Silver alloy wire and preparation method thereof

A technology of silver alloy and pre-alloying, which is applied in the field of silver alloy wire, can solve the problem that bonding silver wire is easily sulfided and corroded, and achieve the effects of reducing electrochemical corrosion, enhancing mechanical properties, improving wettability and casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples.

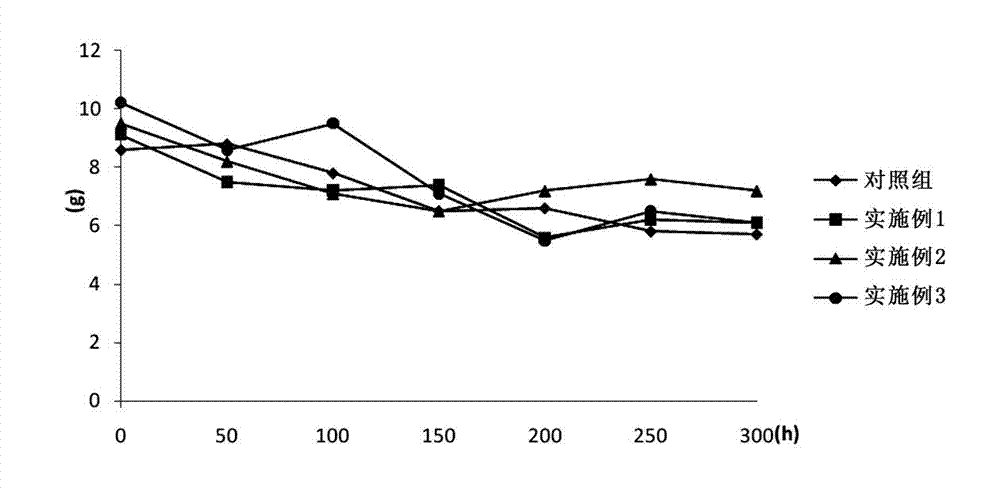

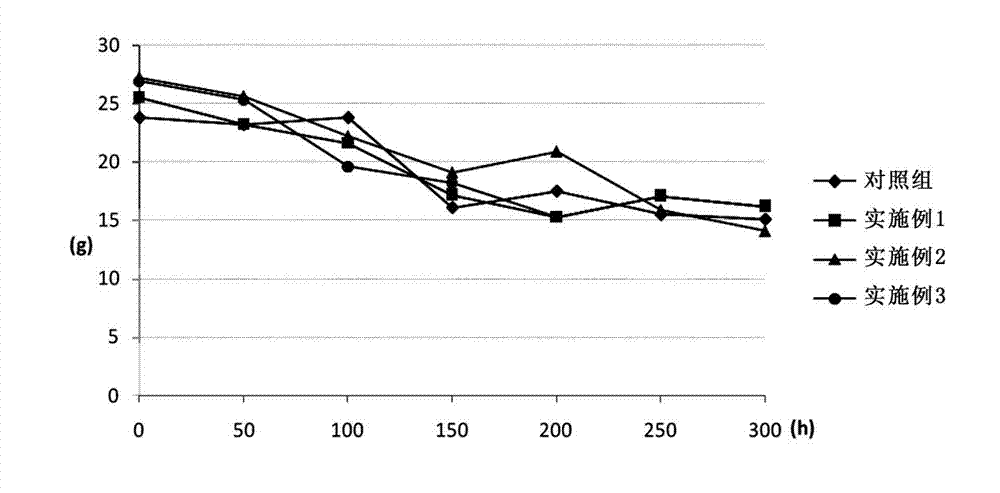

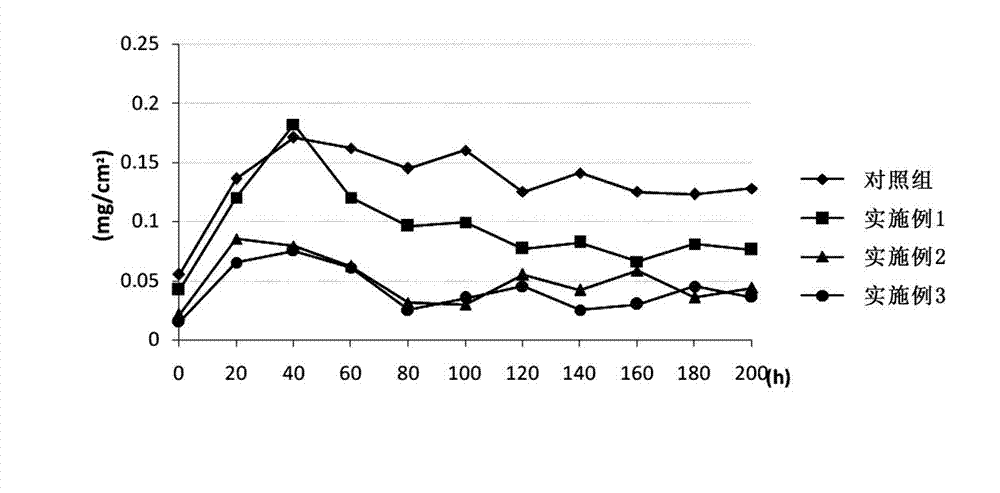

[0034] Prepare silver alloy wire according to the proportioning listed in Table 1 (surplus is silver),

[0035] Table 1 Raw material ratio embodiment

[0036]

[0037] The preparation process is carried out according to the following steps:

[0038] a. Silver raw material: choose silver with a purity of more than 99.999%;

[0039] b. Melting and casting: Add the various metals mentioned in proportion to the 80% silver raw material, and melt and cast it into a round bar through pre-alloying, master alloy and directional continuous drawing casting process;

[0040] c. Wire drawing: the round bar is drawn into a wire by a wire drawing machine;

[0041] d. Annealing;

[0042] e. Mechanical performance testing;

[0043] f. Winding: the wire is divided into small shafts of different lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com