Concrete-curing agent applicable to strong-wind arid area and preparation method thereof

A concrete curing agent and drought technology, applied in the field of building materials, can solve problems such as difficulty in concrete curing, and achieve the effects of solving difficult curing, good weather resistance and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

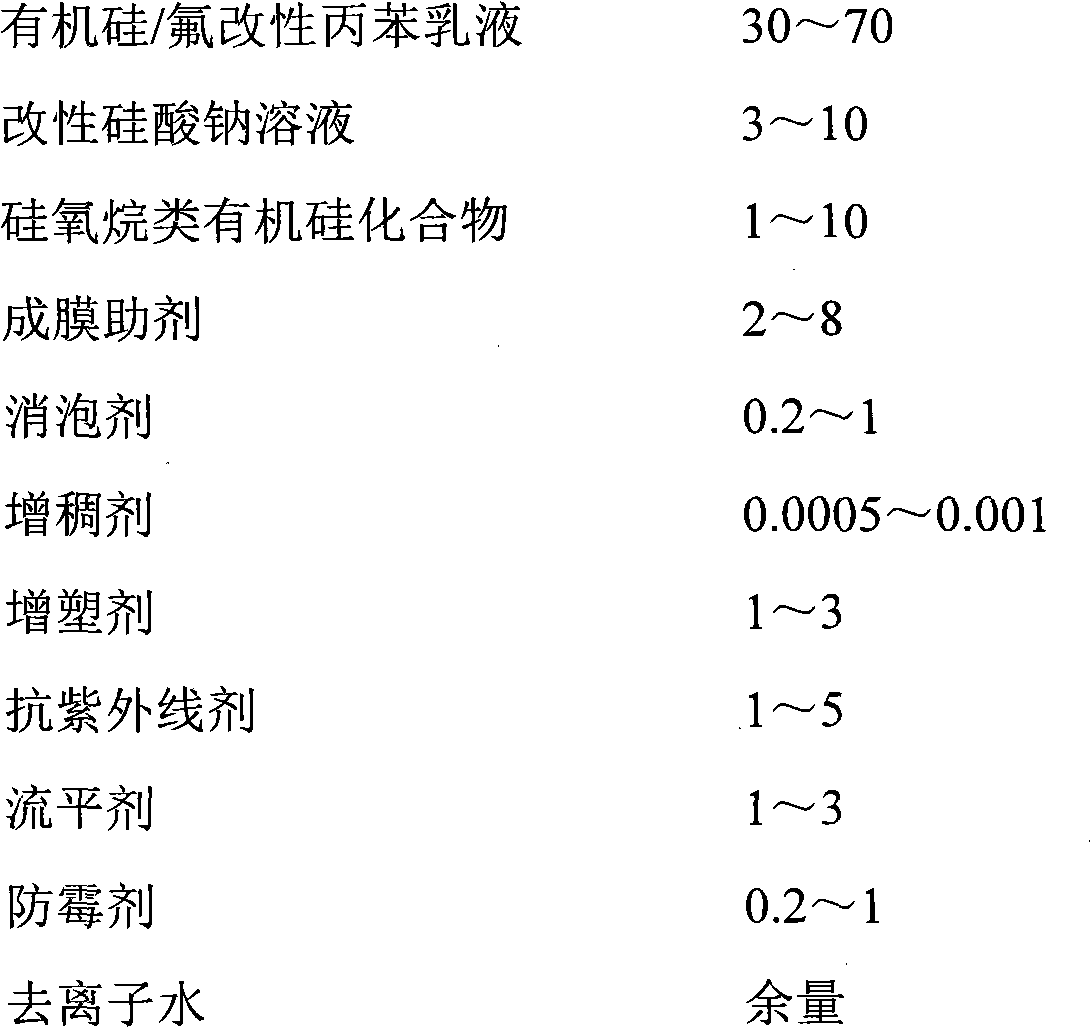

[0031] Embodiment 1 (the following components and content are by mass parts):

[0032]

[0033]

[0034] (1) First, weigh the remaining amount of deionized water according to the preparation ratio, and then add thickener, organic silicon / fluorine modified propylbenzene emulsion, siloxane organic silicon compound, film-forming aid, Plasticizer and anti-ultraviolet agent to make mixed emulsion.

[0035] (2) Adjust the pH value of the mixed emulsion to slightly alkaline, and add the modified sodium silicate solution prepared in advance under the condition of low-speed stirring.

[0036] (3) Add defoaming agent, stir at high speed for a period of time, then add antifungal agent and leveling agent at low speed, and stand for a period of time to obtain a concrete curing agent suitable for strong wind and dry areas. The water retention rate is 86%.

Embodiment 2

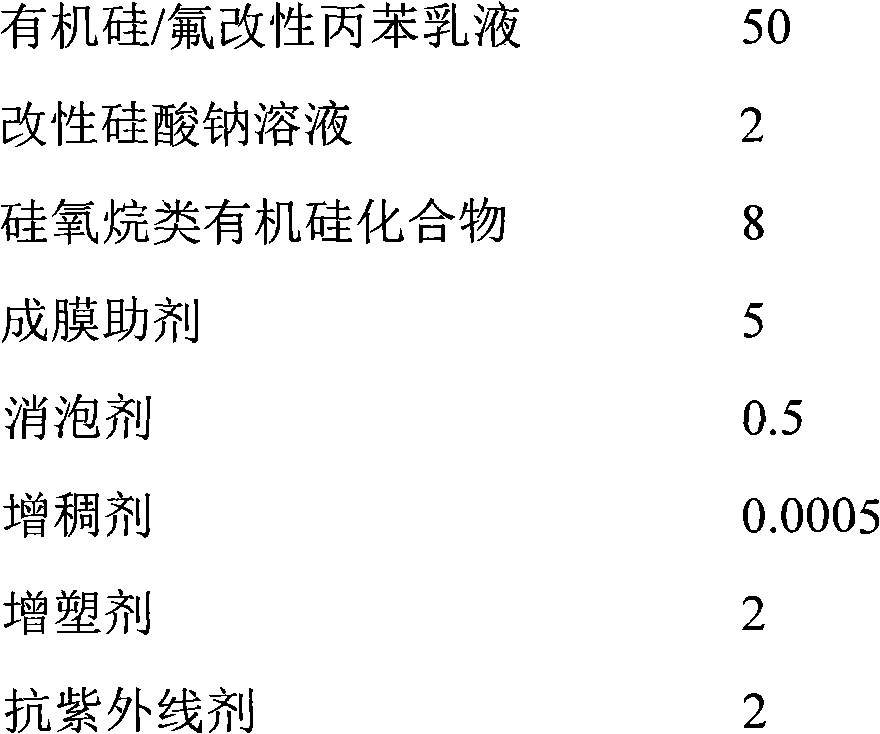

[0037] Embodiment 2 (the following components and content are by mass parts)

[0038]

[0039] (1) First, weigh the remaining amount of deionized water according to the preparation ratio, and then add thickener, organic silicon / fluorine-modified propylbenzene emulsion, siloxane organic silicon compound, film-forming aid, Plasticizer and anti-ultraviolet agent to make mixed emulsion.

[0040] (2) Adjust the pH value of the mixed emulsion to slightly alkaline, and add the modified sodium silicate solution prepared in advance under the condition of low-speed stirring.

[0041] (3) Add defoamer, stir at high speed for a period of time, then add antifungal agent and leveling agent at low speed, and stand for a period of time to obtain a concrete curing agent suitable for windy and dry areas. The water retention rate is 94%.

Embodiment 3

[0042] Embodiment 3 (the following components and content are by mass parts)

[0043]

[0044]

[0045] (1) First, weigh the remaining amount of deionized water according to the preparation ratio, and then add thickener, organic silicon / fluorine-modified propylbenzene emulsion, siloxane organic silicon compound, film-forming aid, Plasticizer and anti-ultraviolet agent to make mixed emulsion.

[0046] (2) Adjust the pH value of the mixed emulsion to slightly alkaline, and add the modified sodium silicate solution prepared in advance under the condition of low-speed stirring.

[0047] (3) Add defoamer, stir at high speed for a period of time, then add antifungal agent and leveling agent at low speed, and let stand for a period of time to obtain a concrete curing agent suitable for strong wind and dry areas. The water retention rate is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com