Heat and corrosion resistant steel pipe having multi-layered coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] (1) Steel Pipe a

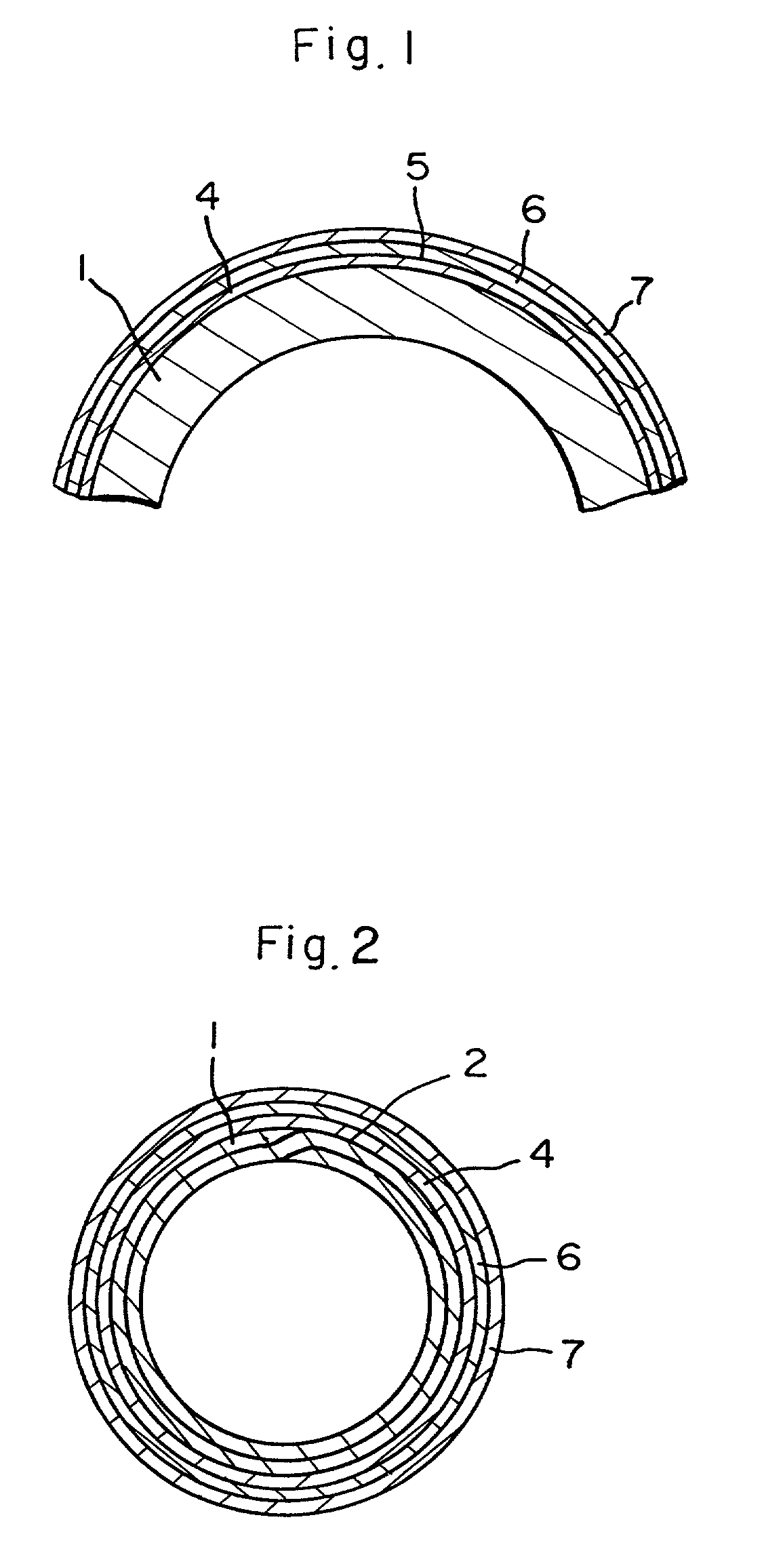

[0020] A double-wound steel pipe with having 8 mm outer diameter, 0.7 mm wall thickness and 330 mm length was prepared by using a hoop sheet made of SPCC and having copper plating layer of 3 um thickness on both surfaces.

[0021] (2) Formation of Zn--Ni Alloy Plating Layer

[0022] An alloy plating layer of 8 um thickness was formed by using a Zn--Ni alloy plating bath comprising a chloride bath (Zn-10MU, manufactured by Ebara-Udylite Co., Ltd.).

[0023] (3) Formation of Resin Layer

[0024] The steel pipe a formed with the Zn--Ni alloy plating layer obtained in (2) above was immersed in a paint prepared from an epoxy resin and a pigment dissolved in a solvent to apply resin coating and then heat-treated at 350.degree. C. for 60 sec to form an intermediate layer of an epoxy resin of about 5 um thickness. Then, it was immersed in a solution comprising polyvinyl fluoride coating dispersed in diethyl phthalate to apply polyvinyl fluoride and then heat-dried at 250.degree. ...

example 2

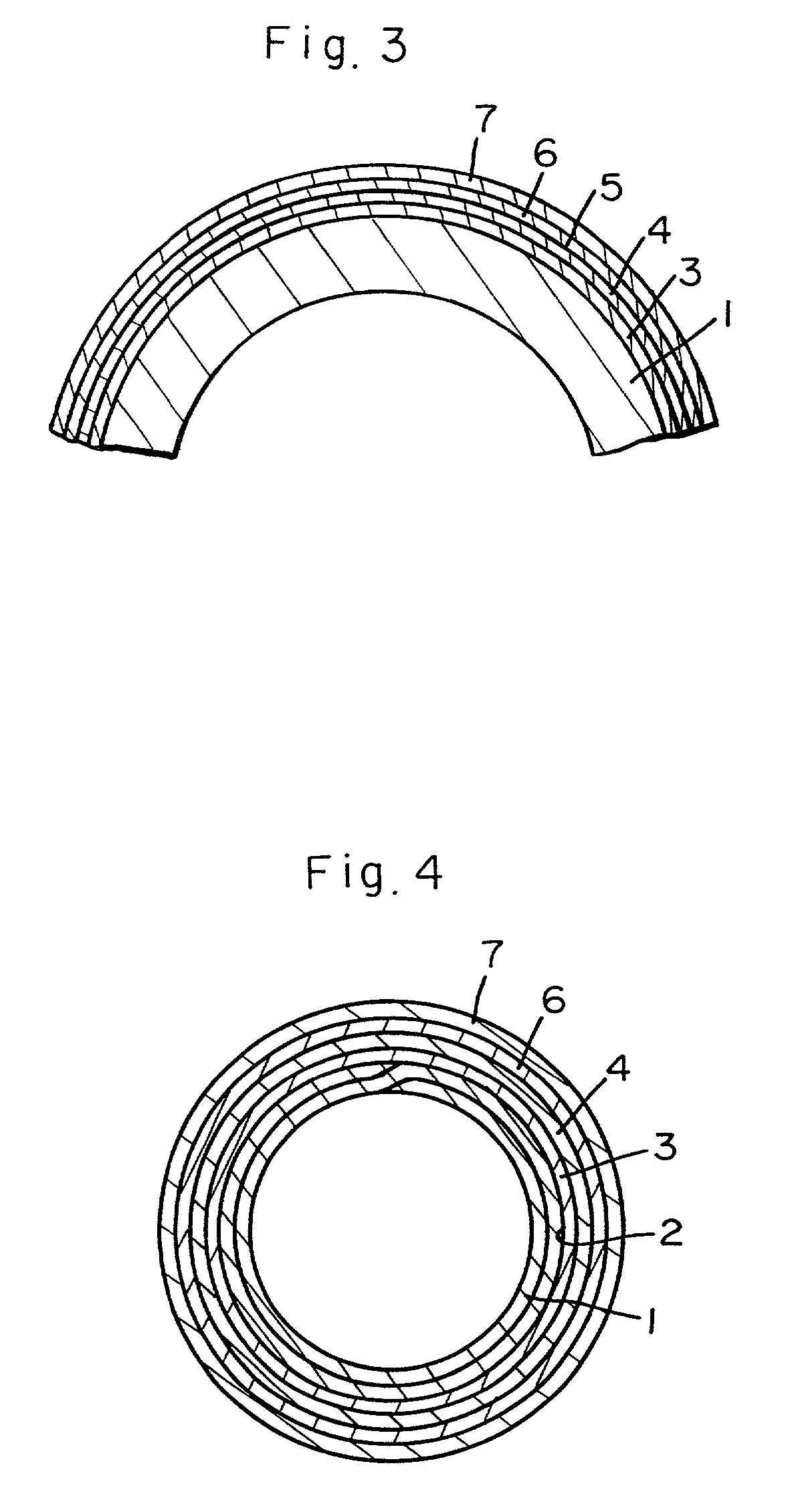

[0029] (1) Steel Pipe b

[0030] Electro-welded pipe made of STPG 38, with 8 mm outer diameter, 0.7 mm wall thickness and 330 mm length.

[0031] (2) Zn--Ni alloy plating Layer and the resin layer were formed in the same procedures as those in Example 1 and various tests were applied in the same manner as in Example 1. The results are shown in Table 1.

example 3

[0032] Formation of Zn--Ni alloy plating layer and chromate treatment.

[0033] After forming a Zn--Ni alloy plating layer by using a steel pipe a in the same manner as in Example 1, a chromate layer was formed by dipping in a chromate processing solution (Zn-80YMU, manufactured by Ebara-Udylite Co., Ltd.) at a solution temperature of 50.degree. C. for 20 sec.

[0034] (2) Subsequently the resin film was formed in the same procedures as in Example 1 and various tests were conducted in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com