Workover operation mechanization system replacing well mouth manual operation

A technology of manual operation and working machine, which is applied to drilling equipment, earthwork drilling, drilling pipes, etc. It can solve the problems that mechanization and automation cannot be realized, achieve a high level of mechanization and automation, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

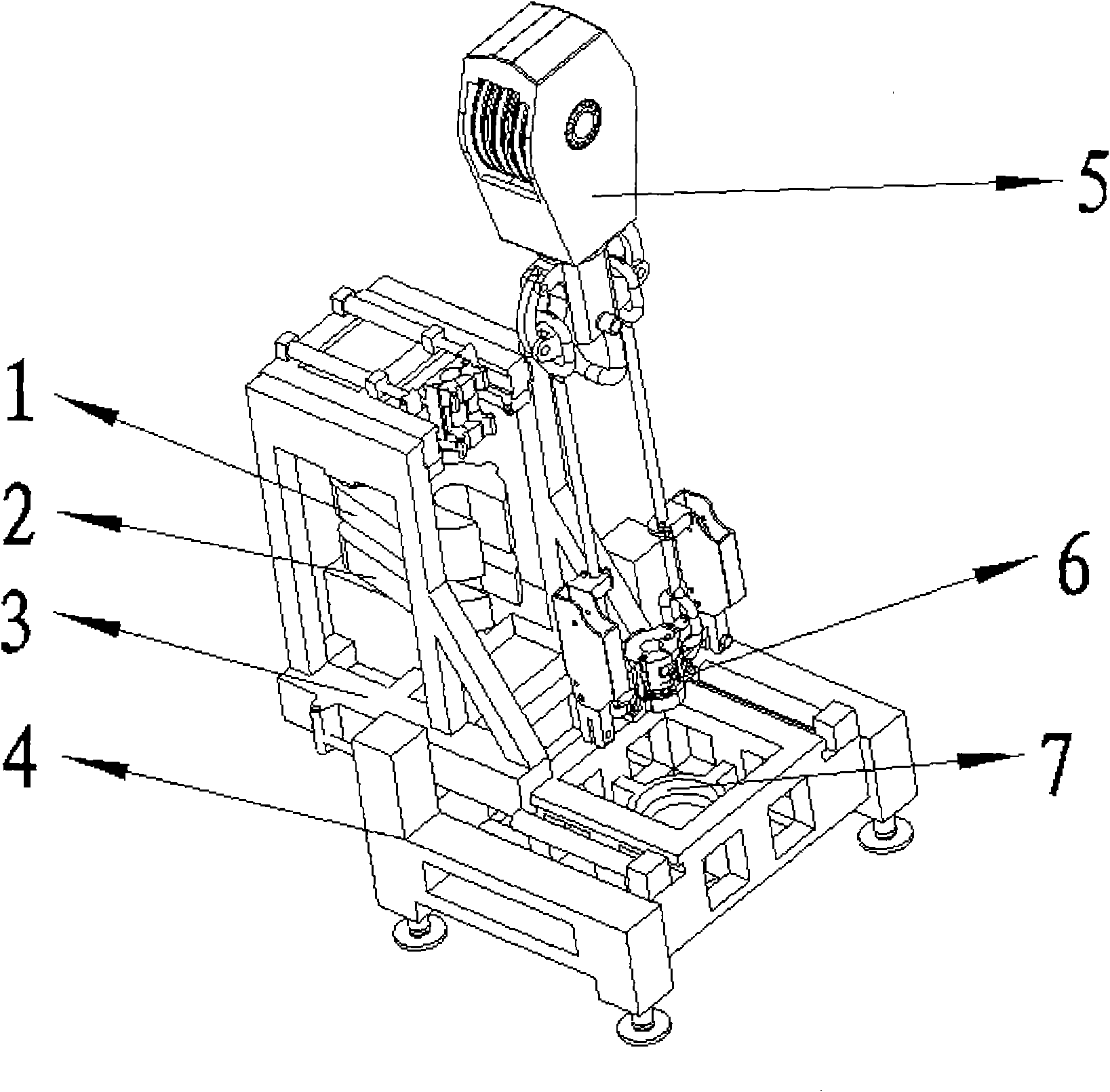

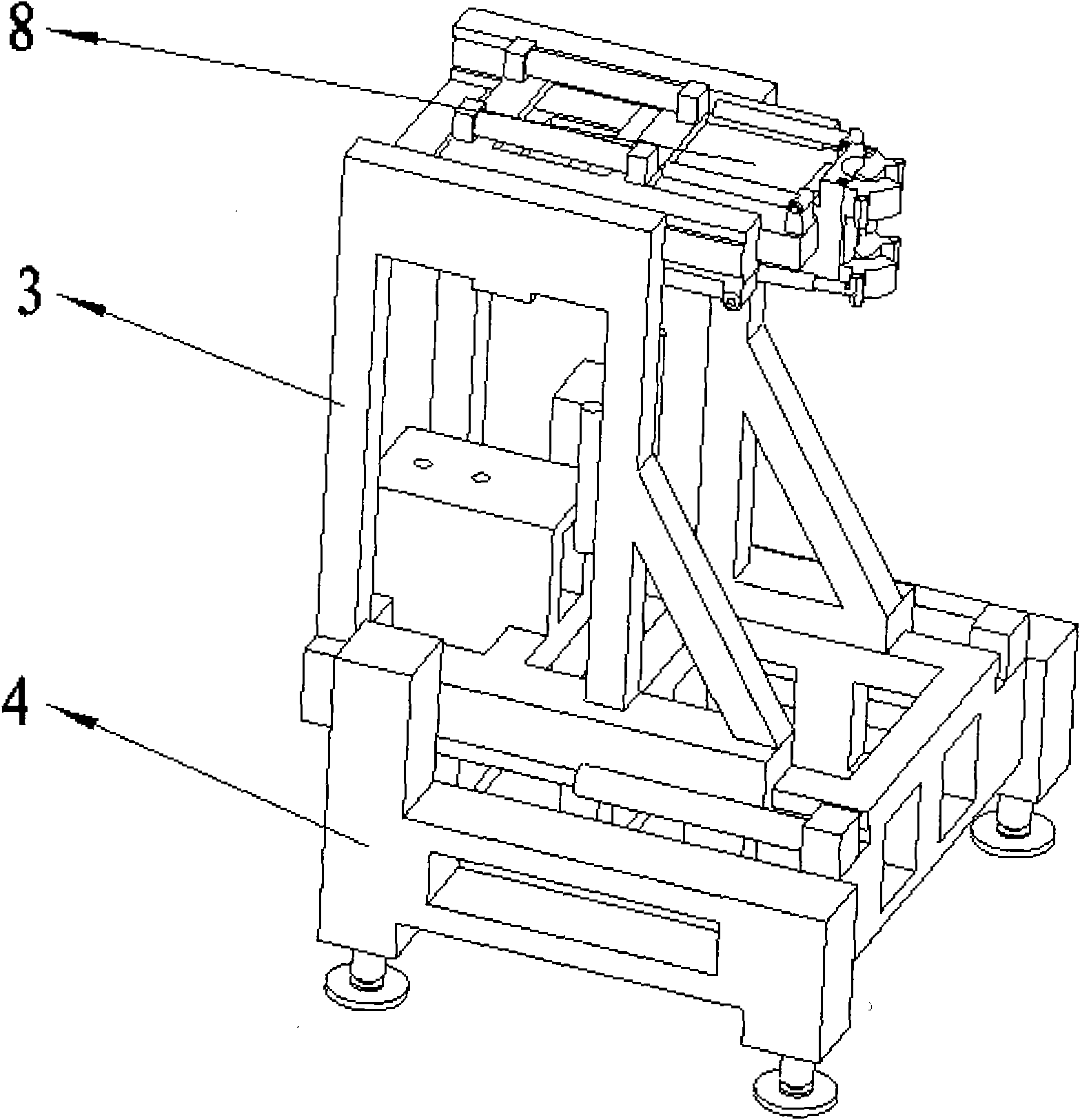

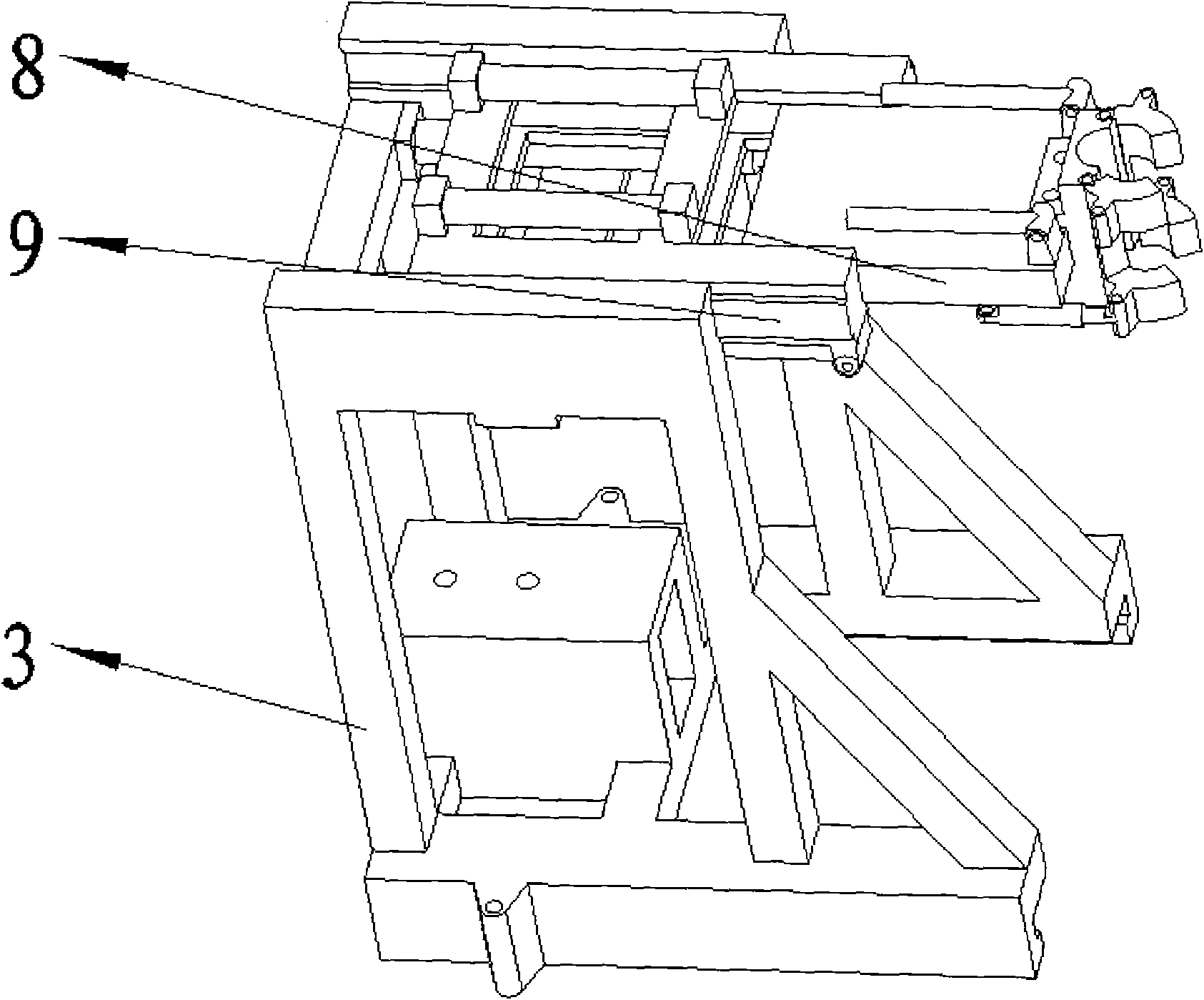

[0050] The workover operation mechanization system that replaces wellhead manual operation described in the present invention, such as figure 1 As shown, its main body is divided into upper and lower parts, which are called mobile working machine 3 and base 4 respectively. Such as figure 2 As shown, it is a sliding fit between the mobile working machine 3 and the base 4 . Wherein, a pair of power main tongs 1 and power back tongs 2 are vertically fixed on the mobile working machine 3, both of which are open-shaped, and shock absorbing springs are placed between them for unloading pipes. Adjust the distance between the main tong and back-up tong. The structure of each part is described in detail below.

[0051] The outside of the power master tongs 1 is a shell structure, and the inside includes a driving mechanism, a clamping mechanism, a braking mechanism, a reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com