Preparation method of heat-conducting silicone grease

A technology of thermal conductive silicone grease and silicone oil, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problem of inertness on the surface of graphene agglomeration and graphene, and achieves compatibility and affinity improvement and reduction. Effect of contact thermal resistance and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

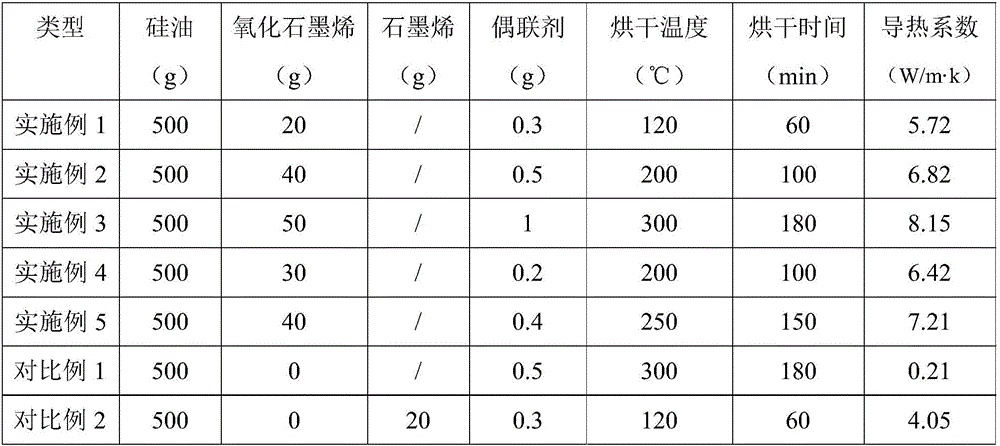

Examples

Embodiment 1

[0023] 30 g of graphene oxide was added to an ethanol solution containing 0.3 g of KH-550 (concentration: 20 mg / mL), ultrasonically mixed for one hour, and dried by suction filtration. After the above-mentioned graphene oxide treated with the coupling agent was uniformly mixed with 500 g of simethicone oil, it was ground on a three-roll mill until there was no grainy feeling when observed with the naked eye, and the particle size did not exceed 100 μm. Put the mixture in an oven at 120°C, bake for 60 minutes, and then process it in a vacuum mixer for 30 minutes with a vacuum of -0.06mPa to obtain thermally conductive silicone grease.

Embodiment 2

[0025] 30 g of graphene oxide was added to an ethanol solution containing 0.5 g of KH-550 (concentration: 20 mg / mL), ultrasonically mixed for one hour, and dried by suction filtration. After the above-mentioned graphene oxide treated with the coupling agent is mixed with 500 g of silicone oil and amino silicone oil, it is ground on a three-roll mill until there is no grainy feeling when observed with the naked eye, and the particle size does not exceed 100 μm. Put the mixture in an oven at 200°C, bake for 100 minutes, and then process it in a vacuum mixer for 30 minutes with a vacuum of -0.099mPa to obtain thermally conductive silicone grease.

Embodiment 3

[0027] 50 g of graphene oxide was added to an ethanol solution containing 1 g of KH-550 (concentration: 20 mg / mL), ultrasonically mixed for one hour, and dried by suction filtration. After the graphene oxide treated with the above coupling agent was uniformly mixed with 500 g of dimethyl silicone oil, it was ground on a three-roll mill until there was no grainy feeling when observed with the naked eye, and the particle size did not exceed 100 μm. The mixture was placed in an oven at 300°C, baked for 180 minutes, and then processed in a vacuum mixer for 30 minutes with a vacuum degree of -0.079mPa to obtain thermally conductive silicone grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com