Heat-conducting gasket and preparation method thereof

A technology of thermally conductive gasket and thermally conductive film, applied in chemical instruments and methods, modification by conduction heat transfer, cooling/ventilation/heating transformation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] An exemplary method for preparing the thermal pad of the present invention includes the following steps:

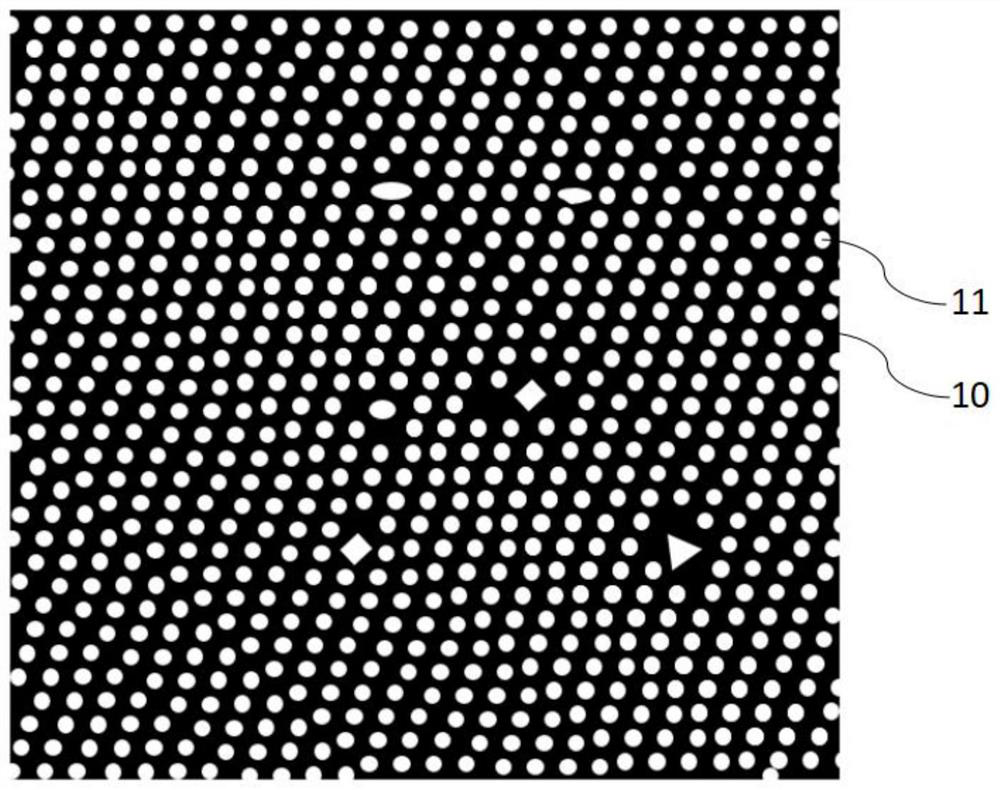

[0057] (1) Form a plurality of holes 11 through the upper and lower surfaces of the thermally conductive film 10 on the thermally conductive film, such as figure 1 shown;

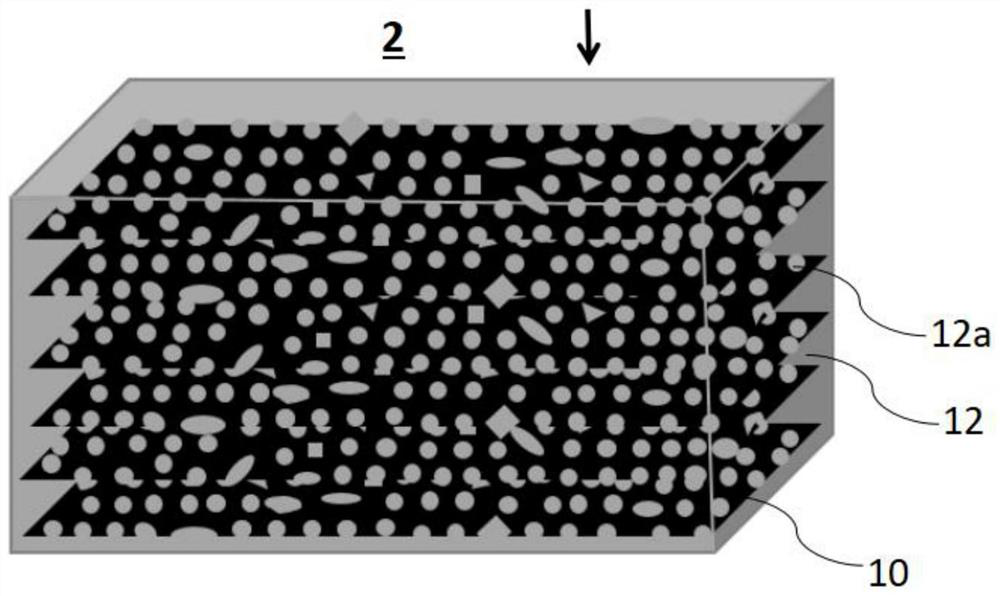

[0058] (2) The adhesive layer 12 is laminated on the thermally conductive film 10 formed in the step (1), and then the thermally conductive film 10 formed in the step (1) is further laminated on the adhesive layer. This step allows the adhesive 12a to enter the plurality of holes 11 . Repeat this layer-by-layer alternate stacking process to form a stack 2, such as figure 2 shown;

[0059] (3) Pressing and molding the stacked body 2 obtained in step (2), and performing vulcanization treatment;

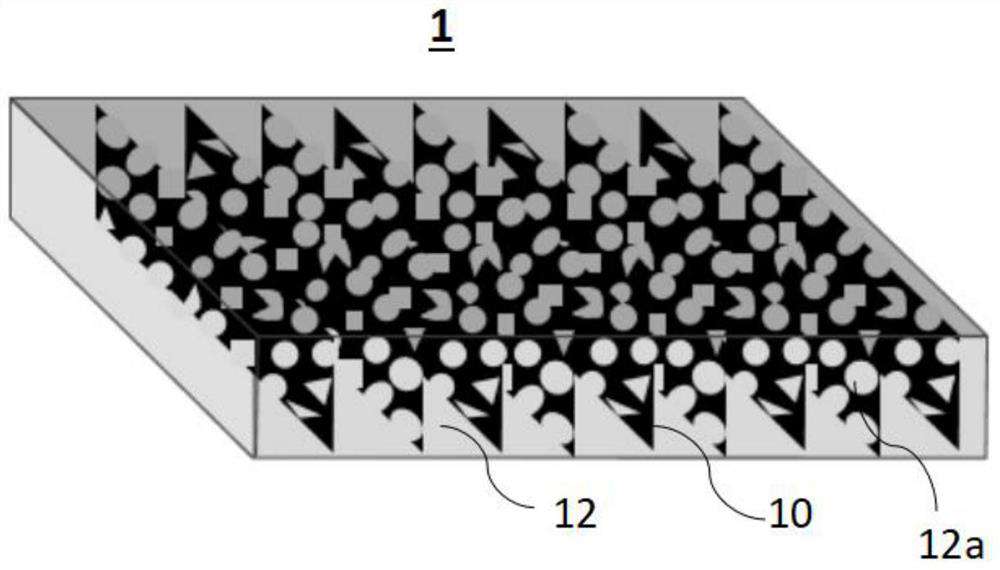

[0060] (4) the molded body obtained in step (3) along the direction perpendicular to the plane of the heat-conducting film (such as figure 2 The direction indicated by the arrow in the middle) slic...

Embodiment 1

[0074] In this embodiment, the preparation process of the vertical high thermal conductivity gasket reinforced by graphene thermal film includes the following steps:

[0075] 1) The graphene heat conduction film with a thickness of 4 μm is perforated by laser technology, running through the upper and lower surfaces, the hole size is 200 μm, and the hole spacing is 200 μm;

[0076] 2) uniformly mixing the silica gel and heat-conducting alumina powder, and performing defoaming treatment to obtain a mixed silica gel, wherein the alumina content is 70%;

[0077] 3) Apply the mixed silicone gel obtained in step 2) evenly on the surface of the graphene heat conduction film perforated in step 1) by scraping, and stack the graphene heat conduction film staggered to form a stack ;

[0078] 4) Place the stacked body in step 3) in a mold, and perform hot-press molding at 60° C. after vacuum defoaming;

[0079] 5) directly carry out vulcanization treatment on the basis of step 4), and t...

Embodiment 2

[0084] In this embodiment, the preparation process of the vertical high thermal conductivity gasket reinforced by graphene thermal film includes the following steps:

[0085] 1) The graphene heat-conducting film with a thickness of 60 μm is drilled by laser technology, running through the upper and lower surfaces, the hole size is 0.5 μm, and the hole spacing is 5 μm;

[0086] 2) Uniformly mixing silica gel and heat-conducting aluminum nitride, and performing defoaming treatment to obtain a mixed silica gel, wherein the content of aluminum nitride is 60%;

[0087] 3) Evenly apply the mixed silicone gel obtained in step 2) to the surface of the graphene heat-conducting film perforated in step 1) by scraping, and stack the graphene heat-conducting film staggered to form a stack;

[0088] 4) Place the stacked body in step 3) in a mold, and perform hot-press molding at 80° C. after vacuum defoaming;

[0089] 5) directly carry out vulcanization treatment on the basis of step 4), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com