Special back seal film for solar cell

A solar cell and back-sealing technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult heat dissipation, cumbersome processing of solar cell back-sealing films, etc., to prevent hydrolysis, good air insulation performance, and good electrical insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

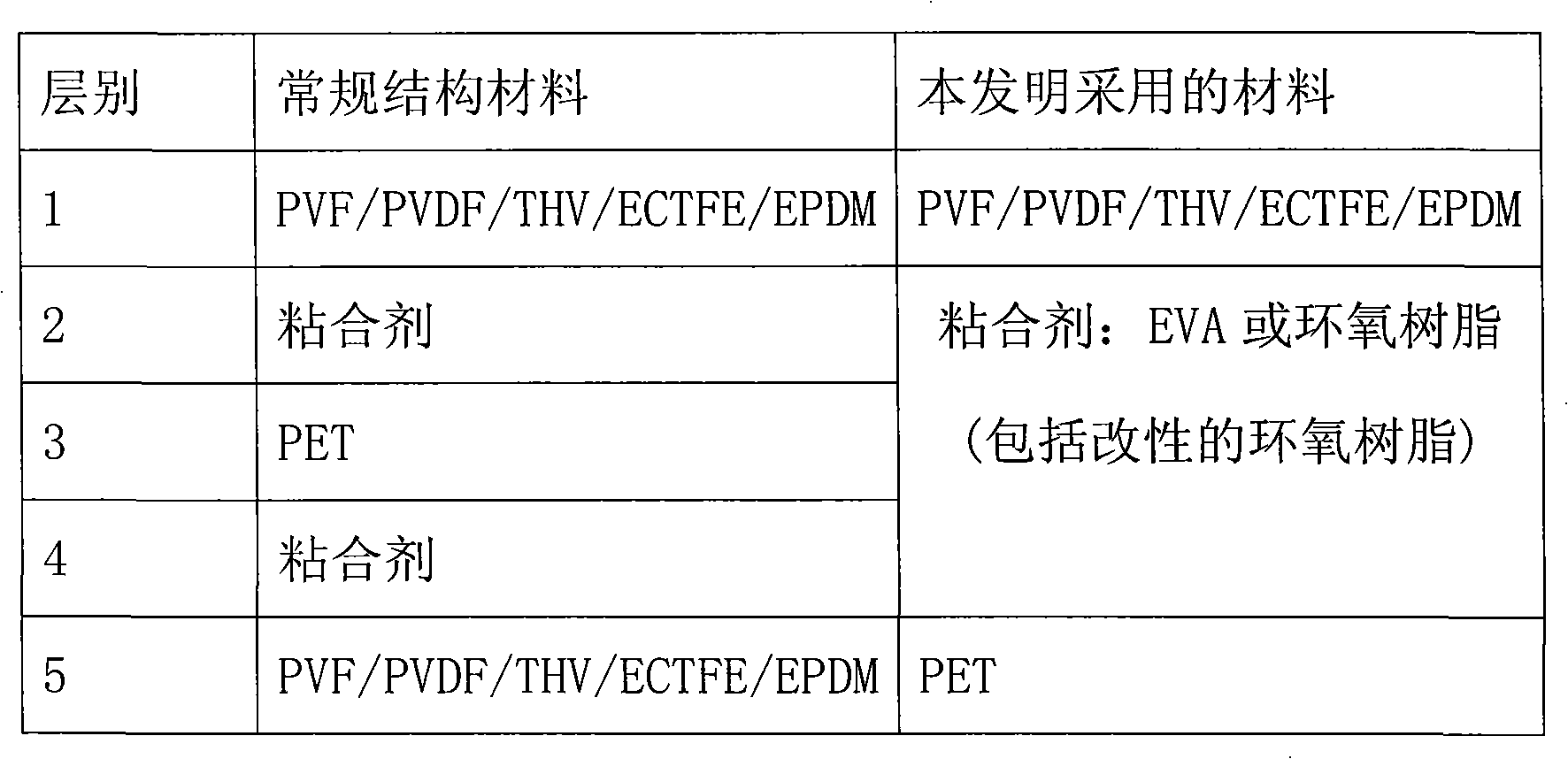

[0007] Because the PET in the middle of the existing TPT composite film mainly plays the role of insulation, and the fluorine material mainly plays the role of isolating air, water vapor and preventing oxidation. Just based on the functions played by the above two materials in the composite membrane, only PET and fluorine materials are reserved in the present invention. Due to the reduction of one layer of fluorine material and the use of two layers of adhesive EVA, the cost of the composite film is greatly reduced, and the dimensional stability of the composite film is improved due to the reduction of the number of layers.

[0008] The difference between the present invention and the prior art is mainly reflected in:

[0009] 1. Replace the polyethylene terephthalate (PET) in the TPT back-sealing film structure with ethylene-vinyl acetate (EVA);

[0010] 2. Put EVA or epoxy resin (including modified epoxy resin) on polyvinyl fluoride (PVF) or polyvinylidene fluoride (PVDF) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com