Phase-change heat-conducting silicone grease and preparation method thereof

A technology of phase change heat conduction and silicone grease, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of rapid accumulation of heat, affecting the fluidity of silicone grease, temperature rise, etc., to achieve rapid absorption and storage, and improve absorption rate, the effect of enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

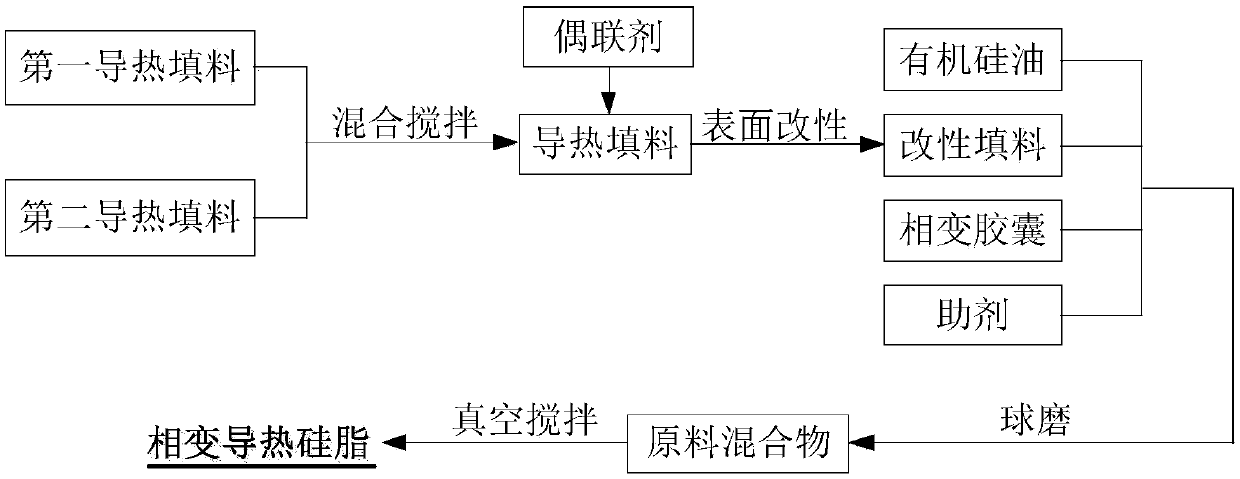

Method used

Image

Examples

Embodiment 1

[0044] A phase-change heat-conducting silicone grease, comprising the following composition in mass percentage: 15% of organic silicone oil, 70% of heat-conducting filler, 13% of phase-change capsule, and 2% of additives; the organic silicone oil is dimethyl silicone oil with a viscosity of 350mPa·s; The thermally conductive filler is spherical alumina, including two kinds of spherical alumina with different particle sizes, the middle particle size is 10μm and 2μm respectively, and the mass ratio is 8:2; the phase change capsule is wrapped with urea-formaldehyde resin, and the phase change temperature is 50°C The high-purity paraffin wax (purity of nominal 97 mass%) has an average particle size of 10 μm; the auxiliary agent includes two kinds of flame retardant and coupling agent, the flame retardant is selected from aluminum hydroxide, and the coupling agent is vinyl trimethoxy base silane.

[0045] The preparation method of the phase change thermally conductive silicone grea...

Embodiment 2

[0051] A phase-change heat-conducting silicone grease, comprising the following composition by mass percentage: 27% of organic silicone oil, 60% of heat-conducting filler, 10% of phase-change capsule, and 3% of additives; the organic silicone oil is dimethyl silicone oil with a viscosity of 350mPa·s; The thermally conductive filler is spherical alumina, including two types of spherical alumina with different particle sizes, the median particle size is 10 μm and 2 μm, and the mass ratio is 7:3; the phase change capsule is wrapped with urea-formaldehyde resin, and the phase change temperature is 50 °C The high-purity paraffin wax (purity of nominal 97 mass%) has an average particle size of 10 μm; the auxiliary agent includes two kinds of flame retardant and coupling agent, the flame retardant is selected from aluminum hydroxide, and the coupling agent is vinyl trimethoxy base silane.

[0052] The preparation method of the phase change thermally conductive silicone grease in this...

Embodiment 3

[0058] A phase-change heat-conducting silicone grease, comprising the following composition in mass percentage: 20% of organic silicone oil, 65% of heat-conducting filler, 13% of phase-change capsule, and 2% of additives; the organic silicone oil is dimethyl silicone oil with a viscosity of 200mPa·s; The thermally conductive filler is spherical alumina, including two kinds of spherical alumina with different particle sizes, the middle particle size is 40μm and 5μm respectively, and the mass ratio is 6:4; the phase change capsule is wrapped with urea-formaldehyde resin and has a phase change temperature of 50°C. High-purity paraffin wax (purity of nominally 97% by mass), with an average particle size of 10 μm; additives include flame retardant and coupling agent, the flame retardant is selected from aluminum hydroxide, and the coupling agent is aminopropyl trioxide base silane.

[0059] The preparation method of the phase change thermally conductive silicone grease in this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com