Preparation method of ultra oil-resistant coated fabric, obtained product and application thereof

A technology for coating fabrics and oil resistance, applied in the field of materials, can solve the problems of reduced service life, oil pollution, poor oil resistance, etc., and achieve the effect of long service life, good weather resistance, and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of super oil resistant coated fabric

[0037] First, the fiber reinforcement layer woven into high-strength polyester square fabric is dipped (121 parts of epoxy resin E81, 10 parts by weight of phenol-blocked MDI, 40 parts by weight of 40% butylpyridine latex, 50 parts by weight of water) and processed at 230 ° C. After the qualitative type, the polyether thermoplastic polyurethane elastomer (produced by Yantai Wanhua Polyurethane Co., Ltd.) is melt-coated on the upper primer layer to form an outer coating, and the polyester thermoplastic polyurethane elastomer (Yantai Wanhua Polyurethane Co., Ltd. Produced by the company) is melt-coated on the lower base coat to form an inner coat to prepare oil-resistant coated fabrics. The inner coating of this oil-resistant type coated fabric is scraped and coated with two-component polyurethane adhesive (100 parts by weight of polyethylene adipate glycol and 8 parts by weight of toluene diisocyanate and 30...

Embodiment 2

[0038] Example 2: Preparation of super oil resistant coated fabric

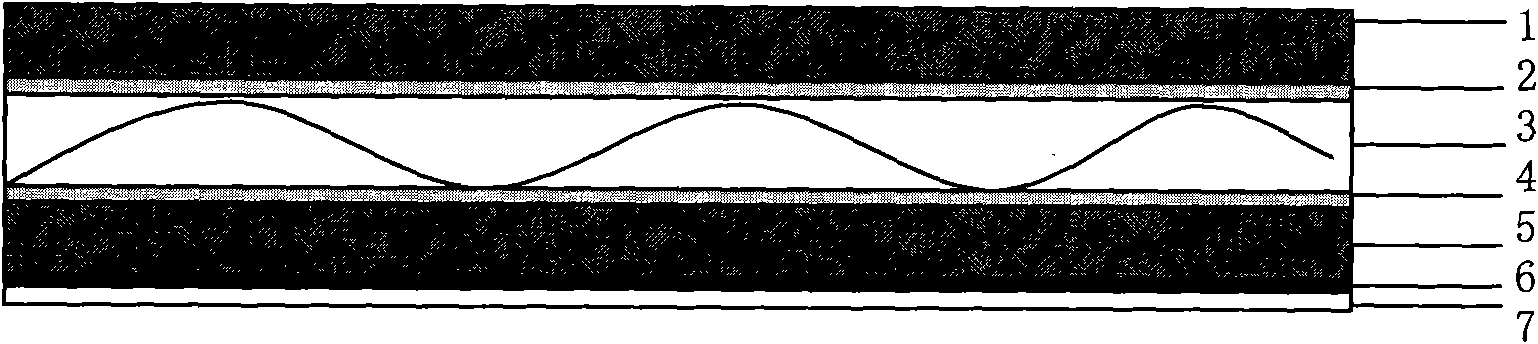

[0039] Prepare as described in Example 1, except that the polyvinyl fluoride film produced by Zhejiang Lantian Environmental Protection High-Tech Co., Ltd. is used instead of the PVF film produced by DuPont get as figure 1 Super oil resistant coated fabric shown.

Embodiment 3

[0040] Example 3: Preparation of super oil resistant coated fabric

[0041] First, the fiber reinforced layer woven into high-strength nylon square fabric is dipped (1 part of epoxy resin E812, 10 parts by weight of phenol-blocked MDI, 40 parts by weight of 40% butylpyridine latex, 50 parts by weight of water) and treated at 230 ° C. After heat-setting, the composite glue of nitrile rubber and polyvinyl chloride is pasted on the upper and lower primer coats to form an outer coat and an inner coat respectively, and an oil-resistant coated fabric is prepared. The inner coating of this oil-resistant type coated fabric is scraped-coated with acrylonitrile-butadiene rubber-based adhesive (40-100 parts by weight of nitrile, 30 parts by weight of ammonia water catalytic phenolic resin, 25 parts by weight of magnesium oxide, 5 parts by weight of tricumyl peroxide parts by weight, 10 parts by weight of carbon black, 800 parts by weight of ethyl acetate), after drying for 60 seconds a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com