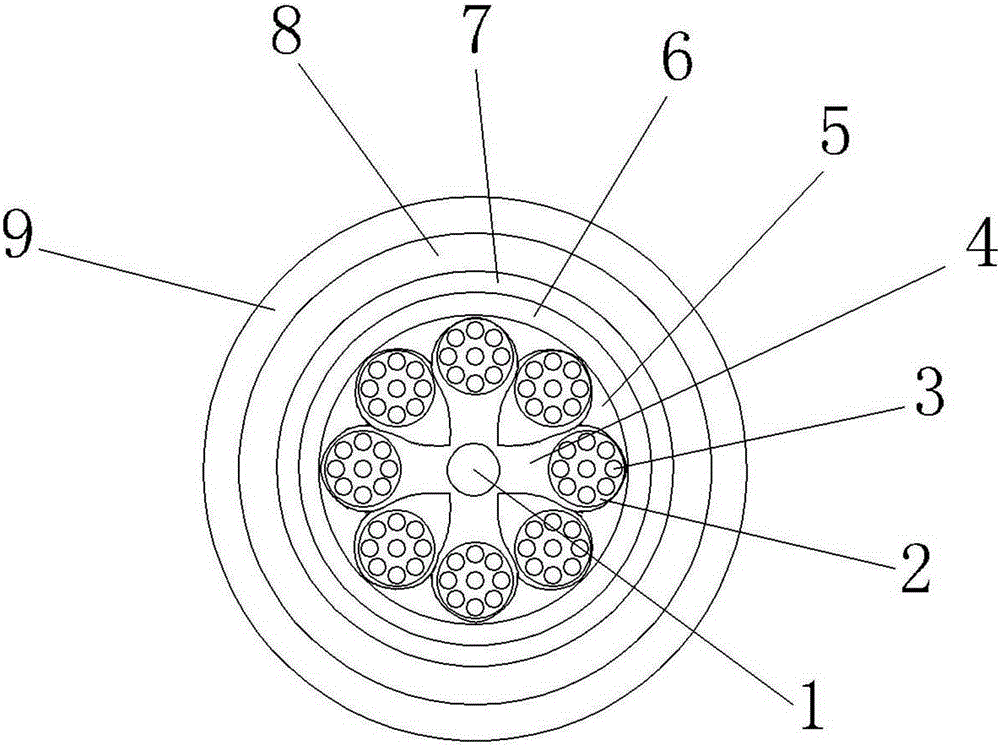

High-intensity wear resistant cable used for construction

A high-strength, construction technology, used in insulated cables, power cables, power cables with shielding/conductive layers, etc. The effect of stable and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The raw materials of the sheath layer 8 include by weight: 75 parts of EPDM rubber, 45 parts of W-type neoprene rubber, 60 parts of nitrile rubber, 45 parts of polyvinyl fluoride resin, 35 parts of EVA resin, modified epoxy resin 45 parts, 17 parts of fluorinated polyethylene, 8.5 parts of zinc oxide, 5.5 parts of magnesium oxide, 5.5 parts of calcium stearate, 6 parts of nylon, 7 parts of activated white carbon black, 5 parts of nano white carbon black, 4 parts of activated calcium silicate 5.5 parts of nano-silica, 3 parts of vulcanizing agent DCP, 5 parts of chloranil, 6 parts of accelerator DM, 6 parts of polyethylene glycol, 5 parts of dispersant CNF, 3 parts of anti-aging agent RD, 4 parts of anti-aging agent AW, N- 3.5 parts of cyclohexylthiophthalimide.

[0036] Among them, the modified epoxy resin is prepared according to the following process: 100 parts of epoxy resin and 10 parts of polymethyltriethoxysilane are mixed, then 5 parts of dibutyltin dilaurate are...

Embodiment 2

[0038] The raw materials of the sheath layer 8 include by weight: 60 parts of EPDM rubber, 60 parts of W-type neoprene rubber, 40 parts of nitrile rubber, 60 parts of polyvinyl fluoride resin, 20 parts of EVA resin, modified epoxy resin 60 parts, 12 parts of fluorinated polyethylene, 12 parts of zinc oxide, 3 parts of magnesium oxide, 9 parts of calcium stearate, 3 parts of nylon, 12 parts of activated white carbon black, 2 parts of nano white carbon black, 6 parts of activated calcium silicate , 3 parts of nano-silica, 5 parts of vulcanizing agent DCP, 2 parts of chlorobenzoquinone, 9 parts of accelerator DM, 3 parts of polyethylene glycol, 8 parts of dispersant CNF, 1 part of anti-aging agent RD, 6 parts of anti-aging agent AW, N- 1 part of cyclohexylthiophthalimide.

[0039] Among them, the modified epoxy resin is prepared according to the following process: 100 parts of epoxy resin and 4 parts of polymethyltriethoxysilane are mixed, then 8 parts of dibutyltin dilaurate are...

Embodiment 3

[0041] The raw materials of the sheath layer 8 include by weight: 90 parts of EPDM rubber, 30 parts of W-type neoprene rubber, 80 parts of nitrile rubber, 30 parts of polyvinyl fluoride resin, 50 parts of EVA resin, modified epoxy resin 30 parts, 22 parts of fluorinated polyethylene, 5 parts of zinc oxide, 8 parts of magnesium oxide, 2 parts of calcium stearate, 9 parts of nylon, 2 parts of activated white carbon black, 8 parts of nano white carbon black, 2 parts of activated calcium silicate , 8 parts of nano-silica, 1 part of vulcanizing agent DCP, 8 parts of chlorobenzoquinone, 3 parts of accelerator DM, 9 parts of polyethylene glycol, 2 parts of dispersant CNF, 5 parts of anti-aging agent RD, 2 parts of anti-aging agent AW, N- 6 parts of cyclohexylthiophthalimide.

[0042] Among them, the modified epoxy resin is prepared according to the following process: 100 parts of epoxy resin and 16 parts of polymethyltriethoxysilane are mixed, then 2 parts of dibutyltin dilaurate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com