Light-weight high-performance heat-insulating protective clothing fabric and preparation method thereof

A protective clothing and high-performance technology, applied in protective clothing, chemical instruments and methods, clothing, etc., can solve the problems of skin burns, etc., and achieve the effects of reduced release, wide application fields, and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned light and thin high-performance heat-insulating protective clothing fabric includes the following steps:

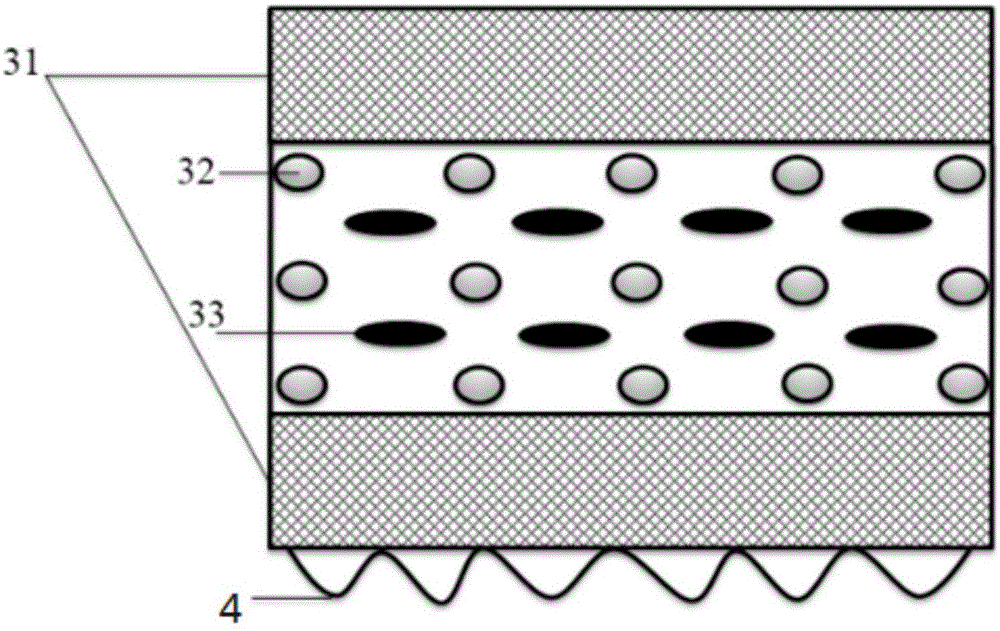

[0038]In the first step, during the airgel synthesis process, the powder microcapsule phase change material is uniformly dispersed in the airgel layered structure by the percolation method to prevent the leakage of the microcapsule phase change powder during processing and use;

[0039] The second step is to combine the outer and inner non-woven fabrics with the airgel and microcapsule phase change material mixed middle layer through lamination and sewing technology to form a heat insulation layer, so that the heat insulation layer has good performance;

[0040] The third step is to laminate the flame-retardant outer layer, waterproof and moisture-permeable layer, and heat-insulating layer through layer-by-layer sewing technology to form an airtight, flat, and non-damaged light and thin high-performance heat-insulating p...

Embodiment 1

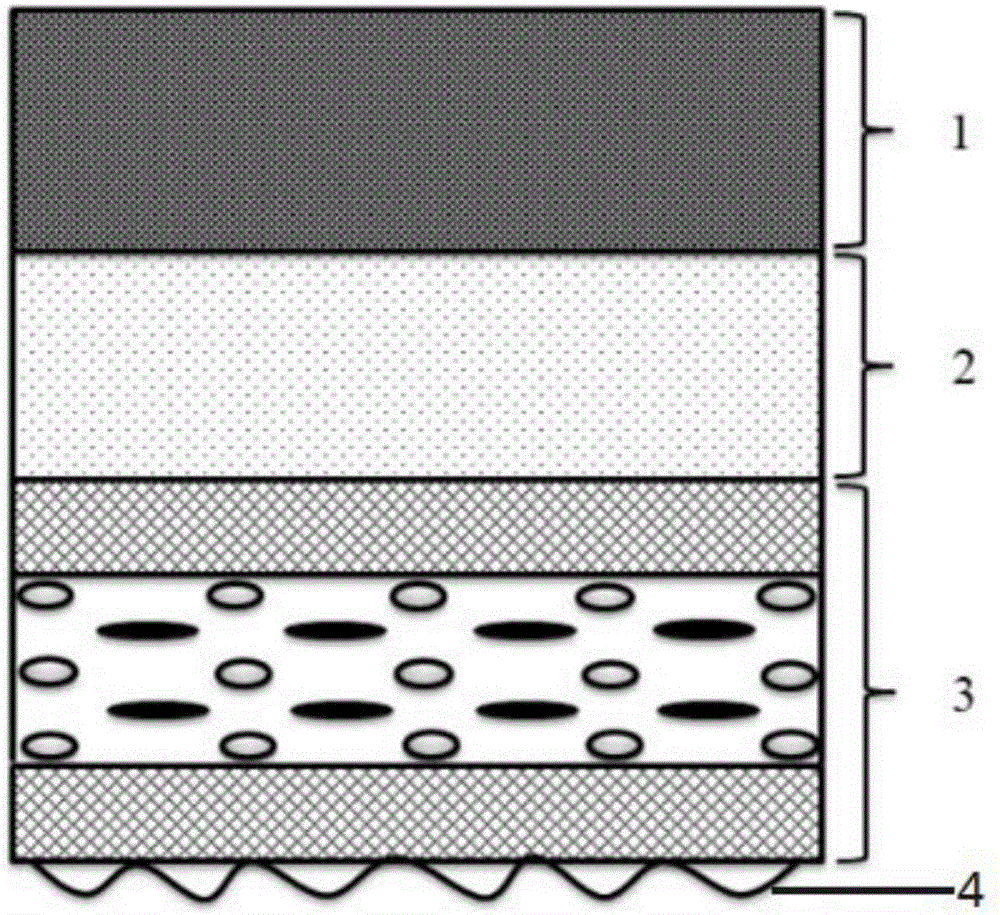

[0043] like figure 1 As shown, a light and thin high-performance heat-insulating protective clothing fabric, in which the flame-retardant outer layer is made of Kevlar-PBI fabric, used to prevent burning under fire or high-temperature radiation conditions, the natural thickness of this fabric is 0.47mm, square meters The weight is 238.4g / m 2 The waterproof and moisture-permeable layer is made of PTFE membrane material attached to 100% aramid felt. The natural thickness of this fabric is 0.52mm, and the weight per square meter is 110g / m 2 ; The microcapsule phase change material in the insulation layer is paraffin wax with 26 carbon atoms, its phase transition temperature is 56.3°C, and the airgel particle size is 650nm. The inner and outer layers of the sandwich structure are both non-woven fabric layers, and face One side of the human body is provided with an auxiliary heat insulation layer 4, and the natural thickness of the fabric obtained after the heat insulation layer i...

Embodiment 2

[0046] A light and thin high-performance heat-insulating protective clothing fabric, in which the flame-retardant outer layer is made of aramid blended fabric, which is used to prevent burning under fire or high-temperature radiation conditions. The natural thickness of this fabric is 0.39mm, and the weight per square meter is 212.5 g / m 2 The waterproof and moisture-permeable layer is made of PTFE membrane material attached to 100% aramid felt. The natural thickness of this fabric is 0.52mm, and the weight per square meter is 110g / m 2 ; The microcapsule phase change material in the heat insulation layer is paraffin wax with a carbon number of 27, its phase transition temperature is 58.8°C, and the airgel particle size is 650nm. The inner and outer layers of the sandwich structure are both non-woven fabric layers, facing the human body There is no auxiliary heat insulation layer 4 on one side, the thickness of the fabric obtained by the heat insulation layer is 2.7mm, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com