Acoustic-electric detection device for insulation defects of power cable

A technology for insulation defects and power cables, applied in the direction of testing dielectric strength, etc., can solve problems such as poor anti-interference ability, inability to locate, and low precision, and achieve the effect of reducing interface contact thermal resistance and increasing detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

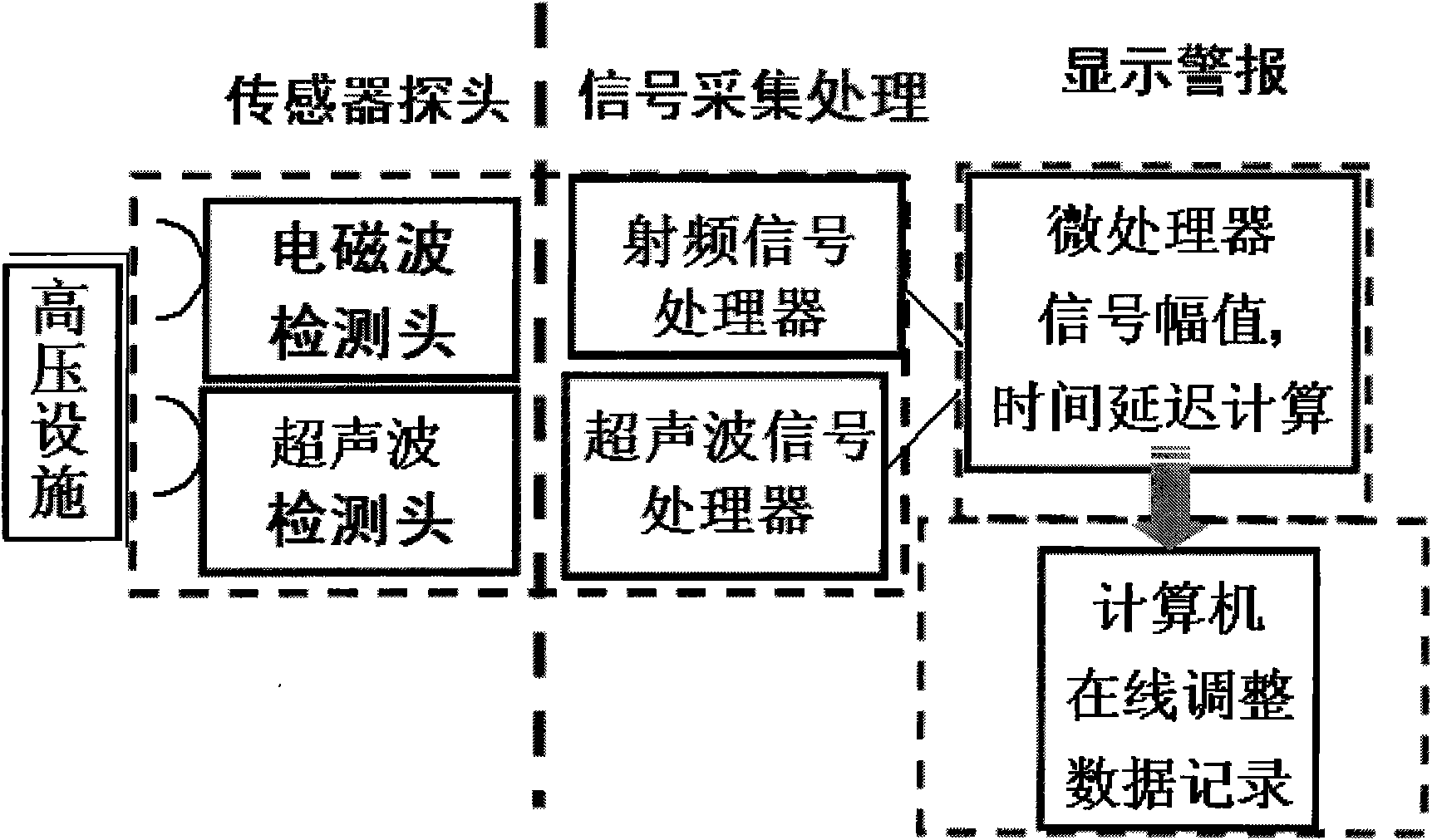

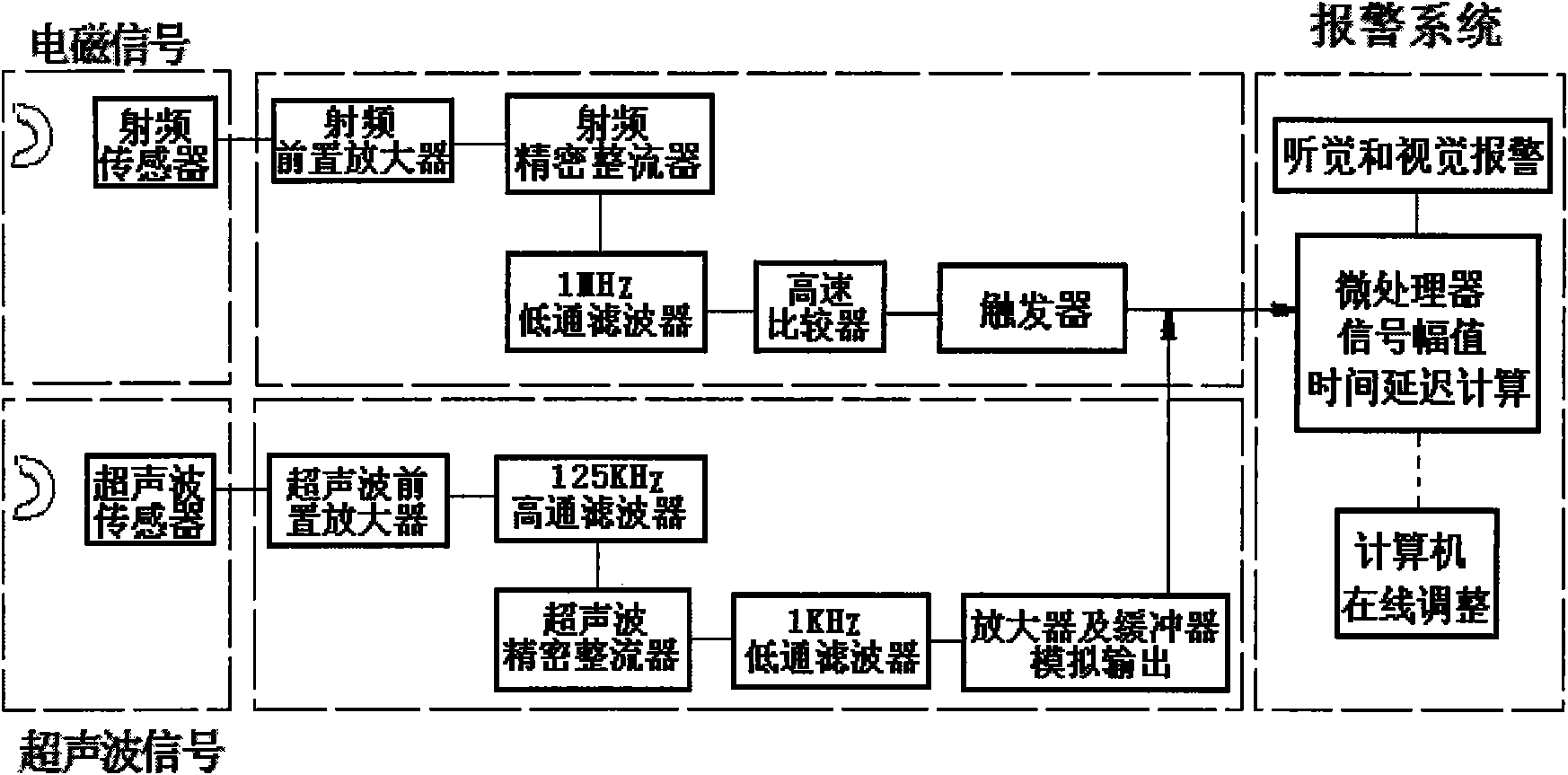

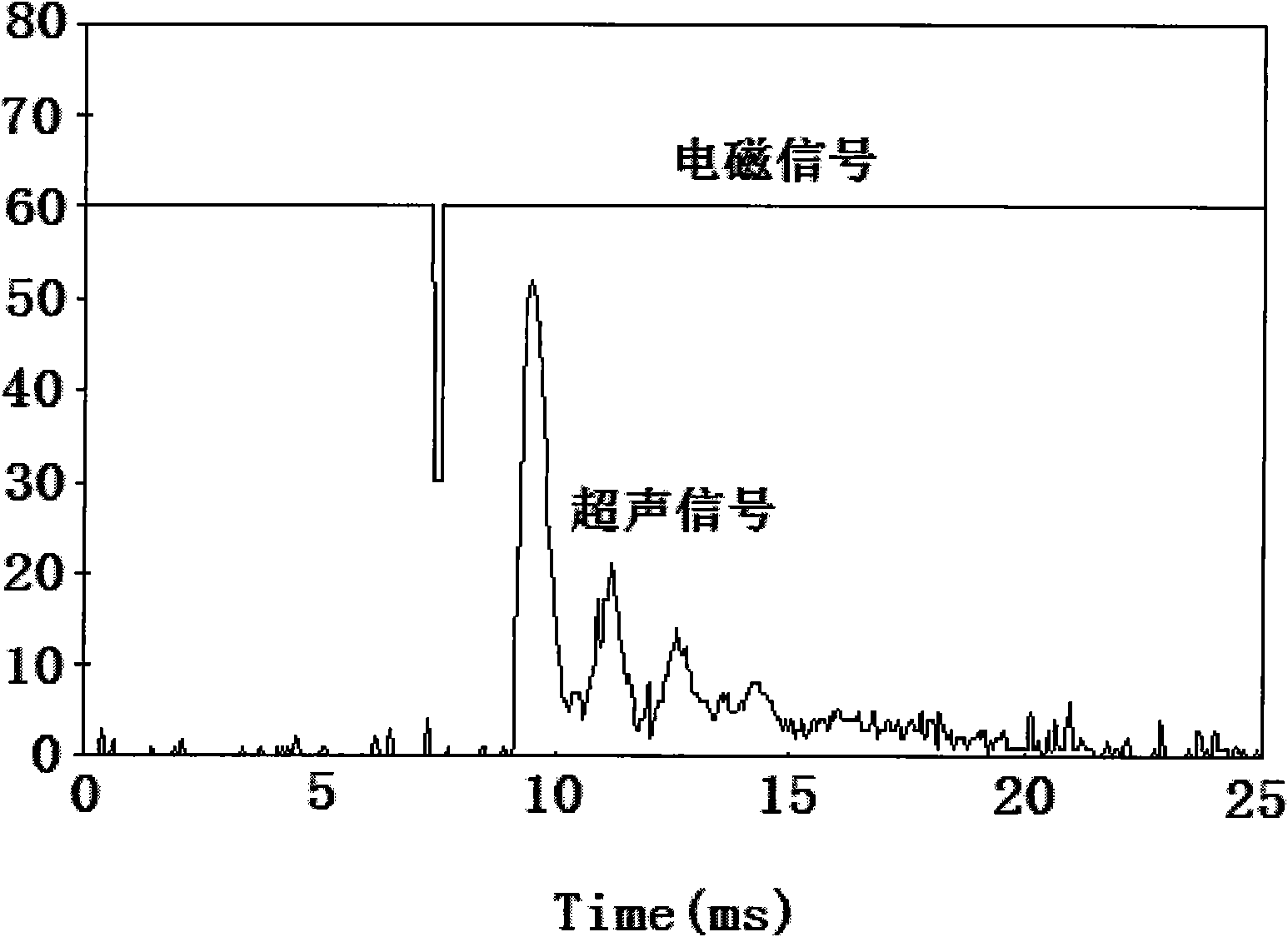

[0026] see figure 1 As shown, the acoustoelectric detection device for cable insulation defects uses acoustoelectric detection technology and acoustoelectric insulation defect or fault location technology to conduct inspections by on-line monitoring of partial discharge of cables, early detection of local defects in cables and positioning. The device includes a cable to be detected and a dual-channel detection mechanism connected to the cable to be detected, the output end of the dual-channel detection mechanism is connected to the receiving device,

[0027] The dual-channel detection mechanism includes an electromagnetic wave detection head and a probe ultrasonic detection head which are respectively connected to the cable to be inspected. The surface of the ultrasonic detection head is coated with silicon gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com