Joint robot of automatic material turning numerical control equipment

A numerical control equipment and automatic material turning technology, applied in the direction of comprehensive factory control, metal processing, etc., can solve the problems of reducing processing technology circulation and unevenness, and achieve the effect of reducing processing technology circulation and reducing stacking space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

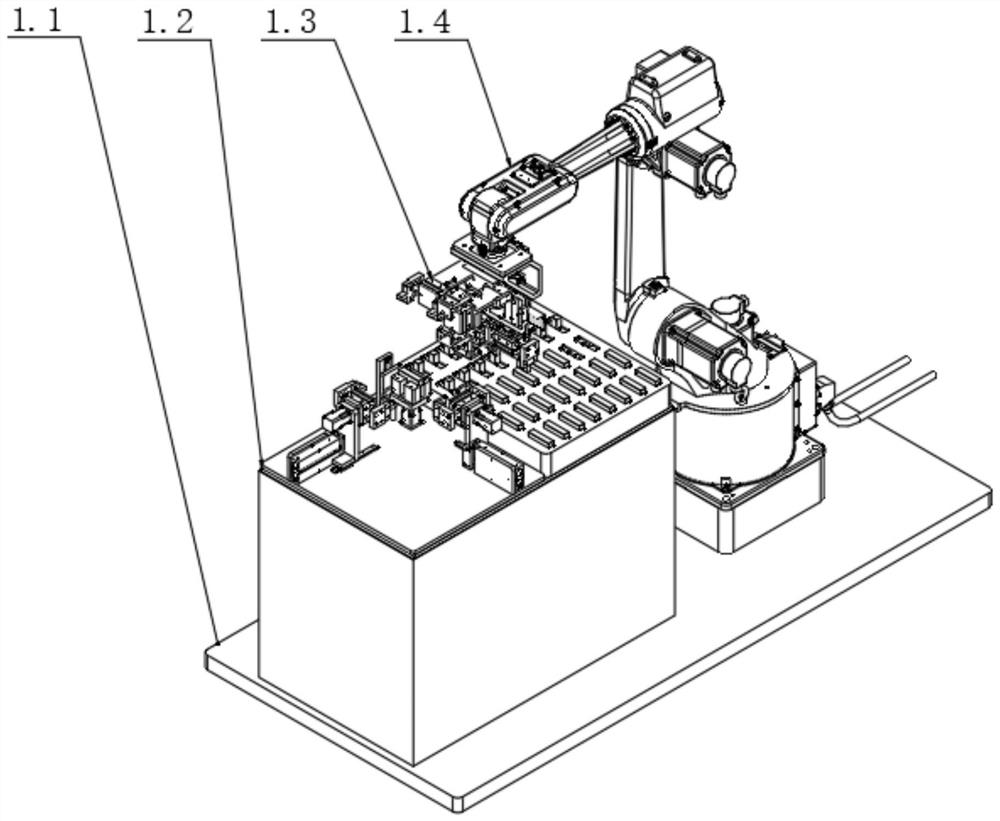

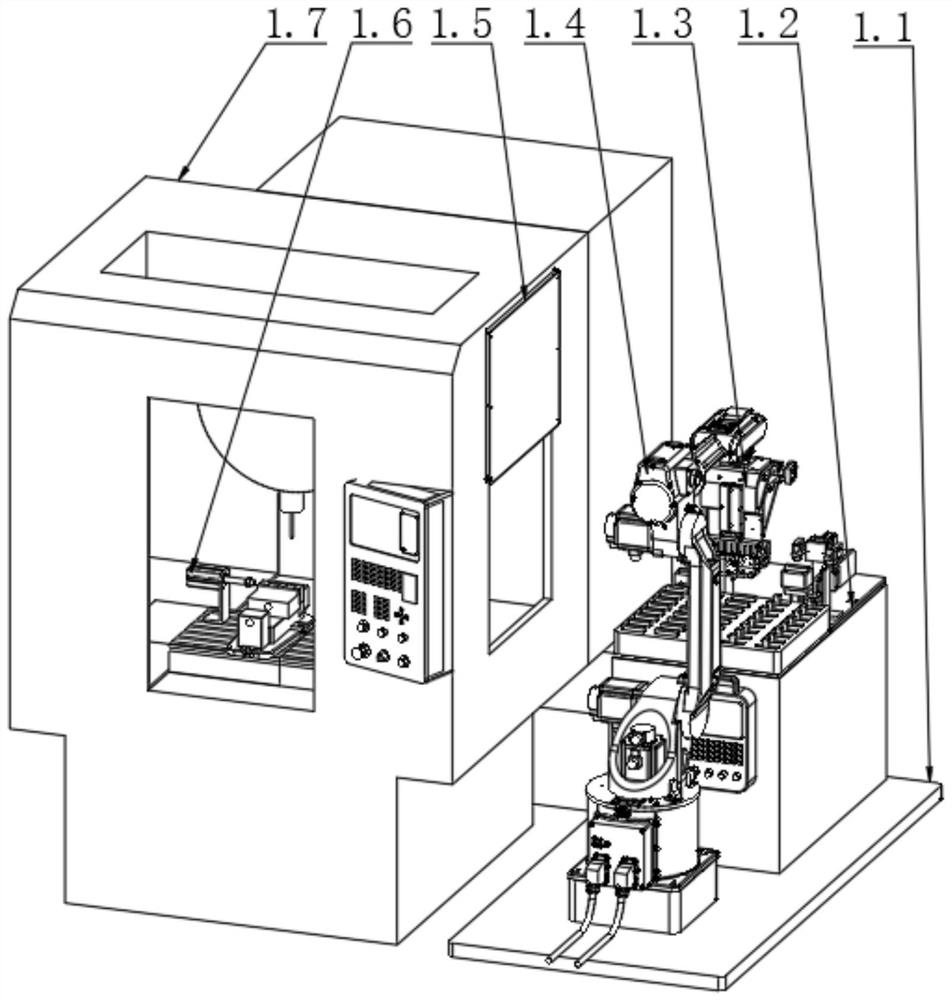

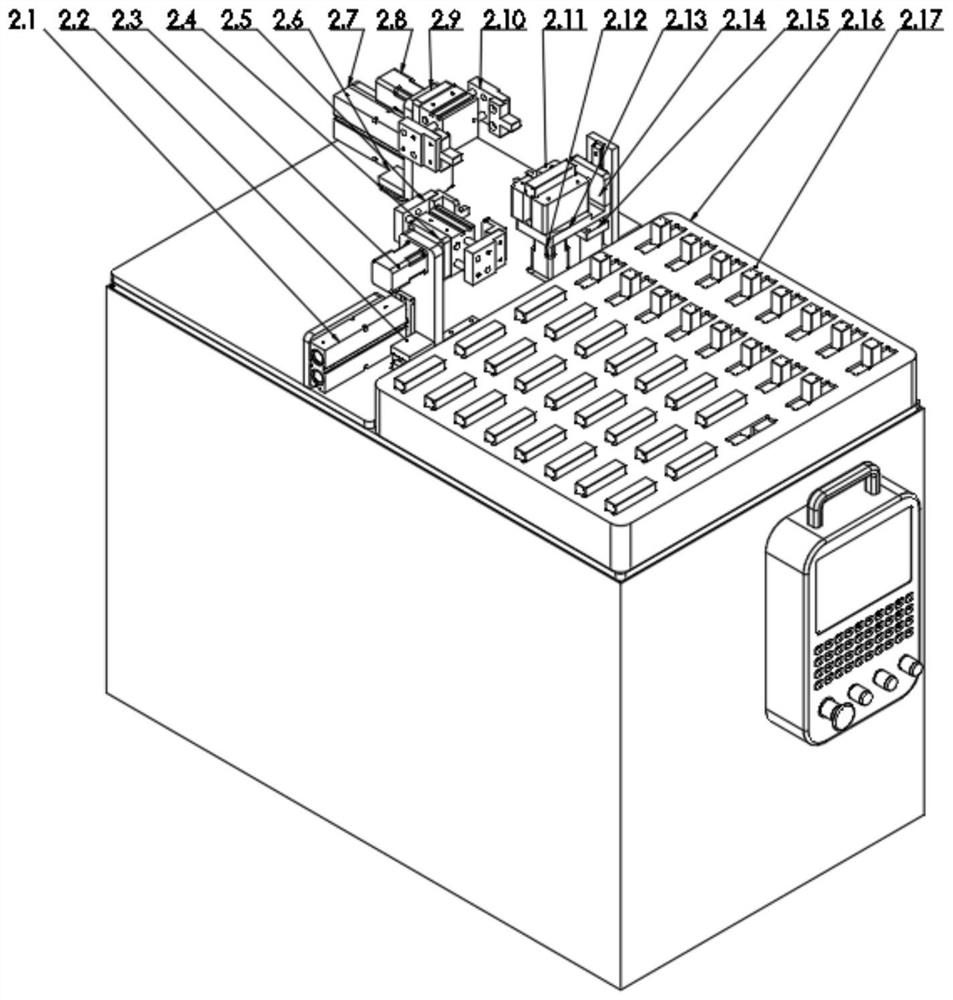

[0042] see Figure 1-2 , automatic turning over CNC equipment joint robot, including a first fixed bracket 1.1, the outer end of the first fixed bracket 1.1 is respectively equipped with a joint robot body 1.4 and a second fixed bracket 1.2, the upper end of the joint robot body 1.4 is equipped with a clamping jaw The grasping mechanism 1.3, the outer end of the joint robot body 1.4 is equipped with a numerical control device 1.7, the numerical control device 1.7 is provided with an auxiliary positioning mechanism 1.6, the outer end of the numerical control device 1.7 is equipped with a numerical control device telescopic door 1.5, on the second fixed bracket 1.2 The automatic turning mechanism of the processing surface, the rotating mechanism of the positioning surface and the material tray 1 2.16 are respectively installed, and the workpiece body 2.17 is arranged on the material tray 1 2.16. In this scheme, a multi-unit for turning the workpiece body 2.17 is added on the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com