LCD display panel and device

A liquid crystal display panel and liquid crystal layer technology, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of easy damage to the sealant of the liquid crystal display panel, and achieve the effects of reducing impact force, reducing damage, and slowing the diffusion speed of liquid crystal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

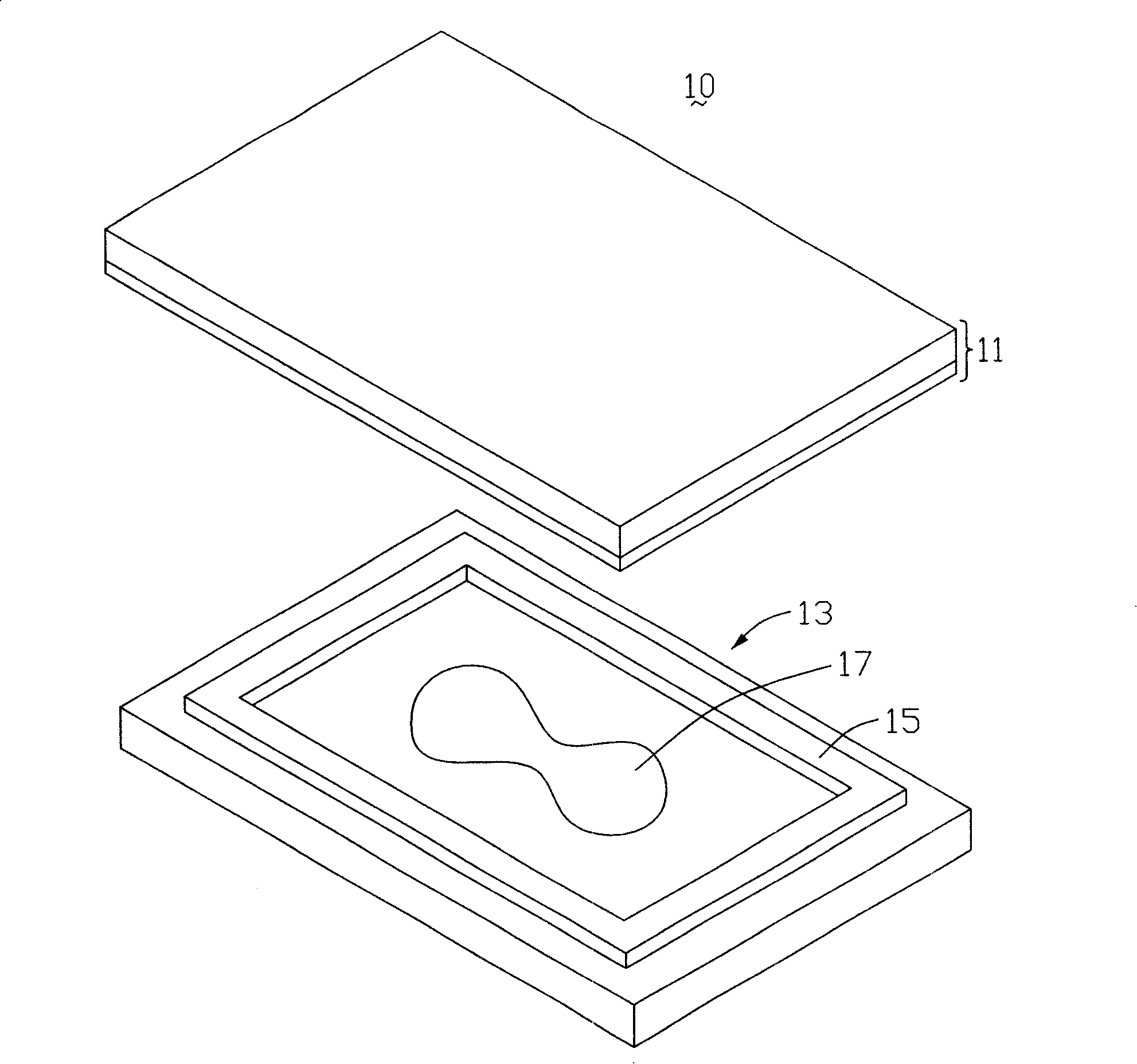

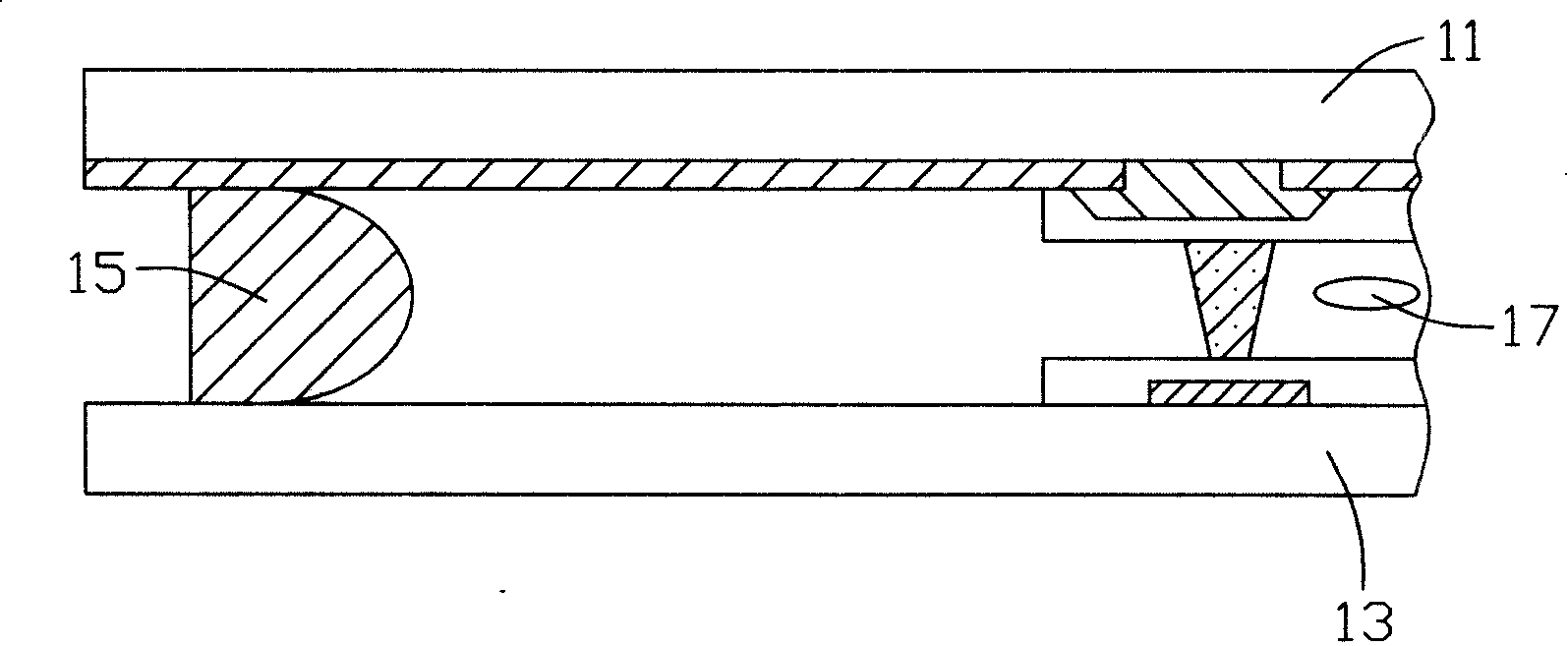

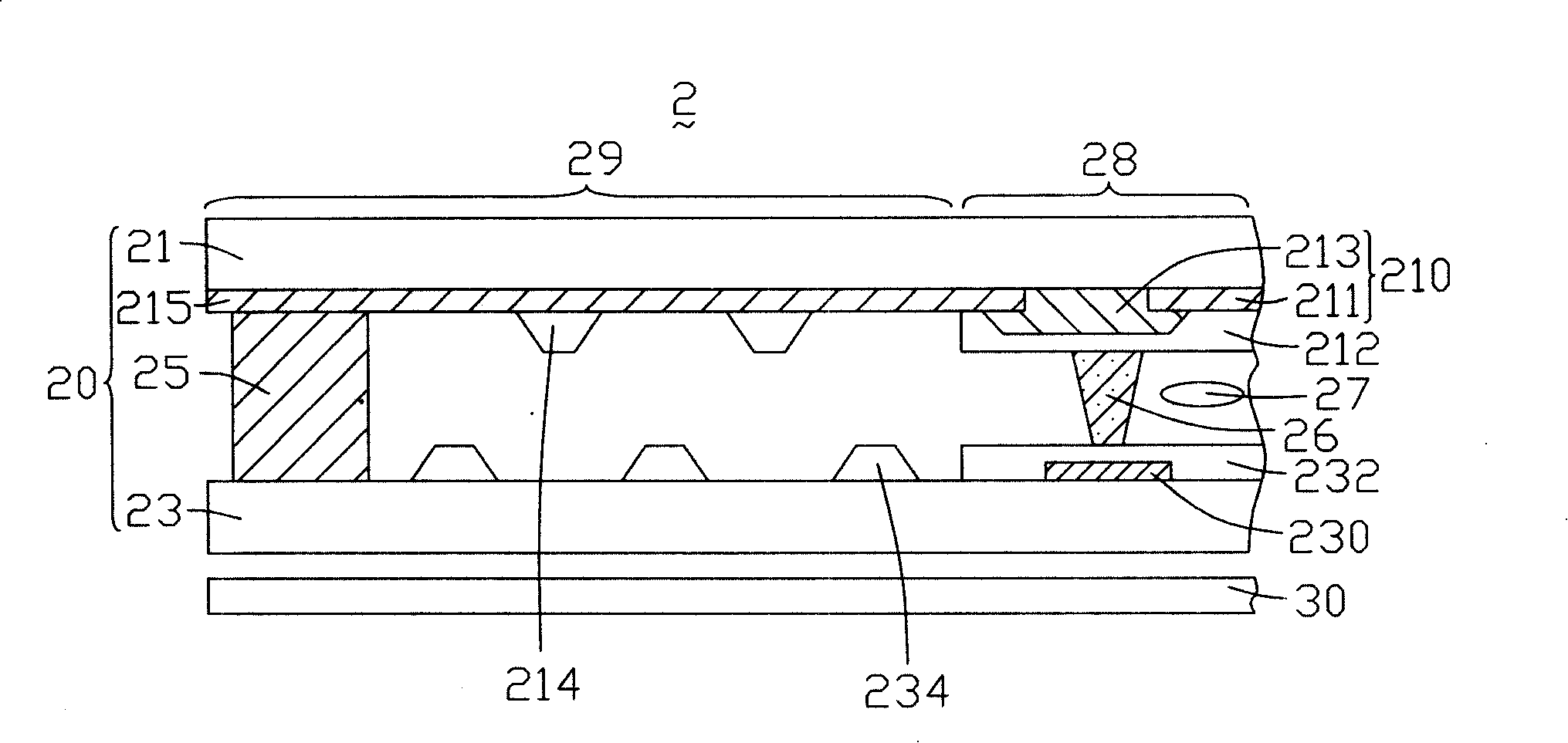

[0020] see image 3 , is a partial cross-sectional schematic diagram of the first embodiment of the liquid crystal display of the present invention. The liquid crystal display 2 includes a liquid crystal display panel 20 and a backlight module 30 , and light emitted from the backlight module 30 enters the liquid crystal display panel 20 .

[0021] The LCD panel 20 has a display area 28 and a non-display area 29 located around the display area 28 . The liquid crystal display panel 20 includes a first substrate 21 , a second substrate 23 , a sealant 25 , a plurality of spacers 26 and a liquid crystal layer 27 . The second substrate 23 is opposite to the first substrate 21 . The sealant 25 is sandwiched between the second substrate 23 and the first substrate 21 , disposed in the non-display area 29 , and forms a liquid crystal cell (not shown) with the second substrate 23 and the first substrate 21 . The plurality of spacers 26 are distributed in the liquid crystal cell at int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com