Laminated solar battery pack and manufacture method thereof

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of poor aging resistance and short service life, and achieve the effect of improving aging resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

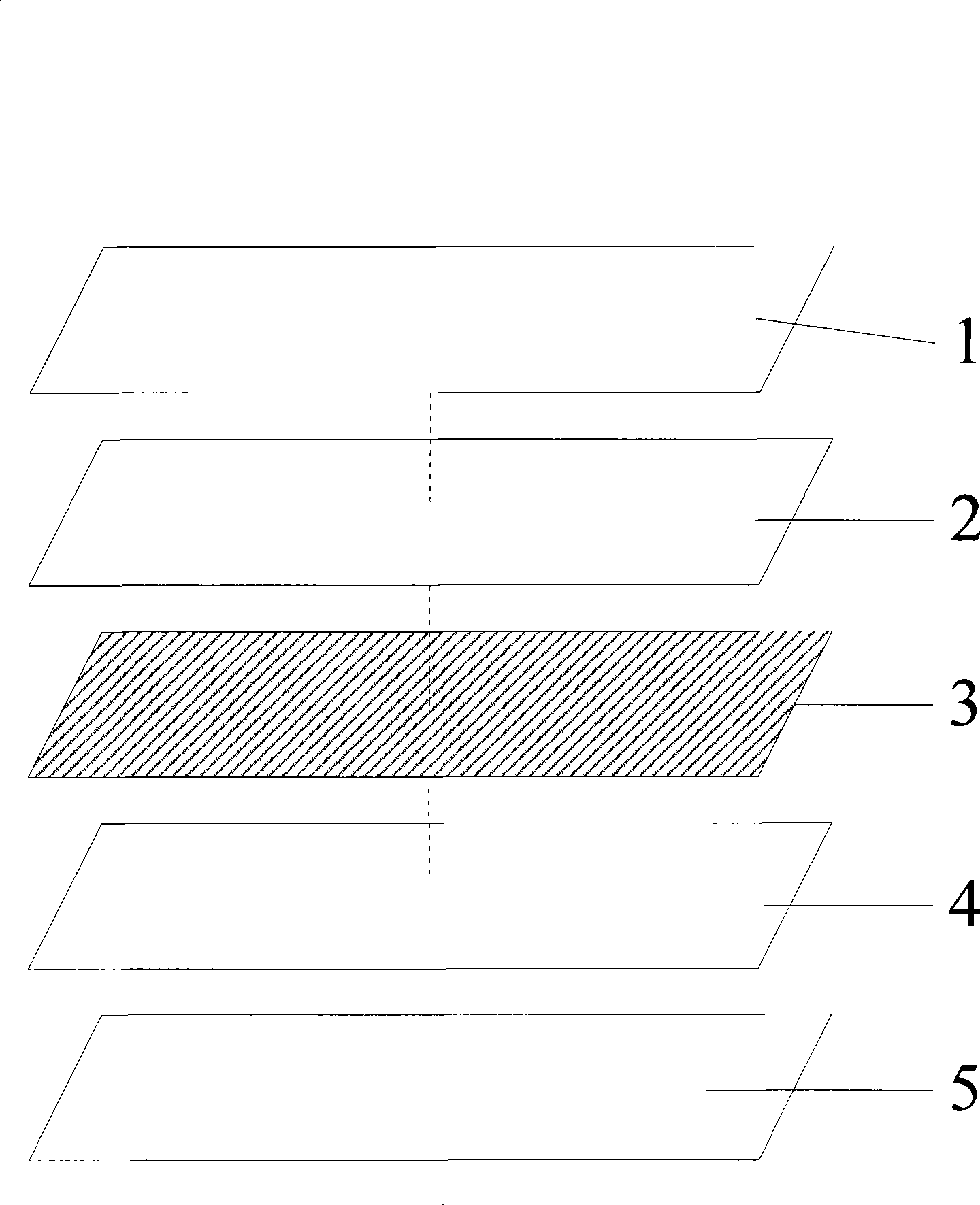

[0019] A laminated solar cell module, consisting of a surface layer 1, an upper ethylene-vinyl acetate copolymer layer 2, a solar cell layer 3, a lower ethylene-vinyl acetate copolymer layer 4 and a backsheet layer 5, stacked in sequence from top to bottom Cloth, encapsulation structure, the surface layer 1 is a polyvinyl fluoride composite film, and the back plate layer 5 is an epoxy resin board.

[0020] The method for preparing the above-mentioned laminated solar cell module includes the following steps: a. Put the tempered glass on the workbench at room temperature of 25°C, spread a high-temperature cloth, and spread a layer of polyvinyl fluoride composite film on the high-temperature cloth in turn and a layer of ethylene-vinyl acetate copolymer; b. take an epoxy resin plate, spread a layer of ethylene-vinyl acetate copolymer on it, and then fix the welded battery sheet on the ethylene-vinyl acetate copolymer; c . Lay the epoxy resin plate with the battery sheet fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com