Preparing method and device of composite material of black lead for synthesizing diamond and catalyst

一种合成金刚石、复合材料的技术,应用在发明涉及复合材料的制备方法及设备领域,能够解决难以形成金属膜、影响金刚石晶体生长等问题,达到克服吸附作用差、工艺简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

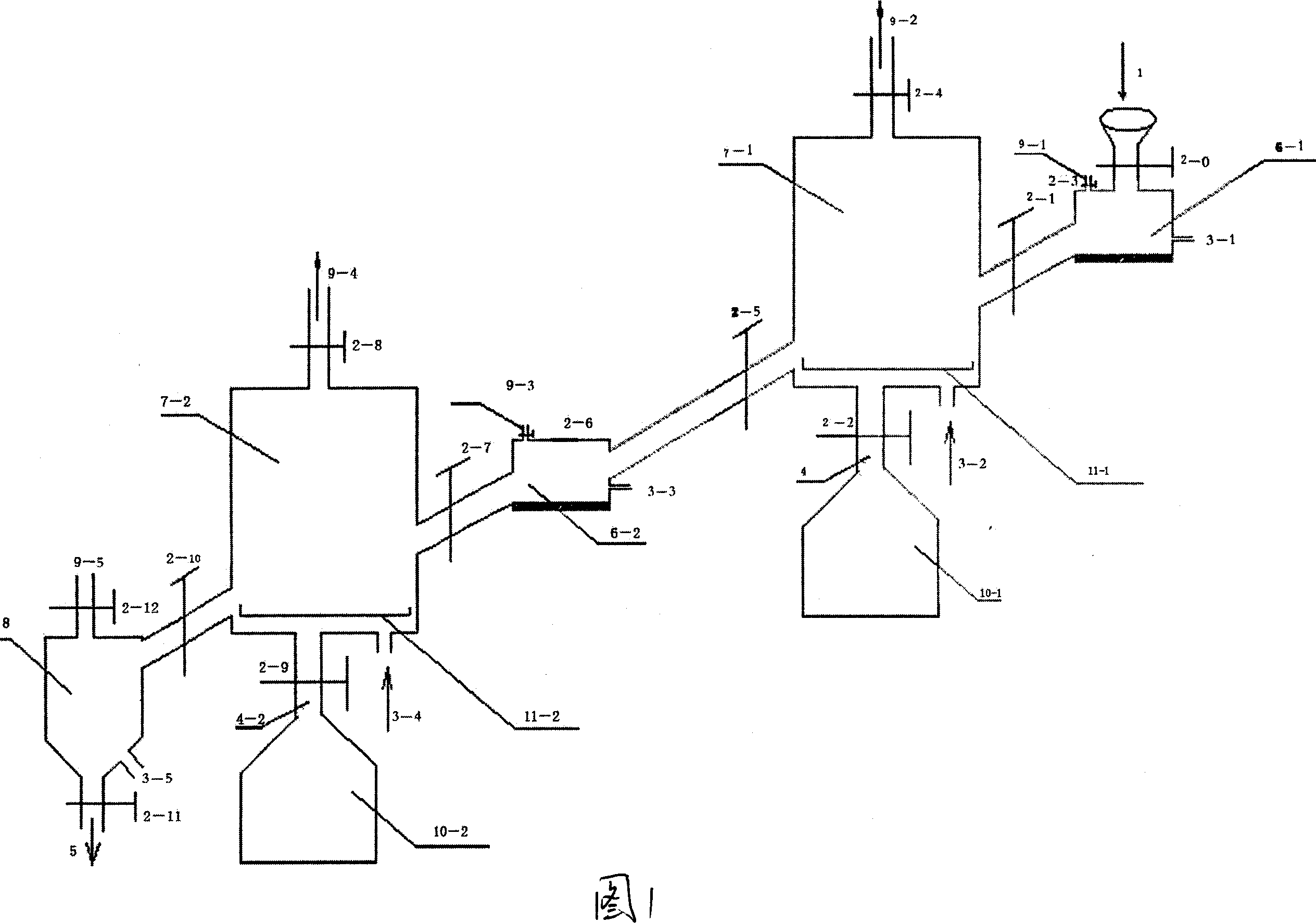

[0019] The method of the present invention specifically comprises the following steps:

[0020] a. Clean and pollution-free high-purity graphite particles are placed in the heating chamber 6. In order to prevent the graphite particles from being oxidized and polluted during the heating process, the heating chamber must be heated to the graphite particles under a protective atmosphere such as vacuum or nitrogen or argon. For heating, the lower limit of the temperature should be higher than the boiling point of the metal carbonyl complex used for plating. The upper limit of the temperature is set according to the thickness of the required plating. The temperature is set lower, which is determined by calculation according to the heat required by the metal carbonyl complex per molar volume of the decomposed unit;

[0021] B. transport the graphite particles heated to the required temperature into the coating chamber 7 with vibration or stirring device 11, open the metal carbonyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com