Mobile hydraulic workover rig

a technology of hydraulic workover rig and mobile rig, which is applied in the direction of drilling rods, drilling pipes, drilling/well accessories, etc., to achieve the effect of reliable and efficient manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

DETAILED DESCRIPTION OF SECOND EMBODIMENT

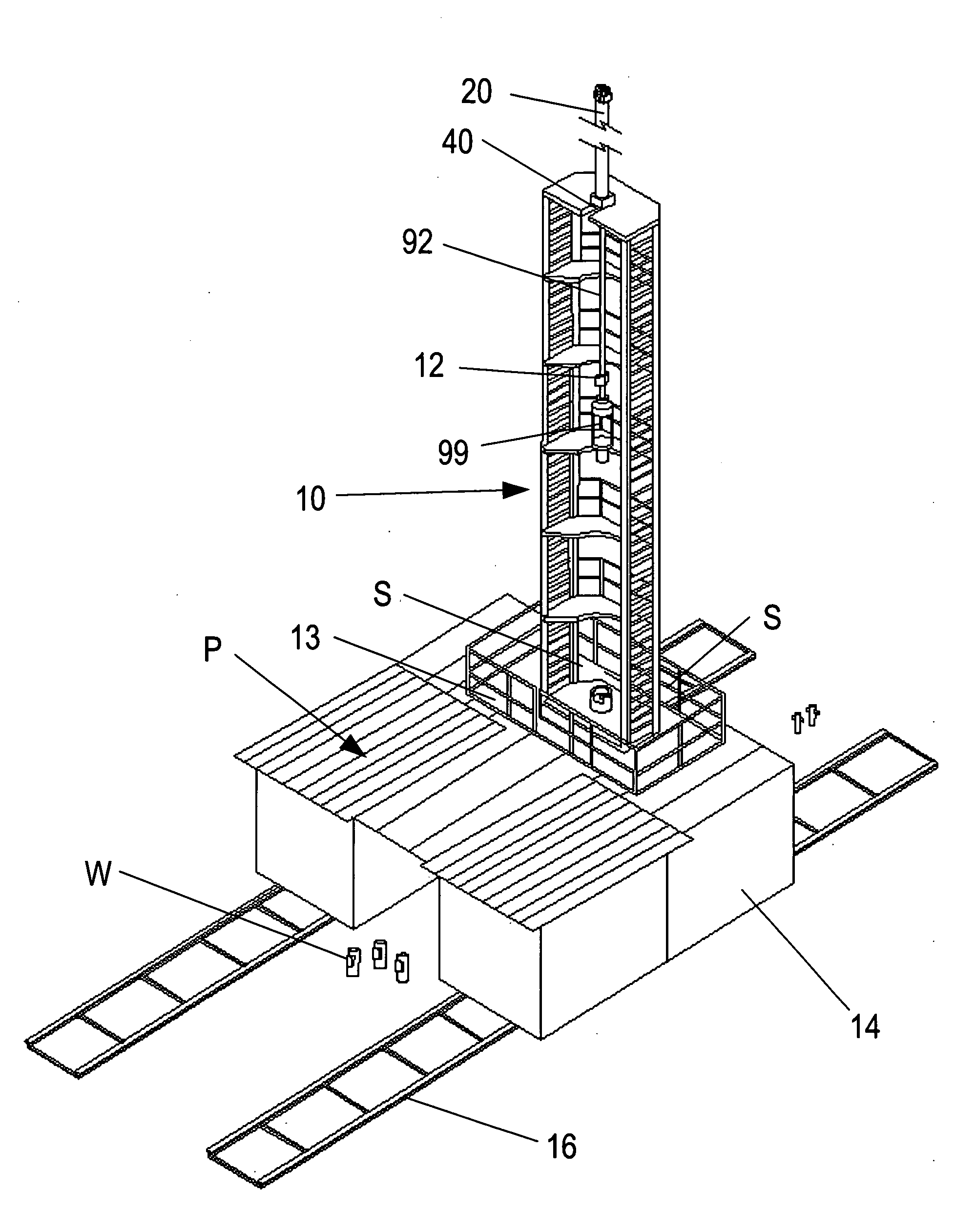

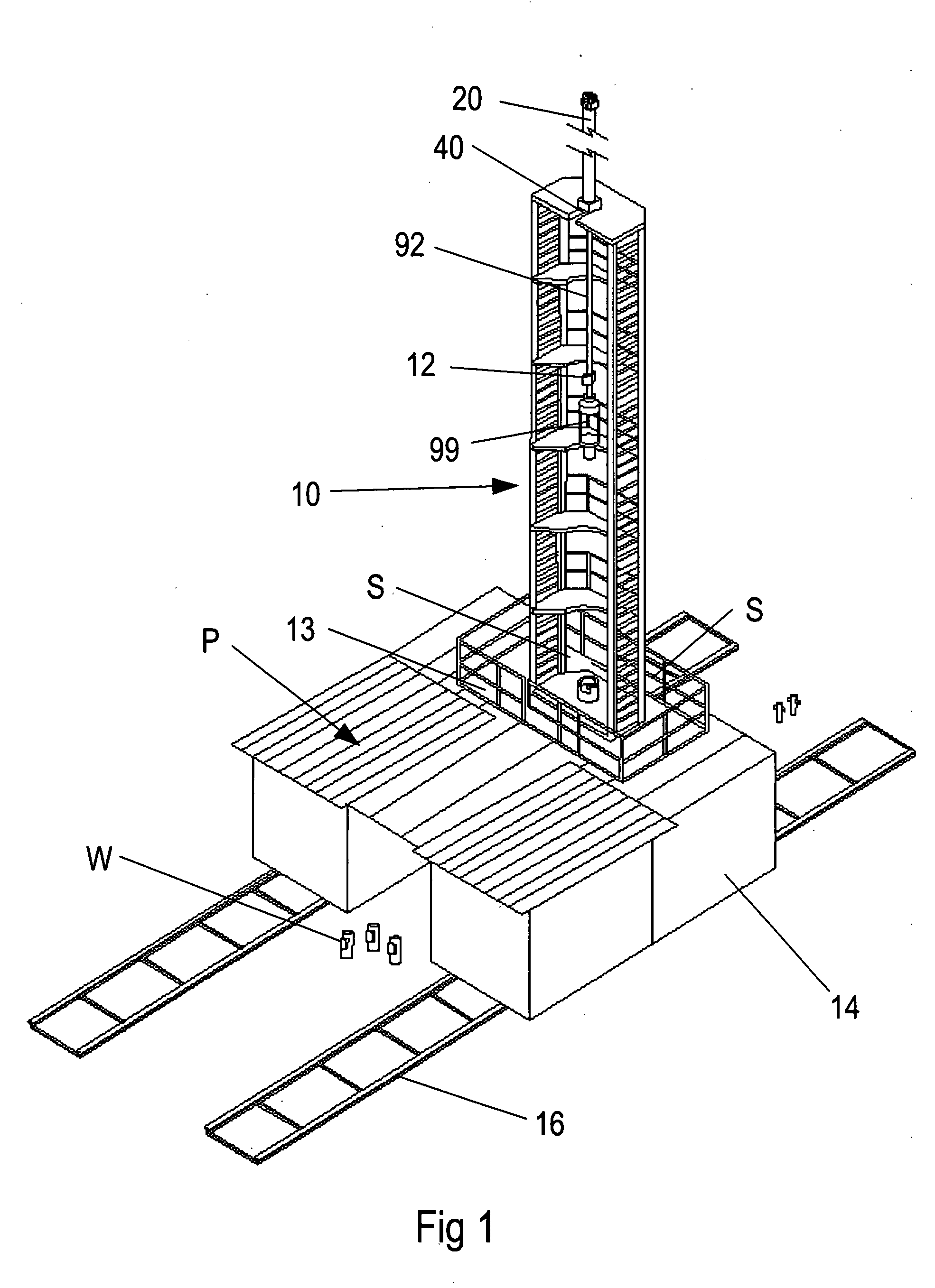

[0052]An offshore drilling 10′ is illustrated in FIG. 26 wherein like parts are correspondingly enumerated with prime numerals. Again, the rig 10′ is made up of a derrick 12′ mounted on base housing members or containers, not shown, which can be affixed or mounted on the standard offshore drilling platform, not shown, and therefore can utilize the existing positioning controls on the drilling platform to advance the derrick into position for the workover operation. The work floor 13′ has the same components including the catwalk, grating spacers, and pipe racks as described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com