%, conduct the second anodic oxidation with a voltage of 25V...

Embodiment 3

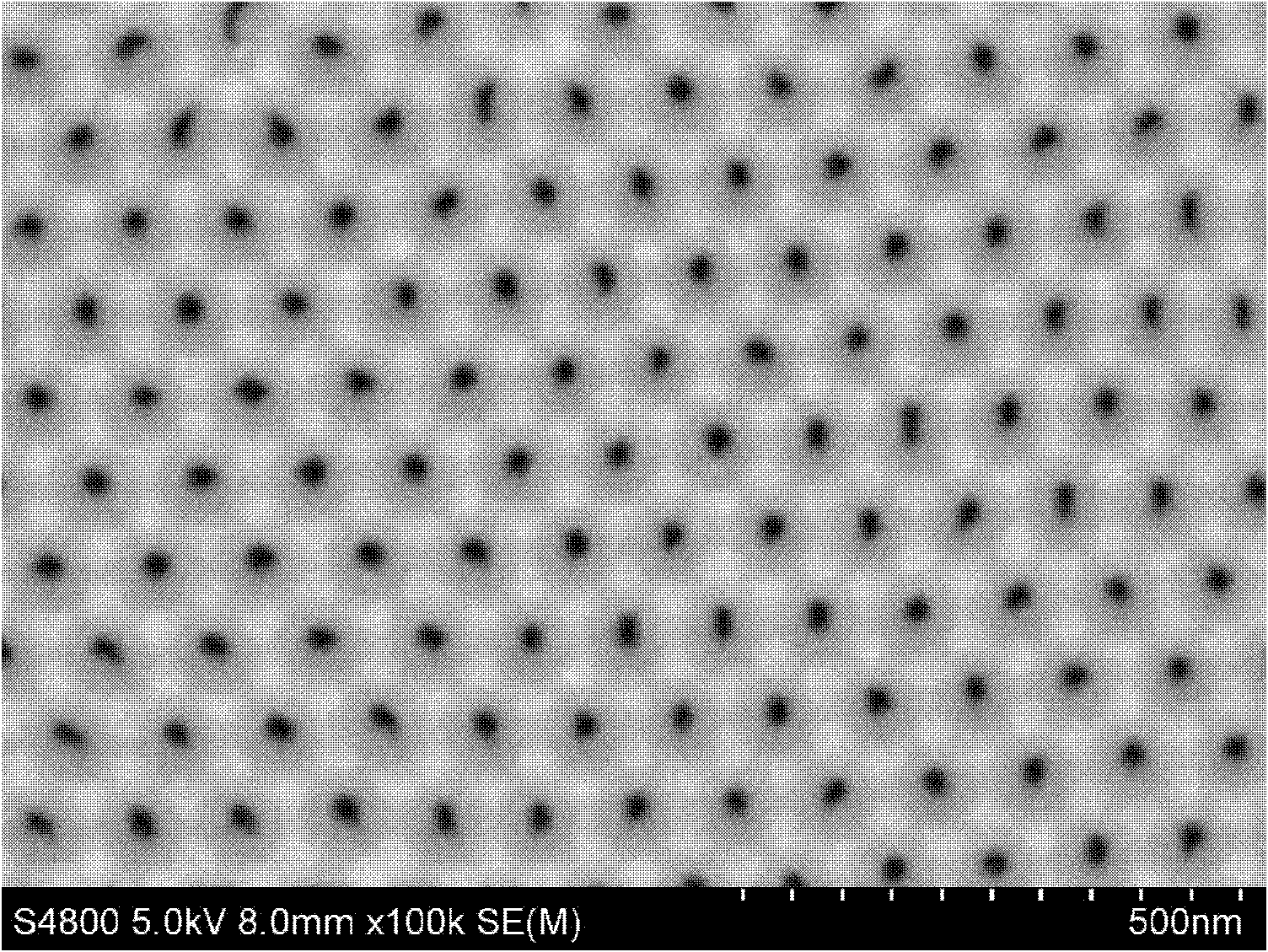

[0028] Under the protection of argon, 99.99wt% of the aluminum sheet was annealed at a high temperature, the annealing temperature was 500°C, and the annealing time was 3 hours; the surface oil was removed by ultrasonic cleaning in acetone for about 30 minutes, and then the Electrochemical polishing in absolute ethanol and perchloric acid for 5-8 minutes, the polishing voltage is 15-18V, the temperature of the polishing solution is 20-25°C; the polished aluminum sheet is kept at a temperature of 5°C and a concentration of 0.4mol / In the oxalic acid of L, carry out anodic oxidation for the first time with the voltage of 40V, and oxidation time is 3~4 hours; The template oxidized for the first time is immersed in the mixed solution of 6wt% phosphoric acid and 1.8wt% chromic acid at room temperature for 24 After hours, the surface oxide film is completely removed; in sulfuric acid with a temperature of 1°C and a concentration of 0.04wt%, the second anodic oxidation is performed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com