Acid-rain-resistant water-based exterior wall paintand preparation method thereof

An exterior wall paint and acid rain-resistant technology, which is applied in the field of building exterior wall decoration materials, can solve the problems of reduced adhesion between the coating and the substrate, affecting the durability of the coating, bubbling or peeling, etc., to enhance water resistance and improve adhesion. Improves knot strength, stain resistance and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

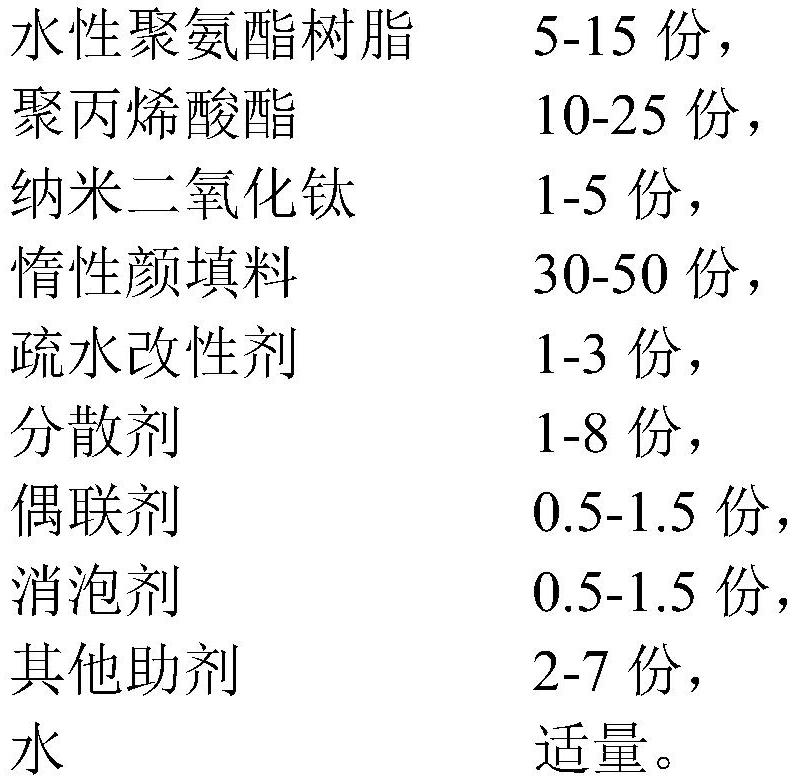

[0023] In the present embodiment, by weight, the specific formula is:

[0024] Waterborne polyurethane resin 5 copies Polyacrylate 10 copies Nano Titanium Dioxide 1 copy Inert pigments and fillers 30 copies Hydrophobic modifier 1 copy Dispersant 1 copy coupling agent 0.5 parts Defoamer 0.5 parts Other additives 2 copies water Appropriate amount

[0025] Among them, the inert pigment and filler is high titanium powder; the hydrophobic modifier is polyethylene oxide; the dispersant is unsaturated carboxylic acid polymer; the coupling agent is silane KH-550; the defoaming agent is acrylic acid polymer.

[0026] Other additives include 0.5 part of leveling agent, 1 part of plasticizer and 0.5 part of film-forming aid, wherein, the leveling agent is fumed silica, the plasticizer is epoxy fatty acid methyl ester, and the film-forming aid is ten dicarboxylates.

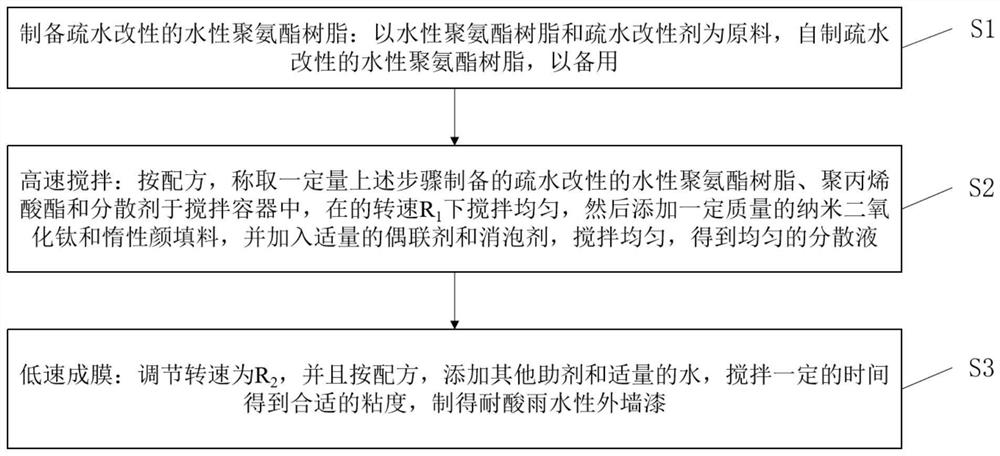

[0027] figure 1 Be the flow chart of the ...

specific Embodiment 2

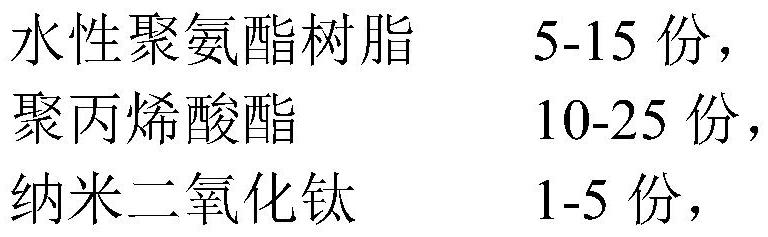

[0032] In the present embodiment, by weight, the specific formula is:

[0033]

[0034]

[0035] Among them, the inert pigment and filler is barite powder; the hydrophobic modifier is polyethylene oxide; the dispersant is methyl cellulose; the coupling agent is silane KH-551; the defoaming agent is fatty acid ester.

[0036] Other additives include 1.5 parts of leveling agent, 2.5 parts of plasticizer and 3 parts of film-forming aid, wherein, the leveling agent is fumed silica, the plasticizer is bismaleimide, and the film-forming aid is Aliphatic carboxylic acid diester.

[0037] figure 1 Be the flow chart of the preparation method of a kind of acid rainwater resistant exterior wall paint of the present invention, can find out from it, the concrete preparation method of this implementation is:

[0038] Step S1: preparing hydrophobically modified waterborne polyurethane resin: using waterborne polyurethane resin and hydrophobic modifier as raw materials, self-made hydr...

specific Embodiment 3

[0042] In the present embodiment, by weight, the specific formula is:

[0043] Waterborne polyurethane resin 10 copies Polyacrylate 15 copies Nano Titanium Dioxide 2 copies Inert pigments and fillers 40 copies Hydrophobic modifier 2 copies Dispersant 4 parts coupling agent 1 copy Defoamer 0.8 parts Other additives 3.5 servings water Appropriate amount

[0044] Among them, the inert pigment and filler is wollastonite powder; the hydrophobic modifier is polyethylene oxide; the dispersant is unsaturated carboxylic acid polymer; the coupling agent is silane KH-551; the defoaming agent is polydimethylsiloxane alkyl.

[0045] Other additives include 1 part of leveling agent, 1.5 parts of plasticizer and 1 part of film-forming aid, wherein, the leveling agent is fumed silica, the plasticizer is epoxy fatty acid methyl ester, and the film-forming aid is ten dicarboxylates.

[0046] figure 1 Be the flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com