Case clipped with decorative layer and machining apparatus and method

A processing method and decorative layer technology are applied in the field of a casing sandwiched with a decorative layer and a processing device thereof, which can solve the problems of increased scrap rate, unsatisfactory appearance effect and manufacturing process, and decreased product yield rate, etc., so as to improve the performance and Flexibility, good appearance, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

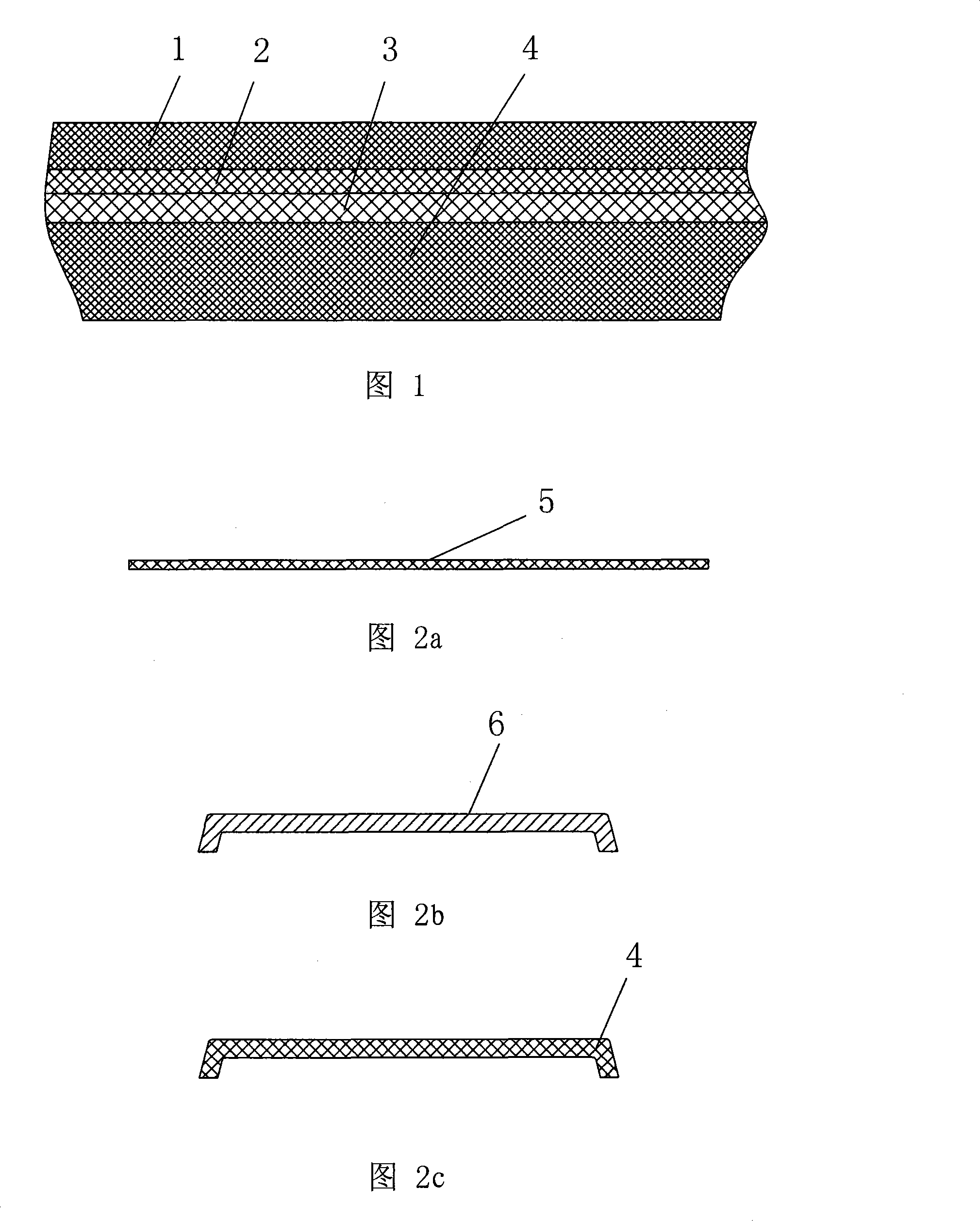

[0024] Fig. 1 is a kind of casing that is used as a TV panel with a decorative layer sandwiched therein, which includes a film sheet 5 composed of successively stacked film sheets 1, a printing layer 2 with patterns and / or characters, and an adhesive layer 3 , and the plastic base material 4 that sticks with the bonding layer 3 of this film sheet. Wherein the outer surface of the film diaphragm 1 is the exterior surface of the panel, and the outer surface of the plastic substrate 4 is the inner surface of the panel. The film diaphragm 1 can be made of materials such as polymethyl methacrylate (PMMA) and polyethylene phthalate (PET) with high hardness, high gloss, and high friction resistance. The specific materials used are mainly determined by the appearance and decoration requirements of the product. Depending on the function of use, the pencil hardness on the front surface of the shell can be as high as 3H-4H. The printing layer 2 is mainly used to reflect the appearance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com