Fully hydraulic intelligent workover rig

A workover rig and full hydraulic technology, which is applied in drilling equipment, earthwork drilling, drilling pipes, etc., can solve problems such as high risk, harsh working environment at the wellhead, and failure to realize the function of pressing down the tubing string, so as to improve safety , Easy installation and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in detail.

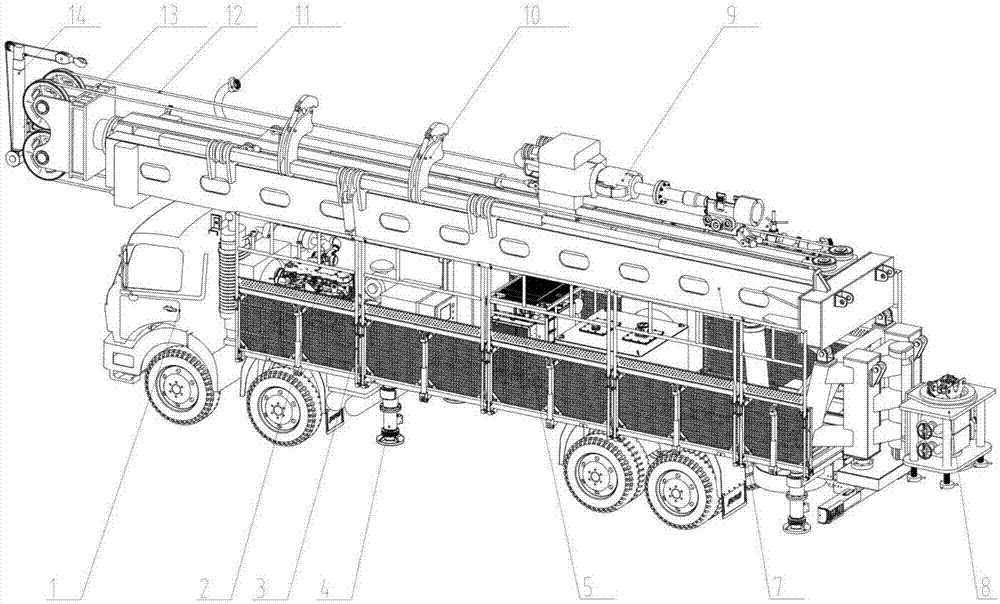

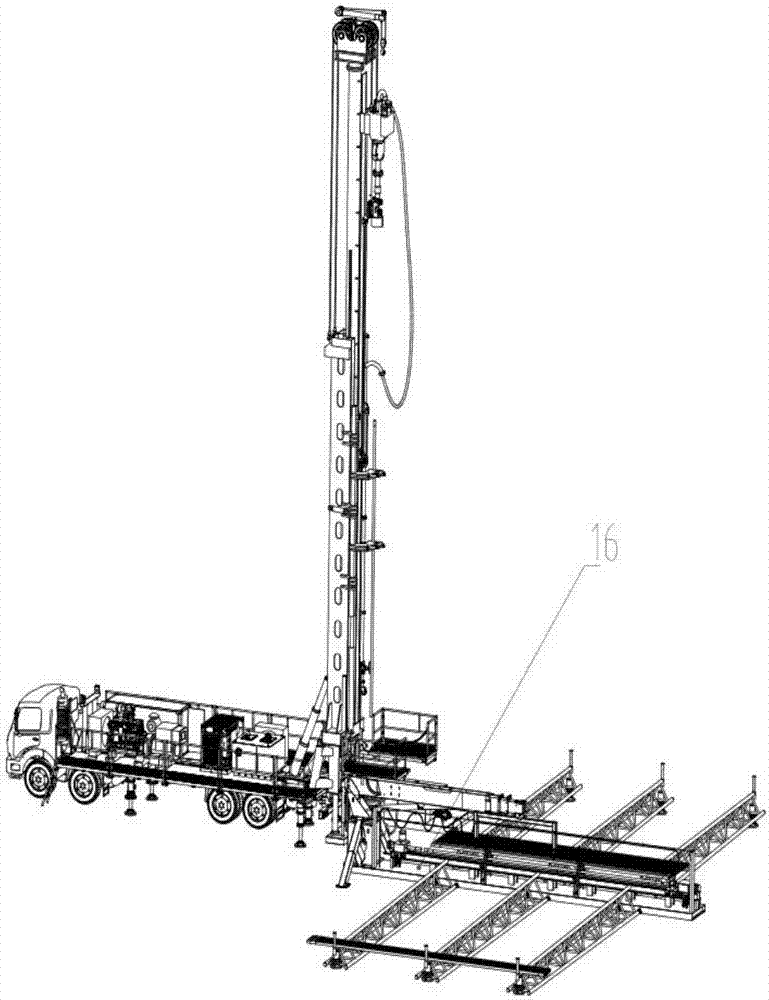

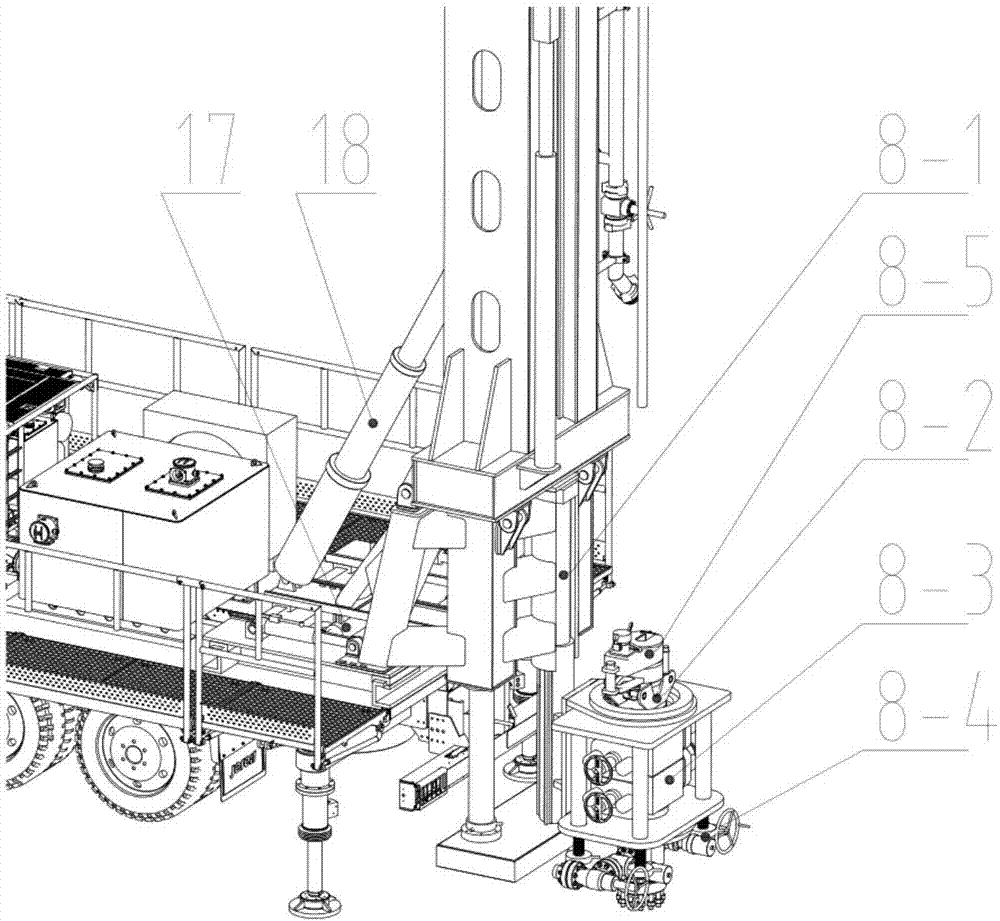

[0021] A fully automatic intelligent workover rig, including 1-chassis vehicle, 2-engine, 3-automatic turning walkway, 4-hydraulic adjustment leg, 5-hydraulic station, 7-luffing derrick, 8-wellhead device, 9 -Workover top drive, 10-Pipe grasping mechanism, 11-High pressure manifold, 12-Guiding wire rope, 13-Crown block, 14-Rotary hydraulic lifting small winch, 16-Tubing string automatic discharge device, 17-Derrick moving fast Positioning device, 18-Lifting cylinder, 19-Derrick support seat, 3-1. Guardrail assembly, 3-2. Walkway assembly, 3-3. Overturning tie rod assembly, 3-4 Overturning cylinder assembly, 8-1 Lifting adjustment device, 8-2 Automatic slips, 8-3 BOP, 8-4 Cross, 8-5 Oil pipe clamp, 16-1 Turning arm, 16-2, pick-up handle, 16-3 , Turnover mechanism, 16-4, oil pipe detection and maintenance device, 16-5, pipe rack, 16-6, pipe rack liquid cylinder.

[0022] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com