Membrane electrode assembly for fuel cell, method of preparing the same, and fuel cell using the membrane electrode assembly for fuel cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

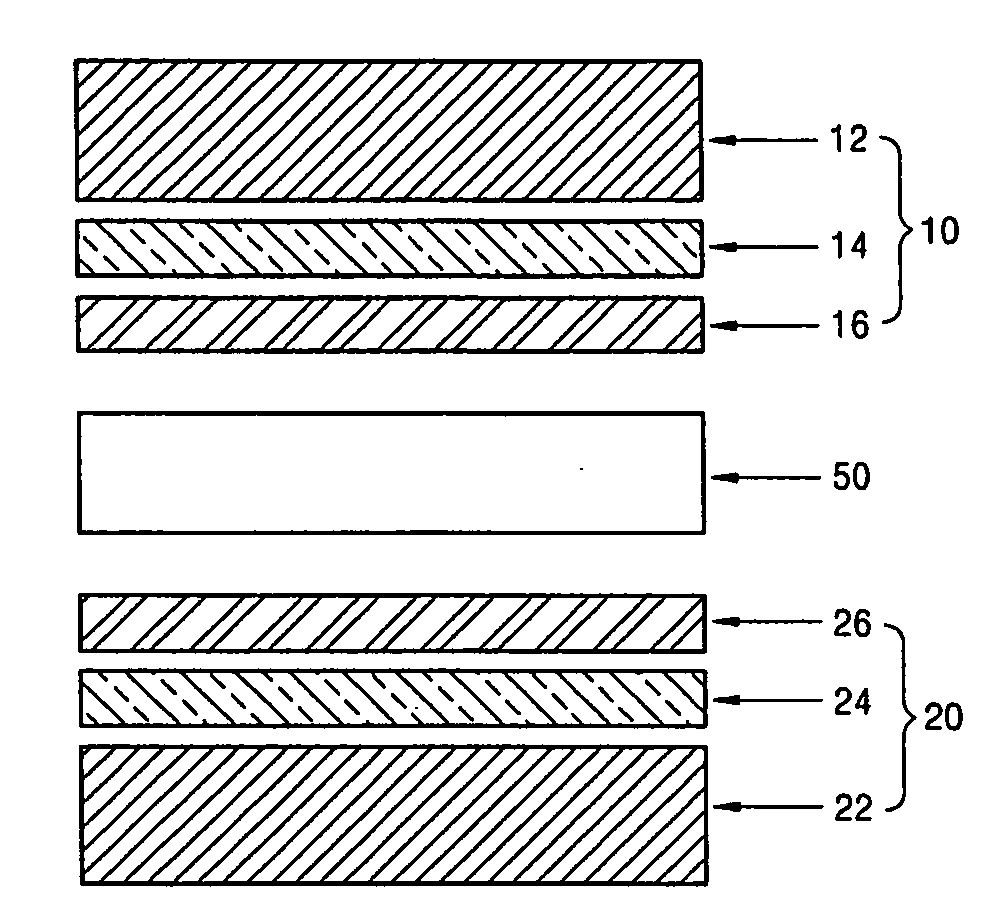

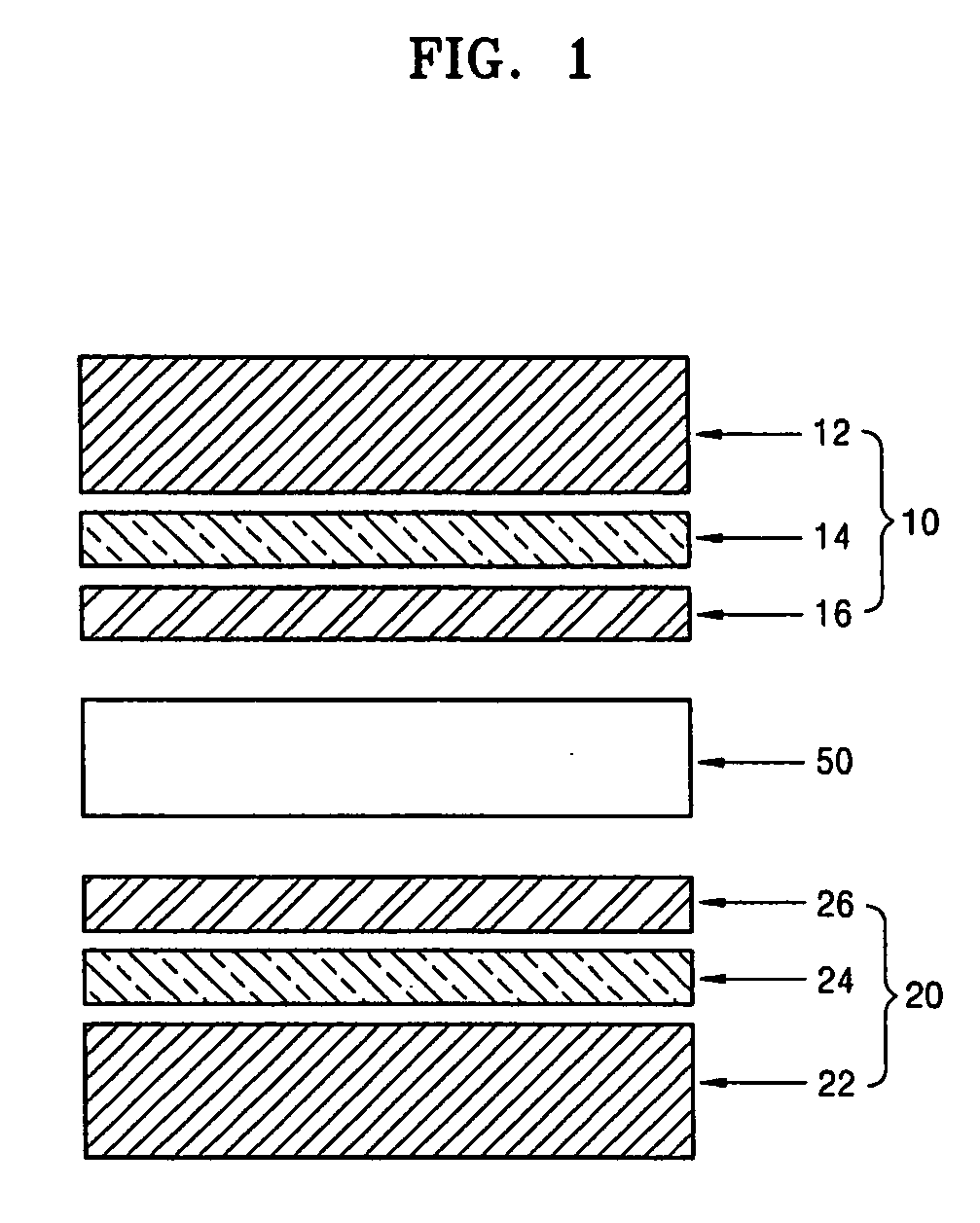

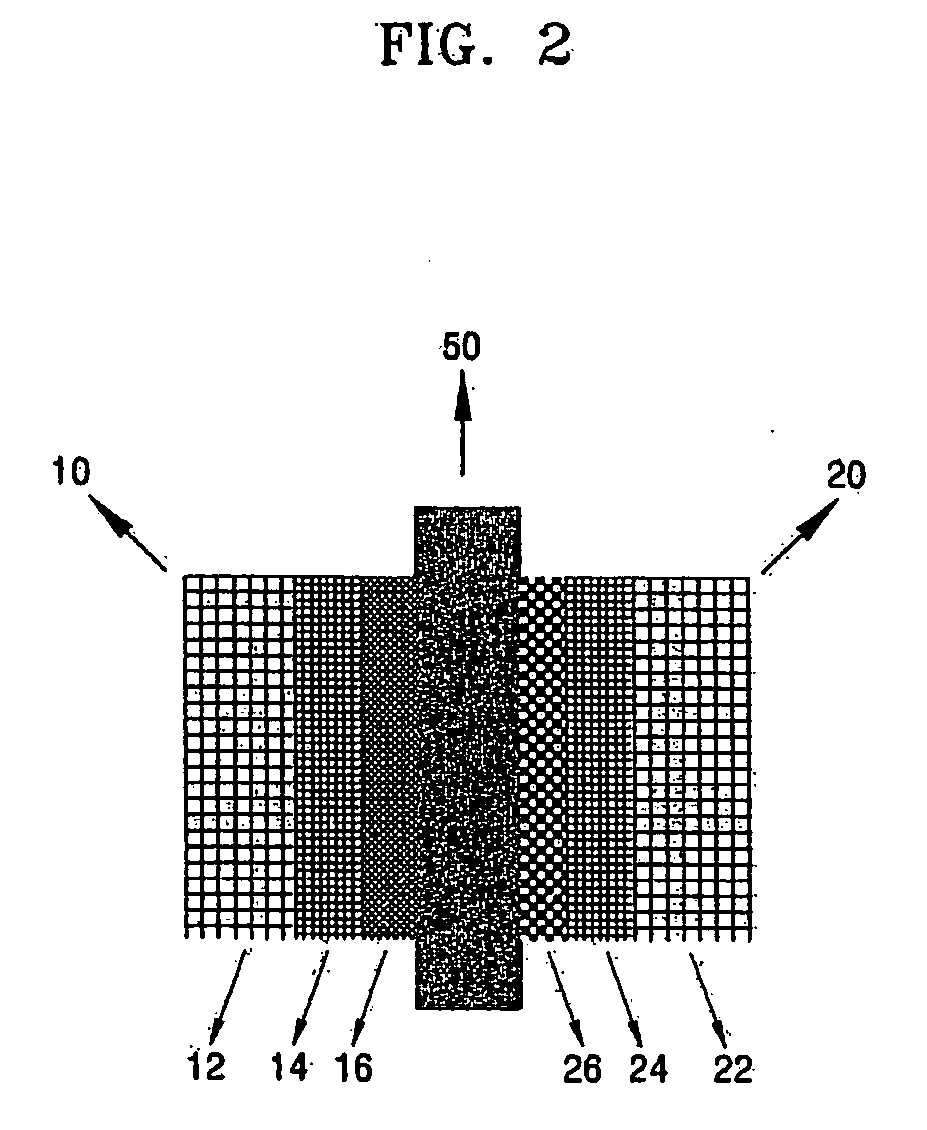

Image

Examples

example 1

[0068] Example 1

[0069] Carbon black powder, polytetrafluoroethylene, and isopropylalcohol were mixed in a weight ratio of 100: 5: 500 in a sonic bath for 2 hours, thereby preparing an anode diffusion layer slurry. The prepared anode diffusion layer slurry was coated onto 400 nm-thick carbon paper (GDL 10 series, SGL carbon group) and sintered at 170° C. for one hour, thereby preparing an anode diffusion layer unit.

[0070] PtRu black, used as an anode catalyst, was mixed with water, NAFION, and isopropylalcohol in a weight ratio of 10: 15: 200 based on 100 parts by weight of the anode catalyst in a sonic bath for two hours, thereby preparing an anode catalyst layer slurry. The prepared anode catalyst layer slurry was coated onto a PET film by screen printing and then dried at 70° C. for 2 hours, thereby preparing an anode unit, which was transferred onto an electrolyte membrane (NAFION 115 membrane produced by Dupont Co.) The anode unit was transferred to the electrolyte membrane by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com